Abstract

Currently, the viscoelastic properties of standard asphalt cement cannot sustain the increasing demands resulting from heavier traffic loads, greater stress levels, and changing environmental conditions. Thus, the usage of modifiers is encouraged. Also, the Sustainable Development Goal (SDG) encourages the use of waste resources and emerging technologies in asphalt pavement technology. This study intends to harness this gap by examining the use of oil palm clinker (OPC) as an asphalt-cement modification to improve its viscoelastic properties using an innovative prediction approach. The modified asphalt-cement was produced by varying the acid-treated OPC powder (OPCP) content at 2%, 4%, 6%, and 8% and the rutting and fatigue performance was evaluated. This paper also presents an optimization approach and prediction comparison based on statistical modeling and artificial intelligence (AI) algorithms for the fatigue and rutting parameters of the modified asphalt cement. Model variables for the predictive models include OPCP content and test temperatures. The AI algorithms use 70% of the data for training, 15% for testing, and 15% for validation. The results showed that the incorporation of OPCP improves the properties of pure asphalt-cement by increasing stiffness and temperature susceptibility and that the crystalline phase of Si–O formed a novel structural group Si–OH. The RSM R2 for rutting for unaged and RTFO aged responses was (99.743 and 99.893), the RMSE was (436.210 and 954.945), and the MRE was 3.269 and 2.315) for the model statistical performance index, respectively. The ANN R2 for rutting for unaged and RTFO aged responses were (99.903 and 99.970) the RMSE (106.283 and 528.500) and MRE (1.759 and 1.039). PAV fatigue RSM R2 values were (99.984), RMSE (77979.750), and MRE (12.089), while ANN R2 values were (99.997), RMSE (53933.500), and MRE (5.262). The findings demonstrated that the generated model and algorithm could predict the fatigue and rutting performance of the OPCP-modified asphalt cement accurately with the AI algorithms model outperforming the statistical model. Also, the study aligns with SDG 9 by developing advanced modeling techniques and enhancing infrastructure durability through innovative use of modified materials as well as SDG 12 by incorporating recycled materials into sustainable production practices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Asphalt cement is an essential component of an asphalt mixture because it holds the aggregate particles together, provides load bearing, and is crucial in increasing the service life of an asphalt mixture [1]. As a result, the type and qualities of asphalt cement employed in an asphalt mixture have a significant impact on its overall performance. Asphalt cement serves as a glue, holding the mixture together and providing the essential flexibility and durability to the asphalt pavement. In addition, when designing and building pavements, it is critical to consider both short-term and long-term aging of asphalt cement to ensure long-term performance [2]. Short-term aging is caused by heating and cooling during production, as well as exposure to air and water, whereas long-term aging is caused by exposure to environmental variables such as temperature, sunlight, water, and air, which cause the binder to become more brittle and elastic, making it more prone to cracking [3, 4]. The viscosity, flexibility, and aging resistance of the binder can all have an impact on how resistant the combination is to various types of distress [5, 6]. Rutting and fatigue cracking are two prominent pavement issues in tropical regions with intermediate to high temperatures. Repeated loads and temperature variations create fatigue cracking, which results in the creation of tiny fractures that can grow and intersect over time [7, 8].

Rutting is a type of deformation caused by automobiles continuously loading an asphalt pavement, permanently deforming the asphalt cement, and forming longitudinal depressions. In tropical climates with intermediate to high temperatures, both fatigue cracking and rutting can drastically limit the service life of asphalt pavement [8,9,10]. As a result, selecting an asphalt cement with the necessary qualities is crucial for resolving pavement difficulties and extending the service life of asphalt. Modifiers are applied to a mix to increase its performance and design life [11, 12]. Biomass waste is an effective modifier, and employing oil palm waste as a modifier is an environmentally benign way to improve asphalt mixture performance and promote asphalt pavement sustainability [12,13,14].

Malaysia is a major producer of oil palm, and the oil palm business is significant to the Malaysian economy [15]. The oil palm operations generate a substantial quantity of trash, including empty fruit bunches, palm kernel shells, and mesocarp fiber, all of which can be recycled for energy production and other industrial applications [12, 16]. However, inadequate management and a lack of infrastructure can result in waste accumulation and environmental problems such as air and water pollution [17, 18]. To alleviate this issue, initiatives such as using oil palm trash as a resource or construction material are advocated [19]. Oil palm clinker is a byproduct of the oil palm industry. It is a solid material formed from the combustion of fibers, shells, and other materials used in the oil palm industry to generate power [15]. Oil palm industrial clinker is a solid substance comprised primarily of calcium oxide and silicon dioxide [18]. Thus, the goal of this research is to identify opportunities for waste management improvement as well as the application of sustainable practices in the oil palm and pavement industries. Several studies have demonstrated that the use of agricultural and industrial by-products in asphalt cement and mixtures [20,21,22] can increase asphalt cement resistance to rutting and fatigue [16, 23]. However, testing asphalt cement in the laboratory for fatigue and rutting resistance requires specialised equipment, several sample runs, and a significant amount of time. Furthermore, understanding and modelling the performance of asphalt cement and mixes is difficult since the elements used in the mix respond differently under different loads and climatic circumstances. Furthermore, the components in the mix can behave differently to different loads and climatic circumstances, making it difficult to predict their performance [24]. To improve predictions, a clear mathematical relationship between inputs and outputs must be established, and statistical approaches such as response surface methodology (RSM) and design of experiments (DOE) can be employed to analyse laboratory test data from the DSR test to identify key variables influencing the viscoelastic properties of the binder. Artificial neural networks (ANNs) and other AI techniques can also be utilized to accurately predict the viscoelastic properties of asphalt cement.

Predictive models are commonly used in pavement construction to forecast the properties of asphalt mixtures under varied loads and environmental conditions by utilizing mechanical performance indicators. However, these models do not account for the unique qualities of the asphalt cement utilized, which influence rutting and fatigue cracking resistance [25, 26]. Thus, this study aims to tackle this constraint by utilizing statistical models and AI algorithms by adding binder selection as key determinants of rutting and fatigue cracking resistance in asphalt cement, such as asphalt cement complex shear modulus and phase angle. RSM has been used to explore the influence and interplay between frequency and temperature, and how these affect the rutting resistance of asphalt mixes [27]. Badri, et al. [26] also utilize RSM to evaluate asphalt cement behavior under various aging situations by considering the complex modulus and phase angle. Furthermore, Al-Sabaeei, et al. [28] also used RSM to predict the high-temperature rheological properties of crude oil palm bio-binder under different aging conditions. They measured the complex modulus and phase angle of bio-binders at various concentrations (0%, 5%, 10%, and 15%) and test temperatures ranging from 40 °C to 76 °C. The results demonstrate the effectiveness of using RSM statistical analysis to model and predict the complex modulus and phase angle of bio-binders. In addition, Al-Sabaeei, et al. [29] employed RSM and machine learning to predict high-temperature rheological properties from nonlinear viscoelastic properties. In terms of accuracy and efficacy in predicting asphalt cement rutting parameters, the study results and statistical criteria show that machine learning models outperform RSM. Ghasemi, et al. [30] use machine learning models to predict the performance of asphalt cement and mixtures. The results show that the dynamic modulus of asphalt mixtures was correctly predicted using the ANN model. Furthermore, Hamzah, et al. [31] used RSM to examine and optimize the voids and Marshall properties of warm mix asphalt and enhanced the Rediset proportion in asphalt cement.

The use of statistical models and artificial intelligence algorithms to optimize and anticipate pavement performance parameters is a rapidly developing topic with tremendous potential to improve asphalt pavement performance. Using both statistical approaches and AI algorithms to evaluate asphalt binders' viscoelastic properties can enhance forecast accuracy and dependability, allowing binder behavior and performance to be optimized during pavement building. These methods have been used to achieve a variety of goals, including predicting asphalt mixture rutting [24], identifying asphalt distresses, examining and predicting the rutting parameter of composite modified asphalt cement [29], and assessing the viscoelastic performance of modified asphalt cement [26]. However, it is vital to examine the feasibility of using AI algorithms to anticipate asphalt cement fatigue and rutting parameters at intermediate and high temperatures. One of the key advantages of utilizing AI algorithm approaches is their capacity to comprehend complicated behaviors without requiring a prior understanding of the relationship between input components and outputs. Furthermore, these methodologies facilitate the comparison and selection of ideal running parameters for asphalt mixtures with fewer test runs. As a result, the procedure becomes more efficient, and the number of experiments is reduced [24, 32, 33]. However, there has been limited research on using Response Surface Methodology (RSM) and Artificial Neural Network (ANN) modeling techniques to develop and test predictive models for the fatigue and rutting parameters of oil palm clinker-modified asphalt cement (OPCP-MAC). This study aims to fill that gap by employing laboratory testing along with statistical models such as RSM and AI algorithms to predict and optimize the properties of the modified asphalt cement. Thus, this study is significant for several reasons. It promotes the use of sustainable materials, enhances pavement performance and durability, and applies advanced predictive modeling approaches. The study also provides economic benefits, advances scientific knowledge, and offers practical applications. The approach used in this research is both logical and modern, enabling efficient and accurate analysis of complex data sets. This data can then be used to optimize the properties of the modified asphalt cement, thereby improving its performance in pavement construction.

