Abstract

Layered double hydroxides (LDHs) are widely used as effective adsorbents for wastewater treatment due to their simple synthesis, controllable structure, strong stability, large surface area, and large interfacial spacing. In this study, modified-biochar (BMBC) and Mg/Al modified-biochar composite (Mg/Al-BC) were directly prepared using ball milling technology to effectively adsorb As(V), and nitrogen-rich biochar was obtained through pyrolysis using shrimp shells as precursors. Compared to pristine biochar, the oxygen-containing functional groups of Mg/Al-BC increased by 71.9%, and the particle average diameter decreased from 14.26 nm to 12.56 nm. The kinetics and isothermal models of arsenic adsorption were examined in batch experiments to investigate the impacts of pH, temperature, and co-existing anions. The adsorption capacities for As(V) followed the order: Mg/Al-BC > BMBC > BC, with their respective maximum adsorption capacities measured at 22.65, 6.73, and 0.48 mg/g. The arsenic adsorbed onto Mg/Al-BC was dependent on pH and coexisting anions. Precipitation, ion exchange, surface complexation, and electrostatic interaction were the possible governing adsorption mechanisms. Protonation of pyridinic-N/quinone groups in biochar contributed to the electrostatic attraction between arsenic anion and quaternary ammonium cation. Stable reusability indicates that the ball milled Mg/Al-BC composite could be a promising adsorbent for arsenate removal from polluted water.

Graphical Abstract

Highlights

• N-rich biochar pyrolysis at 500 ℃ by Shrimp shell with natural sources of nitrogen.

• Mg/Al hydroxides-modified biochar (Mg/Al-BC) can be obtained through dry ball milling process.

• Maximum adsorption capacity of Mg/Al-BC for arsenic removal is 22.65 mg/g.

• Precipitation, ion exchange, and surface complexation are the main sorption mechanisms.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Arsenic (As) is a common metalloid element in the aquatic environment, known for its toxicity and carcinogenicity (Zhu et al. 2019). The World Health Organization (WHO) set the drinking water limit concentration for arsenic as 10 µg/L (Lee et al. 2019). The industrial discharge and weathering of arsenic-bearing minerals may result in the release of inorganic As into water and wastewater (Mudhoo et al. 2011). Inorganic As is highly soluble and mobile in water, commonly existing as arsenite and arsenate at neutral pH (Bhattacharya et al. 2007). Soluble inorganic arsenic in water forms numerous noxious substances mainly influenced by anthropogenic activity, such as mining and agricultural production (Zhang et al. 2017). Unfortunately, As(V) contamination in drinking water has resulted in severe environmental and human health effects throughout the world (Liao et al. 2016). It invariably increases the risk of human health including skin cancer and neurological disorder (Bhowmick et al. 2018). Therefore, it is necessary to exploit eco-friendly and cost-effective adsorbents to remove arsenic from water and maintain the environmental sustainability. Recently, a variety of methods were applied to treat wastewater containing As(V), including adsorption, chemical precipitation, flocculation, and ion exchange. Among these, adsorption was recognized as the most promising approach to treat As(V) because of its high efficiency and easy operation (Zhang et al. 2017).

Biochar (BC), as an emerging material, has been applied in the environment and is derived from various waste biomass rich in carbon pyrolysis under anoxic conditions (Liu et al. 2019). Due to its distinctive characteristics, such as, large specific surface area (SSA), rich porosity, and abundant surface functional groups, BC has exhibited enormous potential in environmental applications (Hu et al. 2015). Furthermore, for the sake of sufficiently low-cost waste materials (e.g., straw, fruit shells, leaf, poultry manure, and shrimp shells) as feedstock for production, biochar has been regarded as a renewable and sustainable adsorbent for remediating contaminated water resources (Zhao et al. 2021). Among this biochar, the Nitrogen (N)-rich biochar deserves more attention unsurprisingly because of its lone pair electron in the N atom, which could mediate mutual effects with heavy metals (Ahmad et al. 2020). In our previous research, N-rich biochar obtained from waste shrimp shells exhibits high quinone group and high content of pyridinic-N on its surface. This increased active sites for the methylene blue removal in solution (Wang et al. 2022). However, the performance of the pristine biochar in adsorbing anionic pollutants is restricted by the predominantly net negative charged surface (Han et al. 2016). Hence, it is inevitable to modify and functionalize the surface of pristine biochar for enhancing the adsorption affinity between bare biochar and anionic pollutants.

Furthermore, LDHs are considered an effective avenue to functionalize the surface of biochar due to their excellent anionic pollutant sorption abilities and non-toxicity (Yang et al. 2019). LDHs, as multifunctional anionic clays, possess an intercalation structure that provides a large surface area and superior thermal stability (Mittal 2021). However, the major synthesis processes to form LDHs on the biochar surface applied in previous research were time-consuming and contain many steps, especially precipitating and aging in the liquid phase, which typically require approximately 3 days (Jung et al. 2021). To address the challenges for large-scale production, the ball-milling technique can be adopted to produce the LDHs/biochar composites due to its reproducibility and eco-friendly characteristics. It is well known that ball milling can strengthen the functional characteristics of biochar and improve the surface area, thereby enhancing the adsorption ability (Kumar et al. 2020). Nevertheless, few studies are available for preparing LDHs/biochar composites by this method, it is worth noting that direct research using metal hydroxides for this specific preparation method has not been conducted to our knowledge.

In this work, waste shrimp shells biochar was pyrolyzed at 500 ℃, then biochar was modified by ball milling, and biochar was modified with Mg/Al hydroxides through ball milling. The adsorption performance of these materials on As removal in aqueous phase was investigated by batch adsorption experiments. The objectives of this work are (1) to investigate the LDHs modification route of BC (Mg/Al-BC) through ball-milling; (2) to discuss the As(V) adsorption performance by BC, BMBC, and Mg/Al-BC; (3) to reveal the governing synergistic mechanism in As removal by Mg/Al-BC.

