Abstract

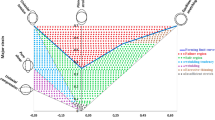

In this paper, instrumented impact test results obtained using V-notch and precracked Charpy specimens of AISI 308 weld and AISI 316 stainless steels are analysed for determining the plastic η-factor for three-point bend specimens used in J-integral evaluation. Tested 316 stainless steel specimens were in various thermal aging/cold-work conditions whereas 308 weld specimens were in the as-welded condition. The results are analysed using the various procedures proposed in the literature and compared with experimental and finite element results reported in the literature. Based on our analysis, two polynomial expressions of a/W for ηpl are presented: one gives a sort of upper-bound in the a/W range 0.05–1.0 while the other gives conservative values (i.e., use of this results in J-R curves and J sufficiently conservative for engineering purposes). Both provide a smooth variation of ηpl over the entire a/W range unlike some of the expressions given in the literature which show a discontinuous change at an intermediate a/W.

Similar content being viewed by others

References

Begley, J.A and Landes, J.D. (1972). The J-integral as a fracture criterion. Fracture Toughness, Proceedings of the 1971 National Symposium on Fracture Mechanics, Part Ii.ASTMSTP 514, American Society for Testing and Materials, Philadelphia, PA, 1–20.

Ernst, H.A., Paris, P.C and Landes, J.D. (1981). Estimation of the J-integral and tearing modulus Tfrom single specimen test records. Fracture Mechanics: Thirteenth Symposium, ASTM STP 743, American Society for Testing and Materials, Philadelphia, PA, 476–502.

Haigh, J.R. and Richards, C.E. (1974). Yield point loads and compliance functions for fracture mechanics specimens. CEGB Report RD/L/M461.

Herrera, R., Carcagno, G. and Vedia L.A. (1993). Evaluation of dynamic fracture toughness using normalisation method. Fracture Mechanics: Twenty-Third Symposium(Edited by C. Ravinder), ASTM STP 1189, American Society for Testing and Materials, Philadelphia, PA, 168–184.

Joyce, J.A. (1992). J-resistance curve testing of short crack bend specimens using unloading compliance. Fracture Mechanics: Twenty-Second Symposium (Vol. I)(Edited by H.A. Ernst, A. Saxena and D.L. McDowell), ASTM STP 1131, American Society for Testing and Materials, Philadelphia, PA, 904–924.

Kirk, M.T. and Dodds, R.H. (1993). Jand CTOD estimation equations for shallow cracks in single edge notch bend specimens. Journal of Testing and Evaluation, JTEVA 21(4), 228–238.

Kumar, V., German, M.D. and Shih, C.F. (1981). An engineering approach for elastic-plastic fracture analysis. EPRI Report NP-1931, Palo Alto, CA.

Landes, J.D. and Begley, J.A. (1974). Test results from J-integral studies: An attempt to establish a JIC testing procedure. Fracture Analysis.ASTM STP 560, American Society for Testing and Materials, Philadelphia, PA, 170–186.

Nevalainen, M. and Wallin, K. (1994). The effect of crack depth and absolute thickness on fracture toughness of 3PB specimens. Proceedings of 10th European Conference on Fracture, EMAS Publishing, 997–1006.

Rice, J.R., Paris, P.C. and Merkle, J.G. (1973). Some further results of J-integral analysis and estimates. Progress in Falw Growth and Fracture Toughness Testing. ASTMSTP 536, American Society for Testing and Materials, Philadelphia, PA, 231–245.

Schindler, H.J. and Veidt, M. (1998). Fracture toughness evaluation from instrumented sub-size Charpy-type tests. Small Specimen Test Techniques(Edited by W.R. Corwin, S.T. Rosinski and E. van Walle), ASTM STP 1329 American Society for Testing and Materials, Philadelphia, PA.

Sorem, W.A., Dodds, R.H., Jr. and Rolfe, S.T. (1991). A comparison of the J-integral and CTOD parameters for short crack specimen testing. Elastic-Plastic Fracture Test Methods: The User's Experience(Second Volume) (Edited by J.A. Joyce), ASTM STP 1114, American Society for Testing and Materials, Philadelphia, PA, 19–41.

Sreenivasan, P.R., Ray, S.K. and Mannan, S.L. (1999a). Dynamic J-Rcurves and tension-impact results for an AISI 308 weld stainless steel. Being communicated to International Journal of Fracture.

Sreenivasan, P.R., Ray, S.K. and Mannan, S.L. (1999b). Dynamic J-Rcurves and tensile-toughness correlation for AISI 316 stainless steel in various thermal aging/cold-work conditions. Being communicated to Metallurgical and Materials Transactions.

Strawley, J. (1976). On the relation of JI to work done per unit area: 'total', or 'component' 'due to crack'. International Journal of Fracture 12, 470–474.

Sumpter, J.D.G. (1987). JCdetermination for shallow notched weld bend specimens. Fatigue and Fracture of Engineering Materials and Structures 10(6) 479–493.

Sumpter, J.D.G. and Turner, C.E. (1976). Method for laboratory determination of J IC. Cracks and Fracture, ASTM STP 601, American Society for Testing and Materials, Philadelphia, PA, 3–18.

Tvergaard, V. and Needleman, A. (1986). Effect of material rate sensitivity on failure modes in the Charpy V-notch test. Journal of the Mechanics and Physics of Solids 34(3), 213–241.

Tvergaard, V. and Needleman, A. (1988). An analysis of the temperature and rate dependence of Charpy V-notch energies for a high nitrogen steel. International Journal of Fracture 37, 197–215.

Zhang, D.Z. and Lin, J. (1990). A general formula for three-point bend specimen J-integral calculation. Engineering Fracture Mechanics 36(5), 789–793.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sreenivasan, P., Mannan, S. Plastic n-factor for three-point bend specimens: Analysis of instrumented Charpy impact test results for AISI 308 weld and AISI 316 stainless steels. International Journal of Fracture 101, 215–228 (2000). https://doi.org/10.1023/A:1007686321002

Issue Date:

DOI: https://doi.org/10.1023/A:1007686321002