Abstract

Coconut snowball (Naru/ Ladoo) is a conventional Indian sweet made out of coconut endosperm and sugar/ jaggery. However, coconut snowball has a limited shelf-life (3–4 weeks) and lose their textural properties with time in refrigerated conditions, due to the presence of high amounts of saturated fatty acids. This present study is aimed to utilize tender endosperm (Talsas/ Nungu) of Palmyra palm (Borassus flabellifer) as an ingredient for coconut snowball to improve its nutritional and sensory attributes. In this study, the optimum cooking time, amount of coconut, and Talsas endosperm obtained through Box-Behnken model were 22.5 min, 52.25% and 22.5%, respectively. Fortification increased the levels of total polyphenol content, total flavonoid content, ferric reducing antioxidant activity, and 2, 2′-Azinobis (3-ethylbenzothiazoline-6 sulfonic acid) radical scavenging property by 45.39%, 3.25-fold, 6.68-fold and 2.34-fold, respectively. HPLC analysis of Naru samples revealed the presence of six polyphenols (kaemferol, myricetin, gallic acid, protocatechuic acid, quercetin, rutin). Additionally, in-vitro lipid digestibility, lipid oxidation studies microbiological analysis, and sensory studies were conducted to determine the role of Talsas endosperm substitution in coconut snowball. Based on these experiments, it can be concluded that fortification of Coconut Naru with Talsas endosperm significantly enhanced its nutritional profile, antioxidant capacity, sensory characteristics, and shelf life by only up to 75 days.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The coconut palm (Cocos nucifera L.), is a monocotyledon that is a member of the Palmae or Arecaceae family [1]. Coconut is made up of an inner rigid protective endocarp, or shell, and an exterior fiber coat, or husk, known as an exocarp. Endosperm, or coconut meat, is a white albuminous portion, and coconut water fills the interior cavity. The coconut tree holds immense importance in tropical places as it offers food, work, and economic prospects to millions of people [2]. Because of its innately rich source of macronutrients and micronutrients for human nutrition and health, this fruit is also known as a "miracle fruit." Commercial processing yields a variety of products, including coconut oil [3], coconut sugar [4], water [5], milk [6], raw kernels [7], and dried coconut [8]. Fresh, mature coconut kernels are used to extract Virgin Coconut Oil (VCO) mechanically, either with or without heat. In order to preserve all of its natural qualities, VCO extraction avoids refining, bleaching, or deodorizing [9]. Virgin Coconut Meal (VCM) is the term for the white residue, or meal, that remains following the extraction of VCO. It can be ground into flour to produce dietary fiber-rich flour, which is therefore appropriate for use as an ingredient in functional food recipes [10]. Recently, coconut flour has been used worldwide as an alternative to wheat flour for the preparation of many bakery [11], snacks [12], sweets [10], and extruded products [13]. Food items made from coconut are often devoid of gluten, and have anti-cancerous, antidiabetic, and cardiovascular disease prevention properties, as well as immune system strengthening properties [14]. Globally the top three coconut-producing countries are Indonesia, Philippines, and India accounting for 70% of the World’s copra production [15]. Worldwide, coconut production in India stands third [16]. In 2023, India was expected to produce 13.5 million metric tons of coconuts overall, with an increase of 1.50% from than previous year [17]. In India, Karnataka’s coconut production is 30.83%, followed by Tamil Nadu (27.47%), Kerala (24.22%), Andra Pradesh (8.25%) and West Bengal (2.04%), which accounts for about 92.81% of total coconut production in the country.

"Naru" refers to a customary confection or sweet in several South Asian nations, including India [18]. A common and traditional dessert prepared from coconut, sugar, and occasionally additional components [19]. Coconut Naru is also known as Coconut Ladoo. It is frequently made for celebrations and other special occasions. However, coconut snowball has a limited shelf-life (3–4 weeks) and due to the presence of high amounts of saturated fatty acids it loses its textural properties with time in refrigerated condition [20]. Like many confectioneries and sweets, Coconut Naru's shelf life can be affected by several factors, such as the ingredients used, storage system, and usage of preservatives. Apart from that, as storage time increases, the hardness of Coconut Naru increases making it difficult to consume. Several reasons, including overcooking, sugar crystallization, excessive moisture level, and fat content, can be considered for the hardness issue in preserved Coconut Naru (coconut ladoos). The tissue that envelops and feeds the growing embryo inside a flowering plant seed is called the endosperm [21]. The endosperm of coconuts is an important source of nutrients, especially lipids [22]. Because of its high lipid content, the coconut endosperm is different from many other plant endosperms. Medium-chain triglycerides (MCTs), or saturated fat, make up the majority of the fat in coconut endosperm. An extended cooking duration increases the temperature, hastening the disintegration of oil bodies found in seed endosperms [23]. Therefore, overcooking the mixture of coconut and sugar releases oil, which may result in a more rigid texture. Researchers have found that certain food items can have their shelf life extended by using vegetable and fruit seeds. Tender endosperm (Talsas, Nungu) of Palmyra palm (Borassus flabellifer) is highly consumed and well-demanding in off season, due to its various health potentials [24]. Tropical fruits like sugar palms (Borassus flabellifer) are widely consumed in Southeast Asia and the Indian subcontinent. In addition to sugar palm fruit pulp (SPFP), the people of Bangladesh also frequently eat germinated and immature endosperms. The jelly-like endosperm of young palmyra fruit (60–70 days) can be eaten raw or cooked, sun-dried, or in a variety of other ways. While this soft endosperm (moisture: 9.27 ± 0.04 g/100 g, crude protein: 5.20 ± 0.02 g/100 g, carbohydrate: 73.80 ± 0.16 g/100 g, crude fiber: 7.79 ± 0.06 g/100 g, crude fat: 0.60 ± 0.02 g/100 g, ash: 2.80 ± 0.01 g/100 g) gradually hardens to form a fibrous, yellow-colored mesocarp [25]. Additionally, they generate a pulpy extract that is combined with rice, peppers, herbs, and chilies to make porridge. Palmyra palm is sweet and palatable when raw, while the juice of ripe fruit is used to produce "Pitha", or rice flour porridge “Bara” [26,27,28,29]. In addition of being an excellent source of micro and macronutrients, the tender endosperm of Palmyra palm has a variety of pharmacological properties, including antibacterial, anti-inflammatory, analgesic, anti-arthritic, antioxidant, hypoglycemic, and antipyretic properties [26]. Jana et al. [30] showed that the seed coat of Palmyra palm has antimicrobial activity [30]. According to Rahman et al. [25], the endosperm's fiber, zinc, and phytochemical content may be the reason for restoring pancreatic β-cell function in alloxan-induced diabetic rats [25]. To the best of our knowledge, there is no information available on the usage of tender endosperm of Palmyra palm as a fortifying agent. Textural properties of raw tender Palmyra palm endosperm are well described in previous literature [24]. Mathanghi et al. [24] analyzed the hardness, springiness, cohesiveness, gumminess, and chewiness of Palmyra palm endosperm. Additionally, XRD and SEM analysis of galactomannan isolated from Borassus flabellifer (L.) revealed pores and cervices in its rough surface. This confirmed its amorphous nature. Further, rheometer studies showed non-Newtonian and pseudo-plastic behavior of BFG [31]. In this study, these potentials of immature Palmyra palm endosperm have been studied to address the issues of Naru.