2 Materials and methods

2.1 Materials and reagents

Waste shrimp shells were obtained and crushed (3–4 mm) according to our previous work (Wang et al. 2022). The process for pretreatment of shrimp shells was as follows:1) washing shrimp shells with deionized water (DI, 18.2 MΩ) several times to remove impurities thoroughly (e.g., dust, protein, and fat); 2) drying at 80 ℃ for 12 h in DHG-9053A oven. Analytical grade Al(OH)3, and Mg(OH)2 were utilized for fabricating materials, and guaranteed grade KBH4, KOH, HCl, Na2HAsO4·7H2O, vitamin C, and thiourea were utilized for determining and analyzing. The chemical reagents used were purchased from Sinopharm Group (Shanghai, China) and were not purified during use.

2.2 Synthesis of adsorbents

The pretreatment shrimp shell was pyrolyzed in a quartz tube furnace at 500 ℃ for 2 h with N2 while maintaining a 5 ℃/min heating rate (NBD-O1200, Henan Nuobadi Material Technology Co., Ltd). The shrimp shell biochar was obtained by using DI water to rinse several times and being dried at 80 ℃ overnight, labeled BC. 3.0 g of BC and 300 g agate balls (balls to biochar mass ratio = 100:1) were transferred into a 500 mL agate tank and placed in a XQM-2 ball mill machine. The procedure was rotated for 8 h at 300 rpm with the direction of rotation altered every 30 min, and the obtained biochar was labeled BMBC. All biochar samples were stored airtight and ground before use. 1.5 g BC was mixed with 1.5 g Mg/Al hydroxides (0.897 g Mg(OH)2 and 0.603 g Al(OH)3) maintaining a constant Mg/Al mole ratio of 2:1 for preparation of Mg/Al-BC according to the above process.

2.3 Biochar characterization

The C, N, and H compositions of the samples were determined by Vario EL Cube (Elementar, Germany). The pore volume and SSA of biochar samples were detected using a Beckman Coulter SA3100 (Beckman Coulter, USA) on account of N2 adsorption and Brunauer–Emmett–Teller (BET) theory at 77 K. Adsorbents were degassed in the vacuum for approximately 24 h at 180 ℃ before measuring. Zeta potentials were determined using a Zetasizer Analyzer (ZS90, Malvern, UK). The biochar surface morphology was tested by Nova NanoSEM 450 (FEI, USA). The crystallinity before and after As(V) adsorption was measured by X-ray diffraction (XRD, XPert Pro) at 20–70°. ESCALAB 250Xi X-ray photoelectron spectroscopy (XPS, Thermo Fisher, and USA) and NEXUS-670 Fourier transform infrared (FT-IR, NICOLET, USA) were applied for surface functional groups and chemical properties detection. The TG/DTA thermogravimetric analyzer (7300, SEIKO, Japan) was operated to carry out the thermogravimetric analysis (TGA) of adsorbents in the N2 environment at a 5 ℃/min heating rate from 30 to 800 ℃.

2.4 Batch adsorption experiments

4.16 g of Na2HAsO4·7H2O was dissolved in DI water for 1000 mg/L As(V) stock solution. As(V) solutions were diluted with DI water to the desired content. All experiments of batch adsorption were carried out in 100 mL PET bottles and placed into a temperature-controlled orbital shaker (THZ-320, Shanghai, China) with a constant oscillation frequency of 200 rpm/min under room temperature except for the thermodynamics tests. To evaluate the modifications of biochar samples on the adsorption performance, dosage effect (0.2- 1.0 g/L), pH values (3.0- 11.0, adjust pH with 0.1- 1 mol/L HCl or NaOH solutions), 0.02–0.1 mol/L different single ionic species (Cl−, NO3−, HCO3−, SO42−, and PO43−), and temperature (25- 55 ℃) were fully investigated. The adsorption kinetics test was conducted using 50 mL of 10 mg/L As(V) solution with 1.0 g/L adsorbent at a 0.5- 18 h period. Adsorption thermodynamics tests were conducted at 25- 55 ℃ by mixing 1.0 g/L dosage of Mg/Al-BC with different initial concentrations of As(V) solution (10- 100 mg/L) for 20 h to achieve equilibrium. The adsorption isotherm experiments were performed with varied initial As(V) concentrations ranging from 5- 40 mg/L for BC and BMBC, and 10- 100 mg/L for Mg/Al-BC. After achieving adsorption equilibrium, the supernatant was filtered by 0.22 µm nylon membrane, and As(V) concentration was measured by atomic fluorescence spectroscopy (PF5, Puxi General Instrument Co., Ltd, Beijing). The adsorption capacity of As(V) (Qe, mg/g) was computed according to the initial (C0, mg/L) and the ultimate equilibrium concentration (Ce, mg/L) of As(V), which can be expressed with the following formula:

The adsorption kinetics (pseudo-first order and pseudo-second order kinetic models), adsorption isotherm (Langmuir model and Freundlich model), and thermodynamics analysis were described in the Supplementary Material.

3 Results and discussion

3.1 Characterization

The SEM and particle sizes of the BC, BMBC, and Mg/Al-BC have displayed in Fig. 1. BC appeared as the irregular geometry of particles in Fig. 1a, c, e. Compared to BC, the sizes of BMBC and Mg/Al-BC were smaller. The images (Fig. 1b, d, f) were magnified at 20,000X with more details showing coherent and comparatively smooth BC surface. On the contrary, the ball-milled BMBC and Mg/Al-BC particles appeared coarse and fragmented, indicating the effective reduction of grain size at the microscale through ball-milling technology (Lyu et al. 2018). Previous studies of ball-milled biochar derived from plant waste were also carried out, and similar conclusions were obtained (Cao et al. 2019b).

