Abstract

In the infrastructure of the future, based on intelligent computerized systems and control and monitoring devices, the smart home is part of the Internet of Things (IoT). However, in addition to the need to address energy consumption, the widespread adoption of smart homes may also exacerbate the growing problem of increasing amounts of non-recyclable e-waste from IoT devices. Compared to synthetic plastics, biopolymers offer many unique advantages such as robust structure, light weight, mechanical flexibility, biocompatibility, biodegradability and renewability. Biopolymers, which are abundant in natural products such as cellulose, silk fibroin, polylactic acid, chitosan, collagen, keratin, alginate, starch and gelatin, have great promise for the production of environmentally friendly Internet of Things devices. They are ideal candidates for the use of low-temperature sol–gel coating and ink-printing processes to facilitate the development of low-cost, large-area flexible electronic devices. This work presents developments known from the literature, as well as the results of original research on the use of biopolymer materials to create flexible, wearable and textile electronic devices, such as sensors, energy storage devices and nanogenerators, soft hydrogel actuators and wireless communication devices that are promising for the Internet of Things but have not yet been implemented in smart homes.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Current trends in all industries and in the infrastructure of the future are based on intelligent computerized control and monitoring systems [1, 2]. In particular, the Internet of Things (IoT) is considered [1,2,3] as one of the most important aspects of the successful implementation of smart city infrastructure. The most common explanation for the IoT is the ability to provide valuable and useful information by various user devices through wireless and wired Internet networks [2]. Smart home is one of the applications of IoT. In a smart home, household appliances can be monitored and controlled remotely using various sensors, actuators and wireless communication devices [1,2,3,4,5,6,7,8]. The IoT acts as a convergence of multiple technologies. Home IoT sensors, actuators and wireless communication devices must provide home automation, home security, child and elderly protection. In addition, the smart home system can also be applied in the medical field for smart healthcare, especially for occupants entering the recovery period after hospitalization, when it is necessary to continuously measure and monitor some physiological parameters [2, 6]. The purposes of a large number of smart home IoT sensors and actuators include monitoring air temperature and humidity, speech recognition, activity detection through floor vibration, opening and closing doors, and the like. Figure 1 shows a diagram of a smart home IoT system similar to that proposed in [3, 7].

Recently, the amount of energy consumed in homes represents a significant portion of the world’s energy consumption as people spend most of their time at home [8]. Moreover, smart homes need IoT systems that integrate as many devices as possible, since they must guarantee the convenience and safety of occupants, while also saving energy [3, 7]. To achieve this goal, optimal management of energy consumption in the home is essential [3, 7, 8]. As one of the approaches to use in smart home IoT systems, preference should be given to self-powered piezoelectric and triboelectric sensors and renewable energy sources, such as triboelectric nanogenerators (TENG), piezoelectric nanogenerators (PENG) and thermoelectric nanogenerators (TEG), as well as small-sized thin-film solar cells (SC). In addition to the need to address energy consumption, the widespread adoption of smart homes may also exacerbate the growing problem of increasing amounts of non-recyclable electronic waste (e-waste) from IoT devices. To replace petrochemical-derived non-renewable plastics and reduce e-waste, the demand for the use of renewable and degradable biopolymers and their composites in flexible electronics [9,10,11,12,13,14,15] and healthcare [14, 15] is growing rapidly. Biopolymers are derived from natural biological materials of plant, animal and marine origin using physicochemical, chemical and biological methods. For example, according to [13], a huge amount of agricultural waste is generated every year, which is a serious problem from an economic and environmental point of view. From an agricultural waste management perspective, these wastes can be used as secondary raw materials to create value-added products of flexible electronics and healthcare in accordance with circular economy guidelines. To date, many studies have been carried out on the use of various types of biopolymers, such as polysaccharides (cellulose and its nanocellulose derivatives, alginate, starch, chitin/chitosan) and proteins (silk fibroin, collagen, keratin, gelatin), as well as composites based on biopolymers in flexible electronics and healthcare [9,10,11,12, 14, 15]. Compared to synthetic nanomaterials, biopolymers have many unique advantages such as natural abundance, robust structure, multiple active sites, self-cleaning, self-healing, lightweight, mechanical flexibility, hydrophilicity, biocompatibility, biodegradability, non-toxicity, renewability, low cost and smartness [9, 12, 16]. Diagram in Fig. 2 demonstrates sustainability of biopolymers.

Due to the abundance of functional groups, biopolymer molecules have a stable dispersion in water and other common liquids with the formation of sols and gels, including the production of solution-processable electronic inks [12]. This property makes them ideal candidates for producing electronic devices using low-temperature manufacturing methods without the need for expensive photolithography or other patterning technologies used for inorganic semiconductors. Among various manufacturing technologies, solution coating and printing processes are useful techniques to promote development of inexpensive, large-area and flexible electronic devices based on biopolymers. The authors [9, 12, 15] showed examples of biopolymers and their composites used in wearable, implantable and biodegradable electronic devices, such as supercapacitors and batteries, nanogenerators and solar cells, various sensors and actuators, displays, transistors, memory devices and wireless communications. Biopolymers are used in these devices as substrates, active and support layers, adhesives or electrodes, providing flexibility and biodegradability, as well as large-scale production at low cost, while maintaining high performance for successful applications in biomedical implants, artificial electronic skin, environmental monitoring systems and many other applications to ensure human and environmental sustainability [9,10,11,12, 14,15,16]. Moreover, some low-strength and non-water-resistant biopolymers are especially suitable for short-lived fashionable modern electronics products, as their styles quickly become obsolete [11].

Considering the relevance of the problem of creating a sustainable Internet of Things based on biopolymers for smart homes, this paper presents modern developments known from the literature, as well as the results of original research concerning the use of biopolymer materials to create flexible, wearable and textile electronic devices, such as sensors, energy harvesters and nanogenerators, actuators and wireless communication devices etc., which are promising for the IoT, but have not yet been implemented in smart homes. Figure 3 provides a brief overview of electronic biopolymers and their promising applications in functional IoT devices for the smart home, which are discussed in more detail later in this paper.

2 Smart home IoT sensors and energy harvesters based on biopolymers

The Internet of Things of a smart home receives information from numerous sensors. Among them, non-wearable sensors are usually installed on stationary objects or places in a house or room, such as the floor or furniture, to monitor the occupants’ daily activities, such as walking, using objects, opening/closing a door, or for fall detection [7]. At the same time, despite the fact that the video camera provides detailed information about all the actions of residents, it cannot be used in most rooms due to heavy privacy violations [7]. Thus, pressure and vibration sensors based on biopolymers and biocomposites must replace it. Pressure and vibration sensors, which are mainly used to detect walking and falling, can generate electrical signals under certain periodically repeated mechanical pressures. Based on different signal transmission mechanisms, these sensors can be divided into different types: piezoresistive type, capacitive type, piezoelectric and triboelectric type [15]. As a rule, flexible pressure and vibration sensors are made by integrating conductive sensitive nanomaterials with flexible polymers. Therefore, biopolymers, such as nanocellulose, silk fibroin, etc., have great prospects for the production of environmentally friendly pressure and vibration sensors for IoT of smart homes. Due to low electrical conductivity, biopolymers are used as matrices of functional composite materials of such sensors.