In light of the aforementioned, the current study's goal was to create Talsas-fortified Coconut Naru by combining refined sugar and Talsas endosperm. This study aims to compare the antioxidant potential of conventional Coconut Naru with Coconut Naru that has been combined with Talsas endosperm. Eventually, lipid oxidation analysis, microbiological analysis, and sensory analysis were also used to investigate the effect on the shelf-life of fortified Naru. Enhancing the nutritional value and storage capacity of Naru with natural items may attract more consumers. The nutritional composition, in-vitro digestibility, phytochemical profile (using HPLC), and structural profile (using XRD) of the control and supplemented Naru samples were also examined. This is the first approach to identify and quantify the phytochemical composition of Coconut Naru, or coconut snowball, a traditional Indian treat, and its Talsas endosperm fortified moiety.

2 Materials and methods

Mature coconuts (Cocos nucifera) and immature Palmyra palm (Borassus flabellifer) seeds or Talsas were purchased from the local supermarket of Behala, Kolkata, West Bengal, India (22.4981°N, 88.3108°E). The fruits are cultivated and marketed widely in the local market, and the collection of the coconut and Talsas used in this study complied with local (West Bengal agriculture marketing guidelines) guidelines. Coconuts were selected according to their size and the presence of coconut water whereas palmyra palm seeds (Talsas) were selected according to their age, softness, and pulpiness. The seed coats of Talsas were hand-picked and washed thoroughly with distilled water and the Talsas endosperm was isolated. Then the Talsas endosperm was cut into small pieces and a paste was made with the help of a mixture grinder (Lexus MG 1853, 550 W) for 2–3 min. This Talsas paste was kept aside. Refined cane sugar was procured from local shops, in Kolkata, West Bengal.

Two solvents distilled water (HPLC grade), ethanol (HPLC grade) and standards needed for HPLC analysis (rutin, protocatechuic acid, catechin, epicatechin, myricetin, kaempferol, quercetin, p-chlorogenic acid, ferulic acid, apigenin, and gallic acid) of chromatography grade were procured from Sigma-Aldrich, India and Merck, Germany. Other solvents used in this study such as chloroform (99%), ethyl alcohol, isooctane solutions, distilled water and 0.1% peptone water were obtained from HiMedia, India. Other reagents used in this experiment such as sodium carbonate (NaCO3); sodium bicarbonate (NaHCO3); sodium hydroxide (NaOH); sodium chloride (NaCl); aluminum chloride (AlCl3); ammonium carbonate ((NH4)2CO3); ferric chloride (FeCl3); trichloroacetic acid (TCAA, N); hydrochloric acid (35%); 2,2-diphenyl-2-picrylhydrazyl (DPPH); phenolphthalein; bovine bile extract; Folin-Ciocalteus's phenol reagent; sodium nitrite (NaNO2); potassium iodide (KI); potassium ferricyanide (K3[Fe(CN)6]); potassium iodide (KI); potassium dihydrogen phosphate (KH2PO4); potassium chloride (KCl); corn starch; 2,20-azinobis(3-ethylbenzothiazoline-6-sulfonicacid) (ABTS); sodium thiosulphate (Na2S2O3); pepsin from porcine gastric mucosa (2500 U/g protein); magnesium chloride (MgCl2(H2O)6); calcium chloride (CaCl2); ascorbic acid, gallic acid, quercetin; acetic acid; phosphoric acid; 2-thiobarbituric acid and phosphate-buffered saline (pH 6.4); were of analytical grade. All these chemicals were procured from Sigma-Aldrich, India and Merck, Germany.

2.1 Preparation of Coconut Naru & Talsas Naru

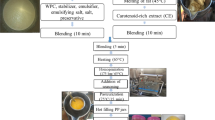

Firstly, fresh coconut endosperm was grated. Then a pan was heated on a medium flame and the grated coconut (300 g) was added. This grated coconut endosperm was sautéed until it became slightly aromatic. In the case of Coconut Naru preparation, only sugar (100 g) was added to the coconut mixture. This mixture was then cooked (with continuous stirring) until the sugar was melted and well combined with the coconut endosperm. Once the mixture became consistent, it would start to come out together. Thereafter, this consistent mixture should be removed from heat, allowed to cool down and rolled into small balls, each weighing about 10 g (Fig. 1).

In the case of Talsas Naru preparation, similarly, grated coconut (90–225 g) was sautéed until it became slightly aromatic. Then Talsas paste (15–120 g) and sugar (100 g) were added (Table 2). This mixture was then cooked (with continuous stirring) for different time periods (10–35 min). Thereafter, this mixture should be removed from heat, allowed to cool down and rolled into small balls, each weighing about 10 g (Fig. 1).

2.2 Evaluation of textural characteristics

Textural properties of Naru samples (cohesiveness, hardness, adhesiveness, springiness, chewiness, and gumminess) were evaluated by using a Texture Profile Analyser or TPA (TA.HD Plus Texture Analyzer, USA) [32]. This TPA had an aluminum cylinder P5 probe, with a diameter of 5 mm. In this current study, the deformation range for TPA was 30–80% and cross-head speed was 0.1–2 mm/sec. The Naru sample was placed on the aluminum base (containing a hole at the center) of TPA. The P5 probe was then allowed to move down freely with pre-test speed of 1 mm/sec, test speed of 5 mm/sec, post-speed of 5 mm/sec, trigger force of 5.0 g and strain 75%, in order to compress the Naru sample. The compressive force's direction was adjusted to be perpendicular to the core of the Naru sample. Three sets of experiments were carried out and the TPA data were obtained by using an inbuild software (Texture Expert Exceed version 2.55). Lastly, average values of triplicate data had been reported.

2.3 Response surface methodology (RSM) optimization

Every experiment was run three times, and average observations were recorded. Design-Expert Version 7.0.0 (Statease Inc.; Minneapolis, USA) was used to analyze every observation. The independent variables or processing parameters were the percentages of coconut endosperm (30–75%) and Talsas endosperm (5–40%) and cooking time (10–35 min). By taking into account Box–Behnken design (BBD), mathematical optimization of these independent factors was considered to reduce the hardness value (N) of Talsas Naru generated. The Coconut Naru is coded as CN in this study, while the optimized Talsas fortified Coconut Naru is coded as TN.

2.4 Sample extract preparation

In a glass beaker, 1 g of Naru sample was added in the extraction solution (distilled water and ethanol in a 1:1 ratio) and homogenized thoroughly. After that, extraction was carried out using ultrasonication (Trans-O-Sonic, Mumbai) for 30 min at a temperature of 35 °C and 40 kHz. Whatman filter paper No. 1 was used to filter the ultrasonicated solution. Lastly, for further analysis those filtrates were stored at 4 °C.

2.5 Analysis of nutritional composition

Based on earlier research [33,34,35], the moisture, carbohydrate, protein, fat, ash and fiber content were measured.

2.6 Color analysis

The total color difference (ΔE), chroma, hue, whiteness index (WI), and yellowness index (YI) of the Naru samples were determined using the procedure described by [36,37,38] and the equations provided below, using the values of L, a, and b.

LTN, aTN, bTN, LCN, aCN, and bCN depict lightness, green–red, and yellow-blue values for TN and CN respectively.

2.7 Quantitative analysis of phytochemicals

The technique of Sarkar et al. (2021) was followed in order to estimate the total phenolic content (TPC) of Naru samples [39]. To put it briefly, 1.58 ml of distilled water was used to dilute 20 µl of sample extract and 20 µl of blank solution (50% ethanol), individually. Subsequently, NaCO3 solution (300 µl) and Folin-Ciocalteu reagent (100 µl) were added to each test tube and thoroughly mixed. Following thorough homogenization, each test tube was incubated for 30 min at 40 °C in the dark. Finally, absorbance was measured at 765 nm by using a UV–visible spectrophotometer (U-2000, Hitachi, Japan). A standard curve of gallic acid (50–250 µg/ml) was used as reference. The obtained TPC values were expressed as mg of gallic acid equivalent (GAE) per 100 g of dry basis (DB).