The objective of this study is to evaluate the influence of OPCP content and test temperature on the fatigue and rutting parameters of OPCP-modified asphalt cement. Furthermore, using experimental data, the study investigates the effectiveness of two optimization methods, RSM and ANN, in determining the optimal OPCP content and temperature for optimal OPCP-MAC performance. The study uses OPCP content and test temperature as input variables to predict fatigue parameters for PAV-aged samples and rutting parameters for unaged and RTFO-aged samples. This study aims to develop and validate predictive models using RSM and ANN methods using laboratory experimental data. This will be accomplished through data collection, preprocessing, model development, training, validation, and optimization analysis.

2 Material and methodology

2.1 Oil palm clinker powder (OPCP)

This study used waste from palm oil production, specifically oil palm clinker (OPC), obtained from a company that processes locally supplied waste oil palm. The OPC was cleansed of debris, dried at 100 ºC for 24 h, then ground into a powder using a Los Angeles abrasion machine (LAAV) at 150 revolutions per minute for 8 h. The resultant powder was sieved through a 200 mm aperture size, yielding oil palm clinker powder (OPCP), which was employed in the study. OPCPs are formed by burning palm fiber and shells at extremely high temperatures. Acid pre-treatment was used to increase the purity of silicon dioxide (SiO2) in the OPCP. This procedure helped to separate any metal linkages and remove unburned organic debris from the OPCP, resulting in purer and more soluble SiO2. In this investigation, 50 g of OPCP were acid pre-treated with 500 ml of dilute sulphuric acid solution at a concentration of 0.1 mol. For 1 h, the mixture was magnetically stirred at 80 ºC. After cooling to room temperature, the pre-treated OPCP was filtered using a vacuum pump, rinsed with distilled water to remove sediment, and dried in an oven overnight before being utilized in the study.Fig. 1 shows the OPCP before and after treatment.

2.2 Asphalt cement

This study used pure asphalt cement, which is commonly employed in Malaysia for asphalt applications and has a penetration grade of 80/100. The physical and chemical qualities of this asphalt cement were assessed to guarantee compliance with standard criteria. The results of these experiments on pure asphalt cement are presented in Table 1.

2.3 Microstructural characterizations

The study used several analytical approaches to investigate the material and asphalt cement. The chemical composition of OPCP was evaluated using the S8 TIGER Series Bruker spectrometer and an X-ray fluorescence (XRF) analyzer under helium gas conditions. Using an FTIR spectrometer (PerkinElmer Frontier 01 model), transmittance was measured in the 480–4000 cm⁻1 wave number range to explore the chemical composition of OPCP and the structural features of pure and OPCP-modified asphalt cement. The material's crystal structure and mineral phases were analyzed using XRD (Bruker D2 Phaser) using scans from 5° to 80° across a 2θ range. The XRD peaks were then analyzed using the HighScore Plus analytical tool. FESEM (Tescan Clara) was used to study the material's morphology and physical changes.

2.4 Modified sample preparation and characterization using conventional tests

The study OPCP-modified asphalt cement (OPCP-MAC) was prepared with a high-shear multi-mix laboratory stirrer. To simplify mixing and modification, penetration grade 80/100 pure asphalt cement was first heated in an oven at 130 °C. A steel mixing vessel was then filled with predetermined amounts of heated pure asphalt cement. To avoid clumping, varied amounts of OPCP were added progressively based on the weight of pure asphalt cement. The OPCP and pure asphalt cement were blended for 52 min at 140 °C using an automatic blender set to 1000 rpm, yielding a homogenous mixture [17]. Standard tests were used to determine the properties of the asphalt cement blend. The standard properties of the pure and OPCP-MAC blends were evaluated using standard conventional methods, such as determining penetration values and softening points per ASTM D5 and ASTM D36 standards and evaluating mix ductility following ASTM D113. To test the temperature sensitivity of the asphalt cement, the Shell bitumen manual recommended using the Penetration Index (PI) of pure and OPCP-MAC blends. Furthermore, using the PN-EN 13399, a storage stability test was done to examine the high-temperature stability of pure asphalt cement and OPCP-MAC during high-temperature storage conditions.

2.5 Laboratory short-term aging for rutting using a rolling thin film oven (RTFO).

Short-term aging was carried out following ASTM D2872-12 to model the effects of temperature and air on binders during asphalt mixture blending. Eight glass vials with 35 ± 0.5 g of binder samples were spun vertically in the Rolling Thin Film Oven (RTFO) for 85 min at 163 °C. To avoid a blended crust from forming, a thin layer of binder sample flowed continually inside the jar during the test [34]. The specimen revolved at 15 rpm and had an airflow rate of 4000 ± 300 mL/min. Following RTFO testing, conventional and rheological tests were performed on the short-term aged samples. The percentage mass loss of the aged binder, calculated using Eq. (1), was determined to ensure it did not exceed 1%, as required by the Superpave standard.

2.6 Laboratory long-term aging for fatigue evaluation using a pressure aging vessel (PAV).

In this study, the long-term aging effects of asphalt cement were evaluated using the Pressurised Ageing Vessel (PAV) method in accordance with ASTM D6521-13. To replicate the oxidative ageing that happens over the service life of asphalt cement, residue from previous RTFOT experiments was subjected to pressurized circumstances at high temperatures. A PAV pan with 50 g of RTFOT-aged material was placed inside a temperature-controlled pressure vessel. The PAV compartment was heated to 100 °C for a minimum of two hours. After preheating, an air pressure of 2.10 ± 0.1 MPa was supplied to begin the aging process. The samples were left to mature for 20 h and 10 min at 100 °C. After the aging period, the pressure was progressively relieved, and the samples were taken from the PAV pan. They were then degassed in a 163 °C oven for 15 min before cooling and being placed in metal trays for further testing. The PAV residue samples were then subjected to Dynamic Shear Rheometer (DSR) testing to determine the binders' resistance to long-term aging.

2.7 Assessment of amplitude and temperature sweep test for rheological parameters

The amplitude sweep test was used to determine the LVE region in each sample. Pure and OPCP-MAC samples were analyzed in unaged, RTFO-aged, and PAV-aged conditions using a temperature sweep test in strain-controlled mode with a standard loading frequency of 10 rad/s and a shear strain amplitude of 0.01 to 100%. The LVE limit was calculated by plotting the complex shear modulus G* vs strain. The asphalt cement sample's LVE limit was determined as the strain percentage (%) at which the G* was reduced to 95% of its beginning value [35]. Because asphalt mixes' viscoelastic behavior varies with temperature, they behave elastic at low temperatures and viscous at high temperatures. Thus, temperature sweep tests were used to investigate the effect of temperature on asphalt cement rheological metrics. The experiment involved employing a dynamic shear rheometer at temperatures ranging from 20 to 80 ºC with a constant frequency of 10 rad/s. The samples underwent LVE testing with a temperature ramp of 2ºC/min. Table 2 displays the test parameters used for binder rheological testing.

2.8 Superpave fatigue and rutting parameters

This study used fatigue and rutting characteristics to determine asphalt cement's fatigue and rutting resistance capacities at moderate and high temperatures, respectively. To establish the fatigue and rutting parameters of the asphalt cement, a temperature sweep test at a frequency of 10 rad/s was performed. The fatigue and rutting resistance of asphalt cement were calculated using the G* value, and the Sin and G*/Sin values were shown against temperature. To guarantee acceptable fatigue resistance, the G*. Sin should be less than 5000 kPa, whereas the G*/Sin value for unaged and RTFOT aged binders should be greater than 1.0 kPa and 2.2 kPa, respectively, according to Superpave standards.

