Abstract

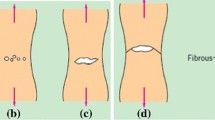

Issues related to the size dependence of the upper shelf energy (USE) and the ductile-to-brittle transition temperature (DBTT) in the Charpy V-notch test are investigated. Emphasis is placed on the interplay between inertial, strain rate hardening, strain hardening, thermal softening and material length scale effects. Geometrically similar specimens are considered first. For such specimens, the ductile-to-brittle transition temperature is found to increase with specimen size, with the amount of the increase depending on the material properties. To model available experiments, calculations are also carried out for Charpy specimens where only the ligament size is varied and two classes of pipe steels are considered. For a relatively high strength pipe steel, the experimental results exhibit no size dependence of the DBTT. On the other hand, a significant shift in the DBTT is obtained for a low strength steel. The numerical studies are used to understand the difference between these two classes of steels. The extent to which the size effect is material dependent is investigated.

Similar content being viewed by others

References

Argon, A.S.: 2001, ‘Mechanics and Physics of Brittle to Ductile Transitions in Fracture’. Journal of Engineering Materials and Technology 123, 1–11.

Batisse, R.: 2000. private communication.

Belytschko, T., R.L. Chiapetta, and H.D. Bartel: 1976, ‘Efficient large scale non-linear transient analysis by finite elements’. International Journal of Numerical Methods in Engineering 10, 579–596.

Benzerga, A.A.: 2000, ‘Rupture ductile des tôles anisotropes’. Ph.D. thesis, Ecole des Mines de Paris. parts in English.

Benzerga, A.A.: 2002, ‘Micromechanics of Coalescence in Ductile Fracture’. Journal of the Mechanics and Physics of Solids 50, 1331–1362.

Benzerga, A.A., J. Besson, and A. Pineau: 1999, ‘Coalescence–Controlled Anisotropic Ductile Fracture’. Journal of Engineering Materials and Technology 121, 221–229.

Beremin, F.: 1983, ‘A local criterion for cleavage fracture of a nuclear pressure vessel steel’. Metallurgical Transactions 14A, 2277–2287.

Chu, C. and A. Needleman: 1980, ‘Void nucleation effects in biaxially stretched sheets’. Journal of Engineering Materials and Technology 102, 249–256.

Curie, F. and R. Batisse: 1996, ‘Influence des paramètres dimensionnels d’une éprouvette Charpy sur les valeurs de résilience’. Technical report, Direction de la Recherche, Gaz de France, Paris.

Gray, G.R. and S.-R. Chen: 1998. private communication.

Gurson, A.L.: 1977, ‘Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I– Yield Criteria and Flow Rules for Porous Ductile Media’. Journal of Engineering Materials and Technology 99, 2–15.

Henry, M., B. Maradendet, F. Mudry and A. Pineau: 1985,’Effects of temperature and loading rate on the fracture toughness of a low alloy steel. Interpretation by local criteria approaches’. Journal of Theoretical and Applied Mechanics 4, 741–768.

Koplik, J. and A. Needleman: 1988, ‘Void growth and coalescence in porous plastic solids’. International Journal of Solids and Structures 24, 835–853.

Krieg, R.O. and S.W. Key: 1973, ‘Transient shell response by numerical time integration’. International Journal of Numerical Methods in Engineering 7, 273–286.

Louden, B.S., A.S. Kumar, F.A. Garner, M.L. Hamilton, and W.L. Hu: 1988, ‘The influence of specimen size on Charpy impact testing of unirradiated HT-9’. Journal of Nuclear Materials 155–157, 662–667.

Lucas, G.E., G.R. Odette, J.W. Sheckherd, P. McConnell, and J. Perrin: 1986, ‘Subsized Bend and Charpy V-Notch Specimens for Irradiated Testing’. In: W.R. Corwin and G.E. Lucas (eds.): The use of Small-Scale Specimens for Testing Irradiated Material, ASTM STP 888. American Society for Testing and Materials, pp. 305–325.