The technique of Sarkar et al. [39] was followed in order to estimate the total flavonoid content (TFC) of Naru samples [39]. In summary, 150 µl of 5% aqueous NaNO2 was homogenized with sample extract (2.5 ml) and 2.5 ml of blank solution (2.5 ml), individually. A 5-min incubation was done (27 ± 3 °C), followed by addition of 1 M NaOH (1 ml) and 10% aqueous AlCl3 solution (150 µl). Finally, absorbance was measured at 510 nm by using a standard curve of quercetin (10–70 µg/ml) as reference. The obtained TFC values were presented as mg quercetin/100 g DB.

2.8 Antioxidant activities

2.8.1 Ferric reducing Antioxidant potential (FRAP)

The FRAP of Naru samples was measured by using a previously established technique [40, 41]. K3[Fe (CN)6] solution (1%, 2.5 ml) and phosphate buffer (2.5 ml, 0.2 M, pH 6.6) were added to sample extract (1 ml) and the blank solution (1 ml), individually. Following a 20-min incubation period at 50 °C, 10% TCAA (2.5 ml) was added. Thereafter centrifugation (3000 rpm, 10 min) was carried out, followed by addition of 0.1% FeCl3 solution (0.5 ml) and distilled water (2.5 ml) to the supernatant. Finally, absorbance was measured at 700 nm by using a standard curve of ascorbic acid (25–100 µg/ml) as reference. The results were given as millimoles of ascorbic acid equivalent (mM AAE) per 100 g of dry matter.

2.8.2 ABTS radical scavenging activity

The ABTS radical scavenging activity of Naru samples was measured by using a previously established technique [39, 42]. After treating every sample extract (40 µl) and the blank solution (40 µl) with 4 ml of ABTS reagent, all test tubes were incubated for 6 min in the dark. Later, absorbance was measured at 734 nm by using a standard curve of Trolox (20–200 µM/L) as reference. Percentages (%) were used to express the readings by using equation no. 2.6.

2.8.3 DPPH radical scavenging activity

All Naru samples' DPPH radical scavenging activity was measured by using the technique outlined in [40]. After treating every sample extract (0.1 ml) and the blank solution (0.1 ml) with 3.9 ml of DPPH reagent (2 mg in 50 ml ethanol), all test tubes were incubated in the dark for 45 min. Later, absorbance was measured at 515 nm by using a standard curve of ascorbic acid (25–100 µg/ml) was as reference. Percentages (%) were used to express the readings by using equation no. 2.6.

2.9 HPLC analysis of phenolic compounds

For sample extract preparation: 1 g of each Naru sample was extracted with 30 ml of HPLC-grade ethanol by ultra-sonication for 30 min. It was then filtered by using syringe filter (with pore size 0.2 µm). This filtrate (40 mg/ml) was used as sample for HPLC analysis. The approved procedures of Harbone et al. (1984) and Boxi et al. (2010) were used to identify and quantify phenolic chemicals from the ethanolic extract of the Naru samples [43, 44]. An RP-HPLC system (Alliance2695 HPLC system, Waters Corporation, Massachusetts, USA) with a C18 reversed-phase column (250 mm × 4.6 mm and 5 μm particle size) was used to analyze the sample extracts. Two solutions were employed as eluents: solvent B was a 9:1 mixture of methanol and water, while solvent A was a 0.5% aqueous H3PO4 solution. The flow rate was 1 ml per minute in the subsequent order: 100% A for the first eight minutes, for the next 7 min (A: B in a 7:3), next 5 min (A: B in a 1:1 ratio), next 5 min (A: B in a 2:3), next 10 min (A: B in a 3:7), and lastly 5 min (100% B). Empower 2 software (Waters Corporation) was utilized for data processing during the identification and quantification processes, which were conducted at 38 °C using a dual lambda (λ) absorbance UV detector 2487 at 280 nm [39, 45]. 280 nm is the maximum absorption wavelength for most of the phenolic compounds as per the previously published literature [46,47,48,49,50], so a fixed wavelength of 280 nm was maintained. The standards used for RP-HPLC were: rutin, protocatechuic acid, catechin, epicatechin, myricetin, kaempferol, quercetin, p-chlorogenic acid, ferulic acid, apigenin and gallic acid. These standards' chromatographic peaks were utilized as reference phenolic compounds. Every computation was performed using a dry basis (DB).

2.10 XRD

All Naru samples underwent XRD analysis utilizing a Rigaku MiNiflex diffractometer. Every Naru specimen was positioned on a Quartz slide with a grove size of (0.5 × 100 × 50) mm. The XRD analysis of Naru samples was conducted under the following operating conditions: step angle (0.02°), 30 mA, diffraction angle (5–50°), 35 kV, wavelength (0.15 nm), and a scan rate of 1 s/step was maintained. Similar operating conditions were observed in Sarkar et al. (2020) [36].

2.11 In-vitro digestibility of lipids

In-vitro digestibility of lipids for all Naru samples was measured by using a previously established technique with slight modifications [51, 52]. Briefly, this static in-vitro digestion consists of three stages: oral, gastric, and intestinal as per the cost action-INFOGEST. In the oral stage, the Naru sample (5 g) was homogenized with 5 ml of stimulated salivary fluid (SSF; pH 7) by using a mixer grinder for 3 min. In the gastric stage, stimulated gastric fluid (SGF; pH 3) and oral bolus were mixed in a ratio of 1: 1 (v/w). The addition of pepsin was done till the concentration of the gastric mixture was 2000 U/ml. Thereafter, PERT dose 2000 LU/g lipid, resistant to gastric digestion was added to stimulate the oral administration of the supplemented enzyme mixture. pH was adjusted to pH 2.8 by using HCl (1 N). After pH adjustment, an Intell-Mixer RM-2 (Elmi Ltd, Riga, LV-1006, Latvia) was used for head-over-heels rotation of all samples for 2 h at 55 rpm, 37 °C. In the intestinal stage, stimulated intestinal fluid (SIF; pH 6 or 7) containing bile salts (10 mM) was mixed with the gastric chyme in the ratio of 1: 1(v/w). pH was adjusted to pH 7 by using NaOH (1N), followed by head-over-heels rotation for 2 h at 55 rpm, 37 °C. During incubation, pH should not be less than 5.7 as lipase is inactive at pH below 5.7. After 2 h of incubation, lipase activity was stopped by raising the pH to pH 9. Finally, the released FFA content after in-vitro digestion was measured by following this protocol [52].

2.12 Lipid oxidation analysis

The Naru samples were stored for 90 days at room temperature to study lipid oxidation analysis, including free fatty acid (FFA) concentration, ultra-violet absorptivity (UA), and peroxide value (PV). Periodically, readings were obtained every 15 days. All experiments were done at least three times and average values were calculated.

2.12.1 FFA analysis

Naru sample (25 ± 0.5 g) was combined with 65 ml of chloroform and blended for 4–5 min using a mixer grinder. This was followed by centrifugation at 5000 g for 25 min and the supernatant was filtered by using Whatman no. 1 filter paper. Then ethanol (99.9%) and filtrate were combined in a conical flask at a 1:1 ratio for each treatment. The mixture was then titrated against a NaOH solution (0.1 N), with phenolphthalein serving as an indicator [53]. The values were expressed in percentages (%).