The relevant changes in surface functional groups and chemical bonds of the adsorbents were explored by FTIR characterization (Fig. 2). The sharp peak of 3750 cm−1 in Mg/Al-BC, attributed to free stretching vibration of the -OH group, while the wider peak of 3462 cm−1 referred to the associated stretching vibration of the -OH group in all adsorbents, suggesting that the structure of phenols and alcohols remained in biochar samples after pyrolysis (Yu et al. 2015). The obvious peaks of CO32− were observed at 713, 876, and 1427 cm−1 and were typical characteristics of calcite, corresponding to the in-plane flexural vibration, the out-of-plane flexural vibration, and the antisymmetric tensile vibration, respectively (Zhang et al. 2019). During the pyrolysis process, organic calcium was gradually converted into calcium carbonate (CaCO3), thereby visible peaks of CO32− in biochar samples were more evident. The overlapping peaks at 1049 cm−1 can be ascribed to the C–O–C functional groups stretching vibrations (Shadangi & Mohanty 2014). Furthermore, the peak of NH at 1630 cm−1 can only be detected in biochar samples derived from shrimp shells, due to certain N-containing groups in the chitin transforming into volatile matter during the pyrolysis process (Wei et al. 2017).

Based on the IUPAC category, the isotherms of N2 adsorption–desorption for BC, BMBC, and Mg/Al-BC present in Fig. 3a were classified as type I/IV adsorption isotherms with H3 hysteresis curves, confirming that biochar samples all possessed mesoporous structures (Jung et al. 2019). The SSA of BMBC and Mg/Al-BC improved after ball milling (Fig. 3b and Table 1), attributing to the existence of emerging produced pores by the release of volatiles (Kloss et al. 2012). At the same time, the pore size of all adsorbents was mainly distributed in the range of 20–60 nm. As displayed in Table 1, the contents of N and C showed a slight decrease. The weight percentage of N and C decreased from 3.51% to 3.27%, and 25.87% to 24.17%, respectively. The reduction of C might be caused by the destruction of C = O groups, carboxyl C, aliphatic C, and fused cyclic aromatic hydrocarbons in the biochar-DOC or the tar particles during the ball milling process (Xu et al. 2019). The decrease of N in BMBC is mainly due to the rise in the surface area of adsorbents and the opening of the interior pores. In addition, the H content of BMBC increased slightly compared with BC, this trend was similar to the conclusion of Xu et.al., the H content of Mg/Al-BC increased 126.8% because of the addition of Mg/Al hydroxides (Xu et al. 2019).

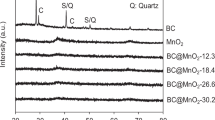

As illustrated in Fig. 3c, the biochar sample features were determined in the range of 10–70° using XRD analysis, and the shape of diffraction peaks in these adsorbents had similarities. In the spectrum of BC and BMBC, the 2θ values of peaks centered at 23.02°, 29.41°, 31.42°, 35.97°, 43.15°, 47.49°, 48.51°, 57.4°, 60.68°, and 65.6° proved the existence of CaCO3 (PDF#05–0586). The intensity of peaks of CaCO3 in BMBC and Mg/Al-BC was lower than that in BC, indicating the CaCO3 crystalline was damaged during the ball milling process and experienced dilution effect from Mg/Al hydroxides loading. Furthermore, strong diffraction peaks in Mg/Al-BC were related to single-metal hydroxide or double-metal hydroxides.

XPS was conducted to further analyze the chemical state of the element. The characteristic peaks of C, O, N, and Ca elements were presented on the full XPS survey of BC and BMBC, while the peaks of 1306 eV and 74.4 eV were observed in Mg/Al-BC full XPS attributing to the successful loading of Mg and Al (Fig. 3d and Table S1). The O atomic percentage of modified biochar increased, indicating that mechanochemical modification can introduce oxygen-containing functional groups on modified biochar surfaces. Moreover, more detailed results on the surface group characteristics of materials were depicted in Fig. 4 and Table S2. Four dominant peaks of C1s spectra attributed to CO32− groups at ~ 289.8 eV, C = O groups at 288 eV, C-O and C-N groups at 286 eV, and C = C and C–C groups at 284.7 eV, respectively (Fig. 4a) (Fan et al. 2018). Furthermore, the peaks that appeared on the O1s and N1s spectrogram (Fig. 4b, c) are corresponding to the C = O groups for ~ 531.8 eV, C-O groups for ~ 533 eV, pyridinic-N for ~ 398.6 eV, and pyrrolic-N for ~ 400.2 eV, respectively (Xiao et al. 2020). While after modification, the relative peaks areas of the C1s, O1s, and N1s spectra had changed, and the total ratios of C = C/C–C, C-O/C-N in BMBC were found to be decreased from 62.57% to 62.13%, from 23.18% to 20.38% compared with BC. Meanwhile, the proportion of the C = O groups and CO32− groups of BMBC increased from 4.4% to 5.15%, and from 9.84% to 12.34% after ball milling. Although the gross percentage of C-O groups and pyridinic-N groups of three samples (BC, BMBC, and Mg/Al-BC) showed an apparent decreasing trend from 29.86% to 20.39% and from 39.08% to 20.39%, the C = O groups and pyrrolic-N revealed a reverse tendency from 70.14% to 79.61% and from 60.92% to 63.29%, respectively. These results mainly depended on the materials and O-containing groups, which were broken in the process of ball milling. In addition, compared to BC, the proportion of characteristic peaks of Mg/Al-BC on C1s spectra showed an obvious increase except for C-O groups. The C-O group of O1s spectra also reduced with the addition of Mg/Al hydroxides, attributing to the C-O group oxidation during the ball milling process. In contrast, the C = O group of C1s and O1s spectra both increased from 4.4% to 5.04% and from 70.14% to 79.61%, suggesting that more carboxyl functional groups were produced on the surface of Mg/Al-BC after ball milling. Hence, the shrimp shell-derived biochar possessed plenty of O-containing groups and N-containing groups. It would be anticipated that modified biochar (BMBC, Mg/Al-BC) will show better performance than BC due to the increase of O-containing groups on the surface and various adsorption sites of condensation As(V) in the aqueous solution.

