Abstract

Insects are receiving a lot of attention as an alternative protein source, especially the black soldier fly, Hermetia illucens. This insect is of particular interest due to its potential as a waste converter as it can be grown on low-value organic substrates, such as agricultural side-streams, manure and decomposing materials. It’s capacity to turn low-value biomass into high-quality protein provide new opportunities in organic waste management. Unfortunately, rearing of black soldier fly larvae (BSFL) does not run efficiently on most substrates. Several parameters influence the rearing efficiency of BSFL. One of the parameters that is often overlooked is the moisture content of the substrate and the physical properties, such as water release/holding, associated with it. In this study the water release properties of 3 BSFL feeds, each at a dry matter content ranging from 10 to 90%, were investigated using 4 different methods, being water release by (1) filtration, (2) sedimentation, (3) syneresis and (4) centrifugation. Rearing of BSFL on the substrates with different dry matter content showed that water release influences larval performance and survival. Moreover, correlating survival to water release indicated that when substrates are hydrated to the minimum dry matter content, at which no water release is measured by the sedimentation method, the highest BSFL survival can be achieved for that substrate. In addition, a standardised method for determining the most optimal dry matter content of substrates based on substrate water holding capacity was developed.

Highlights

-

Novel findings: BSF larval growth linked to substrate water release properties.

-

Innovative method: Water Holding Capacity to determine optimal dry matter content.

-

Standardization potential: WHC as approach to optimize BSF rearing conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Unsustainable consumption and production practices along with population growth is challenging the balance of life on earth. For example, the depletion of natural resources, climate change, biodiversity loss, and pollution, caused by the food system today, negatively affect all life on our planet [1]. Therefore, in the last decades, an evolution towards a more sustainable food system is emerging, which is reflected by the Sustainable Development Goals of the United Nations [2, 3]. Challenges in sustainable food production and waste management, among others, need to be addressed rapidly.

Alternative proteins offer a promising pathway for sustainable food production. In recent years, insects have gained increasing attention as an alternative protein source for food and feed [4]. Insects are highly nutritious as they are rich in protein, which includes all essential amino acids, have unsaturated fatty acids, vitamins, and minerals [5]. Moreover the production of insects can have less impact on the environment than conventional protein sources as insects can be grown on organic waste streams, require less land and water, have a high feed conversion ratio etc. [4]. By growing insects on organic waste streams, this low-value biomass is converted into a valuable resource, thereby closing nutrient cycles and promote a circular economy. As such, insects may also provide new opportunities in organic waste management [6]

When it comes to the use of insects to process organic waste, the black soldier fly (Hermetia illucens) is of special interest as black soldier fly larvae (BSFL) can be reared on a wide variety of low-value organic substrates such as agricultural side-streams, manure and decomposing materials [7,8,9,10,11]. However, rearing of BSFL larvae on these low value organic substrates is often far from efficient resulting in low yields. This is because the composition of these substrates is in many cases not optimal. The potential of a side stream as an ingredient of a substrate for BSFL depends, among other things, on its chemical and physical properties. The influence of chemical parameters such as pH, macronutrient concentration and ratio have already been investigated, but the influence of the physical properties are often neglected [10, 12,13,14,15,16].

In this study the influence of the substrate moisture content on BSFL rearing is investigated. The moisture content of the substrate is pivotal as larval performance, e.g., growth, bioconversion efficiency, waste reduction and survival, is highly affected by the substrate moisture content [14, 16,17,18,19,20]. Understanding the influence of substrate moisture content on the rearing process is therefore crucial for the optimization of BSFL rearing. Studies have shown that substrate moisture content is positively correlated to larval growth, however when substrate moisture contents are too high, survival drop significantly, often leading to inconsistencies in yield per box [17,18,19,20].

Currently, there is no consensus about substrate moisture content for optimal BSFL rearing. In order to standardise substrate moisture many studies apply a 30% substrate dry matter content [11, 15, 21, 22]. However, depending on the physicochemical characteristics of the substrate, the substrate can be too dry, too wet or optimal for larval growth at 30% dry matter content. To overcome this problem, many studies report the addition of water or fibres to the substrate until visual full hydration and/or keep the total amount of dry matter used constant [15, 23,24,25]. However, this approach is often subjective and makes it difficult to compare results between studies. Therefore, there is a need for a new approach to standardise the moisture of BSFL substrates, based on the physical properties of the substrates.

There are a lot of physical parameters and associated measurement methods that describe the physical properties of materials. For this study, the physical properties related to substrate moisture content are of specific interest. Water release is one of these properties. Different methods have been described to measure water release/holding. They all measure the ability of a matrix to hold inherent or added water, but result in different outcomes as a different method is used. For instance water holding measured by allowing water to drip out of a matrix using only gravity may result in a higher water holding capacity measurement than when a centrifugal force is applied [26, 27].