2.12.2 UA analysis

The isooctane solution (15 ml) and the Naru sample (5 g) were blended together by using a mixer grinder. Considering this isooctane solution as blank, the absorbance of the filtrate was measured by UV scanning between 230 and 320 nm [39]. Absorbance at 235 nm was found to be maximum for all Naru samples in an isooctane solution. UA was measured by using the formulae given below:

2.12.3 PV analysis

The acetic acid-chloroform solution (25 ml), saturated KI solution (0.5 ml), and Naru sample (5 g) were well combined. The mixture was then filtered by using Whatman no. 1 filter paper. Next titration of this solution was done against 0.1 M Na2S2O3 solution, using starch as an indicator [39]. The milliequivalent of oxygen/kg oil (MEO/kg oil) was used to display the results.

2.12.4 TBA value determination

Thiobarbituric acid (TBA) value determination of all Naru samples was performed by using a previously established technique outlined in Witte et al. (1970) [54]. Naru sample (20 g) was blended with 50 ml of chilled extracting solution (20% TCCA in 2 M phosphoric acid). This slurry was then diluted to 100 ml and homogenized with vigorous shaking. A Whatman No. 1 filter paper was used to obtain the filtrate. Then, 5 ml of filtrate was homogenized with 2-thiobarbituric acid (5 ml; 5 mM), followed by incubation at room temperature (15 h, in dark). After incubation, absorbance was measured at 530 nm by using a calibration curve of malonaldehyde was considered as reference. The results were expressed as the mg malonaldehyde/kg sample.

2.13 Microbial analysis

10 g of the Naru sample was homogenized in 90 ml of 0.1% (w/v) peptone water by using a mixer grinder (Lexus MG 1853, 550 W), for microbiological examination. For plating, 1 ml of the homogenized sample was serially diluted up to 108 times. Petriplates with plate count agar (DIFCO, USA) were made. 1 ml of the 108-fold diluted material was streak plated (in triplicate) on petriplates, and it was then incubated for 48 h at 37 °C. Using a colony counter (Bentex, India), colony forming units (CFU) were tallied and reported as log (cfu/g of the sample). Potato-dextrose agar (DIFCO, USA) petriplates were made to count the yeast and mold. After that, 1 ml of the 108-fold diluted material was streak plated (in triplicate) on petriplates and it was then incubated for 72 h at 30 °C.

2.14 Sensory analysis

Sensory characteristics of the Naru samples were carried out following ISO 8586-1 (1993). Due to the widespread consumption of the sample (Naru) as a food product and there is no maximum permissible limit associated with the consumption of both coconut and Talsas, the study was exempted from requiring ethics approval (IRB Jadavpur University). For this study, a panel of individuals between the ages of 25–35 was chosen, with 21 men and 24 women (All participants have informed consent to participate). The panelists received a detailed explanation of the product, and it was observed that they had no objections to the prepared food. Juárez-Barrientos et al. [55] stated some modifications in addition to the standard for triangular discrimination (ISO 4120:2004), competency for identifying taste and odor (ISO 5496:2005), and the ability to distinguish between two samples based on the sensory attribute (ISO 10399:2004) [55]. With a small adjustment, the ISO 11035:1994 sensory evaluation of prepared Talsas fortified Coconut Naru (TN) was compared to Coconut Naru (CN). Color, texture, flavor, and overall acceptability were all assessed by the panel. Each sample was placed into a distinct white plastic cup that was coded with a three-digit number to account for each attribute and individual identity [36]. After tasting each sample, it was required to rinse with warm water.

2.15 Statistical analysis

The findings were analyzed using a one-way analysis of variance (ANOVA) and presented as the average of three distinct experiments, each carried out in triplicate. 95% probability was used in the Tukey test. The experimental sensory data were analyzed using the Statistical Analysis System (SAS) University Edition (SAS® 9.4 TS1M8, 2014, USA).

3 Results and discussion

3.1 RSM optimization

The level of variables for defining the coordinates of axial (3.1), central (3.2), and factorial (3.3) points are given in the following equations:

where, H = independent variables, δ = 2number of variables/4

The model was constructed by the below-mentioned equation:

where, N is response; A, B, C are the independent variables.

Nevertheless, the anticipated or predicted response was expressed as the following second-degree polynomial equation, which is:

where, N′ = predicted response.

δ = equation constant.

δi = linear factor.

δii = quadratic factor.

δij = coefficient of interaction.

n = number of parameters.

ȇ = error in this model.

As per the experimental observations, the model can also be expressed by the following equation:

where, H′′: n × 1 vector of the experimental output;

H: n × m matrix of independent variables;

δ: m × 1 vector of regression coefficients;

ȇ: n × 1 vector of the errors.

The ANOVA table (Table 1) for the developed RSM model shows that coconut amount, Talsas amount, and cooking time have a significant (p < 0.05) effect on the hardness value of Naru samples. The effect of independent variables on the hardness of Naru samples is shown in Figs. 2, 3, 4. Maximum hardness value (5.34 N) was found in Naru containing 75% coconut amount, 22.5% Talsas amount, and 35 min of cooking time. However, the minimum hardness value (4.1 N) was found in Naru containing 30% coconut amount, 22.5% Talsas amount, and 10 min of cooking time (Table 2). The Model F-value of 94.54 implies the model is significant. There is only a 0.01% chance that a "Model F-value" this large could occur due to noise during cooking time. The regression model associated with hardness of the Naru samples contented the lack of fit test (p > 0.05). This showed an R2 value and Adj R2 value of 0.9918 and 0.9813 respectively.

The final equation of this BBD model in terms of actual factors:

3.2 Validation of experimental results

TN was prepared by a series of studies including various combinations of processing parameters to determine the ideal hardness value using the RSM methodology. Through a comparison of the expected and obtained hardness values, the prediction power of the BBD modeling approach was estimated.

Hardness is an important textural characteristic of any food item. Hardness is the measure of how much resistance a food item can withstand from an external force. In other words, the force needed to make the first deformation of food is known as hardness. In this study, we tried to develop Talsas fortified Coconut Naru, by substituting a portion of coconut endosperm with Talsas endosperm. Here, refined sugar was used as a sweetener. Different cooking times (10–35 min) and various amounts of coconut (30–75%) and Talsas endosperm (5–40%) were the process parameters. As a result, a wide range of hardness values in the fortified Narus was developed. From the optimized BBD model, it is evident that higher cooking time and the presence of a higher amount of coconut endosperm have a positive effect on increasing the hardness value of Naru samples. However, the presence of a higher amount of Talsas endosperm has a negative effect on increasing the hardness value of Naru samples. A longer cooking time raises the temperature, which accelerates the breakdown of oil bodies present in seed endosperms. This released oil helps in the proper binding of seed endosperm with caramelized refined sugar and give Naru samples a compact structure. Compactness of a food item is directly proportional to its hardness value. Other than that, a longer cooking time results in a greater amount of moisture loss. As a result, food items with minimal moisture content become harder on their own. Since coconut endosperm has a far higher fat content than Talsas endosperm, the presence of more coconut endosperm implies the presence of more oil bodies. Thus, maximum hardness (5.36 N) was observed in Talsas Naru containing 75% coconut endosperm, 40% Talsas endosperm, and a cooking time of 22.5 min. Minimum hardness (4.13 N) was observed in Talsas Naru containing 30% coconut endosperm, 22. 5% Talsas endosperm, and a cooking time of 10 min. In this study, the RSM-optimized processing parameters were a fixed cooking time (22.5 min), 52.25% coconut endosperm, and 22.5% Talsas endosperm.