Thermogravimetric analysis (TGA) was carried out in the pure N atmosphere to determine the thermostability of adsorbents. The curves of TG, DTG, and DTA were present in Fig. 5. TG curves (Fig. 5a) of adsorbents can be deconvoluted into I-IV different stages (Cimo et al. 2014). Part I at 20–210 ℃ is due to moisture dehydration; Part II at 210–410 ℃ is associated with the chitin and protein decomposition; Part III at 410–570 ℃ means more aromatic compounds have been pyrolyzed, and part IV at 570–800 ℃ describes the conversion of inorganic matters in the biochar. As shown in Fig. 5b, BC and BMBC had the main mass losses at 660–710 ℃, which were caused by the release of CO2 from the decomposition of CaCO3 (Zhang et al. 2019). Whereas, the weight loss peak of Mg/Al-BC around 235 ℃ and 355 ℃ was caused by the decomposition of Mg(OH)2 and the cracking of some residual nitrogen-containing organic matter (Kameda et al. 2010; Zhang et al. 2019). In addition, Mg/Al-BC had better stability at 660–710 ℃ attributed to well crystallized calcite. Mass loss observed at 30–100 ℃ proves the endothermic process from DTA in Fig. 5c, because of the moisture and chemisorbed carbon dioxide (CO2) released (Szymanski et al. 2002). A flat mass loss in part III could attribute the formation of aromatic compounds to the pyrolysis of heterocyclics.

3.2 Effects of pH on As(V) removal

As it can be seen in Fig. 6a, the Zeta potential of BC, BMBC, and Mg/Al-BC were negative in the pH range of 5–11 and the zero potential point values were 3.42, 3.66, and 4.56, respectively. Compared with bare biochar, ball-milled biochar especially for Mg/Al-BC, the Zeta potential value increased from -38.54 mV to -24.23 mV significantly at pH 11 due to the positive charge of Mg/Al hydroxides and high charge density. In fact, Zeta potential value reflects the stability of samples. Relative low potential value leads to conduciveness of adsorption. The pH can be considered a crucial factor in the environmental system to evaluate the applications of materials, such as its ability to alter the adsorbent’s surface charge density and influence adsorption performance. As shown in Fig. 6b, the initial pH effect on the removal of As(V) had been investigated. The adsorption capacities of BMBC and Mg/Al-BC enhanced with the increase of pH (3–7), and obtained the maximum adsorption capacity when pH reached 7. While pH > 7, the removal efficiency of all biochar samples decreased as the Zeta potential values declined, which might be mainly related to the existence of H2AsO4− and HAsO42− forms of the solution at pH 5–11, proving that weak alkaline or neutral environment is favorable for As(V) adsorption (Xu et al. 2022; Zubair et al. 2021). Thus, pH 7 was chosen as the ideal pH condition for As(V) adsorption.

3.3 Effect of co-existing anions and ionic strength on As(V) removal

Generally, abundant co-existing anions are present in the water environment and interfere with the adsorption of As(V) (Cao et al. 2019a). Thus, a batch of adsorption experiments was performed to test the effect of various co-existing anions with different concentrations on As(V) removal by Mg/Al-BC. As displayed in Fig. 7, Cl− and NO3− had negligible impact on As(V) removal. Nevertheless, the existence of HCO3− in aqueous solutions increased the As(V) adsorption capacity, which could be ascribed to the changed pH values of solutions which made the water environment more suitable for adsorption. On the contrary, the inhibition of As(V) adsorption by sulfate and phosphate ions may be due to the strong competition of the binding sites on the adsorbent surface by these ions. From a chemical perspective, the ionic radius of SO42− (0.230 nm) and PO43− (0.238 nm) are all larger than those of Cl− and NO3− (all smaller than 0.200 nm), and have the similar characteristics and structure of AsO4− (0.335 nm) (Li et al. 2016; Xu et al. 2022).

Real-world water environmental conditions are more complex, which may affect the adsorption effect. In order to verify its high removal performance in complex water environment, polluted water was prepared using river water. According to the adsorption result (Fig. S2a), the adsorption capacity in river water reached 8.62 mg/g and was slightly lower than DI water (8.98 mg/g), indicating that Mg/Al-BC can be used to treat arsenic wastewater. To further investigate the regeneration stability of Mg/Al-BC, four consecutive adsorption–desorption experiments were shown in Fig. S2b. After four cycles, the maximum of As(V) adsorption capacity showed a slight decrease, but it was still as high as 5.68 mg/g. Thus, stable reusability indicates that the ball milled Mg/Al-BC composite could be a promising adsorbent for arsenate removal from water.

3.4 Adsorption kinetics

A series of absorption kinetic experiments of As(V) was conducted to evaluate the performance of various adsorbents. As depicted in Fig. 8a, all biochar samples exhibited a similar adsorption tendency towards As(V) throughout the whole adsorption process. The adsorbed amount increased fast in 3 h because there were abundant active sites for As(V). Whereas, the adsorption equilibrium was gradually reached due to numerous adsorption sites being occupied. The adsorption capacities of ball-milled biochar for As(V) were significantly higher than that of bare biochar at any time. Compared with other biochar samples, Mg/Al-BC had the largest adsorption capacity and removal rate, because of the enhanced adsorption affinity between the adsorbent and As(V).

The kinetic data of As(V) was fitted by applying the pseudo-first order model and pseudo-second order mode to further explore adsorption behavior (Fig. 8b). The kinetic data could be described better with the pseudo-second model than the pseudo-first order model on account of the equilibrium capacity of calculation and correlation coefficients (Table S3), suggesting that As(V) adsorbed onto biochar samples may be under different mechanisms.

3.5 Adsorption isotherm

The influence of initial As(V) concentration in the range of 5 to 100 mg/L was investigated. As present in Fig. 9a, the As(V) adsorption capacities of adsorbents were in the following order: Mg/Al-BC > BMBC > BC, and the adsorption capacities of corresponding equilibrium were 26.497 mg/g, 5.311 mg/g, and 0.3639 mg/g. It proved that modifications of ball milling technology and Mg/Al hydroxides can effectively improve the adsorption capacities of As(V). Furthermore, the Langmuir and Freundlich models are often used to depict the isothermal model of samples interacting with pollutants. The corresponding parameters of the two models have been listed in Table S4.