This study explores variations in the physical characteristics among various BSFL substrates and examines how these properties are influenced by substrate moisture content. By rearing BSFL on the different substrates with different moisture content the aim is to determine how these physical properties influence larval performance and survival.

2 Material and methods

2.1 Substrates

Three feeds were used for the experiments, two types of chicken feed (Chicken Start Mash and Farmer Crumb, both purchased from AVEVE, Belgium) and Gainesville diet (50% wheat bran, 30% alfalfa meal, 20% corn meal—all ingredients purchased from AVEVE, Belgium). The two types of chicken feed had similar nutritional compositions (Table 1), but differed in texture. Chicken start mash is made from crushed grains and Farmer Crumb is a crumble made from pellets. For the experiments, the moisture content was adjusted by mixing with water up to a dry matter content (DM) of 10, 15, 20, 25, 30, 35, 40, 50, 60, 70, 80 and 90%, resulting in a total of 36 substrates. This was done at least 1 h before the start of the experiments. Except for the experiment to figure out the optimal soaking time for water holding capacity determination in which incubation times of 5, 30, 60 and 120 min were tested.

2.2 H. illucens larvae origin and maintenance

H. illucens are continuously propagated by the Centre of Expertise in Sustainable Biomass and Chemistry at Thomas More University of Applied Sciences, Belgium at the Insect Pilot Plant. For the feed experiments in this study, 1 g of eggs (deposited in a timespan of 24 h) was collected and transferred to a plastic weighing dish. The dish was put into a plastic container (diameter 95 mm) on a mixture of 100 g chicken feed (Chicken Start Mash (CSM), AVEVE, Belgium) and 100 mL tap water. The container with the eggs was incubated in a climate chamber at 27 °C and 60% relative humidity. On day 5 after egg collection the weighing dish was removed, 240 g chicken feed and 360 mL tap water was added to the larvae and gently mixed using a table spoon. 7 days after harvesting the eggs, larvae were separated from the residue by sieving and by forceps to start the feed experiments.

2.3 Physicochemical characterization:

Dry matter content (DM) was determined by drying the samples in an oven at 105 °C for 24 h (Heraeus, UT 6420) until constant weight. DM was calculated as:

In total 4 different techniques were performed to measure water release from the substrates: water release by (1) filtration, (2) sedimentation, (3) syneresis and (4) centrifugation. Both filtration and sedimentation use only gravity to separate excess water from the substrate. For the last two techniques a centrifugal force is applied (respectively 220 g and 10,000 g). The measurements were taken before the substrates were fed to the larvae.

To measure water release with the funnel method the protocol used by Hemmingsen was adapted [28]. A filter paper with a pore size of 12–15 µm was weighed. Subsequently, the filter paper was placed in a funnel, wettened and placed on a 100 mL graduated cylinder. An exact amount of 15 g of the substrate was weighed and added to the funnel. The cylinder was left undisturbed for one hour or until no further water was observed to drip out of the funnel. Afterward, the substrate, along with the filter paper, was weighed again. Finally, the water release by means of the filtration method (WRF) was calculated as:

with Mbefore and Mafter being the mass of the filter paper and substrate before and after filtration, respectively.

The sedimentation method was performed as follows. A 250 mL pre-weighted graduated cylinder was filled with 100 mL substrate and weighed. The cylinder was stored overnight in a refrigerator at 4 °C. The next day, the volume of the sediment was measured allowing to calculate the volume of supernatant. The volume of the supernatant was converted in weight (1 g/mL) and the percentage of supernatant was calculated as:

To measure syneresis the method of Keogh was used with slight modifications [29]. A 50 mL Falcon tube containing an amount between 10 and 20 mL substrate was weighed. The tube is centrifuged at 220 g for 10 min (Sorvall Lynx 4000, Thermo Scientific, USA). Subsequently, the water layer on top of the substrate was decanted. The Falcon tube with the remaining substrate was weighed. Water release by syneresis (WRS) was calculated as:

To measure water release by means of centrifugation (WRC) previously described methods to measure water holding capacity were used with slight modifications [30, 31]. A 50 mL Falcon tube containing an amount between 10 and 20 mL substrate was weighed. The tube is placed in a centrifuge (Sorvall Lynx 4000, Thermo Scientific, USA) that was set to 10,000 g for 30 min at 20 °C. Afterwards, the supernatant was discarded and the tube is turned upside down to leak out for 60 min. By weighing the Falcon tube with the substrate and remaining water, WRC was calculated as:

Water holding capacity (WHC) was measured using previously described methods with slight modifications [30, 31]. Approximately 2–3 g of substrate is weighed and put in a pre-weighted 50 mL Falcon tube. Water is added to the substrate until it is visually oversaturated. The tube is shaken vigorously and then incubated for 60 min. The tube is then centrifuged at 10,000 g for 30 min at 20 °C) (Sorvall Lynx 4000, Thermo Scientific, USA). The cap is removed and excess water is decanted. The tube is then turned upside down to allow free water to leak out for 30 min. Finally, the tube with the substrate and the retained water is weighed. Water holding capacity was expressed as the percentage of grams of retained water per grams of sample:

The dry matter content at water holding capacity (DM@WHC) is calculated as:

2.4 Experimental set-up of feed experiment:

For each substrate, 4 plastic containers (17.5 cm × 11.9 cm × 5.9 cm) were filled with 100 g dry matter of the substrate and water was added until a DM content of 25, 30, 35, 40 or 45% was reached (the containers were filled with 400, 333, 286, 250 or 222 g of wet substrate). Subsequently, 500 H. illucens larvae of ± 5 days old were added to each container. The weight and DM content of the larvae at the start of the experiment was determined. All containers were placed in a climate chamber (WEISS Pharma 600, Weiss Technik, Belgium) at 27 °C and 60% RH. Over the course of 9 days, on a daily basis, at random 20 larvae of each condition were picked using tweezers and weighed in order to draft a growth curve. After weighing larvae were returned to the corresponding containers. At day 9 of the experiment, all larvae were separated from their frass. Larvae were counted, weighed and their DM content was determined. The amount of prepupae was determined based on the dark colour of this larval phase. After harvesting the larvae, the total mass and DM content of the residues (i.e. frass) was determined.

Larval survival calculated as:

With #Lend and #Lstart respectively being the total amount of larvae at the end and the start of the feeding experiment.

Bioconversion efficiency (BE) and waste reduction (WR) were calculated at harvest as:

With Lend and Lstart respectively being the total larval mass at the end and the start of the feeding experiment. D is the total mass of the substrate provided and R is the mass of the frass at the end of the experiment. For calculation all fractions were expressed in DM.

2.5 Statistical analysis

All statistical analyses and graphical illustrations were generated using the JMP Pro15.1.0 software package from SAS (Buckinghamshire, UK). Least square linear regression was performed to investigate the relationship between DM of the substrate (independent variable) and water release by filtration, sedimentation, syneresis and water release by centrifugation (independent variables). Additionally, least square linear regression was performed to investigate the association between DM of the substrate (independent variable) and average larval end mass (independent variable). To model larval survival in function of water release by the free water method, the study evaluated both the quadratic and main effects through the application of standard least squares regression. To compare soaking times, one-way ANOVA and Tukey’s HSD post hoc tests were used. In all statistical analyses, a significance level of 0.05 was employed for hypothesis testing.

3 Results and discussion

3.1 Water release properties

The water release of the 3 feeds, each at a DM content ranging from 10 to 90%, was evaluated using 4 different methods being water release by filtration, sedimentation, syneresis and water release by centrifugation (Fig. 1, Tables 2 and S1).

Scatterplot of water release in function of DM content for Chicken Start Mash (CSM), Farmer Crumb (FC) and Gainesville diet (GD) measured by filtration (red), sedimentation (green), syneresis (purple) and centrifugation (blue) method. Points represent measurements, lines represent least square linear regression between water release and DM content. Vertical dashed lines indicate DM@WHC

Each tested method shows a strong negative linear correlation between water release and substrate DM content. The higher the DM content of the substrates the less water that is being released by all methods. Water release is measured until a DM content is reached after which no more water release occurs. The diverse methodologies employed yielded distinct rates of water release from the substrates. Centrifugation at 10,000 g and filtration consistently have a greater capacity for extracting higher quantities of water compared to the sedimentation and syneresis method, irrespective of the substrate's DM content and type of feed.

When comparing the same method for the different feeds it can be observed that the amount of water released, also depended on the type of feed. For instance, for the sedimentation method water release stops at approximately 30% DM for CSM and FC, whereas for GD this ‘threshold’ is already reached around 20% DM. Remarkably, for FC the difference in water release between the method using centrifugation at 10,000 g and the other methods is much higher than in the others feeds.

These findings indicate that variations in the physicochemical properties of the substrates influence the release of water from that substrate. Indeed, the differences observed between the feeds may depend on the ingredients used and how they were processed. For example, in chicken start mash, the ingredients are ground. Crumble starts as a mash that has steam added and is compressed into pellets, which are then crushed [32]. The extra processing steps for crumble causes it to have a better water absorption capacity and thus less water release than the mash [28, 33]. GD was composed in the lab by mixing finely ground wheat bran, maize and alfalfa [34]. Wheat bran and maize are also present in CSM and FC, but alfalfa is not. For alfalfa, pellets were used, for which it is known that it has a high water absorption capacity [35]. In addition, GD is much more finely ground than the other feeds, which may also cause the increase in water absorption capacity [28].