3.3 Nutritional composition

The proximate composition of Naru samples is given in Table 3. The optimized TN contains 52.25% of coconut endosperm and 22.5% of Talsas endosperm. The moisture content of CN was 34.99 ± 0.34% which is comparable to previous literature [18]. The initial moisture content of coconut endosperm and Talsas endosperm was 47.02 ± 0.87% and 8.97 ± 0.12%, respectively. Parallelly, a decrease of 31.54% in moisture content was observed in TN samples. This difference was found to be significant (p < 0.05) in comparison to CN samples. However, the fat content of coconut endosperm was found to be significantly (p < 0.05) higher in comparison with Talsas endosperm. Thus, in case of fat content a decrease of 39.38% was observed in TN samples, which is significant (p < 0.05) in comparison with CN samples. According to Rahman et al. (2021), the endosperm of sugar palm (Talsas) is a rich source of protein, carbohydrates, and fiber [25]. A similar observation was found in this study. A significant increase (35.77%) in the carbohydrate content of TN samples was observed, due to higher carbohydrate content of Talsas endosperm. The high protein content of both coconut and Talsas endosperm contributed to an insignificant increase (0.04%) in protein content of TN, in comparison with CN. The high fiber and ash content of Talsas endosperm resulted in a significant (p < 0.05) increase of 4.98% and 37.63% in the fiber and ash content of TN samples, respectively. Higher ash content of TN samples denotes the presence of a higher amount of minerals compared to CN.

3.4 Color analysis

Whiter coconut endosperm contributed to the higher lightness value of CN. The addition of Talsas endosperm in CN has lowered the lightness value (L*) and redness/ greenness value (a*) by 15.05% and 0.05%, respectively. This lowering in L* was significant (p < 0.05), while lowering in a* was insignificant (p > 0.05). This resulted in an off-white color of the fortified product. However, an insignificant increase (0.01%) in yellowness/ blueness value (b*) was observed in TN in comparison to CN. The L*, a*, and b* values of CN are relatable in comparison with optimized milk-coconut sweet [56]. The total color difference (∆E) between Talsas fortified Coconut Naru (TN) and Coconut Naru (CN) sample was 8.77%. These values also contributed an insignificant (p > 0.05) increase of chroma and hue angle in TN than that of CN. The Whiteness Index (WI) of CN and TN was 63.90 ± 1.24 and 55.68 ± 1.02, respectively. While the degree of yellowness (YI) of CN and TN was 30.83 ± 0.85 and 36.05 ± 0.52, respectively. According to [57, 58], sugar and virgin coconut meal (VCM) have a significant (p < 0.05) linear detrimental effect on L* of VCM-based instant suji halwa mix. But here, the addition of Talsas endosperm showed a negative effect on lightness value. Again, a significant increase in a* was observed with increasing sugar amount in milk-coconut sweet [56] and VCM-based instant suji halwa mix [58]. Again, b* of milk-coconut sweet and VCM-based instant suji halwa mix increased with increasing sugar amount [56, 58]. Similarly, a significant (p < 0.05) increase in WI (14.76%) and YI (16.93%) was observed in TN, in comparison with CN.

3.5 Texture profile analysis (TPA)

Texture profile analysis is an essential parameter for evaluating any food material. It deals with measuring certain characteristics such as cohesiveness, hardness, adhesiveness, springiness, chewiness, and gumminess. Analysis of textural properties of coconut-based food products such as milk-coconut sweets, VCM-based instant suji halwa mix, and VCM ladoo, under various conditions and ingredients, has been reported, previously [56, 58, 59]. Textural characteristics of Naru samples have been portrayed in Fig. 5.

Textural properties of Naru samples. All calculations have been done on a dry basis. The values are expressed as mean ± SD of experiments performed three times. Significant differences (p < 0.05) have been coded as superscripts a and b, for the same parameters of different samples as shown in the figure

The force needed for the first bite of a food is defined as hardness. A vivid deformation is obtained during this compression cycle due to this force [60]. In this study, a significant decrease (11.49%) in hardness value of TN was observed, in comparison with CN. The fat content of TN was found to be significantly lower (p < 0.05), while the protein content of TN was found to be significantly higher (p < 0.05) in comparison with CN. According to previous literature, the higher fat content has a negative impact on the hardness of any food material. Whereas, the opposite is true in the case of protein content. According to [61], an increase in protein degradation of a food product lowers the hardness of that product. Thus, the hardness of the Naru samples is dependent on their fat and protein content.

Adhesiveness is defined as the work done to pull away the compressing plunger from the food material, before the second bite [60]. Researchers have also found protein content of a food item is directly proportional to its adhesiveness value [62]. In the case of Naru samples, a similar result has been found here. In this study, an insignificant increase (p > 0.05) in protein content has been found in TN in comparison with CN. Thus, an insignificant increase (p > 0.05) in adhesiveness has been found in TN in comparison with CN.

Cohesiveness is defined as the extent of compression a food substance can resist between teeth, without breaking it. Numerically, the ratio between the area of the second and first bite (A2/A1) is known as cohesiveness [60]. Springiness is the distance covered by a food item, within the time interval after the first bite and before the second bite [60]. In this study, both the cohesiveness and springiness of TN was significantly higher than CN. Researchers have seen that increasing fat content has a negative effect on both the cohesiveness and springiness of a food item [63]. Cohesiveness and springiness values of TN was found to be significantly (p < 0.05) higher than CN, due to significantly lower fat content of TN.

Numerically, the gumminess of a food product is defined as the product of hardness and cohesiveness, while chewiness is the product of gumminess and springiness of a food product. As hardness, springiness, and cohesiveness of TN were significantly (p < 0.05) higher than CN, gumminess and chewiness of TN were significantly (p < 0.05) higher than CN.

3.6 Quantitative analysis of phytochemicals

Plant parts mainly fruits and vegetables are natural sources of phytochemicals. Phytochemicals such as alkaloids, glucomannan, albuminoids, anthracene, flavonoids, steroids, free anthraquinone, betulinic acid gums, glycoside, quercetin, tannin, terpenoid, phenols, carotenoids, saponin, and lupeol are found in Talsas endosperm [25]. Coconut cotyledons also contain various phytochemicals such as phenol, flavonoids, tannins, and alkaloids [64]. Phenolic compounds are a category of phytochemicals that exhibit antioxidant properties [65]. The Total Phenolic Content (TPC) of coconut endosperm was 9.01 ± 0.21 mg GAE/100 g DB, which is comparable to a previous study [66]. Whereas, the TPC of Talsas endosperm was 42.12 ± 0.23 mg GAE/ 100 g DB. According to [67], the TPC of Nypa fruticans endosperm was in the range of 0.14–7.93 mg GAE/g. In TN, 30% of coconut endosperm was replaced with Talsas endosperm. Thus, the TPC of TN was found significantly higher (p < 0.05) in comparison to CN (Table 4).

Similar to phenolic compounds, flavonoids also fall under a significant class of polyphenols found in a wide range of plant species. They contain benzopyrone, which is employed for scavenging free radicals [68]. The Total Flavonoid Content (TFC) of coconut endosperm was 50.55 ± 1.21 µg QE/ g DB which is comparable to a previous study [64]. Whereas, the TFC of Talsas endosperm was 1015.12 ± 41.23 µg QE/ g DB. According to [67], the TFC of Nypa fruticans endosperm was in the range of 1.03–27.27 mg QE/ g. In TN, 30% of coconut endosperm was replaced with Talsas endosperm. Thus, a significant (p < 0.05) increase in TFC was observed in TN, compared to CN (Table 4).

3.7 Antioxidant activities

In order to get a better understanding of antioxidant activity of a complex material, such as plant extract, essential oil, etc., one test is not adequate. A series of test such as, determination of ABTS radical scavenging activity, DPPH activity and FRAP assay need to be performed. DPPH is a generic approach that is sensitive to phenolic compounds and organic acids, while FRAP assesses the reducing power. However, antioxidant capacity of chemicals that are soluble in water can be evaluated via ABTS radical scavenging activity assay.