For example, piezoresistive sensors work by inversely increasing or decreasing electrical resistance when pressing on a flexible conductive material. The authors of [17] presented a material for a piezoresistive type sensor, in which biopolymer fibrillar nanocellulose obtained from wood waste is used as an elastic matrix of a functional composite filled with conductive silver nanowires with a diameter of ⁓ 150 nm and an average length of 20–30 μm. To create a piezoresistive functional material, silver nanowires were uniformly dispersed in an aqueous nanocellulose sol, which ensured the electrical conductivity of the composite layer obtained after evaporation of water. To manufacture a piezoresistive sensor, first, a polyurethane sponge was immersed in the sol of silver and nanocellulose and treated with ultrasound for better penetration of the solution into the polyurethane sponge. After each immersion, the excess solution was squeezed out of the polyurethane and dried at 80 °C. The procedure for applying an electrically conductive layer to produce an electrically conductive sponge was repeated 24 times. Secondly, to transform the electrically conductive sponge into a functional material of the piezoresistive type pressure sensor, cracks in the conductive layer of nanocellulose and silver nanowires composite were created by compressing the sponge to a large deformation at a strain ε of about 80% and then releasing it. Here ε = Δb/b, where Δb – change in size relative to the original size value b. After this, the resistivity of the resulting functional material CA@PU became ~ 102 Ω·cm. Third, to create a piezoresistive pressure sensor, conductive silver paste was applied to two opposite faces of the CA@PU material to obtain a stable electrical resistance R between the sensor contacts without pressing. During the pressing process, the cracks between the conductive regions of the composite in the CA@PU material were reversibly reduced or even disappeared, resulting in a decrease in the contact resistance by ΔR. Studies of mechanical properties showed excellent elasticity of the SA@PU material due to the absence of plastic deformation after compression to ε ≈ 40%. Strain gauge coefficient GF, that is, the ratio of the coefficient of change in electrical resistance ΔR/R0 to mechanical deformation (GF = (ΔR/R0)/ε), was measured in the range 0.2% < ε < 70%. The highest GF of − 5.71 was obtained for small values of ε. Tests have shown that this pressure sensor has a low detection limit and a wide detection range. Due to the elasticity of CA@PU, after removing mechanical stress, the resistance of the sensor quickly recovered to its original value. Importantly, the sensor demonstrated stable signal repeatability under different compression strains over 500 compression/relaxation cycles, which is critical for its practical application in a Smart Home IoT system. Moreover, it turned out that this sensor can be used not only as a non-wearable, but also as a wearable one, attached with a medical patch to the human body for smart healthcare. In particular, it was effective in recognizing small movements of the human body to detect small periodic pressures caused by phonation, thereby confirming that it has great potential to work as a voice recognition device, as well as for monitoring pulse and heartbeat by accurately recording small contractions and releases from large changes in its resistance. When mounted on the knee or elbow, the sensor provided clear and reproducible signals when bending the leg at the knee or bending the arm at the elbow, respectively. To record high pressures, the CA@PU sensor was attached to the sole of a shoe and provided clear and repeatable signals of changes in its electrical resistance during walking.

Authors [18] showed a capacitive-type pressure sensor, the principle of which is to register, in the event of an increase in pressure δp, an increase in the electrical capacity C of the capacitor with covers capable of elastic compression. The sensitivity of the capacitive sensor to pressure Sp is defined as the ratio of the change in relative capacitance δ(ΔC/C0) (where C0 is the capacitance before compression, ΔC is the difference in capacitance before and after compression) to the applied pressure δp, according to the equation:

The pressure sensor was fabricated using polyvinyl alcohol/fibrillar nanocellulose (PVA/CNF) composite hydrogel with double cross-linked network to create ionic conductor and for impregnation of porous dielectric supercapacitor material in a capacitive-type pressure sensor. To improve dimensional stability, mechanical strength and flexibility, as well as to give it self-healing properties, the PVA/CNF hydrogel contained additives of calcium chloride and sodium tetraborate. Due to these additives, in addition to hydrogen bonds between PVA and CNF, this hydrogel contained dynamic borate coordination bonds and calcium-carboxylate bonds due to the large number of carboxyl groups in cellulose nanofibrils. The dynamic properties of the bonds in the PVA/CNF hydrogel gave it the ability to quickly self-heal within 15 s in case of damage. The presence of free sodium and chloride ions in the PVA/CNF composite hydrogel determined its ionic electrical conductivity. The capacitive pressure sensor with a total thickness of 1 mm has the shape of a sandwich in which a dielectric film of polyethylene terephthalate with a thickness of 50 μm is sandwiched between two layers of PVA/CNF. Each layer of PVA/CNF was connected to a metal electrode and covered with polyethylene film to prevent evaporation of water from the hydrogel. The tests showed that the change in capacity δ(ΔC/C0) was proportional to the pressure δp in the range from 0 to 4 kPa. The sensitivity Sp of the sensor was equal to 0.75 kPa−1. To test the ability of the PVA/CNF-based pressure sensor to detect subtle pressure changes that can occur when water droplets fall on a surface inside a smart home, small water drops weighing 30 mg were used that fell on the surface of the sensor from a height of 15 cm, which led to a change in the capacity δ(ΔC/C0) at the level of 0.02%. Also, the pressure sensor based on PVA/CNF was able to detect and monitor various human movements. For example, with very gentle periodic touches with a finger, an instantaneous sharp increase in capacity at the level of 0.5% was recorded. In addition, when the PVA/CNF-based sensor was attached to the wrist, it was able to detect the change in blood flow during fist clenching by δ(ΔC/C0) at the level of 0.6%, which confirmed its suitability for use as a wearable sensor for human health monitoring in a smart home. Special experiments have shown that the PVA/CNF material has excellent biocompatibility not only in the case of direct contact with the skin, but also for use in biomedical devices that require direct contact with tissues.

The paper [19] presents an innovative strategy for manufacturing a five-layer piezoresistive pressure and vibration sensor with a wide working pressure range of 0–200 kPa and ultra-high sensitivity in the pressure range of 0–6 kPa, in which carbonized cellulose of cotton fabric was used to build a three-dimensional conductive network. For carbonization, the cotton fabric was kept at a temperature of 900 °C for 3 h in an argon atmosphere, thanks to which the cellulose was transformed into electrically conductive carbon, which had the morphology of fabric fibers with a characteristic microstructure and numerous air-filled gaps. After that, to give the carbonized cotton fabric mechanical flexibility, strength, and elasticity, it was immersed in a solution containing polydimethylsiloxane (PDMS), a crosslinker, and a photoinitiator. Subsequently, the sample was treated with ultraviolet light to form a polymer composite with a dielectric crosslinked organosilicon polymer matrix and an electrically conductive carbonized fiber filler, and dried in air. This composite covered most of the area of the carbonized fabric, but there were also some conductive areas that were not covered by PDMS. The obtained C/PDMS material had a surface resistance of 293 Ω/□, and its morphology reproduced the structure of cotton fabric. To make a piezoresistive pressure and vibration sensor, five plates of C/PDMS material were stacked in a column, the upper and lower layers were connected with thin wires of the external electric circuit using silver paste. After that, two pieces of polyvinylchloride plates were attached to the top and bottom layers of C/PDMS with tape. The sensitivity of the sensor Sp was calculated according to the equation:

where R0 is the initial resistance of the pressure sensor; ΔR is the decrease in the electrical resistance of the sensor in case of applying pressure Δp due to the close connection between the carbon particles in the C/PDMS composite.

The piezoresistive mechanism of operation pressure and vibration sensor in [19] consisted in reducing the air gaps between the conductive carbon fibers in the event of pressing on the sensor and increasing the contact area between those areas of electrically conductive carbonized cellulose fibers that were not covered with PDMS. It is important that these changes under pressure occurred both in the plane of the C/PDMS layer and between adjacent layers of the sensor. Due to the rough corrugated surface of the partially covered PDMS carbonized fabric, a large number of electrical paths were formed in the five-layer sensor even at low pressure Δp, which ensured a sharp decrease in electrical resistance. In the region of low pressure (0–6 kPa), the sensitivity Sp was equal to 12.62 kPa−1, and in the range of high pressure (20–200 kPa) Sp was 0.053 kPa−1. Thus, the five-layer C/PDMS-based pressure and vibration sensor had not only ultra-high sensitivity, but also a wide operating range. In addition, due to the excellent elastic flexibility and mechanical strength of the C/PDMS composite, the output characteristics of this pressure and vibration sensor were stable, fast, reproducible and able to ensure its long-term use. The C/PDMS piezoresistive sensor detected even tiny pressure changes as a series of regular and well-identified electric current oscillations accurately. When measuring the pulse with this sensor attached to the wrist, it was possible to obtain typical characteristics of pulse waves, which should enable medical workers to remotely observe in real time some paroxysmal diseases, such as asthma and heart attack. In addition, this sensor can be attached with a patch to the skin near the throat to recognize light muscle movements when swallowing and saying words, can recognize muscle movements around the eyes. For example, when looking up, closing the eyes, and looking forward, specific electrical current signals were generated with each movement. Thus, the research results showed that the pressure and vibration sensor based on carbonized biopolymer cellulose composite has a wide range of applications in healthcare and new smart home Internet of Things electronics.