2.9 Experiment design based on response surface methodology

The response surface methodology is a technique for developing, improving, and optimizing issues in which one input variable affects several response variables [29]. The RSM generates synergistic effects between input and response variables through the central composite design (CCD), a fractional factorial design approach [36]. In this study, the CCD technique was used with Stat-Ease Inc.'s Design Expert (V13.0.13) software to design the experiment, as well as perform statistical analysis, modeling, and optimization. Based on prior research, the study used the CDD technique for experiment design due to its adaptability to experimental data, reliable prediction, reduced number of experimental runs, and the number of dependent variables [32, 37, 38]. In general, optimal CDD is suitable for analyzing experimental data and constructing prediction models. The levels and ranges of the input components for the fatigue and rutting parameter responses were determined using previous research and standard guidelines [17, 28, 29, 39]. The variables investigated were the OPCP content, which was mixed at five contents (0%, 2%, 4%, 6%, and 8%), and the test temperature, which was varied at five levels (20 ºC, 25 ºC, 30 ºC, 35 ºC, and 40 ºC) for fatigue parameter and five levels (40 ºC, 50 ºC, 60 ºC, 70 ºC, and 80 ºC) for both unaged and RTF0 aged rutting parameter response. Following the input of levels into the CCD-RSM DoE, the software generated a total of sixteen (16) experimental runs, as shown in Table 3.

To improve consistency in the experiment and analysis, the software reproduced the central point four times to calculate the pure error based on the number of DOE runs. The performance of the model was assessed by examining the model responses (Y) to the input factors. \({X}_{1},{X}_{2},{X}_{3}, {X}_{4}...{X}_{n}\). Equation 2 represents the correlation between the output responses and the input processing factors.

3 Study Model approach

3.1 Statistical method (Response surface method)

RSM was used to optimize the correlation between input factors and response parameters to protect and improve the fatigue and rutting resistance of OPCP-MAC using the RSM-CCD technique in software applications. This method uses polynomials as a realistic modeling methodology, rather than local approximations for the actual input–output relationships. Randomly selected tests were carried out to address biases created by systematic patterns in the parameters. The ideal input factors were identified by analyzing the data with a suitable second-order polynomial equation, as shown in Eq. 3.

where Y is the predicted variable, \({\beta }_{0}\) is the design center point fixed response value, \({X}_{r}\) and \({X}_{m}\) are input factors, \({\beta }_{r}\) is the linear coefficient, \({\beta }_{rm}\) is the interactive coefficient, where r and m are the linear and quadratic coefficients, v is the number of variables and \(\varepsilon\) denotes a model error.

To assess the model's accuracy, adequacy, and significance, an analysis of variance (ANOVA) was carried out at a 95% confidence level using p-values and Fisher's test values (F-values). Diagnostic tests were used to evaluate the model's performance, including the coefficient of determination (R2), projected R2, and modified R2. To demonstrate the cumulative impact of the input variables on the model, 2D and 3D graphs created with design tools were employed. To verify the model, statistically produced responses were compared to those derived from the RSM equations. The best conditions were then determined by numerical optimization, and these were utilized to validate the RSM predictions and confirm the results [40]. The optimum condition was determined via numerical optimization, and it may be used to validate the RSM predicted outcome as well as verify the RSM design outcomes. To confirm RSM results, validation and assessment of the statistically generated response outputs were also conducted. This was accomplished by conducting an additional laboratory activity based on the RSM model's predicted values.

3.1.1 Artificial neural network

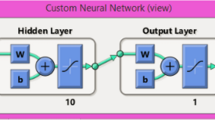

Statistics errors can occasionally lead to misleading and unrealistic results during analysis, especially when linearisation is employed incorrectly. In some circumstances, the variables in a study may have a nonlinear connection, which can be misinterpreted if only the R-squared value is evaluated. This might lead to errors and inconsistency [41, 42]. The R-squared value alone cannot accurately detect bias parameters since it varies based on the range of input variables [24, 42]. To overcome this challenge, modern algorithms such as the ANN model can forecast the non-linear relationship between the input variables and responses. An Artificial Neural Network (ANN) is a computer or mathematical model based on the structure and function of biological neurons. ANNs are used to describe complex interactions between inputs and outputs, as well as to identify data patterns [33]. It is intended to identify trends and make predictions or judgments. ANNs consist of layers of interconnected "neurons," which process and transfer information over the network [24].

There are various approaches to increasing the precision of an ANN model. However, backpropagation is one of the most effective algorithms [33, 42]. An ANN consists of three layers: input, one or more hidden layers, and output. An ANN's hidden layer extracts information from input data, and the output layer uses these features to produce predictions. The logarithmic sigmoid transfer function is widely used as the activation function for the hidden and output layers because it transfers the input to a value between 0 and 1. This is advantageous for binary classification tasks.

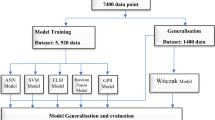

. Each neuron in the network receives information from other neurons, processes it, and then transmits it back. The study employed John's Macintosh Project (JMP) Pro version 16.2.0 to create a feed-forward structure with a single hidden layer and the backpropagation learning method. The hidden and output layers were enabled with a logarithmic sigmoid transfer function [33]. The feedforward neural network (FFNN) model was employed in this investigation, and the data were divided into three sets: training, cross-validation, and testing, to minimize overfitting and over-parameterization. The same 16 mix runs from the RSM dataset were used in the ANN analysis. The data was used for 70% training, 15% validation, and 15% testing. This ratio was determined through experimentation to ensure accuracy and minimize overfitting. The validation set was utilized during training to evaluate the network's performance and select the best fitting based on the coefficient of determination (R2) and root mean square error (RMSE) values. The prediction was then made with the best-performing model.

3.2 Model evaluation and statistical performance metric

The performance of the developed model was assessed utilizing several model evaluation and statistical performance measures. These metrics provide quantifiable measurements of the model's predicted accuracy, which is critical for comparing models and choosing the best one for a given analysis. The RSM and ANN models were evaluated using three essential metrics: R-squared, Root Mean Squared Error (RMSE), and Mean Relative Error. These measures, derived using Eqs. (4) through (6), were used to assess the models' efficacy and significance.

where \({L}_{i}\) represents the values obtained in the laboratory, \({M}_{i}\) represents the data values that were obtained by using RSM and ANN methods, and n represents the total number of data points or sample size.

3.3 Toxicity leaching behavior evaluation

This section describes the environmental compatibility of integrating OPCP-MAC into asphalt mixtures. The Toxicity Characteristic Leaching Procedure (TCLP) test was used to determine the mobility of heavy metals and other contaminants in landfill debris. The TCLP test was performed using the USEPA 1311 standard methodology. The experiment was conducted with both OPCP and OPCP-MAC mixes. The sieved samples were used for the OPCP, while the OPCP-MAC samples were made using the Marshall mixing method at various OPCP content levels, with an ideal asphalt cement percentage of 5%. The dried samples of each OPCP-MAC mixture were then crushed and sieved to a standard size, generating 600 g of 9.5 mm particles. In the conical flask, an ethanoic acid solution with a pH of 2.88 was introduced to the sample at a constant solution: sample ratio of 20:1. The sample was agitated in a shaker machine at 30 revolutions per minute for 18 h at 24 ± 1 ℃. This allowed the extraction fluid to react with the sample and leach out any mobile pollutants. After adequate mixing, the leachate was filtered through a 0.60 µm pore size syringe filter into the flask and analysed for heavy metals using an Agilent 240FS model Atomic Absorption Spectroscopy equipment. This study was limited to seven elements: As, Ba, Cd, Cr, Cu, Ni, Pb, and Zn. Because of their environmental influence, these components have piqued the curiosity of various researchers in earlier studies [43,44,45]. The TCLP test results were then compared to legal limitations for heavy metal concentrations in waste materials to evaluate if the OPCP and OPCP-MAC mixes may be disposed of or reused.