When assessing the antioxidant activity of plant polyphenols, ferric-reducing antioxidant power (FRAP) is frequently employed. The FRAP assay primarily uses a redox-linked colorimetric process to treat the antioxidants in the sample as reductants. The intensity of the dark blue color produced by the reduction of Fe3+ to Fe2+, via accepting an electron (released from an antioxidant) is measured at 700 nm. In our study, CN showed an FRAP value of 26.40 ± 0.56 μM Trolox/100 g, while TN showed an FRAP value of 202.83 ± 1.89 μM Trolox/100 g (Table 4). FRAP value of coconut endosperm was 30.12 ± 0.45 μM Trolox/ 100 g, which falls under the range of 29.89–34.84 μM Trolox/ 100 g [69]. Whereas, the FRAP value of Talsas endosperm was significantly higher (788.31 ± 5.14 μM Trolox/100 g) than that of coconut endosperm. According to [70], at 200 μg/mL TFC of Nypa fruticans endosperm was in the range of 147–819 mmol Fe2 + /100 g. In TN, 30% of coconut endosperm was replaced with Talsas endosperm. Thus, a significant (p < 0.05) increase in FRAP value was observed in TN, compared to CN.

A potent antioxidant can reduce ABTS, by preventing persulfate-induced radical cations. This results in decolorizing the blue color of ABTS to a light blue tint. This decolorization can be detected at 734 nm. The concentration of antioxidants directly correlates with the change in absorbance. In our study, CN and TN showed ABTS radical scavenging activity of 6.76 ± 0.23% and 22.58 ± 0.76%, respectively (Table 4). ABTS activity of coconut endosperm was 7.13 ± 0.42%, which falls under the range of 4.00–7.69 μM Trolox/ g [71]. Whereas, ABTS activity of Talsas endosperm was significantly higher (72.45 ± 1.25%) than that of coconut endosperm. According to Prasad et al. (2020), it was well-established that at 200 μg/mL, ABTS activity of Nypa fruticans endosperm was in the range of 55–78% [70]. In TN, 30% of coconut endosperm was replaced with Talsas endosperm. Thus, a significant (p < 0.05) increase in ABTS activity was observed in TN, compared to CN.

The stable free radical DPPH is frequently employed to study radical scavenging action because it can take on an electron or a hydrogen radical to produce a stable diamagnetic molecule. Antioxidants react with DPPH to produce yellow-colored α, α-diphenyl-β-picryl hydrazine. The degree of discoloration reveals the antioxidant's capacity to scavenge radicals, which is quantified at 515 nm. In our study, CN and TN showed DPPH activity of 58.70 ± 1.01% and 60.37 ± 2.65%, respectively (Table 4). DPPH scavenging activity of coconut endosperm was 65.44 ± 1.43%, which falls under the range of 57.77–77.54% [71]. Whereas, DPPH activity of Talsas endosperm (81.55 ± 1.56%) was higher than that of coconut endosperm. According to [70], at 200 μg/mL DPPH activity of Nypa fruticans endosperm was in the range of 32–85%. In TN, 30% of coconut endosperm was replaced with Talsas endosperm. Thus, an insignificant (p > 0.05) increase in DPPH activity was observed in TN, compared to CN.

In this study, significantly (p < 0.05) higher (45.36%) TPC value was obtained for TN in comparison with CN samples. Similarly, 6.6-fold, 2.34-fold and 2.84% higher values of FRAP, ABTS and DPPH radical scavenging activity was obtained for TN in comparison with CN samples. Wang et al. [72] have suggested that the ability of any plant extract to scavenge free radicals is highly correlated on their polyphenolic contents [72]. As Folin-Ciocalteu (FC) reaction and antioxidant assays like FRAP both are based on single electron transfer [72, 73], so their results were found to be relatable. Again, ABTS activity assay is also based on electron transfer mechanism, thus good correlation was obtained between FRAP, ABTS, and FC reactions, respectively. However, DPPH antioxidant assay which is based on hydrogen atom transfer showed mere relatability with Folin-Ciocalteu reaction. This might be due to its different reaction procedure from other assays [74].

3.8 HPLC analysis of phenolic compounds

Secondary metabolites such as phenolic acids, flavonoids, terpenoids, and carotenoids are found in different plant body parts. Identification of bioactive compounds in NN and TN samples was done by HPLC analysis (Table 5). Reverse-phase HPLC was chosen for polar bioactive components such as phenolic acids and flavonoids. Six phenolic compounds were quantified, where kaempferol and myricetin were predominant in both NN and TN samples. Gallic acid, protocatechuic acid, quercetin, and rutin were the other four phenolic compounds detected in the chromatogram. Fortification of CN with Talsas endosperm considerably boosted the level of three polyphenols in TN samples (Fig. 6). Here, TN samples showed an insignificant (p > 0.05) decrease in myricetin and kaempferol levels of 1.98% and 5.76%, respectively. A significant decrease (p < 0.05) of 32.96% in gallic acid level was observed in TN samples. It was evident that coconut meat contains a high amount of gallic acid at different maturity stages [75]. Thus, the substitution of 30% of coconut endosperm with Talsas endosperm might be the probable reason for the lowering of gallic acid content. It was previously reported that several phenolic compounds such as rutin, quercetin, myricetin, catechin, and kaempferol are present in extra virgin coconut oil [76]. However, during Naru making process some coconut testa might have mixed with coconut endosperm. Thus 3.12 ± 0.25 mg/100 g and 3.43 ± 0.08 mg/100 g protocatechuic acid content was observed in CN and TN samples, respectively. The presence of protocatechuic acid in coconut testa was confirmed by Arivalagan et al. [77]. Here, quercetin and rutin content of TN samples were elevated significantly (p < 0.05) by 50% and 28.43% respectively, in comparison to CN samples. The reason for this elevation might be due to higher quercetin and rutin content in Talsas endosperm in comparison to coconut endosperm. The presence of twenty-five phytochemicals in pulp, immature & germinated endosperm of palmyra palm is well-established in Rahman et al. [25]. Apart from that, previous researchers have stated both coconut and palmyra palm haustorium are rich in phytochemical components [78, 79].

3.9 X-ray diffraction studies (XRD)

Structural properties such as crystallinity or amorphous nature of a food sample can be evaluated through X-ray diffraction studies. The crystalline nature of a food item is depicted by the presence of vivid peaks in the diffractogram. The diffractogram of an amorphous food product is depicted by its broad background and absence of any vivid peaks. The diffractogram of Naru samples is shown in Fig. 7. In this study, both CN and TN samples showed crystalline nature. This crystallinity is mainly due to the crystalline nature of refined sugar. Moreover, refined cane sugar consists of three types of sugars such as glucose, fructose, and sucrose [80]. These low-molecular-weight sugars undergo crystallization when the temperature is higher than 50 °C [81]. Naru preparation requires a temperature higher than 50 °C. Thus, the crystalline nature of all Naru samples is expected, as an equal amount of refined sugar was added in all samples. Therefore, refined cane sugar has a positive role in crystal formation. A similar XRD pattern was observed for desiccated coconut power [82].