The differences between the different methods can be explained on the basis of the force and time used in the method. For instance the two techniques that used centrifugation utilised either 220 g for 10 min (syneresis method) or 10,000 g for 30 min (centrifugation method). The latter technique uses more force and more time and thus is able to extract more water from the substrates [36].

3.2 Influence of substrate moisture content on growth, survival and bioconversion of BSFL

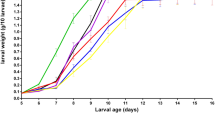

As water release between substrates at the same DM content differs, this may impact growth and survival of BSFL. To investigate this, larval performance parameters (growth, survival and bioconversion) were determined by growing larvae on the 3 different feeds with a varying DM content of 25, 30, 35, 40 or 45% (Tables 3 and S2, Figs. 2 and 3). Larvae grown on FC at 25% DM reached the highest larval end mass (237.02 ± 12.38 mg). For GD the highest larval end mass (136.64 ± 13.25 mg) was also reached at 25% DM. For CSM the highest larval end mass was 219.52 ± 14.78 g at 30% DM. For the tested substrates and moisture content, the larval end mass has a negative correlation with DM content (CSM: Y = 370–5.934*DM (%), R2: 0,725, F(1,18) = 47.42, P-value = < 0.0001; FC: Y = 376.3–5.35*DM (%), R2: 0.816, F(1,18) = 80.02, P-value = < 0.0001; GD: Y = 205–2.945*DM (%), R2: 0.801, F(1,18) = 72.31, P-value = < 0.0001). This trend is also reported in other studies [14, 20]. For survival an opposite trend is observed. The lowest survival rate was found at the lowest DM and is 29.80 ± 15.83%, 70.75 ± 3.65% and 88.86 ± 6.39% for CSM, FC and GD respectively. The lower the DM, and thus the higher the moisture content of the substrates, the lower the survival. However, this decline in survival only starts once a specific threshold is reached when reducing the DM content (Fig. 2b). Notably, this threshold is substrate-dependent. Thus, the DM at which growth and survival are best differs between substrates. These results indicates that setting up experiments with fixed DM contents, irrespective of the used substrate, is not the most optimal approach towards standardisation, as this will highly affect larval growth and survival.

Even though larval end mass increases at lower DM content, the survival rate drops when reaching a certain substrate-dependent DM threshold. One reason why larvae may reach a higher mass at lower DM contents could be explained by the opposite trend in survival. When less larvae survive, more feed is available per larvae, which is known to result in higher larval end mass [37]. Therefore, the bioconversion efficiency can give a better insight into the most optimal DM content for a substrate for BSFL rearing, as it is influenced by both the average larval end mass and the larval survival rate [38]. Optimal bioconversion efficiency can only be achieved when there is a favourable combination of high larval survival rate and substantial average larval end mass. Therefore, it is crucial to identify DM contents of the feeds that maximise the larval growth while minimising adverse effects on larval survival.

The highest bioconversion efficiency was measured at 35%, 30% and 25% DM for respectively CSF (24.86 ± 4.60), FC (33.89 ± 0.77) and GD (14.85 ± 1.15). As can be seen from the scatterplot between bioconversion efficiency and substrate DM content, differences are present between the different substrates (Fig. 3). These findings suggest that a fixed DM content is not advisable for rearing BSFL, as the optimal moisture levels vary depending on the substrate type.

3.3 Larval survival in function of water release

Because the higher larval end mass at lower DM may have been caused by the presence of more feed per larva at lower survival, it is important to keep this survival as high as possible in feeding trials. Larval survival showed to depend on both the DM content and type of substrate. One of the main reasons why larval survival differentiates between substrates at the same DM content could be the presences of excess water in which larvae are drowning [39]. If this is true, larval survival would be correlated with water release. To investigate this, survival was plotted in function of water release (WR) measured by filtration, sedimentation, syneresis or centrifugation (Fig. 4).

For all methods 0% water release (vertical line) corresponds to high survival. However, for the filtration, syneresis and centrifugation method survival also remains high even when water release is already measured. For instance the syneresis method shows high survival rates even at 15% water release. Only for the excess water measured by the sedimentation method, survival drops for all substrates once excess water is measured. This means that when substrates are hydrated to the minimum DM content, at which no water release is measured by the sedimentation method, the highest BSFL survival can be achieved for that substrate.

In Fig. 5 and Table 4, the results of a model are displayed, in which survival was set as dependent variable and both the main and quadratic effect of water release by the sedimentation method, were set as effects (R2 = 0.80, F(2,59) = 117.41, P < 0.0001). The effects of both the main (P < 0.001) and the quadratic effect (P < 0.05) of water release through the sedimentation method is significantly affecting larval survival with maximal survival rates at 0% water release.