4 Results and discussions

4.1 OPCP characterizations.

4.1.1 XRF and physiochemical properties before and after treatment

The pretreatment process was shown to be effective at removing impurities and increasing OPCP's silica content. Table 4 displays the chemical composition of OPCP following processing, indicating an increase in SiO₂, Al₂O₃, and Fe₂O₃. Notably, the silica content of the OPCP increased to 63.95%. The treatment reduced levels of nitrogen, CaO, K₂O, and MgO. The treated OPCP comprises over 70% SiO₂, Al₂O₃, and Fe₂O₃, meeting the ASTM C618 Class F pozzolanic material requirements. The pozzolanic characteristics of OPCP are due to its high concentration of silica, particularly amorphous silica, which has an unstable structure and can engage in a variety of chemical processes. It was discovered that the surface area of OPCP increased after the pretreatment process. Although there was a minor change in particle size, the treatment impacted surface area more than particle size and while the particle size stayed roughly constant, the surface area increased significantly [15].

4.1.2 FT-IR before and after treatment

The FT-IR spectra of POCF were examined to evaluate the presence and connections between functional groups. Figure 2. shows the FTIR analysis of untreated and pre-treated OPCP. The results revealed that vibration peaks in the range of 460.97 to 500 cm-1 were associated with Si–O-Si bending modes, whereas peaks at 1002 and 1037 cm-1 suggested the presence of quartz materials (Si–O). The peaks at 3200 and 3,433 cm-1 indicated O–H stretching and the bending vibration at 1,641 cm-1 for H–O-H, respectively, while the peaks at 554.49 and 584.52 cm-1 exhibited d Si–O-Si/d Si–O-Al. A significant peak at 1030 cm-1 was discovered and was connected to the Si–O asymmetric stretching vibration caused by some metals or nonmetal oxides formed during its production in the boiler. The intensity of the peaks around 468, 1030, 1500, 3236, and 3426 in the infrared spectra varied, indicating that chemical pretreatment affected the production of crystalline silica [46]. The pozzolanic reactivity of silica diminishes with its crystallinity, and similar changes in the peaks following treatment were found [47]. However, POCF quartz has a crystallinity index of 0.81, indicating that it is slightly disturbed and reactive due to its amorphous phase. The structure of metal ions was shown to be significantly affected by the OPCP pre-treatment process. It can lead to the formation of more stable chemical bonds, such as the Si–O-Si link, as well as a rise in the presence of silica-based oxides, as seen by FT-IR spectra.

4.1.3 XRD before and after treatment

Figure 3 shows the X-ray diffraction pattern of the POCF sample, which reveals that it is predominantly formed of quartz with a crystalline structure. The most abundant phase was alpha quartz, however, additional minerals such as cristobalite were discovered at specific diffraction angles. The XRD examination provides POCF a reference number of 01–075-8320, with peaks at 20.79°, 26.59°, and 40.01°, which were compared to the silicon dioxide/quartz reference standard (JCPDS card number 00–46-1045) [48]. The XRD pattern shows peaks stretching at 2 θ = 15°-35°, indicating the existence of amorphous silica. This amorphousness plays a crucial role in the material's physiochemical reactions. Furthermore, chemical pretreatment affects the development of crystalline silica, with the more crystalline silica being less reactive in the pozzolanic process [46]. As a result, the acid pre-treatment enhances the presence of silica-based minerals like quartz and cristobalite in the OPCP by breaking metal ion structures and generating more stable silica bonds [47].

4.2 Asphalt cement conventional properties

Physical parameters including penetration, softening point, and ductility are used to evaluate asphalt cement quality and performance. Table 5 displays the results of conventional testing on pure asphalt cement and POCF-MAC with varying POCF percentages and aging conditions. The findings are examined to establish the impact of POCF and aging circumstances on asphalt cement characteristics. Adding OPCP (0–8%) to pure asphalt cement improved its characteristics. The inclusion of OPCP reduced asphalt cement's penetration value while increasing its softening point. This inverse relationship between penetration and softening point is caused by a rise in asphaltene proportion in asphalt cement because of maltene phase absorption by micro silica found in OPCP. Furthermore, OPCP particles are stiffer than asphalt cement, resulting in a stiffer modified blend with a higher OPCP concentration [33]. The ductility of asphalt cement decreased as OPCP content rose. The reduction in ductility was induced by an increase in viscosity and stiffness as the light constituent maltene in the asphalt cement was absorbed by the OPCP particles, preventing the mix from moving. Table 5 reveals that OPCP-MAC hardened and became less ductile when compared to pure asphalt cement. Furthermore, when the softening point difference was less than 2.2 °C, OPCP-MAC demonstrated greater stability in storage. The study showed the compatibility of asphalt cement with OPCP. This indicates that the two materials work well together and do not easily separate, even at high temperatures.A similar trend was observed by Al-Sabaeei, et al. [29] when incorporating waste denim fiber and nanosilica into asphalt cement. The softening point difference between the top and bottom of the aluminum pipe was less than 2.2 °C, which meets the criteria for this sort of measurement. This low softening point difference suggests that OPCP-MAC has a slow rate of separation, hinting that it will remain stable in storage even at high temperatures as earlier observed by [46].

Furthermore, the findings indicate that the aging process had a considerable impact on the binders, as demonstrated by a decrease in penetration and ductility and an increase in softening points found in all samples following RTFO and PAV aging. The aging process tightened and strengthened the binders, making them more resistant to deformation. These findings underscore the need to take into account the influence of aging on the properties of binders in road building, as well as the requirement for appropriate aging methodologies to reliably evaluate binder performance over time[46]. Short-term RTFO and long-term PAV binder aging results in decreased penetration, ductility, and increased softening point, showing binder hardening caused by increased viscosity and stiffness due to oxidation[40]. Oily compound volatilization decreases penetration and ductility while increasing the softening point due to the loss of volatile oil. According to the data, the average decrease in penetration following RTFO treatment is 38% for RTFO and 56% for PAV aging, respectively, while the average loss in ductility is 43% for RTFO and 58% for PAV aging, and the average increase in softening point is 13% for RTFO and 29% for RTFO PAV. These findings indicate that binder aging raises viscosity, and a similar pattern was seen [49]

4.3 Pure asphalt cement and OPCP-MAC blend rheological properties

The study evaluated the rutting behavior of modified binders at high temperatures. The rutting parameter (G*/sinδ) assessed the binder's resistance to deformation at high temperatures. The findings were utilized to evaluate the modified binders' efficiency in preventing persistent deformation at high temperatures. The asphalt mixture must be firm enough to resist deformation while being flexible enough to recover to its former shape after being loaded [10]. To preserve the integrity and performance of the pavement over time, it is necessary to have a high rutting parameter, especially at the start of pavement service and under high-temperature conditions [46, 50]. Figure 4 shows the relationship between the rutting parameter and temperature in pure asphalt cement and OPCP-MAC blends. The rutting parameter was discovered to be higher in OPCP-MAC than in pure asphalt cement. This suggests that adding OPCP particles to asphalt cement made it more resistant to permanent deformation under high temperatures. This improvement is most likely owing to the modified asphalt cement's improved viscoelasticity and stiffness qualities because of the inclusion of OPCP particles. At lower temperatures, the rutting parameter values did not differ much; however, at higher temperatures, the values of the rutting parameter fell and the changes in the rutting parameter became insignificant [51].

According to the Superpave binder standard, the temperature at which G*/sin = 1000 Pa is regarded as the optimal temperature for asphalt cement to provide appropriate viscoelastic characteristics when employed in asphalt applications [52]. The rutting parameter of the OPCP-MAC was discovered to rise with OPCP content as the test temperature rose. The values, however, stay within the Superpave, which also mandates a minimum G*/Sin value of 1000 Pa for unaged binders. At 1000 Pa, the failure temperature of pure asphalt cement was determined to be around 71.05 ºC. The failure temperatures for OPCP-MAC with 2%, 4%, 6%, and 8% OPCP were found to be 72.52 °C, 72.98 °C, 73.06 °C, and 73.72 °C, respectively. These results align with the expected properties of OPCP-MAC. Strong resistance to rutting is achieved when the rutting parameter is sufficiently high, which is due to the increased viscosity from the incorporation of OPCP. This addition causes the binder to stiffen and exhibit reduced deformation at high temperatures [46].