In addition to the cellulose and materials made from it, silk fibroin (SF), a protein biopolymer obtained from silk fibers, can be used for the manufacture of wearable motion and healthcare sensors. In [20] a strain sensor of the piezoresistive type is presented, which is based on the use of flexible, inexpensive and available single fibers of SF from the silk of the mulberry silkworm, which are covered with electrically conductive graphite flakes. Ultra-thin graphite flakes with an area of approximately 5 µm are used as a shell, and SF fibers with a diameter of ~ 8 µm are used as a core to obtain a material called GSF. The fabricated GSF strain sensor exhibits a high strain gauge coefficient GF = (ΔR/R0)/ε at the level of 14.5 in a wide working range of strains ε from 0 to 15%, and outstanding stability (up to 3000 cycles). The working principle of the GSF sensor is an increase in electrical resistance due to the increase in the distance between the graphite flakes due to the stretching of the graphitized GSF fiber. After release from the tensile deformation, the contact between the graphite flakes is restored, ensuring the functionality of the sensor. To create a flexible strain sensor, individual GSF fibers were deposited onto a commercial substrate made of biodegradable and certified compostable fossil-based Ecoflex plastic. The wires were then connected to each end of the GSF fiber using silver paste. Subsequently, a liquid layer of Ecoflex was uniformly applied to the fabricated samples for encapsulation, and then air-dried. With its high sensitivity and wide working strain range, the GSF single-fiber strain sensor can be placed directly on the human body to monitor joint movements or used in an IoT smart home system to detect any suspicious activity. Since the deformations of the human body are generally complex and multidirectional, it is possible to measure the deformations along multiple axes using several single fibers that are integrated into a GSF multiaxial strain sensor in different directions. Thus, the use of natural silk fibers made it possible to create a light, cheap, durable and sensitive wearable strain sensor to monitor complex human movements and suspicious activities in a smart home.

To power piezoresistive and capacitive sensors, they can be connected to solar cells on the roof and windows in a smart home or, especially for wearable sensors, to wearable thermoelectric nanogenerators. For example, transparent biopolymer films of nanocellulose and silk fibroin have been successfully used as flexible substrates for flexible organic solar cells [21,22,23] due to their ability to enhance the light scattering effect. In particular, thin film of fibrillar nanocellulose obtained from pine wood waste in [21], have ultra-high optical transparency (~ 96%) and at the same time a high light scattering coefficient (~ 60%). The light scattering coefficient quantifies the percentage of diffuse scattering of light passing through, which is important for better light absorption in thin-film solar cells by increasing the path of light in their active semiconductor layers. In [21], the better light absorption due to the nanocellulose substrate ensured the efficiency of converting sunlight energy into electricity and thus increased the efficiency of the organic solar cell by 10%. In the organic SC presented in [22], a flexible and conductive translucent substrate with a high light scattering coefficient was made of biopolymer crystalline nanocellulose covered with a 20 nm thick silver film. The interfacial layer and the photoactive semiconductor layer with a total thickness of 100 nm were applied using the spin-coating method from a mixture of organic polymer molecules. An upper thin-film electrode with a thickness of 165 nm made of a composition of molybdenum oxide and silver was made by vacuum sputtering. Due to the hydrophilicity of nanocellulose, this solar cell completely decomposed after being immersed in water for 30 min, and its main components were easily separated and recycled using minimal solvents and energy, which is attractive for scalable clean solar energy of sustainable infrastructure.

The biopolymer silk fibroin, obtained by processing natural silk fibers from silkworm cocoons, was used in [23] for the production of transparent conductive substrates for flexible solar cells. Silk fibroin is a promising flexible polymer material due to its good biocompatibility, biodegradability, non-toxicity, absence of allergic manifestations and outstanding mechanical properties. The optical transparency of SF film with a thickness of ~ 20 μm was at the level of 90–95%. To make a transparent electrode of a thin-film solar cell, a hydrogel of silk fibroin was filled with silver nanowires and applied to a flat surface by spin-coating. After drying, a thin conductive film was formed, which was used as a flexible substrate and a thin-film bottom electrode of an organic solar cell. The organic solar cell on a substrate made of a composite of silk fibroin and silver nanowires is not only flexible, but also light weight, with an output power to mass ratio of 1.71 W/g. Experiments revealed that the SF film completely decomposes and dissolves in a concentrated lithium bromide salt solution at 60 °C for one hour, organic polymers dissolve in chlorobenzene, and solid residues of silver nanowires and molybdenum oxide electrode materials are easily filtered from the solution. That is, all components of the SC may be separated from each other. The aqueous solution of silk fibroin can be recycled to regenerate the SF film. On the other hand, silk fibroin is easily broken down by enzymes. Thus, the easily controlled degradation, biocompatibility, and recycling of SF allows the use of silk fibroin-based solar cells without environmental pollution, opening the door to their use as energy harvesters in IoT smart homes.

In organic solar cells, in addition to active materials and substrates, interlayers are a very important issue that affect performance, lifetime, and operational stability. In particular, in an organic solar cell in [24] the intermediate layer designed to ensure the efficient transport of electrons from the organic photoactive layer to the cathode was made on the basis of the biopolymer chitosan. Chitosan, derived from the chitin of crustacean and insect shells, is the second most abundant biopolymer on earth after cellulose. The chitosan film, which was applied by the spin-coating method from the solution, increased the efficiency of the conversion of solar energy to electricity in organic SC by about two times. The obtained results demonstrated that chitosan can be used in high-performance and inexpensive ecological organic solar cells.

Wearable thermoelectric nanogenerators can be used in the IoT of smart homes, in particular to power wearable piezoresistive and capacitive sensors. TEGs convert thermal energy into electricity due to the temperature gradient ΔT, i.e. their work is based on the Seebeck effect. The temperature gradient stimulates the transfer of charge carriers (electrons and holes in semiconductors) from the warm part of the semiconductor to the cold part by increasing their kinetic energy and generating additional charge carriers at the heated part of the semiconductor. Due to this, an electrical voltage, also called thermoelectric force, arises between the heated and cold parts of the semiconductor sample. This voltage can be useful to power sensors and actuators of the IoT in a smart home. It is generally accepted that a thermoelectric generator will be cost-effective if the temperature gradient is not lower than 50 °C. However, more recently, devices that use the energy of heat flows with a temperature difference of less than 10 °C have come into practical use, for example, wearable TEGs, which use the difference between the human body temperature and the ambient temperature [25,26,27,28,29,30,31,32]. A typical flexible wearable thin-film TEG consists of series-electrically and parallel-thermally connected thermoelectric elements in the form of strips of p- and n-type semiconductors. In [25,26,27,28,29,30,31,32], biopolymers were used in wearable TEGs as substrates or nanocomposite matrices. Since at temperatures close to room temperature, materials based on bismuth telluride have the best thermoelectric efficiency, their pastes and inks have been used to create thermoelectric nanocomposites with cellulose fibers [25,26,27] and on the surface of silk fabric in wearable thermoelectric generators to harvest energy from human body [28]. Since bismuth telluride and its compounds are quite valuable and, moreover, toxic compounds, the available and biocompatible p-type copper iodide (CuI) semiconductor was used instead in the works [29,30,31,32]. To confirm the biocompatibility of copper iodide, it should be noted that it is used as a source of dietary iodine and copper in table salts and animal feed [32]. In addition, according to [33, 34], CuI demonstrated antibacterial activity. To prepare a nanocellulose (NC) film substrate for a flexible CuI/NC thermoelectric element shown in Fig. 4, the perennial herbaceous plant Miscanthus was used as a raw material. At the National Technical University of Ukraine “Ihor Sikorsky Kyiv Polytechnic Institute” developed an environmentally friendly method of organosolv delignification and hydrolysis to obtain a transparent NC film, shown in the inset in Fig. 4a. A submicrometer-thick copper iodide film was then deposited onto a 12-μm-thick NC substrate using a low-temperature, low-cost, scalable successive ionic layer adsorption and reaction (SILAR) method. The photo in the insert in Fig. 4a demonstrates the hydrophilicity of the nanocellulose substrate. The nanostructured CuI p-type semiconductor film in the CuI/NC thermoelectric element presented in [29, 30] is quite dense and completely covers the substrate surface, as can be seen in the scanning electron microscopy (SEM) image in (Fig. 4b). The Seebeck coefficient of CuI/NC in the temperature range of 290–335 K reaches ~ 228 μV/K, its thermoelectric power coefficient is 140 μW·m−1·K−2, which is a record for biodegradable flexible thermoelectric materials. At a temperature gradient of 40 K, the CuI/NC thermoelectric cell generated an open-circuit voltage of 3.5 mV, a short-circuit current of 4 μA, and an output electric power of 3.8 nW (Fig. 4c).