Mathur, K.K., A. Needleman, and V. Tvergaard: 1994, ‘3D analysis of failure modes in the Charpy impact test’. Modelling and Simulation in Material Science and Engineering 2, 617–635.

Mudry, F.: 1987, ‘A local approach to cleavage fracture’. Nuclear Engineering and Design 105, 65–76.

Pan, J., M. Saje, and A. Needleman: 1983, ‘Localization of deformation in rate sensitive porous plastic solids’. International Journal of Fracture 21, 261–278.

Peirce, D., C.F. Shih, and A. Needleman: 1984, ‘A tangent modulus method for rate dependent solids’. Computers and Structures 18, 875–887.

Ritchie, R.O.: 1978, ‘On the relationship between fracture toughness and Charpy V-Notch energy in ultrahigh strength steels’. In: A.R. Rosenfield, H.L. Gegel, and D.F. Hasson (eds.): What does the Charpy test really tell us? pp. 54–73, American Society for Metals.

Ritchie, R.O., J.F. Knott, and J.R. Rice: 1973, ‘On the relationship between critical tensile stress and fracture toughness in mild steel’. Journal of the Mechanics and Physics of Solids 21, 395–410.

Rossoll, A., C. Berdin, P. Forget, C. Prioul, and B. Marini: 1999, ‘Mechanical aspects of the Charpy impact test’. Nuclear Engineering Design 188, 217–229.

Tanguy, B., R. Piques, L. Laiarinandrasana, and A. Pineau: 2000, ‘Notch stress–strain distribution in Charpy V specimen – Experiments and modelling’. In: M.W. Brown, E.R. de los Rios, and K.J. Miller (eds.): 13th European Conference on Fracture. ESIS, European Group on Fracture Publication.

Taylor, G.I. and H. Quinney: 1934, ‘The latent energy remaining in a metal after cold working’. Proceedings of the Royal Society of London A A143, 307–326.

Tvergaard, V.: 1981, ‘Influence of voids on shear band instabilities under plane strain conditions’. International Journal of Fracture 17, 389–407.

Tvergaard, V.: 1982a, ‘Influence of void nucleation on ductile shear fracture at a free surface’. Journal of the Mechanics and Physics of Solids 30, 399–425.

Tvergaard, V.: 1982b, ‘On localization in ductile materials containing spherical voids’. International Journal of Fracture 18, 237–252.

Tvergaard, V. and A. Needleman: 1984, ‘Analysis of the cup–cone fracture in a round tensile bar’. Acta Metallurgica 32, 157–169.

Tvergaard, V. and A. Needleman: 1986, ‘Effect of material rate sensitivity on the failure modes in the Charpy V–notch test’. Journal of the Mechanics and Physics of Solids 34, 213–241.

Tvergaard, V. and A. Needleman: 1988, ‘An analysis of the temperature and rate dependence of Charpy V–notch energies for a high nitrogen steel’. International Journal of Fracture 37, 197–215.

Tvergaard, V. and A. Needleman: 1993, ‘An analysis of the brittle–ductile transition in dynamic crack growth’. International Journal of Fracture 59, 53–67.

Tvergaard, V. and A. Needleman: 2000, ‘Analysis of the Charpy V–notch test for welds’. Engineering Fracture Mechanics 65, 627–643.

Tvergaard, V. and A. Needleman: 2001, ‘3D Charpy specimen analyses for weldsa’. In: A. Pineau (ed.): Charpy Centenary Conference to be published.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Benzerga, A., Tvergaard, V. & Needleman, A. Size Effects in the Charpy V-Notch Test. International Journal of Fracture 116, 275–296 (2002). https://doi.org/10.1023/A:1020112028641

Issue Date:

DOI: https://doi.org/10.1023/A:1020112028641