The different initial concentrations effect on As(V) adsorption performance (a); the fitting curves of models on the adsorbents (b); the temperature effect on As(V) adsorption performance (c); lnKd linear plot versus 1/T for As(V) adsorbed on Mg/Al-BC (d). Experimental conditions: dosage = 1.0 g/L, pH = 7.0, rpm = 200 r/min

In view of the correlation coefficients (R2), the data for BC was better fitted by the Langmuir rather than the Freundlich isotherm model, manifesting a monolayer As(V) adsorbed onto the active sites of BC (Dong et al. 2017). Moreover, the Freundlich model was more appropriate for Mg/Al-BC with higher R2 value (0.98) rather than the Langmuir model (0.79), confirming multi-layered As(V) adsorbed on the heterogeneous adsorption sites on Mg/Al-BC surfaces. Hence, the SSA is not the sole key factor in the process of As(V) adsorption (Chao et al. 2020). Meanwhile, the constant “n” was above 2, indicating that the adsorption of As(V) was favorable.

To better evaluate the As(V) adsorption performance, the maximum adsorption capacity of Mg/Al-BC was applied to compare with other adsorbents reported recently (Table 2). Even the experimental conditions were different from other adsorbents in the literature. The Mg/Al-BC exhibited excellent performance to adsorb As(V) and its maximum adsorption capacity reached 22.65 mg/g, significantly higher than other adsorbents (all lower than 20 mg/g).

3.6 Thermodynamics

To further determine the internal energy changes during As(V) adsorption process, the temperature effect on As(V) removal was investigated in the range from 25 ℃ to 55 ℃. As illustrated in Fig. 9c, with the increase in temperature, the As(V) adsorption capacity increases, indicating the enhanced interactions between the adsorbent and As(V) at elevated temperatures. Besides, the thermodynamic parameters calculation graphically showed lnKd as a function of 1/T (Fig. 9d and Table S5). The adsorption of As(V) was spontaneous due to the negative Gibbs free energy (∆Go). The values of ∆Go decreased with increasing temperature, confirming that reactions of As(V) adsorption proceed more easily as temperature rises (Fan et al. 2016). The better performance of adsorption with the positive value of enthalpy change (∆Ho) at higher temperatures suggested that As(V) being adsorbed onto Mg/Al-BC was an endothermic process (Liu et al. 2021). The result could be ascribed to the increased random thermal motion at the solid-solution interface during As(V) adsorption (Kılıç et al. 2013).

3.7 Adsorption mechanism

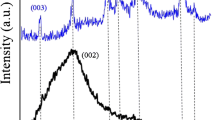

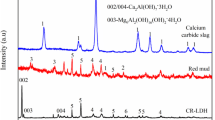

To insight into the adsorption mechanism of As(V) on the surface of Mg/Al-BC, FTIR and XPS analysis before and after As(V) adsorption were performed (Fig. 10). The fresh peak after adsorption of As(V) appeared at approximately 806 cm−1, which was ascribed to the As-O stretching vibration. Meanwhile, the evident shift of -OH and -COO bands indicated that oxygen-containing functional groups were involved in the As(V) adsorption through formatting the surface complexes (Shen et al. 2017). As depicted in Fig. 10b, the Mg/Al-BC showed similar diffraction peaks before and after adsorption, revealing that Mg/Al (hydro)oxides on the surface of biochar were not changed after As adsorption. Nevertheless, the characteristic peaks became broader, and the d101 value which represented the interlayer space, reduced from 13.85 Å to 13.48 Å after adsorption, which could be ascribed to the replacement of origin interlayered anion (CO32−) by As(V) anions via ion exchange (Shen et al. 2017; Zhang et al. 2020). The peak of As3d appeared vividly in wide scan spectra after adsorption, and the binding energy of the Mg/Al-BC absorption As(V) was a bule-shift from 45.5 eV to 49.85 eV, confirming that the As form of the H2AsO4− and HAsO42− distributing on the Mg/Al-BC (Fig. 10c). Pyridinic-N/quinone groups in biochar can be protonated to produce quaternary ammonium salt under neutral conditions, and the zeta potential values of Mg/Al-BC significantly increased, which is conducive to the removal of arsenic-negative ions by electrostatic adsorption (Wang et al. 2022). The percentage of four peak areas in C1s spectra (Fig. 10d) was changed, C = C/C–C from 65.55% to 71.92%, C-O from 19.1% to 12.49%, C = O from 5.04% to 9.1%, and CO32− from 10.31% to 6.48%, respectively, after adsorption, attributed to the close connection of carbon atoms that was broken by As(V) adsorbed onto Mg/Al-BC (Yang et al. 2020). The high-resolution O1s spectra (Fig. 10e) was divided into two peaks (531.6 and 532.5 eV) which correspond to metal oxides (M–O, where M = Mg and Al) and metal hydroxides (M-OH). Following the absorption of As(V), the area percentage of M-OH increased from the initial 20.39% to 21.19%. This indicated that As anions were incorporated into the hydrotalcite-like crystalline structure (Mg(Al)-O-As) via bonding the interlayered hydroxyl groups (Zhang et al. 2020). The binding energies of 74.4 eV (Al2p), 1304 eV, and 1306 eV (Mg1s) (Fig. S2 and Fig. 10f) corresponded to M-OH and MgCO3, respectively. After adsorption, the ratio of M-OH in Mg1s spectra increased from 36.4% to 41.56%, which might be attributed to the interactions between As(V) and Mg hydroxides, containing the formation of the As-O-Mg bonds (Hudcova et al. 2019). Based on the analysis above, the probable adsorption mechanisms of Mg/Al-BC consist of ion exchange, ligand exchange, and electrostatic interaction. Notably, ligand exchange forms endosphere complexes have been regarded as the governing mechanism (Fig. 11) (Yang et al. 2014). The metal-bonded hydroxyl groups of Mg/Al-BC can form the complexation with As(V) (M–O-As). The As content in SEM–EDS of absorption before and after also demonstrated that As(V) was adsorbed on the surface of Mg/Al-BC (Fig. S5).