a Photo of a CuI/NC thermoelectric element with a thin film of copper iodide on the surface of a nanocellulose substrate against the background of the logo of the National Technical University of Ukraine “Ihor Sikorsky Kyiv Polytechnic Institute”. Photograph of a clean nanocellulose substrate with a droplet of water in the inset in a. b Scanning electron microscopy image of the CuI film of the CuI/NC thermoelectric element. c Output voltage Vout (solid symbols) and output power Pout (open symbols) as a function of output current Iout for different temperature gradients ΔT between the ends of the CuI/NC thermoelectric element

The advantages of wearable textile thermoelectric nanogenerators, which harvest the temperature gradient between the human body and the environment, are increased strength and good fit of the textile to the body. Thermoelectric CuI/Ct textile with a nanostructured copper iodide film deposited by SILAR method on the surface of biopolymer cellulose fibers of cotton fabric (Ct) has proven to be a promising flexible, biocompatible and biodegradable material [31]. Figure 5a shows a photo of CuI/Ct with a 12 μm thick CuI layer, demonstrating its high hydrophobicity. SEM images in Fig. 5b and c demonstrate that cellulose fibers are completely coated with copper iodide. Figure 5d shows a flexible planar wearable TEG module of four thermocouples with nanostructured p-CuI films in p-type CuI/Ct textile thermoelectric elements and thin alumel wires as n-type thermoelectric elements placed on cotton fabric. In this thermoelectric module, four thermocouples are connected to each other electrically by means of silver contacts created using conductive glue. Output characteristic of this module are presented in Fig. 5e.

a Photograph of a CuI/Ct thermoelectric textile with a 12 µm thick CuI layer on cotton fabric and water droplets on its surface. b and c SEM images at two different magnifications of this CuI/Ct thermoelectric textile. d Flexible planar wearable TEG module with four thermocouples consisting of this CuI/Ct thermoelectric textile with p-CuI semiconductor films and four thin wires of n-type alumel thermoelectric material. The thermocouples in the thermoelectric module are electrically connected to each other through silver contacts created using conductive glue. e Output voltage Vout (solid symbols) and output power Pout (open symbols) as a function of output current Iout of this planar module for different temperature gradients ΔT

Figure 6a demonstrates a similar flexible planar wearable TEG module with ten such thermocouples, attached with double-sided tape to a cup filled with warm water, so that the bottom contacts of the module are heated while the top contacts remain cold. As you can see on the multimeter screen on the left, the chromel/alumel thermocouple located under the bottom of the cup registered a temperature of 37.2 °C. Thus, the temperature gradient ΔT between the contacts in the TEG was below 17 °C. The voltmeter on the right shows the thermoelectric voltage Uoc of 40.88 mV produced by this TEG module. As can be seen in Fig. 6b, this power is sufficient to power a blood glucose meter used to monitor diabetic patients. Table in Fig. 6c contains experimental results obtained at different temperature gradients. In addition to the thermoelectric voltages, the Table in Fig. 6c shows data on relatively large output powers Pmax, which can be obtained with external load resistances r.

a Photo of a flexible planar wearable TEG module with ten thermocouples made of p-CuI/Ct textile elements and alumel wires on cotton fabric attached with double-sided tape to a cup filled with warm water, so that the bottom contacts of the module heat up during operation, but the upper ones remain cold. The multimeter on the left shows the temperature under the bottom of the cup. The voltmeter on the right shows the thermoelectric voltage Uoc generated by this TEG module. b Photo of powering the glucometer from this TEG module. c Experimental output characteristics of this TEG module, obtained at different temperature gradients

Table in Fig. 6c contains experimental results obtained at different temperature gradients. In addition to the thermoelectric voltages, the table in Fig. 6c shows data on relatively large output powers Pmax, which can be obtained with resistances of external loads r.

To improve the durability and wear resistance of thermoelectric textiles, in [32], cotton fabric was impregnated with nanocellulose hydrogel to create NC/Ct composite textile. Maps of energy dispersive X-ray spectroscopy (EDS) in Fig. 7a and b confirmed the uniform distribution of nanocellulose in the NC/Ct nanocomposite based on the presence of chlorine atoms, small impurities of which, according to [32], were contained in the nanocellulose hydrogel. Then, using the SILAR method, a nanostructured CuI film with a thickness of 8 μm was applied to the NC/Ct surface to obtain a CuI/NC/Ct thermoelectric textile, the SEM images of which are presented in Fig. 7c and d. After coating with nanocellulose hydrogel, a wear-resistant NC/CuI/NC/Ct thermoelectric textile material was obtained, from which the TEG module with ten thermocouples shown in Fig. 7e was manufactured. Due to the temperature gradient of 9.3 °C between the human body and the environment (Fig. 7f), this TEG module was capable of powering wearable motion sensors and healthcare medical sensors [32].

a EDS map confirming the uniform distribution of nanocellulose in the NC/Ct nanocomposite based on the presence of chlorine atoms. b EDS cross-sectional map of NC/Ct nanocomposite confirming uniform distribution of nanocellulose based on the presence of chlorine atoms. c and d SEM images at two different magnifications of the CuI/NC/Ct thermoelectric textile. Photo e and corresponding thermogram f of a flexible planar TEG module with ten thermocouples of NC/CuI/NC/Ct p-type textile elements and thin wires of n-type alumel thermoelectric material on a cotton fabric that was attached to the hand so that the warm contacts were located on the wrist close to the radial artery, and the cold contacts were on the surface of the jacket

Of particular interest for the Internet of Things of a smart home are self-powered sensors, which are both energy harvesters and sensors of pressure, shock, strain or vibration. These sensors are based on triboelectric nanogenerators (TENGs) and piezoelectric nanogenerators (PENGs). Triboelectric nanogenerator is considered as a new technological approach to convert ubiquitous mechanical energy into electrical energy through the contact electrification effect caused by physical contact and separation or friction of the surfaces of two dielectric materials with different electron affinities. After the separation of the contacting surfaces due to the formation of opposite electrostatic charges on them, the corresponding electrodes of the TENG also became oppositely charged due to electrostatic induction. The operation of the TENG is based on the flow of charges accumulated on the electrodes through an external circuit with a load, caused by mechanical action, for example, contact/separation or friction of triboelectric surfaces against each other. The electric potential difference, which is established between two TENG electrodes, is the open circuit voltage Uoc, it can be determined by the equation:

where σ is the triboelectric charge density; εo is the electrical constant; d is the distance between the triboelectric surfaces.

Since biopolymers are dielectrics, they are successfully used in TENG as triboelectric layers [36,37,38,39,40,41,42,43,44,45,46]. In [36], a TENG-based sensor of unauthorized access (tamper sensor) contained a sheet of biopolymer cellulose paper that was inserted into a book. This triboelectric nanogenerator effectively converted the mechanical energy of turning the pages of a book into electricity. When turning the page of the book, an open circuit voltage Uoc ≈ 400 V and a short-circuit current of 0.17 mA were obtained. To demonstrate the self-powered capability, this sensor directly powered 80 commercial white LEDs, which provided illumination for reading printed text in the dark.

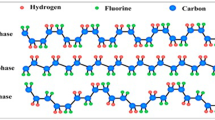

The authors of [37] describe a hierarchically nanostructured triboelectric nanogenerator based on cellulose fibers for self-powered healthcare products. This TENG has two layers of porous dielectrics as triboelectric materials and porous silver thin film contacts on the back side of each triboelectric layer. The upper triboelectric layer is made of microcellulose and fibrillar nanocellulose fibers. The lower triboelectric layer is made of fluorinated ethylene-propylene film, which also has micro-holes for airflow. The entire device is mechanically robust and flexible. This TENG inserted into a medical protective mask converts the mechanical energy of contact/separation of triboelectric layers during human breathing into electricity. During quiet breathing, the TENG is capable of producing a voltage Uoc ≈ 2.22 V, and during physical activity, Uoc ≈ 3.37 V [37]. Such TENG based on micro- and nanocellulose is able to simultaneously remove microbes, dust, soot, dirt, and smoke contained in the air, it can be used in smart home IoT as a sensor for patient monitoring.

