Abstract

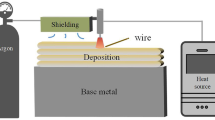

Titanium alloys are widely used in aerospace and other fields due to their high strength, excellent wear resistance, corrosion resistance, biocompatibility and non-magnetic properties. This study validates the temperature evolution of 6-layer TC4 thin-walled parts through simulations and experiments. The simulations were reliable and accurate. The build process was performed by plasma arc additive manufacturing (PAAM) process. Further, the thermal elastic–plastic model and thermal stress field simulation of PAAM performed in reciprocating scanning sequence and unidirectional scanning sequence was carried out. Results showed alternating temperature gradients and uniform residual stress distribution in the reciprocating sequence. PAAM of TC4 thin walls in reciprocating scanning achieved excellent finish, accuracy, and no visible defects. The strength of the wall met ASTM forging standards. Microstructural analysis revealed reduced β phase and improved α phase through PAAM deposition. The lower region had Widmanstätten structure and basket-weave morphology, while the middle portion had relatively coarse basket-weave structure. The top region exhibited martensite structure and basket-weave structure. Tensile tests showed different strengths in scanning and build directions. Ultimate tensile strengths were 1013.7 and 965.1 MPa, with elongations of 6 and 7.9% respectively. Scanning direction had slightly higher strength but lower ductility.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

J.H. Lee, Y.J. Song, D.H. Shin, and C.S. Lee, Microstructural Evolution During Superplastic Bulge Forming of Ti–6Al–4V Alloy, Mater. Sci. Eng. A, 1998, 243(1–2), p 119–125.

J. Zhang, X. Li, D. Xu, and R. Yang, Recent Progress in the Simulation of Microstructure Evolution in Titanium Alloys, Prog. Nat. Sci. Mater. Int., 2019, 29(3), p 295–304.

C.A.F. Salvador, E.L. Maia, F.H. Costa, J.D. Escobar, and J.P. Oliveira, A Compilation of Experimental Data on the Mechanical Properties and Microstructural Features of Ti-Alloys, Sci. Data, 2022, 9(1), p 188.

B. Callegari, J.P. Oliveira, K. Aristizabal, R.S. Coelho, P.P. Brito, L. Wu, N. Schell, F.A. Soldera, F. Mücklich, and H.C. Pinto, In-Situ Synchrotron Radiation Study of the Aging Response of Ti-6Al-4V Alloy with Different Starting Microstructures, Mater Charact, 2020, 165, p 110400.

B. Callegari, J.P. Oliveira, R.S. Coelho, P.P. Brito, N. Schell, F.A. Soldera, F. Mücklich, M.I. Sadik, J.L. García, and H.C. Pinto, New Insights into the Microstructural Evolution of Ti-5Al-5Mo-5V-3Cr Alloy during Hot Working, Mater Charact, 2020, 162, p 110180.

F. Wang, S. Williams, P. Colegrove, and A.A. Antonysamy, Microstructure and Mechanical Properties of Wire and Arc Additive Manufactured Ti-6Al-4V, Metall. Mater. Trans. A, 2013, 44(2), p 968–977.

R.R. Boyer, An Overview on the Use of Titanium in the Aerospace Industry, Mater. Sci. Eng. A, 1996, 213(1–2), p 103–114.

W.D. Brewer, R.K. Bird, and T.A. Wallace, Titanium Alloys and Processing for High Speed Aircraft, Mater. Sci. Eng. A, 1998, 243(1–2), p 299–304.

H. Sharma, D. Parfitt, A.K. Syed, D. Wimpenny, E. Muzangaza, G. Baxter, and B. Chen, A Critical Evaluation of the Microstructural Gradient Along the Build Direction in Electron Beam Melted Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2019, 744, p 182–194.

A. Hattal, T. Chauveau, M. Djemai, J.J. Fouchet, B. Bacroix, and G. Dirras, Effect of Nano-Yttria Stabilized Zirconia Addition on the Microstructure and Mechanical Properties of Ti6Al4V Parts Manufactured by Selective Laser Melting, Mater. Des., 2019, 180, p 107909.

L. Qin, H. Yi, F. Kong, H. Ma, L. Guo, L. Tian, and B. Tang, Effect of Plasma Molybdenized Buffer Layer on Adhesive Properties of TiN Film Coated on Ti6Al4V Alloy, Appl. Surf. Sci., 2017, 403, p 464–471.

