Abstract

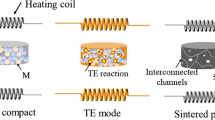

To make use of the porous nature of the SHS reaction products a novel investigation was made to manufacture the highly porous ceramics with SHS method by adding certain amounts of volatile agents to the green compacts. The interconnected open porosity of the obtained highly porous ceramics can be as high as 83% and the interconnected network open pore microstructure was developed in the obtained highly porous ceramics. Large amounts of micropores were found present in the obtained highly porous ceramics, which is a special and important advantage of manufacturing porous ceramics with SHS method. Also this particular combustion process was studied in detail and it was found that the propagation rates are increased considerably due to the unique green compact structure left by the volatile agents.

Similar content being viewed by others

References

Z. A. Munir, Ceram. Bull. 67 (1988) 342.

M. Fu and J. A. Sekhar, Key Engin. Mater. 108–110 (1995) 19.

M. G. Lakshmikantha and J. A. Sekhar, J. Amer. Ceram. Soc. 77 (1994) 202.

S. D. Dunmead, Z. A. Munir, J. B. Holt and D. D. Kingman, J. Mater. Sci. 26 (1991) 2410.

B. H. Rabin, G. E. Korth and R. L. Williamson, J. Amer. Ceram. Soc. 73 (1990) 2156.

O. Yamada, Y. Miyamoto and M. Koizumi, ibid. 70 (1987) C-206–C-208.

J. C. Lasalvia, M. A. Meyers and D. K. Kim, J. Mater. Synth. Process 2 (1994) 255.

V. N. Bloshenko and V. A. Bokij, Inzhenerno-Fizicheskii Zhurnal. 65 (1993) 466.

S. B. Babkin and V. A. Bokij, Fizika Goreniya iVzryva. 29 (1993) 67.

Z. A. Munir and U. Anselmy-Tamburni, Mater. Sci. Rept. 3 (1989) 277.

J. B. Holt, D. D. Kingman and G. M. Bianchini, Mater. Sci. and Eng. 71 (1985) 321.

S. Kumar, in dissertations, State University of New York, Buffalo, 1988.

W. Rice, J. Mater. Sci. 26 (1991) 6533.

A. G. Merzhanov, Arch. Procesow Spalania 5 (1974) 17.

M. G. Lakshmikantha, A. Bhattacharya and J. A. Sekhar, Metall. Trans. 23A (1992) 23.

A. K. Bhattacharya, J. Mater. Sci. 27 (1992) 3050.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhou, W., Hu, W.B. & Zhang, D. Combustion synthesis of highly porous ceramics: The TiC-Al2O3 system. Journal of Materials Science 34, 4469–4473 (1999). https://doi.org/10.1023/A:1004633120727

Issue Date:

DOI: https://doi.org/10.1023/A:1004633120727