3.4 Development of a standardised method for determining the ideal moisture content of substrates

Measurement of water release by the sedimentation method allowed to identify the substrate DM content which results in het highest larval survival rate. Next, the aim was to find or develop a reproducible and quick method to determine the DM content of a substrate at which no water release occurs, without having to measure a range of DM contents for each new substrate tested.

In food technology, water holding capacity (WHC), also called water absorption capacity (WAC) or water binding capacity (WBC), is a method that is often used to determine the amount of water that can be absorbed by a substrate and thereby also the DM content at which no water is released from the substrate. WHC consists of adding water to a substrate, followed by centrifugation and quantification of the water retained by the pelleted substrate in the centrifuge tube [40]. The WHC represents a percentage which displays the mass of water that can physiochemically bind to 1 g of substrate.

When performing the experiment according to Steffolani et al. [30], it was noted that the substrate was not completely retained in the falcon tubes. As a result, the experiment was optimised to centrifuging the falcon tubes at 10,000 g for 30 min. The substrates contain coarser particles making it more difficult to form a compact sediment when wetting and centrifuging. Centrifugation at a higher speed for a longer period of time will ensure that the substrates remain better attached in the falcon tube.

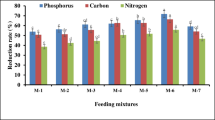

In order to figure out the optimal soaking time, excess water was added to CSM, FC and GD. Incubation times of 5, 30, 60 and 120 min were tested (Fig. 6). For all tested substrates, an incubation period of 60 min showed the highest WHC. For FC and CSM, an incubation period of 60 min resulted in a significantly higher WHC than 5 and 30 min (P < 0.05). Even though for GD the WHC was higher at 60 min incubation compared to 30 min incubation, the P-value was not significant. No significant differences in WHC were present between 60 and 120 min of incubation. Therefore, an incubation time of 60 min was selected for further experiments.

Bar plots displaying water holding capacity (WHC) at soaking/incubation times of 5, 30, 60 and 120 min for three substrates (chicken start mash (CSM), farmer crumb (FC) and Gainesville diet (GD). Bars display mean and error bars display standard deviation (n = 3). Letters represent significant differences (P < 0.05) between soaking time for each feed

Based on the water holding capacity, the corresponding DM contents were calculated to evaluate whether WHC could be used as a method to quickly determine the point of 0% water release by the sedimentation method. The DM at WHC was 35.55% for CSM, 34.21% for FC and 23.08% for GD (Fig. 1). Substrate DM contents at WHC have a slightly higher DM content compared to 0% water release measured by the sedimentation method. Compared to 0% water release measured by centrifugation, the DM content at WHC is lower, especially for FC. Intuitively, WHC is expected to yield similar outcomes to the water release measured through the centrifugation method. However, there exists one crucial distinction between the WHC method and the centrifugation method, which relates to the initial hydration level prior to centrifugation. In the WHC method, the substrate is fully hydrated during a one-hour incubation period. In contrast, the centrifugation method involves testing substrates with varying DM contents mixed with water. Due to this distinction, when water and substrate are solely mixed without achieving 100% contact, the substrate's absorption of water becomes suboptimal. Consequently, even after thorough mixing, certain regions of the substrate may be excessively hydrated while others remain inadequately hydrated. Consequently, during the centrifugation method, water continues to be released, even at the maximum water holding capacity, since some areas of the substrate remain capable of releasing water. This discrepancy explains why more water is extracted through the centrifugation method compared to the amount of water required according to the WHC method, highlighting the stronger association of WHC with the free water method.

Nevertheless, it should be noted that the measured substrate DM contents at WHC are at average 2% higher compared to the DM content at 0% water release measured by the sedimentation method. However, this is likely beneficial. There is a thin line between most optimal DM content and overhydration of the substrate. Overhydration quickly results in a decrease in larval survival and bioconversion efficiency accordingly. Therefore, a safety margin of 2% might be beneficial for BSFL rearing as the increase in DM content can act as a buffer in case too much water was added. It should further be noted that WHC determination also shows a higher reproducibility and is more accurate than the sedimentation method. In conclusion, the WHC method can be a reproducible, standardisable and quick way to determine the most optimal DM content for any type of substrate.

In Fig. 7 the yield, survival, average larval end mass, bioconversion efficiency, as well as the waste reduction of larvae reared on CSM, FC and GD are displayed for the different DM contents. Also, the DM contents corresponding to the WHC for each substrate is displayed. For CSM, the DM content at WHC is very close to the optimal bioconversion efficiency. For FC, the WHC also lies between the two highest measure points regarding bioconversion efficiency. For GD, the WHC is lower than the tested conditions, but as bioconversion efficiency did not reach a visible maximum yet at 25% DM, it is likely that this point would be close to most optimal point for bioconversion efficiency.