3.10 In-vitro digestibility of lipids

In-vitro digestibility of fermented coconut meal [83], and traditional cooked rice with coconut milk [84] has been found. In this study, in-vitro digestibility of lipids of all Naru samples was evaluated. In-vitro digestibility of TN was found to be significantly (p < 0.05) higher in comparison with CN. This is due to the significantly higher fat content in CN in comparison with TN. Whereas, the protein content of TN and CN are almost similar with insignificant increase in TN. Again, carbohydrate content of TN is significantly (p < 0.05) higher than CN. Thus, lipid-carbohydrate binding and lipid-protein binding will be much higher in TN in comparison with CN. These lipid-protein and lipid-carbohydrate interactions have a significant effect on lipolysis. As CN is a type of food having high fat and less carbohydrate content, more amount of lipids will be free for lipolysis. According to [52], the in-vitro lipid digestibility of a food item decreases with decreasing fat and increasing protein or carbohydrate content. Therefore, 5.96% higher in-vitro lipid digestion was observed in CN than that of TN.

3.11 Lipid oxidation analysis

3.11.1 FFA content

The hydrolytic rancidity of a food sample can be evaluated by measuring its free fatty acid (FFA) content. Previously, the FFA content of VCM ladoo [59], traditional coconut-based sweets [85], and coconut burfi [86] has been done. In this study, the FFA content of different Naru samples is displayed in Table 6. Initially, the FFA content of all Naru samples was similar. Till the 30th day, the difference in FFA content of CN and TN samples was insignificant (p > 0.05). During 90 days of storage, the FFA content of CN ranged from 0.17 ± 0.02 to 0.53 ± 0.04% while the FFA content of TN ranged from 0.15 ± 0.04 to 0.41 ± 0.06%. In this study, the change in FFA content of CN samples was increasing insignificantly. However, the change in FFA content of CN samples significantly (p < 0.05) increased (47.05%) on day 30. A 24% increase was observed for CN on day 45, although this increase was statistically insignificant (p > 0.05). As per sensory qualities, the critical value of FFA content is 0.35%. After 45 days, the FFA content of CN had crossed 0.35%. On the 60th day of storage, the FFA content of CN was again found to be statistically significant (p < 0.05). On the 90th day of storage, the statistically highest FFA content of CN was observed. The FFA content of TN samples also increased with storage time. The TN samples showed a significant increase in FFA content until the 60th day of storage. However, on the 90th day of storage, the FFA content of TN crossed its critical value of 0.35%. A similar critical value of FFA content was observed in the case of coconut burfi [86]. The fat and moisture content of coconut endosperm is much higher than that of Talsas endosperm. Thus 30% substitution of coconut endosperm with Talsas endosperm plays an important role in lowering the FFA content of TN samples. Moreover, CN samples have shown higher lipolysis, which infers they have more FFA content in comparison to TN samples.

3.11.2 PV measurement

Oxidation of oils and fats can be evaluated by estimating peroxide value (PV). Previously, the peroxide value of VCM ladoo [59], traditional coconut-based sweets [85], and coconut burfi [86] has been done. In this study, the PV measurement of different Naru samples is done for 90 days and displayed in Table 7. The PV of CN ranged from 6.17 ± 0.17 meqO2/kg to 22.15 ± 0.26 meqO2/kg while, the FFA content of TN ranged from 4.85 ± 0.21 meqO2/kg to 16.40 ± 0.35 meqO2/kg. In this study, a significant (p < 0.05) increase in PV of CN was observed after every 15 days of storage. While PV of TN was found to be statistically insignificant until 30th day of storage. All PV of CN was found to be significantly (p < 0.05) higher in comparison with TN. However, 2.58-fold and 2.38-fold increase in peroxide value have been observed in CN and TN samples, respectively. The fat and moisture content of coconut endosperm is much higher than that of Talsas endosperm. Thus 30% substitution of coconut endosperm with Talsas endosperm plays an important role in lowering PV of TN samples. As CN samples have shown higher lipolysis, which infers they have more FFA content in comparison to TN samples. Therefore, more fatty acids will be free for oxidation in CN samples than that of TN samples.

3.11.3 UV-absorption

Qualitative analysis of food samples can be done by utilizing UV–Vis Absorption Spectroscopy. In this study, the UV absorption of different Naru samples was done for 90 days and displayed in Table 8. The absorption of CN ranged from 0.13 ± 0.09 to 1.93 ± 0.47, while the FFA content of TN ranged from 0.11 ± 0.04 to 1.21 ± 0.35. Here, absorption of both CN and TN samples increases significantly (p < 0.05) from the 30th day. A significant (p < 0.05) increase (56.89%) in the absorption of CN was observed on the 45th day of storage. After the 30th day, a significant (p < 0.05) increase (1.32-fold) in the absorption of TN was observed on the 60th day of storage. As per sensory qualities, the critical value of UV absorption was found to be 1.10. CN and TN samples exceeded this critical value on the 60th day and 90th day, respectively. Initially, all Naru samples showed similar absorbance. From the 30th day, insignificantly different absorbance was observed for CN and TN samples. On day 30, CN showed 87.09% higher absorption than TN. The working principle of UV–Visible spectroscopy focuses on the relative absorption of oxidized fatty acids. Thus, the oxidation of fats plays a major role in UV absorption values. Therefore, for all samples, an increase in absorbance corresponds to a comparable trend of an increase in FFA content.

3.11.4 TBA value determination

Determination of 2-thiobarbituric acid value is a quantitative method of detecting the presence of malonaldehyde in a food product [87]. The oxygen retention in the packaging primarily controls the rate of lipid autoxidation in packaged foods. In this study, TBA of all Naru samples has been done and displayed in Table 9. A significant (p < 0.05) rise in the TBA value of CN samples has been observed in every 15 days of storage. A rise in the TBA value of TN samples was also observed, however, this rise was statistically insignificant until the 15th day. The value of TBA ranged from 0.19 to 1.75 mg malonaldehyde/kg. No rancidity was observed in CN samples until the 30th day. However, after day 30, CN samples started showing rancidity. CN samples having TBA values ranging from 1.12 to 1.75 mg malonaldehyde/kg were not acceptable from the 60th day of storage. According to [88], TBA values ranging from 0.04 to 0.54 mg malonaldehyde/kg showed no rancidity, while TBA values ranging from 0.65 to 1.44 mg malonaldehyde/kg showed rancidity but were acceptable. In the case of TN, a significant (p < 0.05) increase (1.53-fold) in TBA value was observed on the 30th day of storage. TN having a TBA value of 0.65–0.87 showed rancidity but was acceptable until the 75th day. Similar results have been observed by [89]. Therefore, for all samples, an increase in TBA value corresponds to a comparable trend of increase in FFA content and PV measurements.

3.12 Microbial analysis

Microbial contamination is the leading cause of spoilage of dairy products. If ambient environmental conditions and proper nutrients are available bacteria and molds start to grow in foods. Here, the total plate count (TPC) and total yeast and mold count (TMC) of all Naru samples are displayed in Table 10. Initially, the TPC and TMC of both samples were found similar. A significant (p < 0.05) increase in TPC (24.78-fold) and TMC (3.22-fold) values for CN samples was observed on the 30th day of storage, compared to TN. Thereafter, a significant (p < 0.05) increase in TPC and TMC values of CN was observed in every 15 days. In the case of TN, a gradual insignificant increase in TPC and TMC was noticed till the 45th day of storage. On the 60th day, a significant (p < 0.05) increase in TPC (27.33-fold) and TMC (6.09-fold) values for TN samples was found. According to CDA recommendations, the permissible aerobic plate count and yeast and mold count of desiccated coconut were found to be 10,000 CFU/g and 100 CFU/g, respectively [90]. In this experiment, the TPC of CN and TN exceeded the microbiological permissible limit after the 45th and 75th day of storage. Similarly, the TMC of CN and TN exceeded the microbiological permissible limit after the 45th and 75th day of storage. [86] also showed the microbiological permissible limit of yeast count for coconut burfi was < 100 CFU/g.