FTIR spectra of Mg/Al-BC before and after As(V) adsorption (a); XRD patterns of Mg/Al-BC before and after As adsorption (b); XPS wide scan survey of Mg/Al-BC before and after As(V) adsorption (c); XPS high-resolution spectra for C1s (d), O1s (e), Mg1s (f) of Mg/Al-BC before and after As(V) adsorption

4 Conclusion

In this study, the Mg/Al-BC composite could be synthesized from sharp shell biochar by dry ball milling technology with Mg/Al hydroxides and displayed excellent As(V) adsorption performance. SEM-EDXS and XPS analysis demonstrated that Mg(OH)2 and Al(OH)3 adhered to the biochar surface uniformly and that the As(V) was removed by the Mg/Al-BC successfully. Sorption of As(V) was highly pH dependent with optimum pH values found as 7.0. The adsorption kinetics of Mg/Al-BC fit the pseudo-second-order model well and the maximum adsorption capacity could reach 22.65 mg/g, which was better than traditional adsorbents. Furthermore, FTIR and XPS analysis showed that the excellent performance of Mg/Al-BC for As(V) adsorption removal was mainly due to the formation of LDHs precipitation, ion exchange, M–O-As complexation, and the electrostatic interaction of quaternary ammonium cation. Overall, Mg/Al-BC could be recommended as an effective and low-cost adsorbent for treating arsenic-contaminated wastewater.

Availability of data and materials

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

References

Ahmad SZN, Wan Salleh WN, Ismail AF, Yusof N, Mohd Yusop MZ, Aziz F (2020) Adsorptive removal of heavy metal ions using graphene-based nanomaterials: Toxicity, roles of functional groups and mechanisms. Chemosphere 248: 126008. https://doi.org/10.1016/j.chemosphere.2020.126008

Bhattacharya P, Welch AH, Stollenwerk KG, McLaughlin MJ, Bundschuh J, Panaullah G (2007) Arsenic in the environment: Biology and Chemistry. Sci Total Environ 379:(2–3), 109–20. https://doi.org/10.1016/j.scitotenv.2007.02.037

Bhowmick S, Pramanik S, Singh P, Mondal P, Chatterjee D, Nriagu J (2018) Arsenic in groundwater of West Bengal, India: a review of human health risks and assessment of possible intervention options. Sci Total Environ 612: 148–169. https://doi.org/10.1016/j.scitotenv.2017.08.216

Cao J, Lai L, Lai B, Yao G, Chen X, Song L (2019a) Degradation of tetracycline by peroxymonosulfate activated with zero-valent iron: Performance, intermediates, toxicity and mechanism. Chem Eng J 364:45–56. https://doi.org/10.1016/j.cej.2019.01.113

Cao Y, Xiao W, Shen G, Ji G, Zhang Y, Gao C, Han L (2019b) Carbonization and ball milling on the enhancement of Pb(II) adsorption by wheat straw: Competitive effects of ion exchange and precipitation. Bioresour Technol. 273: 70–76. https://doi.org/10.1016/j.biortech.2018.10.065

Chao Y, Zhang J, Li H, Wu P, Li X, Chang H, He J, Wu H, Li H, Zhu W (2020) Synthesis of boron nitride nanosheets with N-defects for efficient tetracycline antibiotics adsorptive removal. Chem Eng J 387:124138. https://doi.org/10.1016/j.cej.2020.124138

Chen T, Quan X, Ji Z, Li X, Pei, Y (2020) Synthesis and characterization of a novel magnetic calcium-rich nanocomposite and its remediation behaviour for As(III) and Pb(II) co-contamination in aqueous systems. Sci Total Environ 706: 135122. https://doi.org/10.1016/j.scitotenv.2019.135122

Cimo G, Kucerik J, Berns AE, Schaumann GE, Alonzo G, Conte P (2014) Effect of heating time and temperature on the chemical characteristics of biochar from poultry manure. J Agric Food Chem 62(8):1912–8. https://doi.org/10.1021/jf405549z

Dong S, Wang Y, Zhao Y, Zhou X, Zheng H (2017) La3+/La(OH)3 loaded magnetic cationic hydrogel composites for phosphate removal: effect of lanthanum species and mechanistic study. Water Res 126:433–441. https://doi.org/10.1016/j.watres.2017.09.050

Fan HT, Shi LQ, Shen H, Chen X, Xie KP (2016) Equilibrium, isotherm, kinetic and thermodynamic studies for removal of tetracycline antibiotics by adsorption onto hazelnut shell derived activated carbons from aqueous media. RSC Adv. 6(111):109983–109991. https://doi.org/10.1039/c6ra23346e

Fan Q, Sun J, Chu L, Cui L, Quan G, Yan J, Hussain Q, Iqbal M (2018) Effects of chemical oxidation on surface oxygen-containing functional groups and adsorption behavior of biochar. Chemosphere 207:33–40. https://doi.org/10.1016/j.chemosphere.2018.05.044

Gao X, Peng Y, Guo L, Wang Q, Guan CY, Yang F, Chen Q (2020) Arsenic adsorption on layered double hydroxides biochars and their amended red and calcareous soils. J Environ Manage 271:111045. https://doi.org/10.1016/j.jenvman.2020.111045

Han Y, Cao X, Ouyang X, Sohi SP, Chen J (2016) Adsorption kinetics of magnetic biochar derived from peanut hull on removal of Cr (VI) from aqueous solution: effects of production conditions and particle size. Chemosphere 145:336–41. https://doi.org/10.1016/j.chemosphere.2015.11.050

Hu X, Ding Z, Zimmerman AR, Wang S, Gao B (2015) Batch and column sorption of arsenic onto iron-impregnated biochar synthesized through hydrolysis. Water Res 68: 206–16. https://doi.org/10.1016/j.watres.2014.10.009

Hudcova B, Vitkova M, Ourednicek P, Komarek M (2019) Stability and stabilizing efficiency of Mg-Fe layered double hydroxides and mixed oxides in aqueous solutions and soils with elevated As(V), Pb(II) and Zn(II) contents. Sci Total Environ 648:1511–1519. https://doi.org/10.1016/j.scitotenv.2018.08.277

Jung KW, Lee SY, Choi JW, Lee YJ (2019) A facile one-pot hydrothermal synthesis of hydroxyapatite/biochar nanocomposites: Adsorption behavior and mechanisms for the removal of copper(II) from aqueous media. Chem Eng J 369:529–541. https://doi.org/10.1016/j.cej.2019.03.102

