Abstract

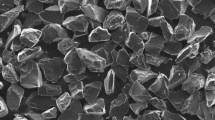

This investigation is mainly aimed to study the influence of SiC and Al2O3 particles on the mechanical properties and damage evolution behaviors of an aluminum alloy Al-2618. Heat treatments for the composites are also studied to optimize their mechanical properties. The results of tensile tests show that SiC particulate reinforcement has advantages over Al2O3 reinforcement in both strength and ductility for the composites. T4 treatment is suggested for the composites rather than conventional peak-aging treatment (T6). T4 heat treatment with an additional of 0.6% pre-strain can result in same UTS and a 0.2% proof stress for the composites as high as T6 treatment but the final elongation under T4 treatment is larger than that under T6 treatment by more than 100%. Based on observation of damage evolution behaviors of the reinforcing particles, a theory that strength of the composites is mainly decided by the balance between reinforcing particles sharing load and making strain discontinuity in the matrix is proposed to interpret the test results. Their tolerance for large local strain at the interface, their high K1c and their low thermal expansion make SiC particles sharing much load and the better reinforcement over Al2O3 particles in respect to both strength and ductility of the composites.

Similar content being viewed by others

References

D. J. Lloyd, Int. Mater. Rev. 39 (1994) 1.

M. Gupta, F. Mphamed, E. Lavernia and T. S. Srivatsan, J. Mater. Sci. 28 (1993) 2245.

T. J. A. Doel and P. Bowen, Comp. Part. 27A (1996) 655.

M. Manoharan and M. Gupta, J. Comp. Mater. 31 (1997) 1431.

D. L. McDanels, Metall. Trans. 16A (1985) 1105.

J. Yang, C. Cady, M. S. Hu, F. Zok, R. Mehrabian and A. G. Evans, Acta Metall. 38 (1990) 2613.

C.-W. Nan and D. R. Clarke, Acta Mater. 44 (1996) 3801.

C.-W. Nan, R. Birringer and H. Gleiter, Scripta Mater. 37 (1997) 969.

J. Ll Orca, Acta Metall. 43 (1995) 181.

P. B. Prangnell, S. J. Barnes, S. M. Robers and P. J. Withers, Mater. Sci. Eng. 220A (1996) 41.

J. C. Lee and K. N. Subramanian, J. Mater. Sci. 29 (1994) 1983.

Y. Flom and R. J. Arsenault, Mater. Sci. Eng. 77 (1986) 191.

J. S. Zhang, X. J. Liu, H. Cui, X. J. Duan, Z. Q. Sun and G. L. Chen, Metall. Trans. 28A(5) (1997) 1261.

J. H. Shyong and B. Derby, Mater. Sci. Eng. 197A (1995) 11.

R. Kapoor and K. S. Vecchio, ibid. 202A (1995) 63

T. Mochida, M. Taya and D. J. Ll oyd, JIM. 32 (1991) 931.

J. Ll orca, A. Martin, J. Ruiz and M. Elices, Metall Trans. 24A (1993) 1575.

B. Y. Zong and B. Derby, J. Mater. Sci. 31 (1996) 297.

Idem., Acta Mater. 45 (1997) 41.

M. Finot, Y.-L. Shen, A. Needleman and S. Suresh, Metall. Trans. 25A (1994) 2403.

Y. Zong and B. Derby, J. Dé Physique IV 3 (1993) 1861.

S. Ghosh and S. Moorthy, Acta Mater. 46 (1998) 965.

D. L. Zhang, P. Mummery and B. Cantor, in “Review of MMCs,” communicated papers of Oxford Center for Advanced Materials and Composites, 1992.

F. J. Humphreys, A. Basu and M. R. Djazeb, in Proceedings of the 12th Risφ International Synposium on Material Science, edited by N. Hansen et al. (Roskilde, Denmark, 1991) p. 51.

F. J. Humphreys, in “Mechnical and Physical Behaviour of Metallic and Ceramic Composites,” edited by S. I. Anderson et al. (Risφ National Laboratory, Denmark, 1988) p. 25.

D. J. Ll ord, P. L. Morris and E. Nehme, Fabrication of Particulate Reinforced Metal Composite, edited by J. Masounave and F. G. Hamel (ASM International, Ohio, 1990).

S. W. Miller and F. J. Humphreys, in “Fundamental Relations between Microstructures and Mechanical Properties in Metal Matrix Composites,” edited by M. N. Gungor and P. Liaw (TMS, Warrendale, PA, 1989) p. 517.

P. Mummery and B. Derby, Mater. Sci. Eng. 135A (1991) 221.

J. P. Hirch, Scripta Metall. Mater. 25 (1991) 1.

R. J. Arsenault and R. M. Fisher, Scripta Metal. Mater. 17 (1983) 67.

V. J. Tennery, “Ceramic Materials and Components for Engineers” (the American Ceramic Society, 1989) p. 1840.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tan, M., Xin, Q., Li, Z. et al. Influence of SiC and Al2O3 particulate reinforcements and heat treatments on mechanical properties and damage evolution of Al-2618 metal matrix composites. Journal of Materials Science 36, 2045–2053 (2001). https://doi.org/10.1023/A:1017591117670

Issue Date:

DOI: https://doi.org/10.1023/A:1017591117670