As can be observed, high survival rates are present at higher DM contents, however, at a substrate-dependent DM content, the survival rates drop, indicating larvae drowning. These findings are supported by other scientific publications [17,18,19,20]. Figure 7 also confirms that lower DM contents are correlated with higher mean individual larval end mass. From that point of view, it would be logical to decrease substrate DM contents and thus increase the moisture content. Currently, that is what many BSFL producers do as they prefer to use wet substrates that allow being transported by pump systems. However, by doing so, inconsistent results are obtained due to fluctuations in larval survival.

Upon close observation of bioconversion efficiency, it becomes evident that blindly increasing the moisture content does not necessarily translate into higher bioconversion efficiency (and thus higher yields), regardless of larvae growing bigger. It is likely that larvae just grow bigger because survival rates drop and therefore, more substrate is available per larva, allowing higher individual mass. The same principle applies to waste reduction. Optimal waste reduction is achieved when there is an ideal combination of substrate DM content and larval survival rate.

In conclusion, utilizing the WHC method as a gravimetric technique, to determine the appropriate substrate DM content allows for maximal larval survival, as well as enhanced bioconversion efficiency, waste reduction, and overall larval yield.

4 Conclusion

This study has provided valuable insights into the relationship between substrate properties, more specifically water release, and larval performance in BSF rearing. The findings highlight the importance of considering the physicochemical characteristics of substrates when determining optimal larval growth parameters. Even though a decrease in substrate DM content leads to increased larval growth, once excess water is present in the feeding substrate at the start larval survival rates drop, leading to a decrease in larval survival, bioconversion efficiency, waste reduction and total larval yield.

Fixed DM contents, irrespective of the substrate, may not be suitable for standardisation, as they can significantly impact larval performance. The results emphasise the need to take into account the hydration capacity of substrates when conducting BSFL experiments and establishing rearing conditions. Use of the WHC as a gravimetric technique to determine the optimal DM content of feeding substrates provided promising results. The WHC method demonstrated reproducibility and accuracy in determining the 0% water release point of a substrate. This approach proved to be a viable way to standardise the BSFL substrate DM content, as it correlated well with larval survival, bioconversion efficiency, waste reduction, and overall larval yield. Therefore, this method would be an innovative approach to standardise the DM content of feeding substrates in experiments and rearing conditions globally.

In this study the DM content and water release properties of the substrates were only analysed prior to feeding them to the BSFL. Further investigation into the dynamics of water content throughout the rearing process could provide valuable insights for optimizing larval rearing conditions. In this study commercially available feeds were used as it was necessary to use substrates with a constant and stable composition over time. Validation of these results with other substrates such as organic waste streams used in the production of BSFL is a next step in the research towards optimization of BSF rearing.

In conclusion, understanding and optimising water release from substrates is essential for maximising larval performance in BSFL rearing. The findings of this study offer valuable insights and provide a foundation for developing standardised protocols that can enhance the efficiency of BSF production systems.

Data availability

The datasets generated during and analysed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

Hellweg S, Pfister S, Cabernard L, Droz-Georget H, Froemelt A, Haupt M, et al. Environmental impacts of natural resource use. Global Resources Outlook. 2019. https://doi.org/10.18356/64c3b469-en.

Fitzherbert EB, Struebig MJ, Morel A, Danielsen F, Brühl CA, Donald PF, et al. How will oil palm expansion affect biodiversity? Trends Ecol Evol. 2008;23:538–45. https://doi.org/10.1016/J.TREE.2008.06.012.

Saxena A, Ramaswamy M, Beale J, Marciniuk D, Smith P. Striving for the United Nations (UN) Sustainable Development Goals (SDGs): What will it take? Discover Sustain. 2021. https://doi.org/10.1007/s43621-021-00029-8.

van Huis A, Oonincx DGAB. The environmental sustainability of insects as food and feed. A review. Agron Sustain Dev. 2017. https://doi.org/10.1007/s13593-017-0452-8.

Orkusz A. Edible insects versus meat—nutritional comparison: knowledge of their composition is the key to good health. Nutrients. 2021. https://doi.org/10.3390/nu13041207.

Tomberlin JK, van Huis A. Black soldier fly from pest to “crown jewel” of the insects as feed industry: an historical perspective. J Insects Food Feed. 2020. https://doi.org/10.3920/JIFF2020.0003.

Gligorescu A, Fischer CH, Larsen PF, Nørgaard JV, Heckman L-HL. Production and optimization of Hermetia illucens (L.) larvae reared on food waste and utilized as feed ingredient. Sustainability. 2020;12:9864. https://doi.org/10.3390/SU12239864.

Surendra KC, Tomberlin JK, van Huis A, Cammack JA, Heckmann LHL, Khanal SK. Rethinking organic wastes bioconversion: evaluating the potential of the black soldier fly (Hermetia illucens (L.)) (Diptera: Stratiomyidae) (BSF). Waste Manag. 2020;117:58–80. https://doi.org/10.1016/j.wasman.2020.07.050.