Jung KW, Lee SY, Choi JW, Hwang MJ, Shim WG (2021) Synthesis of Mg–Al layered double hydroxides-functionalized hydrochar composite via an in situ one-pot hydrothermal method for arsenate and phosphate removal: Structural characterization and adsorption performance. Chem Eng J 420:129775. https://doi.org/10.1016/j.cej.2021.129775

Kameda T, Fubasami Y, Uchiyama N, Yoshioka T (2010) Elimination behavior of nitrogen oxides from a NO3−-intercalated Mg–Al layered double hydroxide during thermal decomposition. Thermochimica Acta 499(1–2):106–110. https://doi.org/10.1016/j.tca.2009.11.009

Kılıç M, Kırbıyık Ç, Çepelioğullar Ö, Pütün AE (2013) Adsorption of heavy metal ions from aqueous solutions by bio-char, a by-product of pyrolysis. Appl Surf Sci 283:856–862. https://doi.org/10.1016/j.apsusc.2013.07.033

Kloss S, Zehetner F, Dellantonio A, Hamid R, Ottner F, Liedtke V, Schwanninger M, Gerzabek MH, Soja G (2012) Characterization of slow pyrolysis biochars: effects of feedstocks and pyrolysis temperature on biochar properties. J Environ Qual 41(4):990–1000. https://doi.org/10.2134/jeq2011.0070

Kumar M, Xiong X, Wan Z, Sun Y, Tsang DCW, Gupta J, Gao B, Cao X, Tang J, Ok YS (2020) Ball milling as a mechanochemical technology for fabrication of novel biochar nanomaterials. Bioresour Technol 312:123613. https://doi.org/10.1016/j.biortech.2020.123613

Lee SY, Jung K-W, Choi J-W, Lee YJ (2019) In situ synthesis of hierarchical cobalt-aluminum layered double hydroxide on boehmite surface for efficient removal of arsenate from aqueous solutions: Effects of solution chemistry factors and sorption mechanism. Chem Eng J 368:914–923. https://doi.org/10.1016/j.cej.2019.03.043

Li R, Wang JJ, Zhou B, Awasthi MK, Ali A, Zhang Z, Gaston LA, Lahori AH, Mahar A (2016) Enhancing phosphate adsorption by Mg/Al layered double hydroxide functionalized biochar with different Mg/Al ratios. Sci Total Environ 559:121–129. https://doi.org/10.1016/j.scitotenv.2016.03.151

Liao G, Wu Q, Feng R, Guo J, Wang R, Xu Y, Ding Y, Fan Z, Mo L (2016) Efficiency evaluation for remediating paddy soil contaminated with cadmium and arsenic using water management, variety screening and foliage dressing technologies. J Environ Manage 170:116–22. https://doi.org/10.1016/j.jenvman.2016.01.008

Liu X, Gao M, Qiu W, Khan ZH, Liu N, Lin L, Song Z (2019) Fe-Mn-Ce oxide-modified biochar composites as efficient adsorbents for removing As(III) from water: adsorption performance and mechanisms. Environ Sci Pollut Res Int 26(17):17373–17382. https://doi.org/10.1007/s11356-019-04914-8

Liu Q, Li D, Cheng H, Cheng J, Du K, Hu Y, Chen Y (2021) High mesoporosity phosphorus-containing biochar fabricated from Camellia oleifera shells: Impressive tetracycline adsorption performance and promotion of pyrophosphate-like surface functional groups (C-O-P bond). Bioresour Technol 329:124922. https://doi.org/10.1016/j.biortech.2021.124922

Lyu H, Gao B, He F, Zimmerman AR, Ding C, Huang H, Tang J (2018) Effects of ball milling on the physicochemical and sorptive properties of biochar: Experimental observations and governing mechanisms. Environ Pollut 233:54–63. https://doi.org/10.1016/j.envpol.2017.10.037

Mittal J (2021) Recent progress in the synthesis of Layered Double Hydroxides and their application for the adsorptive removal of dyes: a review. J Environ Manage 295:113017. https://doi.org/10.1016/j.jenvman.2021.113017

Mudhoo A, Sharma SK, Garg VK, Tseng C-H (2011) Arsenic: an overview of applications, health, and environmental concerns and removal processes. Crit Rev Environ Sci Technol 41(5):435–519. https://doi.org/10.1080/10643380902945771

Shadangi KP, Mohanty K (2014) Kinetic study and thermal analysis of the pyrolysis of non-edible oilseed powders by thermogravimetric and differential scanning calorimetric analysis. Renewable Energy 63:337–344. https://doi.org/10.1016/j.renene.2013.09.039

Shen L, Jiang X, Chen Z, Fu D, Li Q, Ouyang T, Wang Y (2017) Chemical reactive features of novel amino acids intercalated layered double hydroxides in As(III) and As(V) adsorption. Chemosphere 176:57–66. https://doi.org/10.1016/j.chemosphere.2017.02.100

Szymanski GS, Karpinski Z, Biniak S, Świa̧tkowski A (2002) The effect of the gradual thermal decomposition of surface oxygen species on the chemical and catalytic properties of oxidized activated carbon. Carbon 40:13

Wang S, Gao B, Li Y (2016a) Enhanced arsenic removal by biochar modified with nickel (Ni) and manganese (Mn) oxyhydroxides J Ind Eng Chem 37:361–365. https://doi.org/10.1016/j.jiec.2016.03.048

Wang S, Gao B, Li Y, Zimmerman AR, Cao X (2016b) Sorption of arsenic onto Ni/Fe layered double hydroxide (LDH)-biochar composites. RSC Adv. 6(22):17792–17799. https://doi.org/10.1039/c5ra17490b

Wang M, Yan J, Xu Y, Zhou X, Diao Y, Wang H, Bian J, Liu C, Quan G (2022) Mechanochemical modified nitrogen-rich biochar derived from shrimp shell: Dominant mechanism in pyridinic-N for aquatic methylene blue removal. J Environ Manage 329:117049. https://doi.org/10.1016/j.jenvman.2022.117049

