Abstract

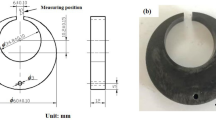

High temperature carburization is becoming more and more attractive because it can remarkably reduce processing time and increase productivity. However, the commonly used gear steels which are microalloyed by Al are not suitable for high temperature carburization due to abnormal grain coarsening. The gear steel 20CrMnTiNb, which is microalloyed with 0.048% Nb and 0.038% Ti, has been compared with the gear steel 20CrMn in terms of microstructure in the case of hardened layer and in the core after carburizing at 1 000 °C for 4 h and mechanical properties after carburizing and pseudo-carburizing. The results indicate that the fine austenite grains exist in the carburized case of 20CrMnTiNb steel, while there is abnormal coarsening and duplex grain structure in the case and core of steel 20CrMn. The average prior austenite grain sizes are 19.5 and 34. 2 μm for the steels 20CrMnTiNb and 20CrMn, respectively. In addition, the mechanical properties of 20CrMnTiNb steel are superior to those of 20CrMn steel. In particular, the HV hardness of the former is higher than that of the later by about 40–70 in the range of less than 0. 7 mm in depth. Therefore, the steel 20CrMnTiNb is suitable for high temperature carburization.

Similar content being viewed by others

References

ZHANG Ying-cai. Development of Automotive Pinion Steel and Its Application Technology [J]. Automible Technology, 2004 (10): 22 (in Chinese).

MA Li, WANG Mao-qiu, XU Xiang-qiu, et al. Austenite Grain Size and Hardenability of NbGB Microaloyed Gear Steels [J]. Transactions of Materials and Heat Treatment, 2009, 30(5): 74 (in Chinese).

Kubota Manabu, Ochi Tatsuro. Development of Anti-coarsening ExtraGfine Steel for Carburizing [J]. Nippon Steel Technical Report, 2003(88): 81 (in Japanese).

Alogab K A, Matlock D K, Speer J G, et al. The Influence of Niobium Microaloying on Austenite Grain Coarsening Behavior of TiModified SAE 8620 Steel [J]. ISIJ International, 2007, 47 (2): 307.

LIU Yan, WANG Mao-qiu, DONG Han, et al. Kinetics of Austenite Grain Coarsening in Nb-Bearing Gear Steels [J]. Journal of Iron and Steel Research, 2008, 20(11): 37 (in Chinese).

De Morais R F, Reguly A, De Almeida L H. Transmission Electron Microscopy Characterization of a Nb Microaloyed Steel for Carburization at High Temperatures [J]. Journal of Materials Engineering and Performance, 2006, 15(4): 494.

Alogab K A, Matlock D K, Speer J G, et al. The Influence of Niobium Microaloying on Austenite Grain Coarsening Behavior of TiModified SAE 8620 Steel [J]. ISIJ International, 2007, 47(2): 307.

Kimura T, Kurebayashi Y. Niobium in Microaloy Engineering Steels, Wire Rods and Case Carburized Products [C]//Proc Int Symp Niobium. Orlando: 2001: 801.

Alogab K A, Matlock D K, Speer J G, et al. The Effects of Heating Rate on Austenite Grain Growth in a Ti-Modified SAE 8620 Steel With Controled Niobium Additions [J]. ISIJ International, 2007, 47(7): 1034.

Thompson R E, Matlock D K, Speer J G. The Fatigue Performance of High Temperature Vacuum Carburized Nb Modified 8620 Steel [C]//SAE World Congress and Exhibition. Detroit: 2007: p 2007G01G1001.

YANG Zhen-guo, ZHANG Ji-ming, LI Shou-xin, et al. Fatigue Behavior of Fine-Grained High Strength Steel 42CrMoVNb [J]. Acta Metalurgica Sinica, 2004, 40(4): 367 (in Chinese).

YONG Qi-long. Secondary Phases in Steels [M]. Beijing: Metallurgical Industry Press, 2006 (in Chinese).

Sha Qing-yun, Sun Zu-qing. Grain Growth Behavior of Coarse-Grained Austenite in a Nb-V-Ti Microaloyed Steel [J]. Materials Science and Engineering, 2009, 523A(1/2): 77.

Morris J W, Guo Z, Krenn C R, et al. The Limit of Strength and Toughness in Steel [J]. ISIJ International, 2001, 41(6) 599.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National High Technology Research and Development Program (863) of China (2006AA03Z526)

Rights and permissions

About this article

Cite this article

Yang, Yh., Wang, Mq., Chen, Jc. et al. Microstructure and Mechanical Properties of Gear Steels After High Temperature Carburization. J. Iron Steel Res. Int. 20, 140–145 (2013). https://doi.org/10.1016/S1006-706X(13)60227-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60227-7