The RTFO test was used to assess the short-term aging process, which simulates binder qualities during mixing and the initial phase of asphalt road use following compaction. Figure 5 depicts the connection between the rutting parameter and temperature following RTFO aging for both pure asphalt cement and OPCP-MAC. The results revealed that the rutting parameter for OPCP-MAC was higher than that of pure asphalt cement. This suggests that adding OPCP into asphalt cement improves its resistance to permanent deformation at elevated temperatures [14]. The higher rutting parameter values in the OPCP-MAC blends indicate that OPCP improves the viscoelasticity of the asphalt cement, effectively thickening the OPCP-MAC blends. Rutting values were greater for the 6% and 8% OPCP-MAC blends. The rise in viscosity is most likely the result of increased asphaltene and resin production during the aging process [4]. Asphalt cement aging alters the composition of the heavy and light components of asphalt cement, leading to an increase in asphaltene and resin content, a decrease in aromatic content, and a steady saturate content [53]. In addition, the recommended minimum G*/Sin value of 2200 Pa by Superpave can be used to ensure appropriate rut resistance in RTFO asphalt cement. Figure 5 demonstrates that the rutting resistance of pure asphalt cement and 2% POCF-MAC is virtually equal, with a failure temperature of around 73.51 °C. However, the failure temperatures for 4% and 6% POCF-MAC are around 74.16 °C. In comparison, the failure temperature of 8% POCF-MAC was found to be 76.79 °C, demonstrating that increasing the POCF content enhances rutting resistance. This study suggests that the hardening impact of POCF may lessen as RTFOT ages. This could be due to the material's capacity to absorb light component volatilization after exposure and aging [4]. Furthermore, the higher viscosity of OPCP-MAC blends is expected to result in the production of gel-like asphalt cement that behaves more like a polymeric solution, resulting in a time-dependent and completely recoverable delayed elastic response [54]. This means that the OPCP-MAC blends take longer to return to regain their initial shape after the stress is applied and removed.

Figure 6 displays the results of fatigue resistance tests on several asphalt cements. The experiments were conducted in a PAV chamber, which simulates the impacts of road aging over time, both short and long-term. The data indicate that increasing the amount of OPCP included in the asphalt cement enhances the binder's fatigue resistance. Furthermore, the Superpave standard specifies that the binder's fatigue strength shall not exceed 5000 kPa [55]. The binder’s fatigue temperature was also measured. In general, the fatigue resistance of asphalt binders increases as the failure temperature drops [56]. As a result, OPCF-MACs are more resistant to fatigue cracking than pure asphalt cement, which had the greatest failure temperature (26.15 °C). The 8% OPCP-MAC had the lowest fracture temperature (22.41 °C) but the maximum crack resistance. Other binder types (2%OPCP-MAC, 4%OPCP-MAC, and 6%OPCP-MAC) showed failure temperatures ranging from 25.49 °C to 23.03 °C. These data suggest that adding OPCP to asphalt cement increases its cracking resistance. The data also demonstrated that including OPCP in asphalt cement had only a minimal impact on fatigue resistance. However, it was shown that a higher concentration of OPCP (6% and 8%) was even more efficient than a lower concentration (2% and 4%), in reducing asphalt cement aging. This is because increased OPCP content builds on the asphalt cement's surface, slowing heat release [51]. This reduced heat loss was found to be particularly effective due to the OPCP's huge surface area. Because OPCP-MAC slowly released heat and heat loss under equilibrium conditions, rather than more quickly, which would have hardened the asphalt cement [51]. Furthermore, at high temperatures, the absorbed heat in OPCP-MAC was held for a longer time than in pure asphalt cement and a similar pattern was seen in previous research that used a range of waste products to modify asphalt cement [57,58,59].

4.4 Microstructural analysis

Understanding the microstructure of asphalt cement is crucial to understanding its compatibility with modifiers. Modifiers added to asphalt cement alter both its chemical composition and microstructure, influencing its rheological and performance properties [60]. Thus, in this study, microstructural analysis was used to gain insight into the possible interaction of OPCP particles in asphalt cement blends and to evaluate the effect on the rheological and mechanical properties of the modified blend.

4.4.1 FTIR analysis of unaged, RTFO, and PAV OPCP-MAC

FTIR was utilized to analyze chemical bonding changes in pure asphalt cement and OPCP-MAC. Figure 7 depicts the OPCP-MAC sample's absorption bands at 480 cm−1 to 4000 cm−1 wavenumbers. Table 6 displays the baseline and OPCP-MAC FT-IR spectra along with their respective assignments. The figures show that the trends for pure asphalt cement and OPCP-MAC differ slightly depending on the composition. According to Fig. 7, aromatic and saturated hydrocarbons dominate the absorption bands between 1375–1650 cm−1 and 2839–3000 cm−1[61]. The primary bands detected in pure asphalt cement were almost identical to those in OPCP-MAC mixes. This is evident from the proportional amount of silica and carbon in OPCP, which is caused by a substantial percentage of the poorly bonded region between asphalt cement's hydrophobic functional groups and the OPCP surface. This implies that the presence of OPCP strengthens the carbonyls and sulfoxides of asphalt cement by making it harder and decreasing the mobility of asphalt cement particles [62]. The wavelengths of the FT-IR spectral bands are largely concentrated between 1640 cm-1 and 1680 cm-1, showing the development of the carbonyl functional group C = O as the binder is exposed to oxygen at high temperatures. Carboxylic acid (carbonyl C = O) occurs naturally in bituminous binders, but oxidative aging (after RTFOT and PAV aging) greatly increases its content. A similar study was observed by Tauste, et al. [34] when the binder was modified. As demonstrated in Fig. 7 and Table 6, the intensity and position of the spectrum peaks of the functional groups of unaged asphalt cement were changed by both RTFO and PAV aging of pure asphalt cement and OPCP-MAC blends. Furthermore, as seen in Fig. 7, pure asphalt cement is the most carbonyl-forming binder. Furthermore, the control binder exhibits more carbonyl group production than the OPCP-MAC blends modified binders, resulting in a lower C = O peak intensity for the OPCP-MAC blends. This shows that adding OPCP has the potential to be an effective material for suppressing oxidizing reactions in the asphalt cement blend by decreasing the oxidation rate of asphaltenes in the modified blend as earlier observed by [61]. This enhancement is most likely due to the OPCP particles' high pore size, vast surface area, and the presence of hydroxyl groups on their surfaces. The reduced oxidative aging seen in the OPCP-MAC blends is comparable with the traditional characteristics evaluation of modified binders, which revealed a drop in penetration value and a rise in softening point.A similar trend was observed by Yaro, et al. [46] when asphalt binder was modified using palm waste.

4.4.2 OPCP-MAC FESEM analysis

Figure 8 shows electron micrographs of pure asphalt cement droplets and OPCP-MAC droplets containing 2% and 6% OPCP. The effective inclusion of OPCP particles into the asphalt cement, accomplished by adequate mixing, resulted in their even distribution. The SEM picture of pure asphalt cement revealed a homogeneous composition, whereas the surfaces of the 2% and 6% OPCP-MAC showed significant variations due to the uniform dispersion of OPCP particles in the modified samples. A similar analysis was also observed by [46]. Notably, the SEM image of the 6% OPCP-MAC showed a characteristic meandering pattern on the asphalt cement surface that was more apparent than the 2% OPCP-MAC. The meandering pattern of OPCP-modified asphalt cement is comparable to that of waste-derived SiO₂ particles. A similar pattern was also observed by [63]. This analogy may imply that the generation of these patterns in the two circumstances is governed by the same process. One theory is that the OPCP particles chemically react with the asphalt cement, creating a new network structure. This reaction could explain the observed changes in surface morphology between OPCP-modified and pure asphalt cement samples [40, 64]. The study's findings indicate that dispersing OPCP particles in asphalt cement improves the physicochemical properties of the resulting OPCP-MAB [46]. The evident changes in surface morphology found in the SEM pictures of the changed samples, as well as the characteristic meandering pattern in the OPCP-MAC samples, lend weight to this hypothesis. These findings are consistent with prior research on siliceous materials used as asphalt cement modifiers [29]. Previous research has shown that these components improve the characteristics of asphalt cement. As a result, the findings of this study are consistent with earlier studies, implying that OPCP may be a suitable sustainable material for use as an asphalt cement modifier [40, 64].