Wei F, Cao J-P, Zhao X-Y, Ren J, Wang J-X, Fan X, Wei X-Y (2017) Nitrogen evolution during fast pyrolysis of sewage sludge under inert and reductive atmospheres. Energy Fuels 31(7):7191–7196. https://doi.org/10.1021/acs.energyfuels.7b00920

Wu J, Huang D, Liu X, Meng J, Tang C, Xu J (2018) Remediation of As(III) and Cd(II) co-contamination and its mechanism in aqueous systems by a novel calcium-based magnetic biochar. J Hazard Mater 348:10–19. https://doi.org/10.1016/j.jhazmat.2018.01.011

Xiao J, Hu R, Chen G (2020) Micro-nano-engineered nitrogenous bone biochar developed with a ball-milling technique for high-efficiency removal of aquatic Cd(II), Cu(II) and Pb(II). J Hazard Mater 387:121980. https://doi.org/10.1016/j.jhazmat.2019.121980

Xu X, Zheng Y, Gao B, Cao X (2019) N-doped biochar synthesized by a facile ball-milling method for enhanced sorption of CO2 and reactive red. Chem Eng J 368:564–572. https://doi.org/10.1016/j.cej.2019.02.165

Xu L, Shu Z, Feng L, Zhou J, Li T, Zhao Z, Wang W (2022) Fresh biomass derived biochar with high-load zero-valent iron prepared in one step for efficient arsenic removal. J Cleaner Prod 352:131616. https://doi.org/10.1016/j.jclepro.2022.131616

Yang K, Yan LG, Yang YM, Yu SJ, Shan RR, Yu HQ, Zhu BC, Du B (2014) Adsorptive removal of phosphate by Mg–Al and Zn–Al layered double hydroxides: Kinetics, isotherms and mechanisms. Sep Purif Technol 124:36–42. https://doi.org/10.1016/j.seppur.2013.12.042

Yang F, Zhang S, Sun Y, Tsang DCW, Cheng K, Ok YS (2019) Assembling biochar with various layered double hydroxides for enhancement of phosphorus recovery. J Hazard Mater 365:665–673. https://doi.org/10.1016/j.jhazmat.2018.11.047

Yang X, Yu IKM, Tsang DCW, Budarin VL, Clark JH, Wu KCW, Yip ACK, Gao B, Lam SS, Ok YS (2020) Ball-milled, solvent-free Sn-functionalisation of wood waste biochar for sugar conversion in food waste valorisation. J Cleaner Prod 268:122300. https://doi.org/10.1016/j.jclepro.2020.122300

Yoon K, Cho DW, Tsang DCW, Bolan N, Rinklebe J, Song H (2017) Fabrication of engineered biochar from paper mill sludge and its application into removal of arsenic and cadmium in acidic water. Bioresour Technol 246:69–75. https://doi.org/10.1016/j.biortech.2017.07.020

Yu Y, Long Y, Wu H (2015) Near-complete recovery of sugar monomers from cellulose and lignocellulosic biomass via a two-step process combining mechanochemical hydrolysis and dilute acid hydrolysis. Energy Fuels 30(3):1571–1578. https://doi.org/10.1021/acs.energyfuels.5b02196

Zhang SW, Yang HC, Huang HY, Gao HH, Wang XX, Cao RY, Li JX, Xu XJ, Wang XK (2017) Unexpected ultrafast and high adsorption capacity of oxygen vacancy-rich WOx/C nanowire networks for aqueous Pb2+ and methylene blue removal. J Mater Chem A 5(30):15913–15922. https://doi.org/10.1039/c7ta04377e

Zhang P, Hu H, Tang H, Yang Y, Liu H, Lu Q, Li X, Worasuwannarak N, Yao H (2019) In-depth experimental study of pyrolysis characteristics of raw and cooking treated shrimp shell samples. Renewable Energy 139:730–738. https://doi.org/10.1016/j.renene.2019.02.119

Zhang W, Cheng H, Peng S, Li D, Gao H, Wang D (2020) Performance and mechanisms of wastewater sludge conditioning with slag-based hydrotalcite-like minerals (Ca/Mg/Al-LDH). Water Res 169:115265. https://doi.org/10.1016/j.watres.2019.115265

Zhao N, Zhao C, Tsang DCW, Liu K, Zhu L, Zhang W, Zhang J, Tang Y, Qiu R (2021) Microscopic mechanism about the selective adsorption of Cr(VI) from salt solution on O-rich and N-rich biochars. J Hazard Mater 404(Pt A):124162. https://doi.org/10.1016/j.jhazmat.2020.124162

Zhu N, Qiao J, Yan T (2019) Arsenic immobilization through regulated ferrolysis in paddy field amendment with bismuth impregnated biochar. Sci Total Environ 648:993–1001. https://doi.org/10.1016/j.scitotenv.2018.08.200

Zubair M, Ihsanullah I, Abdul Aziz H, Azmier Ahmad M, Al-Harthi MA (2021) Sustainable wastewater treatment by biochar/layered double hydroxide composites: progress, challenges, and outlook. Bioresour Technol 319:124128. https://doi.org/10.1016/j.biortech.2020.124128

Funding

The work was supported by the Natural Science Foundation of Jiangsu Province (SBK2022020100), the Major Basic Research Project of the Natural Science Foundation of the Jiangsu Higher Education Institutions (22KJA610004), the National Natural Science Foundation of China (22006127), and Postgraduate Research and Practice Innovation Program of Yancheng Institute of Technology (KYCX21-XY006).

Author information

Authors and Affiliations

Contributions

Ming Wang: investigation, writing- original draft preparation; Jinlong Yan: conceptualization, methodology; Yusen Diao: formal analysis; Xiangqian Zhou: software; Ting Luo: data curation; Hui Wang: supervision; Guixiang Quan: writing- reviewing and editing; Xinyu Sun: resources; Jun Wang: formal analysis. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no financial and non-financial competing interests.

Additional information

Handling Editor: Fengchang Wu.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, M., Yan, J., Diao, Y. et al. Ball milled Mg/Al hydroxides modified nitrogen-rich biochar for arsenic removal: performance and governing mechanism. Carbon Res. 2, 30 (2023). https://doi.org/10.1007/s44246-023-00063-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44246-023-00063-3