A fully biodegradable, transparent, single-electrode TENG-based tamper sensor with an arched structure based on fibrillar nanocellulose substrates, a triboelectric layer made of biopolymer polylactic acid, and electrodes made of conductive polystyrene sulfonate films, operating in vertical contact/separation mode, is presented in [38]. Its open circuit voltage is approximately 75 V. To confirm that this sensor is self-powered, it turned on three LEDs that draw a voltage of 7.5 V and a current of 18 µA [38].

A successful strategy of using environmentally friendly and affordable cellulosic biopolymer materials to replace synthetic polymers in TENG structures was demonstrated in [39]. In a paper TENG, a crepe cellulose paper was used as an electropositive triboelectric material and a nitrocellulose membrane as an electronegative triboelectric layer. Commercial printing paper was used to make the outer covers of the TENG, which was shaped like a book. The electrodes of the paper triboelectric nanogenerator were made of copper foil. Opposite tribopolarities, as well as the morphology of the crepe cellulose paper and nitrocellulose with a porous microstructure resulted in a simple and cost-effective TENG with excellent triboelectric characteristics. Open-circuit voltage Uoc = 196.8 V and short-circuit current 31.5 μA provided a high output electrical power density of 16.1 W/m2 and a reliable durability of more than 10,000 cycles. To demonstrate the ability of the paper triboelectric nanogenerator presented in [39] to implement human–machine interaction and communication, seven such TENGs were assembled into an array and a self-powered paper piano was created. Triboelectric nanogenerators in the keyboard of a paper piano were used to charge capacitors through bridge rectifiers.

Soluble TENG-based vibration sensor based on an electronegative triboelectric layer of biopolymer sodium alginate and an electropositive triboelectric layer of polyvinyl alcohol is presented in [40]. In this TENG thin films of lithium and aluminum were used as the electrodes. The TENG can be completely decomposed within 10 min after being immersed in water due to the dissolution of the polymers, as well as the chemical interaction of Li and Al with water according to the following chemical reactions:

The authors of [41] developed a very simple design of a tamper sensor based on a TENG on approximately 1 mm thick biopolymer starch paper to which was attached a grounded metal wire. Because of the difference in electronegativity between starch and metal, when water was sprayed onto the surface of starch paper attached to a metal electrode, the starch paper became negatively charged and the metal attached to it became positively charged. During physical contact of a person’s hand with starch paper, the surface of the latter was negatively charged, and the skin of the hand was positively charged. When a person removed his hand from the starch paper, the charge on its surface became unbalanced, excess electrons flowed through the load of the grounded wire to the ground. When repeatedly pressing the surface of the starch paper with the hand, a flow of electrons in the reverse direction was observed. The TENG in [41] is not very efficient, its Uoc does not exceed 7.5 V. However, it is soluble, biodegradable and capable of reducing its internal electrical resistance in the presence of moisture. Thus, the self-powered tamper sensor can be used in the smart home IoT to monitor human touch and movement or to detect perspiration.

Natural protein biopolymers have also been used to create TENG-based sensors. In [42], a nonwoven fabric made of silk fibroin nanofibers was used as electropositive triboelectric TENG material. The arch structure of the TENG consists of such a SF nanofiber film, a polyimide (PI) layer as an electronegative triboelectric material, and two aluminum foil electrodes. If the load resistance of the external circuit was 5 MΩ, TENG had a high specific output power of about 4.3 mW/m2. By integrating the TENG electric current signal over time, the surface charge density of the silk fibroin triboelectric material was 1.86 μC/m2. After rectifying the alternating current signal of TENG using a bridge circuit, this charge could be used to charge the battery. It was able to charge the capacitor to 2 V within 5 min. The stability and durability of the TENG, which is due to the ultra-strong mechanical properties of the silk nanofibers and the tear resistance of the non-woven silk textile, has been confirmed by tests during 25,000 cycles of TENG-based pressure and vibration sensor operation.

The authors [43] showed a fully biodegradable triboelectric nanogenerator with two magnesium foil electrodes, a gelatin film as an electronegative triboelectric layer, and an electrospun film of polylactic acid as an electropositive triboelectric layer. The gelatin film in was produced by sol–gel technology using a sandpaper template to create a rough surface. An output voltage of 500 V, a short-circuit current density of 10.6 mA/m2, and a maximum power density of more than 5 W/m2 were achieved when the TENG was operated as a touch sensor and a green micro-energy source. This TENG also demonstrated excellent mechanical stability and operational reliability over 15,000 cycles for the function of detecting the presence of residents. Biodegradation experiments have shown that all TENG materials can completely degrade in water in about 40 days.

Composites of biopolymers with inorganic fillers are used to give triboelectric materials increased mechanical stability and durability [44,45,46]. As an example, the ZnO@paper triboelectric nanocomposite of cellulose paper and zinc oxide (ZnO) nanosheets, which also has outstanding antibacterial properties [44]. For its production, cellulose fibers were treated with an aqueous solution of an eutectic mixture of zinc chloride and urea. A flexible TENG-based vibration sensor was fabricated by combining ZnO@paper as an electropositive triboelectric layer with a polytetrafluoroethylene film as an electronegative triboelectric layer and applying thin-film gold contacts to the back surfaces of the triboelectric layers. Under the condition of a contact/separation frequency of 1 Hz, its output voltage was equal to 77 V, and the output current reached 0.17 μA, which is sufficient to be used as a portable, self-powered wrist-worn activity detector for sleep/wake classification of the user.

The idea of self-powering smart textiles is based on the combination of biomechanical energy harvesting function through a soft contact interface between the human body and textile TENG with the wearability of textiles, which has great prospects for the development of the next generation of human-oriented wearable electronics used in IoT of smart home. First, the soft contacts between the triboelectric layers inside the textile TENG significantly improve the transfer of electrical charges due to the increase in the contact area, which contributes to more efficient energy harvesting and increased sensitivity of soft TENGs to small external mechanical impulses. Second, textile TENGs made of soft materials are easier to press against curved body surfaces, and most importantly, these triboelectric nanogenerators can quickly adapt to deformations caused by complex body movements. In textile TENG, biopolymers can be used as bases or as triboelectric layers. For example, authors [45] show the use of cotton fabric as the basis of a triboelectric nanogenerator designed to create human–machine interface. The cotton fabric is covered with an electrically conductive layer of silver nanowires and laminated with an electronegative triboelectric layer made of polyurethane. For the production of the electropositive triboelectric layer of this TENG, Kapton polyimide tape was used, which was attached to aluminum foil and covered with a layer of polydimethylsiloxane, a layer of “Ekoflex” polyester fibers, and on top with an electropositive triboelectric film of biopolymer polylactic acid. The maximum output power of the textile TENG [45] reached 1.25 W/m2, the open circuit voltage was 162 V, and the short circuit current was equal to 42 μA. A self-powered electronic bracelet that can provide human–machine interface was based on four such textile TENGs. Associated with the four buttons of braselet, the four textile TENGs were connected via a microcontroller (MCU) to a computer. When the buttons were pressed, an output voltage in the range of 5 to 7 V was created to control the gadgets.

In the textile TENG presented by the authors [46], biopolymer bacterial nanocellulose was used to create ultra-strong even during washing, biodegradable and electrically conductive nanocomposite macrofibers obtained by filling the hydrogel matrix of bacterial nanocellulose with carbon nanotubes and a conductive polymer polypyrrole. These fibers were intertwined with nylon fibers to obtain a textile tribopositive part of the TENG, and a polydimethylsiloxane membrane with a thickness of about 0.1 μm covered with a thin silver film was used as the tribonegative part. The 10.5 cm × 6 cm textile TENG demonstrated a maximum open-circuit voltage of 170 V, a short-circuit current of 0.8 μA, and an output power of 352 μW. This textile TENG was able to power commercial electronics for home automation and home security in a smart home. In addition, it can be attached to the human body and used in smart home IoT as a self-powered sensor for effective motion monitoring to protect children and the elderly.