Pliantiangtam N, Chundang P, Kovitvadhi A. Growth performance, waste reduction efficiency and nutritional composition of black soldier fly (Hermetia illucens) larvae and prepupae reared on coconut endosperm and soybean curd residue with or without supplementation. Insects. 2021. https://doi.org/10.3390/insects12080682.

Meneguz M, Gasco L, Tomberlin JK. Impact of pH and feeding system on black soldier fly (Hermetia illucens, L; Diptera: Stratiomyidae) larval development. PLoS ONE. 2018;13:1–15. https://doi.org/10.1371/journal.pone.0202591.

Broeckx L, Frooninckx L, Slegers L, Berrens S, Noyens I, Goossens S, et al. Growth of black soldier fly larvae reared on organic side-streams. Sustainability. 2021. https://doi.org/10.3390/su132312953.

Ma J, Lei Y, Rehman KU, Yu Z, Zhang J, Li W, et al. Dynamic effects of initial ph of substrate on biological growth and metamorphosis of black soldier fly (Diptera: Stratiomyidae). Environ Entomol. 2018;47:159–65. https://doi.org/10.1093/EE/NVX186.

Gold M, Tomberlin JK, Diener S, Zurbrügg C, Mathys A. Decomposition of biowaste macronutrients, microbes, and chemicals in black soldier fly larval treatment: a review. Waste Manag. 2018;82:302–18. https://doi.org/10.1016/j.wasman.2018.10.022.

Cammack JA, Tomberlin JK. The impact of diet protein and carbohydrate on select life-history traits of the black soldier fly Hermetia illucens (L.) (Diptera: Stratiomyidae). Insects. 2017. https://doi.org/10.3390/insects8020056.

Barragán-Fonseca KB. Flies are what they eat—tailoring nutrition of BSF (Hermetia illucens) for larval biomass production and fitness; 2018.

Eggink KM, Donoso IG, Dalsgaard J. Optimal dietary protein to carbohydrate ratio for black soldier fly (Hermetia illucens) larvae. J Insects Food Feed. 2023. https://doi.org/10.3920/JIFF2022.0102.

Palma L, Ceballos SJ, Johnson PC, Niemeier D, Pitesky M, VanderGheynst JS. Cultivation of black soldier fly larvae on almond byproducts: impacts of aeration and moisture on larvae growth and composition. J Sci Food Agric. 2018;98:5893. https://doi.org/10.1002/JSFA.9252.

Bekker NS, Heidelbach S, Vestergaard SZ, Nielsen ME, Riisgaard-Jensen M, Zeuner EJ, et al. Impact of substrate moisture content on growth and metabolic performance of black soldier fly larvae. Waste Manage. 2021;127:73–9. https://doi.org/10.1016/J.WASMAN.2021.04.028.

Yakti W, Müller M, Klost M, Mewis I, Dannehl D, Ulrichs C. Physical properties of substrates as a driver for Hermetia illucens (L.) (Diptera: Stratiomyidae) larvae growth. Insects. 2023;2023(14):266. https://doi.org/10.3390/INSECTS14030266.

Cheng JYK, Chiu SLH, Lo IMC. Effects of moisture content of food waste on residue separation, larval growth and larval survival in black soldier fly bioconversion. Waste Manag. 2017;67:315–23. https://doi.org/10.1016/j.wasman.2017.05.046.

Holmes LA, Vanlaerhoven SL, Tomberlin JK. Substrate effects on pupation and adult emergence of Hermetia illucens (Diptera: Stratiomyidae). Environ Entomol. 2013;42:370–4. https://doi.org/10.1603/EN12255.

Ribeiro N, Costa R, Ameixa OMCC. The influence of non-optimal rearing conditions and substrates on the performance of the black soldier fly (Hermetia illucens). Insects. 2022. https://doi.org/10.3390/INSECTS13070639/S1.

Gold M, Marie C, Zurbrügg C, Kreuzer M, Boulos S, Diener S, et al. Biowaste treatment with black soldier fly Larvae: increasing performance through the formulation of biowastes based on protein and carbohydrates. Waste Manag. 2020;102:319–29. https://doi.org/10.1016/j.wasman.2019.10.036.

Veldkamp T, van Rozen K, Elissen H, van Wikselaar P, van der Weide R. Bioconversion of digestate, pig manure and vegetal residue-based waste operated by black soldier fly larvae, Hermetia illucens L. (diptera: Stratiomyidae). Animals. 2021. https://doi.org/10.3390/ani11113082.

Oemar T, Purwaningrum P, Ruhiyat R, Ashardiono F. Potential of black soldier fly (BSF) in reducing municipal food loss and waste (FLW) at Taman Sari district, West Jakarta. Indones J Urban Environ Technol. 2023. https://doi.org/10.25105/urbanenvirotech.v6i2.16932.