4.4.3 TCLP results for OPCP, pure asphalt cement, and OPCP-MAC mixtures

Table 7 displays heavy metal concentrations in OPCP and OPCP-MAC mixes, which were all found to be far lower than the EPA's permitted threshold [43]. The analysis revealed that all OPCP heavy metal leaching concentrations were within standard limits, with arsenic having the highest values. Palm waste incineration produced POC containing verified K2O, which combined with arsenic to create amorphous minerals, adding to the high arsenic concentration in OPCP. Cu, Ni, and Zn levels were much lower than expected, which could be attributed to vaporisation during burning [43, 45]. Furthermore, Cd, Cr, and Pb levels were discovered to be exceedingly low, indicating that they had vaporised or been redistributed in a stable crystalline form [65]. Furthermore, the heavy metal levels in OPCP-MAC mixtures are significantly lower than the TCLP regulatory levels. A similar outcome was studied when waste sludge was used in asphalt mixtures [66]. Flexible pavements are efficient at retaining elements like Cd, Pb, Cu, and Zinc. However, Pb might have an adverse effect on the moisture and characteristics of the pavement subgrade. In this investigation, Pb leaching was determined to be extremely minimal. In contrast, Zn, a soluble metal typically found in air, water, and soil, had a high leaching value in this investigation, most likely due to its presence in the asphalt cement and the ethanoic acid extraction solution [45]. Additionally, the research revealed that only pure asphalt cement mixtures had greater Ni contents, whereas the other samples had lower leaching values. Ni is a metal that is difficult to degrade in the environment, influencing subsurface characteristics and water content. Concerning human health, dissolved Cr is another highly toxic element that can be harmful depending on the degree and duration of exposure [67]. In this investigation, all the Cr levels in the OPCP-MAC mixture were found to be insignificant when compared to the regulatory limitations. According to Table 7, all heavy metals leached significantly less in the total OPCP content than in OPCP, demonstrating that the asphalt combination may effectively stabilize hazardous metals [43]. Thus, it is possible to conclude that OPCP can be used in the pavement business without generating significant environmental hazards during pavement service years.

4.5 ANOVA analysis and mathematical modeling using RSM

In this study, the CCD-RSM method was used to determine the effect of OPCP content and testing temperature on the rutting and fatigue parameters of OPCP-MAC asphalt. The results were analyzed using RSM software, resulting in the generation of a quadratic polynomial model for predicting both rutting and fatigue characteristics. Table 8 shows the ANOVA findings for the unaged rutting parameter, the RTFO-aged rutting parameter, and the fatigue parameter models. These models were chosen because of their significance and the lack of aliased terms. The degrees of freedom (df) indicate the number of independent variables in the model, whilst Fisher-statistical test results (F-values) are used to determine the model's significance. Probability numbers (p-values) show the possibility that the results were achieved through chance.

The rutting parameter responses of the unaged and RTFO-aged samples were highly significant, with p-values less than 0.0001 and F-values of 85.57 for the unaged samples and 88.29 for the RTFO-aged samples. The significance of both models was determined using the 95% coefficient of determination, and the findings showed that all model variables A, B, AB, and B2 had p-values less than 0.05, indicating that they were important in explaining both the unaged and RTFO aged rutting characteristics. The variable A2, on the other hand, showed a p-value greater than 0.05, indicating that it was not significant and had little effect on both the unaged and RTFO aged rutting parameters. However, the mathematical models generated by the RSM program revealed that, although being a non-significant component, A2 was still included in the model to maintain the model's hierarchy as determined by ANOVA. Furthermore, despite its statistical insignificance, the quadratic component A2 was retained in the model due to its strong theoretical foundation and could not be eliminated. As a result, keeping them is crucial because they can cause issues with the analysis, rendering the model non-orthogonal and non-hierarchical [33]. The F-test for lack of fit (LoF) was used to assess the quadratic polynomial model's ability to predict the OPCP-unaged MACs and RTFO-aged rutting parameters. The results showed that the LoF was non-significant, with probabilities of 2.07 and 2.75 for the unaged and RTFO-aged rutting parameters, respectively. The temperature has more influence on the unaged and RTFO aged rutting parameters than OPCP content, with test temperature having higher F-values of 267.51 and 304.62 compared to OPCP content, which has an F-value of 8.93 and 8.95 for the unaged and RTFO aged rutting parameters, respectively. From the study outcome of the statistical assessment, Eq. 7 and Eq. 8 were developed to predict the OPCP-MAC unaged and RTFO-aged rutting parameters.

For the fatigue parameter responses for the PAV-aged samples, a highly significant p-value of less than 0.0001 and a high F-value of 178.67 was observed. The 95% coefficient of determination was used to determine the model's significance, and the findings revealed that all model variables A, B, AB, A2, and B2 had p-values less than 0.05, showing that they were significant in affecting fatigue parameter response. The F-test for lack of fit (LoF) was used to determine the quadratic polynomial model's ability to predict the OPCP-MAC fatigue parameters. The LoF was found to be non-significant, with a probability of 4.89 for the tiredness parameter. The ANOVA results show that temperature has a stronger influence on fatigue metrics than OPCP content, with the test temperature having a higher F-value of 527.17 than OPCP content, which has an F-value of 22.51. Based on the statistical analysis results, Eq. 5 was generated to predict the OPCP-MAC fatigue parameter.

4.6 Statistical model fit evaluation

Table 9 displays the results of the generated RSM models fit statistical analysis. The model's standard deviation was observed to be 2970.80 and 6637.20 for the unaged and RTFO aged rutting parameters, respectively, which is significantly lower than the mean values of 11,528.34 and 32,598.24 for the unaged and RTFO aged rutting parameters, demonstrating the effectiveness of the variance analysis. The lower the standard deviation relative to the mean value, the lower the variance in the test data, and thus the more reliable the model results [68]. Furthermore, the unaged and RTFO aged rutting parameters' adjusted coefficients of determination (adj. R2) values were 0.9657 and 0.9668, respectively, while the predicted coefficients of determination (pred. R2) values were 0.9134 and 0.9319. This indicates that the difference was less than 0.2, which is considered excellent [69, 70]. Furthermore, Adequate precision (AP), which is used to measure the model's signal-to-noise ratio, was high, with unaged and RTFO aged rutting parameters response values of 25.6849 and 25.408, respectively, both of which were greater than the required having greater than 4. As a result of the analysis, the generated models are suitable, appropriate, and efficient for exploring the design space as well as modeling, optimizing, and predicting the unaged and RTFO aged rutting parameters response of the OPCP-MAC blend.

For the Fatigue parameter, the generated fatigue model's standard deviation was 665300, which was significantly lower than its mean value of 5318000, indicating that variance analysis was appropriate and sufficient. A lower standard deviation to the fatigue model's mean indicates that the test data has less variance, resulting in more reliable results. Furthermore, the adjusted coefficients of determination (adj. R2) values were 0.9834, while the predicted (pred. R2) values were 0.9686. The difference was less than 0.2, indicating that the two were in complete agreement [36, 71]. Furthermore, adequate precision (AP), which is used to measure the model's signal-to-noise ratio, is generally greater than 4 [36]. Response values of 34.366, which are greater than the required, were observed for the Fatigue parameters. This means that the models can be utilized to explore the design area for optimizing and predicting the OPCP-MAC blend's fatigue parameter response.

4.7 RSM-generated model diagnostic plots

Diagnostic charts are pivotal for assessing the performance and accuracy of generated statistical models. In this study, Fig. 9 depicts the various diagnostic chart results, used to assess the fitness and correctness of the model. The predicted versus actual plots (Figs. 9a, c and e) for the unaged, RTFO aged rutting parameter and fatigue parameters response model depict the scatter plot dissemination of data points around the 45° line, which is the visual representation for evaluating model fit and accuracy [17, 68]. Because the 45° line represents a perfect match between predicted and actual values. The symmetric distribution around the 45° line indicates that the model correctly predicted both the unaged, RTFO rutting parameter and the fatigue parameter. As the data points get closer to this line, the model's predictions improve [36]. Furthermore, the dataset distribution suggests that the model's predictions are not biased in any way and closely match the actual experimental values [32].

The residuals versus projected fit plots (Figs. 9b, d and f) are used to assess the regression models' performance for the unaged, RTFO-aged rutting parameters, and fatigue parameters. These charts show the residuals or differences between actual and predicted values. The blue boxes represent experimental runs with the lowest interaction effects, while the green boxes indicate runs with medium interaction effects [46]. The red boxes highlight experimental runs that optimize synergistic interactions. The ideal scenario would be for these residuals to be randomly distributed about zero, showing that the model is correctly capturing the data's underlying pattern [32, 68]. The red borders on the graphs show confidence intervals; residuals that fall within these intervals indicate that the model's predictions are reliable [32]. By reviewing these diagnostic charts, we can check that the model accurately forecasts the effects of OPCP content and test temperature, which improves the model's validity and reliability.