G. Liu, Y. Yang, B. Huang, X. Luo, S. Ouyang, G. Zhao, N. Jin, and P. Li, Effects of Substrate Temperature on the Structure, Residual Stress and Nanohardness of Ti6Al4V Films Prepared by Magnetron Sputtering, Appl. Surf. Sci., 2016, 370, p 53–58.

D. Zhang, A. Liu, B. Yin, and P. Wen, Additive Manufacturing of Duplex Stainless Steels - A Critical Review, J. Manuf. Process., 2022, 73, p 496–517.

A Standard F2792, Standard Terminology for Additive Manufacturing Technologies, Vol 2012 Astm International, West Conshohocken, 2012, p 24

A. Suárez, E. Aldalur, F. Veiga, T. Artaza, I. Tabernero, and A. Lamikiz, Wire Arc Additive Manufacturing of an Aeronautic Fitting with Different Metal Alloys: From the Design to the Part, J. Manuf. Process., 2021, 64, p 188–197.

L.P. Raut and R.V. Taiwade, Wire Arc Additive Manufacturing: A Comprehensive Review and Research Directions, J. Mater. Eng. Perform., 2021, 30(7), p 4768–4791.

C.R. Cunningham, J.M. Flynn, A. Shokrani, V. Dhokia, and S.T. Newman, Invited Review Article: Strategies and Processes for High Quality Wire Arc Additive Manufacturing, Addit. Manuf., 2018, 22, p 672–686.

I.O. Felice, J. Shen, A.F.C. Barragan, I.A.B. Moura, B. Li, B. Wang, H. Khodaverdi, M. Mohri, N. Schell, E. Ghafoori, T.G. Santos, and J.P. Oliveira, Wire and Arc Additive Manufacturing of Fe-Based Shape Memory Alloys: Microstructure, Mech. Funct. Behav. Mater. Design, 2023, 231, p 112004.

F.W. Cipriano Farias, V. Rebelo Duarte, J. Da Cruz Payão Filho, N. Schell, E. Maawad, M. Bordas-Czaplicki, F.M. Alves Da Fonseca, J. Cormier, T.J. Gomes Dos Santos, and J.P. Oliveira, Arc-Based Directed Energy Deposited Inconel 718: Role of Heat Treatments on High-Temperature Tensile Behavior, Mater. Res. Lett., 2024, 12(2), p 97–107.

B. Wu, Z. Pan, D. Ding, D. Cuiuri, H. Li, J. Xu, and J. Norrish, A Review of the Wire Arc Additive Manufacturing of Metals: Properties, Defects Qual. Improv. J. Manuf. Process., 2018, 35, p 127–139.

S. Schwab, R. Selin, and M. Voron, Welding Materials for TIG Welding, Surfacing, and WAAM Technology of Titanium Alloys, Weld World, 2023, 67(4), p 981–986.

J.W. Elmer and G. Gibbs, The Effect of Atmosphere on the Composition of Wire Arc Additive Manufactured Metal Components, Sci. Technol. Weld. Join., 2019, 24(5), p 367–374.

M.R. Jackson, B.P. Bewlay, R.G. Rowe, D.W. Skelly, and H.A. Lipsitt, High-Temperature Refractory Metal-Intermetallic Composites, JOM, 1996, 48(1), p 39–44.

Y. Sharir, A. Grill, and J. Pelleg, Computation of Temperatures in Thin Tantalum Sheet Welding, Metall. Trans. B, 1980, 11(2), p 257–265.

Y. Zheng, Z. Yu, J. Xie, J. Chen, C. Yu, J. Xu, and H. Lu, A Numerical Model-Based Deposition Strategy for Heat Input Regulation during Plasma Arc-Based Additive Manufacturing, Additive Manufacturing, Elsevier, 2022, 58, 102986.

X. Chen, C. Wang, J. Ding, P. Bridgeman, and S. Williams, A Three-Dimensional Wire-Feeding Model for Heat and Metal Transfern Fluid Flow, and Bead Shape in Wire Plasma Arc Additive Manufacturing, J. Manuf. Process., 2022, 83, p 300–312.

M. Arunkumar, V. Dhinakaran, and N. Siva Shanmugam, Numerical Prediction of Temperature Distribution and Residual Stresses on Plasma Arc Welded Thin Titanium Sheets, Int. J. Model. Simul., 2021, 41(2), p 146–216.