Charoenrein S, Tatirat O, Muadklay J. Use of centrifugation-filtration for determination of syneresis in freeze-thaw starch gels. Carbohydr Polym. 2008. https://doi.org/10.1016/j.carbpol.2007.11.012.

Unbehend L, Unbehend G, Strelec I. Water absorption determination of wheat flours applying centrifuge and its relationship to farinograph water absorption determination. Deutsche Lebensmittel Rundschau. 2006;102:1.

Hemmingsen AKT, Stevik AM, Claussen IC, Lundblad KK, Prestløkken E, Sørensen M, et al. Water adsorption in feed ingredients for animal pellets at different temperatures, particle size, and ingredient combinations. Drying Technol. 2008. https://doi.org/10.1080/07373930802046393.

Keogh MK, O’Kennedy BT. Rheology of stirred yogurt as affected by added milk fat, protein and hydrocolloids. J Food Sci. 1998. https://doi.org/10.1111/j.1365-2621.1998.tb15687.x.

Steffolani ME, Villacorta P, Morales-Soriano ER, Repo-Carrasco R, León AE, Pérez GT. Physicochemical and functional characterization of protein isolated from different quinoa varieties (Chenopodium quinoa willd.). Cereal Chem. 2016. https://doi.org/10.1094/CCHEM-04-15-0083-R.

Ma KK, Grossmann L, Nolden AA, McClements DJ, Kinchla AJ. Functional and physical properties of commercial pulse proteins compared to soy derived protein. Fut Foods. 2022. https://doi.org/10.1016/j.fufo.2022.100155.

Al-Nasrawi MAM. The impact of different dietary forms (mash, crumble and pellets) on some growth traits and carcass characteristics of broilers. J Anim Health Prod. 2016. https://doi.org/10.14737/journal.jahp/2016/4.2.31.36.

Liu K, Frost J, Welker TL, Barrows FT. Comparison of new and conventional processing methods for their effects on physical properties of fish feed. Anim Feed Sci Technol. 2021. https://doi.org/10.1016/j.anifeedsci.2021.114818.

Hogsette JA. New diets for production of house flies and stable flies (Diptera: Muscidae) in the laboratory. J Econ Entomol. 1992;85:2291–4. https://doi.org/10.1093/JEE/85.6.2291.

Brachet M, Arroyo J, Bannelier C, Cazals A, Fortun-Lamothe L. Hydration capacity: a new criterion for feed formulation. Anim Feed Sci Technol. 2015. https://doi.org/10.1016/j.anifeedsci.2015.07.014.

Wolfschoon-Pombo AF, Dang BP, Chiriboga B. Forced syneresis determination results from commercial cream cheese samples. Int Dairy J. 2018. https://doi.org/10.1016/j.idairyj.2018.05.006.

Yuan MC, Hasan HA. Effect of feeding rate on growth performance and waste reduction efficiency of black soldier fly larvae (Diptera: Stratiomyidae). Trop Life Sci Res. 2022. https://doi.org/10.21315/tlsr2022.33.1.11.

Bosch G, Oonincx DGAB, Jordan HR, Zhang J, van Loon JJA, van Huis A, et al. Standardisation of quantitative resource conversion studies with black soldier fly larvae. J Insects Food Feed. 2020;6:95–109. https://doi.org/10.3920/jiff2019.0004.

Lalander C, Ermolaev E, Wiklicky V, Vinnerås B. Process efficiency and ventilation requirement in black soldier fly larvae composting of substrates with high water content. Sci Total Environ. 2020. https://doi.org/10.1016/j.scitotenv.2020.138968.

Garcia-Vaquero M, Lopez-Alonso M, Hayes M. Assessment of the functional properties of protein extracted from the brown seaweed Himanthalia elongata (Linnaeus) S. F. Gray. Food Res Int. 2017;99:971–8. https://doi.org/10.1016/J.FOODRES.2016.06.023.

Funding

This research was funded by the Flanders Innovation & Entrepreneurship, project No. HBC.2019.0028, as a part of the Era-Net Cofund “FACCE SURPLUS”.

Author information

Authors and Affiliations

Contributions

Lotte Frooninckx designed the experiments. Lotte Frooninckx, Sarah Goossens, Laurens Broeckx and Ann Wuyts performed the experiments, Lotte Frooninckx and Laurens Broeckx processed the data, drafted the manuscript and designed the figures. Sabine Van Miert supervised the project and reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Ethics approval

No approval of research ethics committees was required to accomplish the goals of this study because experimental work was conducted with an unregulated invertebrate species.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Frooninckx, L., Broeckx, L., Goossens, S. et al. Optimizing substrate moisture content for enhanced larval survival and growth performance in Hermetia illucens: exploring novel approaches. Discov Anim 1, 7 (2024). https://doi.org/10.1007/s44338-024-00005-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44338-024-00005-2