4.8 RSM plots for the influence of synergistic variables

In this study, RSM was used to create 3D response contour plots to examine the relationships between variables and responses and understand how model factors influence outputs. Each input variable is represented along the X and Y axes, while the response is shown on the Z axis. The contour plot uses colors to indicate response levels, with blue, green, yellow, and red hues representing weak, moderate, and strong interactions, respectively [23, 32]. This visual approach simplifies the identification of key factors and their interactions [24].

4.8.1 Unaged and RTFO aged rutting parameter response

Figure 10(a and b) shows the unaged rutting parameter test results of pure asphalt cement and OPCP-MAC at various service temperatures. At high temperatures, every modified asphalt cement has higher rutting parameter values and improved rutting resistance than pure asphalt cement. This finding indicates that OPCP-MAC is more elastic, stiffer, and resistant to permanent deformation than pure asphalt cement, especially at medium to high temperatures. However, at medium temperatures of roughly 40º C, the OPCP-MAC becomes excessively stiff and fractures, lowering rut resistance. As a result, adopting a higher OPCP content for modification at low temperatures may be undesirable since the increase in stiffness will lead to brittleness [29]. This is owing to the binder's high stiffness, which might cause low strain levels during DSR testing. As a result, high POCF dosages at low temperatures are considered less practical since they limit binder performance via viscoelastic rheological qualities, although they are promoted at high temperatures [46]. Figures 10c and d shows the effect of RTFO aging on the rutting parameter of pure asphalt cement and OPCP-MAC, with a similar pattern seen for the unaged rutting parameter. The modified asphalt cement's rutting parameter increased with RTFO aging. This increase in rheological behavior is due to changes in the chemical structure of asphalt cement caused by denaturation and aging [46]. The amount of asphalt and resin in the binder increases as it ages, while the number of aromatics decreases and the amount of saturated fatty acids remains constant [55, 72]. These changes in the chemical structure of the binder influence the elastic properties and thus the rheological properties of the asphalt cement [55]. Previous research has shown that incorporating agricultural waste into a binder improves its rutting resistance [59, 73]. The study emphasizes OPCP's significant effect on asphalt cement viscoelasticity and implies that altering OPCP content has the potential to improve asphalt cement performance. The results also demonstrate that OPCP content and temperature have an impact on the rutting parameter. Temperature, on the other hand, has a higher effect because of asphalt cement's viscoelastic properties [51]. This observation emphasizes the significance of operating temperature when developing and forecasting asphalt pavement performance.

Furthermore, as indicated in Fig. 10e and f, the fatigue parameter of OPCP-MAC was reduced with increasing OPCP content and test temperature. However, adding OPCP to asphalt cement had a minimal impact on fatigue resistance. The fatigue factor for pure asphalt cement was determined to be the highest, while that for 8% OPCP-MAC was discovered to be the lowest. These findings indicate that adding OPCP to asphalt cement can improve fatigue resistance following PAV aging because of chemical structural changes throughout the aging process [51, 74]. This is owing to the OPCP's enormous surface area, which minimizes heat loss and aging [2]. Because OPCP-MAC released heat and heat loss gradually under equilibrium conditions, rather than more quickly as the pure asphalt binder, which would have overstretched the asphalt cement and hampered its fatigue performance [57,58,59]. Also, the degradation and rearrangement of the modified asphalt cement are important factors contributing to the improvement of the fatigue parameter, which alters the elastic behavior of the modified asphalt cement [51, 74]. The findings of this study demonstrate that temperature-related variations in asphalt cement rheology, rather than the presence of OPCP, have a substantial impact on asphalt cement fatigue behavior [28]. In this study, OPCP was found to be effective in increasing fatigue resistance, but the effect was less significant when compared to temperature.

4.9 Multi-objective optimization and validation of RSM-developed models

The model's prediction performance was confirmed by multi-objective optimization, which involved identifying the ideal OPCP content and test temperature. Desirability, a scale-free value ranging from 0 (weak solution) to 1 (optimal solution), represents the intended outcome by placing a point on each ramp and comparing the predicted response to the model's lower and higher bounds of the response parameters [14]. Table 10 shows the desired goals and restrictions for the unaged, RTFO-aged, and Fatigue parameter optimization methods. Figure 11a depicts the optimal input factor values for the unaged and RTFO-aged rutting parameters, as well as the optimum predicted response desirability at the level of 1.0, where the optimal predicted OPCP content and test temperature for improving fatigue resistance were determined to be 6.59% and 57.62 °C, respectively. Figure 11b also illustrates the fatigue parameter optimal values of the input variables and the optimum predicted responses with desirability at the level of 1.0, where the optimal OPCP content and test temperature for enhancing fatigue resistance were determined to be 2.85% and 27.95 °C, respectively. The optimal proposed % was tested three times, with the average outcome used. The error rate and predictability of the model were examined by comparing the RSM optimal predicted values with experimental values, using Eq. 10.

An additional series of tests were conducted utilizing the optimized input factors to validate the dependability of the RSM model's optimization outcomes. Three samples were averaged and then reported. The OPCP-MAC rutting and fatigue parameters were investigated and compared to the predicted values. Using Eq. 10 and the RSM-generated OPCP content and test temperature, the absolute percent error (APE) between experimental and predicted results was calculated [69]. The experimental unaged rutting parameter was 7076.48 Pa, while the RTFO aged rutting parameter was 252,684 Pa. The fatigue parameter was 3,407,873 Pa. The calculated APE for the unaged, RTFO aged, and fatigue parameters were 3.75%, 3.37%, and 4.17%, respectively, all of which were less than the acceptable limit of 5%. This demonstrates a strong correlation between the experimental results and the RSM model's predicted values [7].

4.10 Artificial neural network modelling

Identifying optimal input combinations, developing networks, and dealing with model uncertainty are critical attributes in ANN modeling for developing highly accurate and minimal error ANN networks [24]. As a result, modeling and optimizing the ANN design matrix required the usage of generated RSM data. The neural network was utilized to analyze the performance of the OPCP-MAC, using test temperature and OPCP content as input variables, and the unaged and RTFO aged responses were combined, while the fatigue parameter was determined independently. The RSM model was utilized to optimize the ANN design matrix for data training, testing, and validation, yielding the most optimal data combinations. A same approach was also adopted by [24, 33]. As a result, the optimal RSM design yielded numerous additional experimental data sets that were used to train the ANN prediction model in this study. Feedforward back propagation neural networks, also known as multi-layer perceptrons, are a form of ANN widely employed for complicated system modeling and identification tasks [24, 75]. They were used for modeling and prediction in this study. This method is commonly used in a variety of applications, including the pavement industry [24, 29, 33]. Because it can model nonlinear relationships between inputs and responses, it is a popular choice for modeling complex systems [40].

The number of neurons in an ANN hidden layer is decided by the R2 and RMSE values used to evaluate network performance. In this study, the optimal network architecture was determined by adjusting the number of neurons in the hidden layer and measuring network performance using metrics such as R2 and RMSE, as shown in Table 11. This hyperparameter tuning method is critical when developing an effective artificial neural network. This study found that networks with three structural layers and topologies of 2-7-2 (unaged and RTFO aging parameters) and 2-4-1 (fatigue parameter) had the best R2 values and the lowest RMSE values [33]. The network is fed with two independent variables for this study: OPCP concentration and test temperature. To learn complex and nonlinear interactions between inputs and responses, employ hidden layers of 7 and 4 neurons, respectively, for the rutting parameter (unaged and RTFO aged), as shown in Fig. 12. The OPCP-MAC's rheological performance properties were predicted using an output layer containing two neurons for the rutting parameter and one neuron for the fatigue parameter, respectively.

ANN optimizer techniques were employed to optimize the rutting parameters (unaged and RTFO-aged) and fatigue parameter responses. The purpose of this study was to improve the viscoelastic characteristics and rheological performance of OPCP-MAC by varying the OPCP content, temperature, phase angle, and complex modulus. The target aim was established within a range to help determine the best values for each of these factors to increase performance [32]. The findings will help researchers better understand how different parameters affect the viscoelastic and rheological behavior of asphalt cement, which could lead to the creation of new and improved OPCP-MAC for a variety of applications [51].