M. Chiumenti, M. Cervera, A. Salmi, C. Agelet De Saracibar, N. Dialami, and K. Matsui, Finite Element Modeling of Multi-Pass Welding and Shaped Metal Deposition Processes, Comput. Methods Appl. Mech. Eng., 2010, 199(37–40), p 2343–2359.

H.T. Lee and C.T. Chen, Predicting Effect of Temperature Field on Sensitization of Alloy 690 Weldments, Mater. Trans., 2011, 52(9), p 1824–1831.

A.A. Syed, A. Pittner, M. Rethmeier, and A. De, Modeling of Gas Metal Arc Welding Process Using an Analytically Determined Volumetric Heat Source, ISIJ Int., 2013, 53(4), p 698–703.

J. Cheon and S.-J. Na, Influence of Simulation Methods of Temperature Distribution on Thermal and Metallurgical Characteristics in GMA Welding, Mater. Des., 2016, 108, p 183–194.

P. Prabhakar, W.J. Sames, R. Dehoff, and S.S. Babu, Computational Modeling of Residual Stress Formation during the Electron Beam Melting Process for Inconel 718, Addit. Manuf., 2015, 7, p 83–91.

Z. Nie, G. Wang, J.D. McGuffin-Cawley, B. Narayanan, S. Zhang, D. Schwam, M. Kottman, and Y. Rong, Experimental Study and Modeling of H13 Steel Deposition Using Laser Hot-Wire Additive Manufacturing, J. Mater. Process. Technol., 2016, 235, p 171–186.

F. Kong, J. Ma, and R. Kovacevic, Numerical and Experimental Study of Thermally Induced Residual Stress in the Hybrid Laser–GMA Welding Process, J. Mater. Process. Technol., 2011, 211(6), p 1102–1111.

K. Dai and L. Shaw, Thermal and Stress Modeling of Multi-Material Laser Processing, Acta Mater., 2001, 49(20), p 4171–4181.

A.H. Nickel, D.M. Barnett, and F.B. Prinz, Thermal Stresses and Deposition Patterns in Layered Manufacturing, Mater. Sci. Eng. A, 2001, 317(1–2), p 59–64.

H. Zhao, G. Zhang, Z. Yin, and L. Wu, Three-Dimensional Finite Element Analysis of Thermal Stress in Single-Pass Multi-Layer Weld-Based Rapid Prototyping, J. Mater. Process. Technol., 2012, 212(1), p 276–285.

H. Zhao, G. Zhang, Z. Yin, and L. Wu, A 3D Dynamic Analysis of Thermal Behavior during Single-Pass Multi-Layer Weld-Based Rapid Prototyping, J. Mater. Process. Technol., 2011, 211(3), p 488–495.

J. Chen, D. Fabijanic, T. Zhang, E.W. Lui, M. Brandt, and W. Xu, Deciphering the Transformation Pathway in Laser Powder-Bed Fusion Additive Manufacturing of Ti-6Al-4V Alloy, Addit. Manuf., 2022, 58, p 103041.

M. Muhammad, J.W. Pegues, N. Shamsaei, and M. Haghshenas, Effect of Heat Treatments on Microstructure/Small-Scale Properties of Additive Manufactured Ti-6Al-4V, Int. J. Adv. Manuf. Technol., 2019, 103, p 4161–4172.

S. Sahoo and K. Chou, Phase-Field Simulation of Microstructure Evolution of Ti–6Al–4V in Electron Beam Additive Manufacturing Process, Addit. Manuf., 2016, 9, p 14–24.

A. Kiran, Y. Li, J. Hodek, M. Brázda, M. Urbánek, and J. Džugan, Heat Source Modeling and Residual Stress Analysis for Metal Directed Energy Deposition Additive Manufacturing, Materials, 2022, 15(7), p 2545.

G. Feng, H. Wang, Y. Wang, D. Deng, and J. Zhang, Numerical Simulation of Residual Stress and Deformation in Wire Arc Additive Manufacturing, Crystals, 2022, 12(6), p 803.

J. Goldak, A. Chakravarti, and M. Bibby, A New Finite Element Model for Welding Heat Sources, Metall. Trans. B, 1984, 15(2), p 299–305.

