Abstract

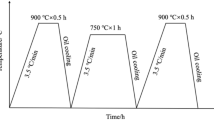

The constant embrittlement curve for constant segregation concentration on grain boundary of impurity element P and relationship between equilibrium grain boundary segregation concentration and operation time for 2. 25Cr-1Mo steel were derived based on the theory of equilibrium grain boundary segregation. The mechanism of step-cooling test and mechanism of de-embrittlement for 2. 25Cr-1Mo steel were explained. The segregation rate will increase but equilibrium grain boundary segregation concentration of impurity element P will decrease as temperature increases in the range of temper embrittlement temperature. There is one critical temperature of embrittlement corresponding to each embrittlement degree. When the further heat treating temperature is higher than critical temperature, the heat treating will become a de-embrittlement process s otherwise, it will be an embrittlement process. The critical temperature of embrittlement will shift to the direction of low temperature as further embrittlement. As a result, some stages of step-cooling test would change into a de-embrittlement process. The grain boundary desegregation function of impurity element P was deduced based on the theory of element diffusion, and the theoretical calculation and experimental results show that the further embrittlement or de-embrittlement mechanism can be interpreted qualitatively and quantitatively by combining the theory of equilibrium grain boundary segregation with constant embrittlement curve.

Similar content being viewed by others

References

Christien F, Le Gall R, Saindrenan G. Phosphorus Grain Boundary Segregation in Steel 17-4PH [J]. Scripta Materillia, 2003, 48: 11.

The Japan Steel Works. Technical Service for Safe Operation of High-Pressure Vessel [RJ]. Tokyo: The Japan Steel Works, 1995.

Doucet Anne B. Effects of Service Exposure of 2 1/4 Cr-1Mo Pressure Vessel Steel in A Heavy Oil Hydrocracking [C] // Firness-in-Service and Decisions for Petroleum and Chemicial Equipment. PVP-Vol. 315. New York: ASME, 1995: 407.

TAN Jin-zhu, HUANG Wen-long. Application of Step-Cooling Test Method for Temper Embrittlement of 2. 25Cr-1 Mo Steel [J]. Journal of Nanjing University of Chemical Technology, 1998, 20(Supplement): 17 (in Chinese). au][5]_Masaaki Katsumata, Hisashi Takada, Hiromichi Hrano, et al, Temper Embrittlement in Pressure Vessel Steel [J]. 1981, 19 (3): 120.

Scott T E. Application of 2 1/4Cr-Mo Steel for Thick-Wall Pressure Vessels [MJ]. Baltimore: American Society for Testing and Materials, 1982.

Viswanathan R, Jaffee R I. 2 1/4Cr-1Mo Steels for Coal Conversion Pressure Vessels [J]. ASME Journal of Engineering Material and Technology, 1982, 104: 220.

McMahon C J, Genter D H, Ucisk A H. An Investigation of Grain Size and Hardness in Temper-Embrittled 2 1/4Cr-1Mo Steel [J]. ASME Journal of Engineering Material and Technology, 1984, 106: 66.

Mclean D. Grain Boundaries in Metals [D]. London: Oxford University Press, 1957. au][10] XU Ting-dong, CHENG Bu-yuan. Kinetics of Non-Equilibrium Grain-boundary Segregation [J]. Progress in Materials Science, 2004, 49: 109. au][11]_ZHANG Xi-liang, ZHOU Chang-yu. Study on Further Embri-ttlement Mechanism Based on the Theory of Equilibrium Grain Boundary Segregation [J]. Transactions of Materials and Heat Treatment, 2009, 30(4): 194.

Ogura T. A Method for Evaluation of the Mount of Grain-Boundary Segregation During Quenching [J]. Trans Japan Inst Met, 1981, 22(2): 109.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by Graduate Student Scientific Innovation Project of Jiangsu Province of China (CX09B_131Z)

Rights and permissions

About this article

Cite this article

Zhang, Xl., Zhou, Cy. Mechanism of Embrittlement and De-Embrittlement for 2. 25Cr-1Mo Steel. J. Iron Steel Res. Int. 18, 47–51 (2011). https://doi.org/10.1016/S1006-706X(11)60036-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(11)60036-8