4.10.1 ANN model diagnostic plots

Figures 13 (a-c) and 13 (d-f) compare the model's predictions to experimental data for the unaged rutting parameter and the RTFO aged rutting parameter, respectively. The R2 values suggest that the model's predictions and actual results are strongly related. The scatterplot also illustrates how well the ANN predictions match the actual test results, with nearly all values falling on the symmetry line. The unaged rutting parameter has R2 values of 0.9984, 0.9886, and 0.9991, while the aged rutting parameter has R2 values of 0.9995, 0.9871, and 0.9891, demonstrating that the model is quite well at predicting both the unaged and RTFO aged rutting parameters. Figure 13e shows an ANN profiler plot for model performance optimization. For the fatigue parameter. Figures 14a–c shows the association between expected and actual fatigue parameter values. The findings suggest that the ANN model can produce accurate predictions, which is supported by the high R2 values. The R2 values of 0.9984, 0.9832, and 0.9961 for the training, validation, and test sets, respectively, show that the model fits the data exceedingly well [40]. The scatterplot also shows that the ANN forecasts are nearly identical to the actual test results, with almost all values falling along the symmetry line [28]. This provides strong evidence that the ANN model accurately represents underlying data relationships. Figure 14d depicts an ANN profiler plot for optimizing the fatigue parameter model performance.

4.10.2 Performance comparison of RSM and ANN models

In this study, RSM and ANN were used to predict the rutting parameter (unaged and RTFO aged) and fatigue parameter responses of OPCP-MAC using two input parameters (OPCP content and test temperature). The statistical model's validity was validated by comparing actual and anticipated results. After analyzing the rutting parameter (unaged and RTFO aged) and fatigue parameter responses with RSM and ANN, it was discovered that both models successfully predicted the outcomes. Tables 12 and 13 display the experimental and RSM predicted outcomes as well as the averaged percentage error (APE) for the rutting parameter (unaged and RTFO aged) and fatigue parameter, respectively.

It is interesting to note that the results of our analysis revealed that both the RSM and ANN models can predict the experimental outcome with reasonable accuracy. However, the results showed that the ANN model outperformed his RSM model in terms of prediction and validation. Furthermore, we investigated the validity of the CCD-RSM and ANN models by evaluating model performance index parameters such as R2, MRE, and RMSE. Models with R2 values close to one are regarded to be more effective at predicting responses [24, 42]. Table 14 shows that both the CCD-RSM and ANN models are statistically significant and accurately predict experimental findings. In terms of predictive accuracy, the ANN model outperforms the RSM model. The ANN model's R2 values for the unaged, RTFO-aged, and fatigue parameter responses were 99.903, 99.970, and 99.997, with MRE values of 1.759, 1.036, and 5.262, respectively. Meanwhile, in the RSM model, the R2 values were 99.743, 99.893, and 99.984, with MRE values of 3.261, 2.315, and 12.089. Furthermore, when the RMSEs of the two models were compared, the ANN forecasts differed less from the true response [33]. Despite the increased accuracy of the ANN model, the RSM model is still beneficial for optimizing the rutting and fatigue parameters. The ANN model's exceptional performance stems from its capacity to learn patterns in datasets, generalize nonlinear connections between actual and anticipated outcomes, and emulate human intelligence [29, 75].

4.10.3 Validation of generated models

Tables 15 and 16 show how statistical approaches such as R2, MRE, and RMSE were used to assess the performance of prediction models. As a result, validation tests were performed to confirm that the predictive model was both accurate and effective at predicting study responses. To ensure the models' accuracy, their performance was tested using a completely new set of tests that did not use the data used during development. To accomplish this, we created five unique combinations with three samples each and averaged the results. Using these values, we computed the rutting parameter (unaged and RTFO aged) and fatigue parameter for OPCP-MAC. The prediction models' validation was evaluated using statistical performance metrics such as R2 and APE. In the RSM model, the unaged and RTFO-aged rutting responses had R2 values of 99.574 and 99.383, respectively, with APE values of 2.88 and 3.25. In the ANN model, the same responses had R2 values of 99.874 and 99.912, with APEs of 2.28 and 2.22, respectively.

The RSM model had an R2 value of 99.725 and an APE of 2.64 for the OPCP-MAC fatigue properties, whereas the ANN model had an R2 value of 99.894 and an APE of 1.56. The results show that the models are highly accurate, with an absolute percent difference of less than 5% between the experimental and predicted values, demonstrating the predictive models' effectiveness and accuracy in predicting the OPCP-MAC rutting parameter (unaged and RTFO aged) and fatigue parameter properties.

The ANN model outperformed the RSM model in predictive accuracy due to its capability to handle multi-dimensional, non-linear, and clustered data. Unlike the RSM model, which relies on a single-step calculation with second-order polynomials, the ANN model uses a multi-step calculation process, enhancing its precision [29, 76]. As a result, the ANN model is regarded as a more reliable option for forecasting OPCP-MAC rutting parameters (both unaged and RTFO-aged) and fatigue characteristics. Combining RSM and ANN modeling helps overcome RSM's shortcomings while allowing for a more in-depth examination of the correlations between input and response parameters [40, 42].

5 Conclusion

This study used laboratory tests and statistical analysis to investigate the feasibility and effects of using pre-treated oil palm clinker waste as a modifier for asphalt cement. The study used CCD-RSM and ANN models to investigate the influence of OPCP content and test temperature on rutting (unaged, RTFO aged) and fatigue parameters. The results of this study are summarised below.

-

The study revealed OPCP as a suitable asphalt cement modifier due to its improved pozzolanic reactivity after pretreatment, which increased active silica and reduced impurities.

-

Pretreated OPCP improved asphalt cement characteristics, including lower penetration and ductility, higher softening points, and increased storage stability across unaged, RTFO-aged, and PAV-aged conditions resulting in a novel Si–OH structural group

-

Adding OPCP improved asphalt cement's viscoelastic characteristics, resulting in superior rutting and fatigue performance than virgin binders due to higher bonding and a stiffer blend. Also, the leaching studies from both OPCP and OPCP-MAC mixtures, as measured by TCLP, are within the USEPA's specified limits, indicating a low environmental impact.

-

RSM analysis revealed high agreement between anticipated and laboratory results, with significant R2 values and low prediction errors. Temperature was more influential on asphalt cement characteristics than OPCP concentration.

-

ANN outperformed RSM in predicting PAV fatigue performance, with R2 values of 99.997 versus 99.984 and lower RMSE and MRE values, highlighting the AI model's accuracy. RSM had R2 values of 99.743 and 99.893, with higher RMSE and MRE.

-

FTIR and FESEM tests demonstrated good OPCP dispersion and low environmental effect, which supports the use of OPCP for sustainable pavement solutions.

Data availability

Data is provided within the manuscript and can be shared upon request as a basic requirement dictated by Springer rules.

References

Lu D, Jiang X, Tan Z, Yin B, Leng Z, Zhong J. Enhancing sustainability in pavement engineering: a-state-of-the-art review of cement asphalt emulsion mixtures. Cleaner Mater. 2023. https://doi.org/10.1016/j.clema.2023.100204.

da Silva TO, et al. Effects of short-term aging on the mechanical and structural performance of hot mix asphalt mixtures: a case study complemented by statistical analysis. Road Mater Pavement Design. 2024. https://doi.org/10.1080/14680629.2024.2341071.

Jeffry SNA, Putra Jaya R, Abdul Hassan N, Yaacob H, Mahmud MZH, Al-Saffar ZH. The influence of nano-carbon from coconut shell ash as modifier on the properties of bitumen. Road Mater Pavement Design. 2022. https://doi.org/10.1080/14680629.2020.1809502.

Guo M, Liang M, Liu H, Bi Y, Du X. Study on the effect of different environmental factors on the aging gradient of asphalt binder based on field aging test. Int J Pavement Eng. 2023;24(1):2245950.

Uwanuakwa ID, Ali SIA, Hasan MRM, Akpinar P, Sani A, Shariff KA. Artificial intelligence prediction of rutting and fatigue parameters in modified asphalt binders. Appl Sci. 2020;10(21):7764.

Guo F, Pei J, Zhang J, Xue B, Sun G, Li R. Study on the adhesion property between asphalt binder and aggregate: a state-of-the-art review. Constr Build Mater. 2020;256: 119474.

Fardin HE, dos Santos AG. Predicted responses of fatigue cracking and rutting on roller compacted concrete base composite pavements. Constr Build Mater. 2021;272: 121847.

Norouzi A, Kim D, Richard Kim Y. Numerical evaluation of pavement design parameters for the fatigue cracking and rutting performance of asphalt pavements. Mater Struct. 2016;49(9):3619–34.