Piezoelectric nanogenerators (PENGs) based on biopolymers and their composites are also suitable for use in self-powered smart home IoT sensors [47,48,49,50,51,52,53,54,55]. A conventional PENG consists of a piezoelectric material sandwiched between two opposite electrodes. Piezoelectric materials (piezoelectrics) are crystalline or semi-crystalline dielectrics or semiconductors with a non-centrosymmetric crystal lattice, in which polarization occurs upon deformation. This phenomenon, called the direct piezoelectric effect (also called the generator or sensor effect), converts mechanical energy into electrical energy. In contrast, the inverse piezoelectric effect used in actuators causes a change in length or deformation of piezoelectric materials when an electrical voltage is applied. The fundamental principles of piezoelectricity in biopolymers are based on their complex dipolar properties and dipole–dipole interactions, facilitated by complex networks of hydrogen bonds and semi-crystalline structure that exhibit varying levels of self-assembly and hierarchical organization [47]. Medical actuators based on the inverse piezoelectric effect of biopolymers such as polylactic acid are described in [54,55,56]. A popular approach is the use of waste from various agricultural and processing industries as PENG piezoelectric biomaterials [48,49,50]. An example is onion skin [48], which consists of α-cellulose, carbonyl, carboxyl and amino groups, as well as nitrogen-containing bioligands and the flavonoid quercetin. Onion skin is built from many layers of equally oriented cellulose fibers (microfibrils) and has a semi-crystalline structure with a degree of crystallinity of about 39%, primarily due to the structure of cellulose, in the microfibrils of which crystalline and amorphous areas are alternately combined. The presence of hydroxyl and carbonyl groups, as well as amino groups in the chemical composition of onion peel ensures the formation of strong hydrogen bonds between neighboring cellulose microfibrils, between cellulose and quercetin, and between cellulose and nitrogen-containing bioligands. Hydrogen bonds cause the alignment of dipoles inside the crystal cells, due to which the spontaneous polarization of the material occurs, which is associated with the piezoelectric properties of the onion peel. The piezoelectric effect in the onion peel is created due to the displacement or reorientation of dipoles in the crystal cells under the action of an external force, for example, when pressed. The research [48] made it possible to determine the equivalent piezoelectric coefficient of the onion peel d33 ≈ 2.8 pC/N. The onion peel-based PENG with gold thin-film electrodes on opposite sides was coated on both sides with polypropylene films and sealed with silicone. During vertical compression, positive and negative piezoelectric potentials were generated on its top and bottom electrodes, respectively, which provided a potential difference between the two electrodes. Thanks to this potential difference, electrons flowed through the load of the external circuit from the lower electrode to the upper one, that is, an electric current was created in the external circuit. The piezoelectric potential disappeared after the PENG was released from the mechanical force, and therefore the electrons flowed through the external circuit in the opposite direction, which provided a current pulse of the opposite sign. When pressed vertically with a force of 17 N, this PENG generated an output voltage of 18 V and a current of 166 nA. Its maximum instantaneous specific electric power was equal to 1.7 μW/cm2, the energy conversion efficiency was 61.7%, which allowed powering up to 30 LEDs. Thus, the onion skin-based flexible piezoelectric nanogenerator can be used in wearable electronics to power gadgets while walking or running, or to monitor human movements. On the other hand, this PENG has demonstrated sensitivity to the very weak pressures that arise from heart contractions and arterial pulses, and can therefore be used to continuously monitor the health of people with cardiovascular disease. Finally, the throat-mounted PENG successfully differentiated cough, swallow, and drink signals as well as speech/voice signals, indicating the potential of this PENG for speech recognition.

Another promising piezoelectric biopolymer turned out to be collagen, the source of which was fish skin. As fish are consumed in large quantities around the world, the disposal of bio-waste such as fish skin is a problem for the environment. Therefore, the processing of fish skin to create a piezoelectric nanogenerator/sensor based on collagen films, has scientific, economic and environmental effects at the same time. Piezoelectric properties of collagen are caused by three polypeptide chains twisted into a unique triple helical structure, which form fibrils that assemble into a collagen fiber. The uniaxial orientation of collagen fibrils and fibers occurs as self-assembly bottom-up due to hydrogen bonds between polypeptide chains with polar amide groups and is stabilized by alternating nanocrystalline cells and amorphous regions in the semi-crystalline structure of collagen. This causes the spontaneous formation of molecular dipoles in collagen and the polarization of collagen films, which is associated with their piezoelectric properties. In work [49], for the production of PENG, a silver paste was applied to both surfaces of a flexible film made of cleaned and demineralized fish skin with a thickness of about 250 μm, which mainly consisted of collagen, to which the wires of the external circuit were attached. To seal and provide the device with high structural stability, including mechanical strength and durability, it was laminated on both sides with layers of silicone elastomer polydimethylsiloxane. Research [49] has shown that the equivalent piezoelectric coefficient of fish skin collagen d33 ≈ 3 pC/N. Due to the piezoelectric effect, this PENG is able to generate an open-circuit voltage Uoc ≈ 2 V and a short-circuit current ≈ 20 nA in response to external pressure ~ 1.8 MPa. The power generated by the PENG ~ 0.75 mW/m2 can be used to power low-power electronics. In addition, the fish skin-based piezoelectric nanogenerator can be used as an ultra-sensitive, long-lasting wearable self-powered pressure sensor to create a human–machine interface. Its mechanosensitivity, i.e. the ratio of the generated Uoc to the contact force F is constant and equal to 27 mV/N at a frequency of mechanical pressures/releases of 5 Hz. Thus, this PENG can successfully monitor human physiological signals in real time, making it valuable for human presence detection and for healthcare using IoT smart home.

Another mass readily available bio-waste with excellent mechanical and piezoelectric properties, a specific microfibrous structure and a high surface area to weight ratio is chicken feather, which is 90% natural protein keratin. Chicken feather keratin consists of repeating amino acid blocks with a flexible α-helical and rigid β-sheet structure and with a certain number of amorphous regions. These α-helical and β-sheet structures are strongly linked by intramolecular and intermolecular hydrogen bonds, which results in the formation of electric dipoles within the ordered crystalline structure of keratin. In addition, due to the presence of disulfide bonds in the structure, feather keratin exhibits excellent mechanical strength and is both biodegradable and biocompatible. The paper [50] shows the use in PENG of aligned chicken feather fibers with an average diameter of 2.5 μm, the equivalent piezoelectric coefficient d33 of which is in the range from 1.6 pC/N to 2.1 pC/N. A flexible piezoelectric nanogenerator with a weight of 1 g and a thickness of 100 μm had a typical electrode/piezoelectric/electrode sandwich design. In it, two layers of cleaned chicken feather fibers as a piezoelectric material with carbon electrodes applied to them were sealed with silicone. When the upper surface of the 2.0 cm × 6.0 cm PENG was pressed with a finger (at a pressure of 0.31 MPa) with an average frequency of 4 Hz, an open circuit voltage of 10 V was generated (at an internal PENG resistance of 1.5 MΏ). The reason for the piezoelectric effect in PENG based on chicken feathers is electric dipoles that spontaneously arise in the structure of highly ordered keratin fibers. The application of an external mechanical force causes compression of the keratin, which causes the deformation of these spontaneous dipoles, thereby creating a piezopotential. Therefore, the mechanical force due to the polarization of keratin in chicken feather fibers contributes to the accumulation of positive and negative charges on the carbon electrodes attached to them. The potential difference between the electrodes results in a positive peak voltage that causes electrons to flow through the external load. Under conditions of release from mechanical pressure, a negative voltage peak is generated, due to which the accumulated electrons flow in the reverse direction. Therefore, the fabricated in [50] PENG can produce an average of 10 V under a biomechanical pressure of 0.13–31 MPa, thereby demonstrating the potential for real-life device applications. The power produced by PENG based on chicken feathers turned out to be enough to light up 26 LEDs simultaneously. This PENG was also used to charge a 2.2 µF capacitor to 2 V in two minutes by repeatedly tapping the PENG with a finger. Attached to a person’s wrist, the chicken feather-based PENG can absorb vibrations from the pulse and is able to distinguish any changes in the person’s pulse rate. That is, the biopolymer keratin-based PENG can be easily used as an environmentally friendly power source in wearable electronics and as a fall detection and occupant presence sensor, as well as for monitoring and protecting human health through the Internet of Things of the smart home.