J. Ding, P. Colegrove, J. Mehnen, S. Ganguly, P.M. Sequeira Almeida, F. Wang, and S. Williams, Thermo-Mechanical Analysis of Wire and Arc Additive Layer Manufacturing Process on Large Multi-Layer Parts, Comput. Mater. Sci., 2011, 50(12), p 3315–3322.

Y. Qi, J. Li, Y. Shen, and W. Hou, Simulation and Experimental Study on Temperature and Flow Field in Friction Stir Welding of TC4 Titanium Alloy Process, Mater. Trans. Jpn Inst. Met. Mater., 2020, 61(12), p 2378–2385.

J. Xiong, R. Li, Y. Lei, and H. Chen, Heat Propagation of Circular Thin-Walled Parts Fabricated in Additive Manufacturing Using Gas Metal Arc Welding, J. Mater. Process. Technol., 2018, 251, p 12–19.

F. Silze, M. Schnick, I. Sizova, and M. Bambach, Laser Metal Deposition of Ti-6Al-4V with a Direct Diode Laser Set-up and Coaxial Material Feed, Procedia Manuf., 2020, 47, p 1154–1158.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. de Wilson-Heid, A. De and W. Zhang, Additive Manufacturing of Metallic Components-Process, Structure and Properties, Prog. Mater. Sci., 2018, 92, p 112–224.

Y. Zhou, G. Qin, L. Li, X. Lu, R. Jing, X. Xing and Q. Yang, Formability, Microstructure and Mechanical Properties of Ti-6Al-4V Deposited by Wire and Arc Additive Manufacturing with Different Deposition Paths, Mater. Sci. Eng. A, 2020, 772, p 138654.

B. Wu, Z. Pan, D. Ding, D. Cuiuri, and H. Li, Effects of Heat Accumulation on Microstructure and Mechanical Properties of Ti6Al4V Alloy Deposited by Wire Arc Additive Manufacturing, Addit. Manuf., 2018, 23, p 151–160.

B. Baufeld, O.V.D. Biest, and R. Gault, Microstructure of Ti-6Al-4V Specimens Produced by Shaped Metal Deposition, Int. J. Mater. Res., 2009, 100(11), p 1536–1542.

S.-T. Oh, K.-D. Woo, J.-H. Kim, and S.-M. Kwak, The Effect of Al and V on Microstructure and Transformation of β Phase during Solution Treatments of Cast Ti-6Al-4V Alloy, Korean J. Met. Mater., 2017, 55(3), p 150–155.

Y.C. Lin, X.-Y. Jiang, C. Shuai, C.-Y. Zhao, D.-G. He, M.-S. Chen, and C. Chen, Effects of Initial Microstructures on Hot Tensile Deformation Behaviors and Fracture Characteristics of Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2018, 711, p 293–302.

H. Matsumoto, H. Yoneda, K. Sato, S. Kurosu, E. Maire, D. Fabregue, T.J. Konno and A. Chiba, Room-Temperature Ductility of Ti–6Al–4V Alloy with Α′ Martensite Microstructure, Mater. Sci. Eng. A, 2011, 528(3), p 1512–1520.

N.A. Rosli, M.R. Alkahari, M.F.B. Abdollah, S. Maidin, F.R. Ramli, and S.G. Herawan, Review on Effect of Heat Input for Wire Arc Additive Manufacturing Process, J. Market. Res., 2021, 11, p 2127–2145.

Z.-Y. Zhao, L. Li, P.-K. Bai, Y. Jin, L.-Y. Wu, J. Li, R.-G. Guan, and H.-Q. Qu, The Heat Treatment Influence on the Microstructure and Hardness of TC4 Titanium Alloy Manufactured via Selective Laser Melting, Materials, 2018, 11(8), p 1318.

Acknowledgments

This project is supported by Key Research and Development Project Zhejiang Province (2021C04022) and National Natural Science Foundation of China (Grant No. 52261135544), author Haoquan Zhang and Yujie Tao have equal contribution on the paper.

Author information

Authors and Affiliations

Contributions

Haoquan Zhang contributed to conceptualization, investigation, methodology, writing–original draft. Yujie Tao contributed to supervision, writing—review and editing. Kang Peng and N. Gangil helped in supervision. Xizhang Chen helped in supervision and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, H., Tao, Y., Peng, K. et al. Numerical Simulation, Microstructure, and Properties of TC4 Plasma Arc Additive Manufactured Thin Wall. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09507-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09507-2