Recently, flexible composite-type PENGs with increased efficiency have been demonstrated, in which biopolymer matrices and fillers of nanowires and nanoparticles of typical inorganic piezoelectrics, such as zinc oxide, and ferroelectrics have been used to create piezoelectric composite films [51,52,53]. Biocomposite piezoelectric nanogenerators are promising for large-scale use due to increased output currents, voltages and powers, ease of fabrication, economic efficiency, and mechanical strength. For example, biocompatible and biodegradable piezoelectric nanogenerators based on flexible composites of silk fibroin biopolymer and non-toxic ferroelectric nanoparticles of barium titanate, zinc stannate and their solid solutions have been developed in [51]. In terms of piezoelectric efficiency, biocomposites exceeded such biomaterials as cellulose, collagen and keratin by approximately one hundred times. To create the flexible biocomposite PENG, a sol of silk fibroin, inorganic ferroelectric nanoparticles and silver nanowires was applied by sol–gel method to a flexible polyethylene terephthalate substrate covered with a conductive layer of tin-doped indium oxide (ITO/PET). Another ITO/PET film served as the upper electrode of this PENG. The output voltage and current density signals of the biocomposite PENG from human walking in place were 2.2 V and 0.12 mA/cm2, respectively. Due to the solubility of silk fibroin in water, the piezoelectric biocomposite was destroyed in an aqueous medium within 10 min. However, by adding glycerol to it, it was possible to slow down the dissolution of biocomposite films, and 20 wt.% of glycerol in the biocomposite ensured their complete insolubility due to the structural transition in silk fibroin from random spirals to nanosheets of β-crystallites. These results indicate the possibility of creating biocomposite PENGs that will degrade in a programmable manner. In addition, paper [51] presented a piezoelectric biocomposite textile, the fibers of which were made in the form of coaxial wires. For this, an aluminum wire with a diameter of 1 mm was immersed in a silk fibroin sol also contained inorganic ferroelectric nanoparticles and silver nanowires. Then, a 20-μm-thick aluminum film was applied to the obtained semi-hardened biocomposite layer with a thickness of 20 μm in a vacuum. Textile PENG based on coaxial biocomposite demonstrated an output voltage of 1.8 V and an output current density of 0.1 µA/cm2. Both biocomposite-based PENG designs described above are promising for creating reliable, self-powered piezoelectric pressure and vibration sensors for the smart home Internet of Things.

The authors of [52] developed a flexible piezoelectric nanogenerator, which uses a biocomposite with a matrix of silk fibroin and a filler made of zinc oxide nanowires. In PENG with an area of 1.5 cm × 3 cm, flexible ITO/PET tape was used as the substrate and top electrode, and the bottom electrode was made of biocomposite. A colloidal solution with a 12.5:1 ratio of silk fibroin to ZnO content was applied to the ITO/PET surface by sol–gel method and converted at a temperature of 60 °C into piezoelectric biocomposite film. To create the top electrode, a thin copper wire was attached to the ZnO/SF using silver paste. During bending of biocomposite PENG, electric voltage was generated, the value of which increased with the bending angle, which can be explained from the point of view of the combined piezoelectric effect in the silk matrix and in the ZnO nanoparticles. Synergistic charge generation in the biocomposite created an increased output voltage between the top and bottom electrodes, as the biocomposite film was spontaneously polarized due to the dual piezoelectric effect of the silk fibroin β-crystallite nanosheets and ZnO nanowires. The equivalent piezoelectric coefficient d33 of the biocomposite was equal to 28.38 pC/N. The biocomposite PENG was able to generate an open-circuit voltage of 12.5 V and an output power density of 6.67 mW cm−3 under periodic bending and was effective in powering four commercial LEDs from the movement of human fingers.

The work [53] shows the process of in situ synthesis of biocomposite piezoelectric paper with evenly distributed microflowers of vanadium-doped zinc oxide (V-ZnO) with ferroelectric properties in a porous biopolymer matrix made of bacterial nanocellulose (BC). For this, the BC membrane was immersed in aqueous solutions for hydrothermal growth of V-ZnO microflowers inside the BC structure. Thin layers of polydimethylsiloxane were then spin-coated onto the resulting V-ZnO/BC paper on both sides, after which thin-film gold electrodes were deposited on both sides, which were covered with titanium protective films and attached to the wires of an external electrical circuit. It has been experimentally proven that the value of the piezoelectric coefficient of the ferroelectric biocomposite V-ZnO/BC d33 is 65.5 pC/N. The PENG was about 40 μm thick and exhibited excellent flexibility, high mechanical strength, and stability for at least 10,000 bend/release cycles. When bending the biocomposite film, axial and transverse tensile/compressive deformations were created, due to which voltage and current pulses were observed. As the bending angle increased, the output current density of the PENG increased linearly up to 70 nA/cm2, the maximum output specific power of the biocomposite PENG was about 60 nW/cm2. The output voltage and current of the PENG were 1.5 V and 80 nA, respectively. The authors of [53] demonstrated the suitability of biocomposite PENG for motion monitoring. In experiments, several such PENGs were attached to book pages and used as self-powered sensors. When the page was turned from left to right (forward), the current signal consisted of a positive peak followed by a negative peak, corresponding to the bending and release of PENG during forward page turning. In contrast, if the page was flipped backwards (right to left), a negative current peak was first observed, followed by a positive peak, because PENG was first folded down and then released. Biocomposite piezoelectric nanogenerators were connected to commercial liquid crystal displays for direct monitoring of page turning. It has been shown that by integrating PENG with communication devices or memory in an IoT smart home, sensitive documents or papers can be tracked, which is useful for confidential applications.

The most representative applications of biopolymers in the smart home IoT sensors and energy harvesters are highlighted in Table 1

3 Smart home IoT actuators based on biopolymer hydrogels

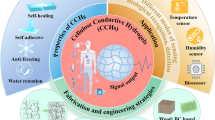

In the context of the smart home, smart IoT devices and human–machine interfaces can provide more convenient interactions through the use of soft actuators based on smart biopolymers with morphing and motion capacities. These include piezoelectric and other shape-changing biopolymers, as well as smart shape-memory and adhesion-changing biopolymer materials [14, 54,55,56,57,58,59,60,61]. Soft actuators have outstanding advantages including low weight, permanent deformability, as well as body compliance and shape adaptation to the environment. Their ability to convert energy, as well as generate mechanical energy and perform flexible movements, has triggered the rapid development of soft actuators in various areas of the Internet of Things, such as circuit switching, soft robotic motion, and manipulation [14, 59,60,61]. Among the biopolymers used as functional materials in these actuators, especially in the healthcare field, smart biopolymer hydrogels can play a crucial role due to their stimulus sensitivity, biocompatibility, and self-healing ability [14, 59,60,61]. Thanks to this advantage, biopolymer hydrogels can safely and friendly interact with human skin and tissues of the human body, and actuators based on these hydrogels can function without negatively affecting human physiological activities, for example, during drug delivery. Hydrogels with high water content (more than 75–90 wt%) can change their size and shape by reversible swelling/deswelling when the water content in the polymer network changes. Stimulus-responsive smart hydrogels are well known as tissue-like smart soft substances that respond positively to various physical and chemical external stimuli. Under external stimuli, smart hydrogels exhibit certain behaviors such as swelling, shrinking, bending, deformation, dehydration, etc. [14, 59,60,61]. These unique properties make stimuli-responsive hydrogels serve as ideal candidates for the preparation of soft actuators used in IoT smart homes as walkers, smart switches, grippers, and artificial muscles. Excellent biocompatibility and tunable structural and physicochemical properties, as well as sensitivity to environmental stimuli such as temperature, humidity, light, electricity and magnetic field, are the main advantages of biopolymer hydrogels [14, 59,60,61,62]. It is noteworthy that the physical and chemical properties of biopolymer hydrogels can be easily tuned through different fabrication scenarios and composition proportions.

For example, the authors of [62] described a soft actuator based on electrosensitive hydrogel of the biopolymer polysaccharide chitosan made from chitin, a component widely distributed in crustacean shells. This chitosan actuator is capable of changing their geometric shape and size by swelling/deswelling under the influence of an electric field. According to [60,61,62], the mechanism of the phenomenon of its electrically induced deformation can be well explained as a synergy of Coulomb, electrophoretic and electroosmotic interactions. Thus, when under the influence of an electric field, the ions inside the hydrogel rearrange in a certain way, leading to a heterogeneous concentration of ions and the creation of osmotic pressure, which leads to compression or expansion. In [62], the electromechanical performance of an actuator in the form of a 3D printed and cast chitosan hydrogel membrane immersed in an aqueous alkali solution was assessed using two non-contact parallel electrodes. When an electrical stimulus of 10 V was applied to the electrodes for 60 s, the chitosan film acted as a semi-permeable membrane, for which the difference in the concentration of hydroxyl ions on its different sides caused an increase in osmotic pressure on one of the sides. Therefore, from the side near the positive electrode, the chitosan membrane swelled and, due to uneven swelling, bent towards the negative electrode, that is, the actuator bent and moved. Chitosan actuator has demonstrated long-term durability and was suitable for biomedical implants as well as muscle repair. This property can be used in smart home IoT actuators for successful applications in healthcare, as well as for helping the elderly and rehabilitating the sick.

In the actuators presented in [63], magnetically sensitive hydrogels consisted of biopolymers of alginate and xanthan gum, cross-linked with calcium ions and modified with magnetic nanoparticles containing iron. Alginate and xanthan gum are anionic polysaccharides widely used as drug carriers due to their non-toxicity, non-immunogenicity, biodegradability and biocompatibility. A magnetically sensitive hydrogel demonstrated superior mechanical and swelling properties for tissue engineering and the treatment of Parkinson’s disease in a low-cost, non-invasive static magnetic field that promoted the orientation of magnetic nanoparticles, inducing local mechanical vibrations of the hydrogel and promoting hydrogel shrinkage. A static external magnetic field of 0.4 T stimulated the release of the antiparkinsonian drug levodopa from a hydrogel patch adhered to a human arm, reaching approximately 64% of the initial load after 30 h. Thus, according to [59,60,61,62,63], magnetically sensitive biopolymer hydrogels with the ability to control the release of drugs under the influence of an external magnetic stimulus may be relevant for the treatment of Parkinson’s disease and other diseases of elderly people in the IoT of a smart home.

According to [61, 64], the stimulus-responsive deformation of hydrogel actuators is also suitable for fabricating smart switches in a smart home circuit. In [64], a thermosensitive hydrogel with shape memory was prepared by a simple method of soaking a biopolymer gelatin gel in an aqueous solution of tannic acid, due to which the resulting gelatin hydrogel was strengthened by hydrogen bonds between these biomaterials. It is significant that this hydrogel, due to the rearrangement of hydrogen bonds under the influence of temperature, reacted extremely quickly by changing its shape. For example, the temporary shape of an actuator made of this hydrogel was fixed at 25 °C in 1 s and restored to its original shape at 37 °C in 1 s. Additionally, this change in hydrogel shape could be programmed at a certain fixed temperature, and another desired shape could be achieved at another specific recovery temperature. The authors of [64] used this programmable temperature-sensitive hydrogel actuator as a switch that precisely controlled its bending, acting as a switch to turn a light bulb and a small fan off and on depending on the room temperature. The excellent properties of thermosensitive biopolymer hydrogels with shape memory will allow the use of new IoT actuators for smart homes based on them, such as soft smart grippers and locomotors [59, 61, 64]. These soft actuators with squeezing and stretching behavior can serve as soft robots for healthcare of smart home residents, namely wearable exoskeletons for the elderly and for muscle tissue rehabilitation, and can also be used as implantable artificial muscles to replace damaged muscles [59, 61, 64].

Due to their high water content, thermosensitive biopolymer hydrogels have excellent diffusion properties and are able to transform from a gel to a sol (melt) or shrink and lose liquid at a certain temperature due to the reversible destruction of non-covalent bonds (hydrogen bonds, π–π-stacking, Van der Waals, etc.) [59, 60]. In thermosensitive hydrogels widely studied for drug delivery [59, 60], the temperature of the specified phase/volume transition is close to human physiological temperature (37 °C), due to which the release of the drug from the hydrogel-based biopolymer system is spontaneously activated as soon as it is attached to the skin or enters into the human body. According to [60], these hydrogels attached to the human body demonstrate the unique advantages of being able to introduce drugs into hard-to-reach places, local and long-term delivery, as well as reducing the dose of the drug delivered, as well as high adhesion to mucous surfaces. Recently, such smart biopolymer hydrogels with a reversible liquid–viscoelastic hydrogel phase transition depending on temperature, prepared on the basis of gelatin, hydroxypropyl cellulose and sodium alginate and modified with lignite humic acids, were shown in [65,66,67]. Since the shape and form of biopolymer hydrogel can be customized using molding and fabrication technologies [59], a promising direction is to create bioadhesive hydrogel devices for conformally attaching a skin-friendly, biocompatible patch for precise health monitoring, drug delivery, or wound healing [12]. Improvements in the interaction of the actuator or sensor with the skin occur when they achieve high adhesion and conformal contact with skin surfaces that may be rough, wet or hairy, through the use of biomimetic binding copied from nature [12]. For example, microneedle hydrogel patches have tiny needles ranging in size from tens to hundreds of micrometers that can mechanically disrupt the superficial layers of the skin to improve drug penetration. Figure 8 shows the process of preparing biopolymer hydrogel transdermal patches with conical microneedles and with microneedles in the form of biomimetic adhesive bumps, developed and presented in [67] to increase adhesion to human skin and successful drug delivery. Smart thermosensitive transdermal patches in [67] were manufactured by micromolding based on a biopolymer hydrogel of gelatin and sodium alginate modified with humic acids. First, a 3D model was created, shown in Fig. 8a, and processed by a slicer to obtain a file with commands for the 3D printer, which was used to print the master mold shown in Fig. 8b. Then, a hydrosol of gelatin, sodium alginate and humic acids was prepared (Fig. 8c) and poured into a master mold to produce a microneedle transdermal biopolymer hydrogel patch according to the mold template using sol–gel technology, as shown in Fig. 8d. Figure 8e and f show the specially programmed two different microneedle shapes in the transdermal biopolymer hydrogel patches.

Schematics for the development of smart biopolymer hydrogel transdermal microneedle patches based on gelatin and sodium alginate modified with humic acids. a Photo of a 3D model of the shape of transdermal hydrogel patches, processed by a slicer to obtain a file with sets of commands for a 3D printer. b Photo of the 3D printed mold for single transdermal hydrogel patch. c Photograph of gelatin and sodium alginate hydrosol modified with humic acids. d Manufacturing of microneedle transdermal biopolymer hydrogel patch according to the mold template using sol–gel technology. e Optical micrograph of the biopolymer hydrogel patch with conical microneedles. f Optical micrograph of the biopolymer hydrogel patch with microneedles in the form of biomimetic adhesive bumps

The most representative applications of biopolymer hydrogels in smart home IoT actuators are presented in Table 2.

4 Smart home IoT wireless communication devices based on biopolymers

The Internet of Things envisions a future in which digital and physical entities can be connected through appropriate information and communication technologies to enable a whole class of new applications and services. Radio Frequency IDentification (RFID) devices, in which radio signals are used to read or record data stored in so-called transponders, also sometimes called RFID tags, play an important role in ensuring IoT identification technologies. Typically, RFID tags consist of three parts: a microchip that stores, modulates, and processes information, antennas for signal reception/transmission, and a support substrate. Given the wide demand, the current trend is to create low-cost and biodegradable RFID tags [15]. For use in wearable devices, the RFID substrate must be flexible. Available, inexpensive and biodegradable cellulose paper is attracting great interest in the creation of disposable RFID devices [15]. Cellulose paper serves as an insulating substrate material, it is able to endow RFID tags with such useful properties as sufficient surface roughness and low absorption of electromagnetic energy due to low dielectric permittivity ε and small dielectric losses tan δ. Commercial paper RFID tags contain a metal antenna, an integrated circuit, and a paper substrate. The cost of the metal antenna is 80% of the total cost of the tag.