3.13 Sensory studies

The primary stage any new food product has to pass is its sensory analysis. Analysis of sensory characteristics such as color, texture, flavor, and overall acceptability of all Naru samples have been done by using a 0 to 9-point hedonic scale (Table 11, Fig. 8).

The color of a food product is the primary attraction for customers. In this study, the white color of CN attracts customers more than the off-white color of TN. Thus, initially, on day 0, CN scored 0.33% higher (p > 0.05) than that of TN. As the storage time increases the color score for both CN and TN gradually decreases. The color difference of CN (11.38%) and TN (9.35%) was found to be insignificant (p > 0.05) until the 75th day of storage. The texture of the Naru plays a big role in customers’ acceptability. The texture of TN was better (6.50% higher score in TN) than that of CN from the very beginning. As storage time increases, the hardness of both CN and TN increases. However, the rate of decrease in texture score of CN was significantly (p < 0.05) higher in comparison to TN. A significant (p < 0.05) decrease (8.61%) in texture scoring of CN was observed on the 30th day of storage. In the case of TN, a significant (p < 0.05) decrease (12.50%) in texture scoring was observed on the 75th day of storage. The rancidity of coconut-based food products is a major factor in lowering their shelf-life. CN containing 75% coconut endosperm becomes rancid within 45 days of storage. While TN containing 52.25% coconut endosperm and 22.5% Talsas endosperm show rancidity after the 75th day of storage. This increase in rancidity has an impact on decreasing the flavor score in Naru samples. A significant (p < 0.05) decrease (19.20%) in the overall acceptability of CN was observed on the 30th day of storage. Whereas, the overall acceptability of TN insignificantly decreases until the 45th day of storage. A significant (p < 0.05) decrease (19.52%) in the overall acceptability of TN was observed on the 75th day of storage. After the 45th day of storage, flavor analysis of CN couldn’t be performed due to spoilage. In the case of TN, flavor analysis couldn’t be performed after the 75th day of storage due to spoilage.

3.14 Conclusion

This study was the first approach to utilize RSM optimization during preparation of Talsas fortified Coconut Naru (TN), for obtaining optimum hardness for differently processed TN samples. In this present study, the polyphenolic compounds present in Coconut Naru (CN) and its Talsas endosperm fortified moiety were identified and quantified using HPLC analysis. Other than that, in-vitro digestibility, structural profiling (using XRD), and storage studies of CN and TN samples were also determined. To the best of our knowledge, this present work is first-of-its-kind concerning shelf-life enhancement of Coconut Naru or coconut snowball, a traditional Indian treat by using underutilized Palmyra palm endosperm. In this current study, the predicted and observed datasets of BBD model underwent rapid optimization of the processing parameters (amount of coconut endosperm, the cooking time required, and the amount of Talsas endosperm). It has been observed that with increasing cooking time, the hardness value of Naru samples increases. Higher coconut endosperm addition has a positive role whereas, higher Talsas endosperm addition showed a negative role in increasing the hardness of TN samples. A fixed cooking time (22.5 min), 52.25% coconut endosperm, and 22.5% Talsas endosperm were the optimized process variables by RSM. TPC and TFC values increased significantly (p < 0.05) by 45.36% and 3.25-fold respectively, in TN in comparison to CN. Similarly, FRAP and ABTS values increased significantly (p < 0.05) by 6.68-fold and 2.34-fold respectively, in TN in comparison to CN. In HPLC analysis, it was found that the level of three polyphenols (protocatechuic acid, quercetin, rutin) considerably boosted in TN when compared to CN. XRD analysis of Naru samples showed that both TN and CN samples are crystalline. In-vitro lipid digestion of CN was found to be 5.96% higher than that of TN. The rate of increase in FFA, PV, UA, and TBA values was found to be significantly higher in CN than in TN. The reason for this significant rise might be the higher fat and moisture content of coconut endosperm than that of Talsas endosperm. Lastly, microbiological analysis and sensory studies of the Naru samples confirmed that fortification of CN with Talsas endosperm significantly enhanced its sensory characteristics and shelf life by up to 75 days. Therefore, the potential of Palmyra palm endosperm or Talsas as a fortifying agent for improving the nutritional, sensory and storage attributes of traditional coconut snowballs is well-established in this current study. In this way, industries can also preserve seasonal fruits by incorporating them into value-added food products. This can also be an alternative method for valorizing of fruit-based wastes in food industries. In the future, researches should pay more attention to these underutilized plant resources in order to maintain food security and good health for mankind.

Data availability

All relevant data are within the paper.

Code availability

Not applicable.

References:

Lima EBC, Sousa CNS, Meneses LN, Ximenes NC, Júnior S, Vasconcelos GS, Lima NBC, Patrocínio MCA, Macedo D, Vasconcelos SMM. Cocos nucifera (L.)(Arecaceae): a phytochemical and pharmacological review, Brazilian. J Med Biol Res. 2015;48:953–64.

Nair KPP. The agronomy and economy of important tree crops of the developing world. Amsterdam: Elsevier; 2010. https://doi.org/10.1016/C2010-0-64818-8s.

da Lima RS, Block JM. Coconut oil: what do we really know about it so far? Food Qual Saf. 2019;3:61–72.

Wrage J, Burmester S, Kuballa J, Rohn S. Coconut sugar (Cocos nucifera L.): production process, chemical characterization, and sensory properties. LWT. 2019;112:108227. https://doi.org/10.1016/j.lwt.2019.05.125.

Prades A, Dornier M, Diop N, Pain J-P. Coconut water uses, composition and properties: a review. Fruits. 2012;67:87–107.

Seow CC, Gwee CN. Coconut milk: chemistry and technology. Int J Food Sci Technol. 1997;32:189–201.

Appaiah P, Sunil L, Prasanth Kumar PK, Gopala Krishna AG. Composition of coconut testa, coconut kernel and its oil. J Am Oil Chem Soc. 2014;91:917–24.

Banzon JA, Velasco JR. Coconut: production and utilization., Coconut Prod Util. 1982.

Ng YJ, Tham PE, Khoo KS, Cheng CK, Chew KW, Show PL. A comprehensive review on the techniques for coconut oil extraction and its application. Bioprocess Biosyst Eng. 2021;44:1807–18.

Yashi S, Anil Dutt S, Gopal Kumar S, Amarinder Singh B. Utilization of virgin coconut meal (VCM) in the production of ready-to-eat Indian traditional sweet meat using response surface methodology. Food Nutr Sci. 2011. https://doi.org/10.4236/fns.2011.23029.

Dat LQ. Functional properties and influences of coconut flour on texture of dough and cookies, Vietnam. J Sci Technol. 2017;55:100–7.

Mihiranie S, Jayasundera M, Perera N. Development of snack crackers incorporated with defatted coconut flour. J Microbiol Biotechnol Food Sci. 2017;7:153–9.

Karandeep K, Navnidhi C, Poorva S, Garg MK, Anil P. Coconut meal: nutraceutical importance and food industry application. Foods Raw Mater. 2019;7:419–27.

Kaur K, Chhikara N, Sharma P, Garg MK, Panghal A. Coconut meal : nutraceutical importance and food industry application. Food Raw Mater. 2019;7:419–27.

Rethinam P. International scenario of coconut sector. In: Krishnakumar V, Thampan PK, Nair MA, editors. Coconut palm (Cocos Nucifera L.)-research dev perspect. Singapore: Springer; 2019. p. 21–56.

Chan E, Elevitch CR. Cocos nucifera (coconut), Species Profiles Pacific Isl. Agrofor. 2006;2:1–27.

Roy S, Sarkar T, Upadhye V, Chakraborty R. Comprehensive review on fruit seeds: nutritional, phytochemical, nanotechnology, toxicity, food biochemistry, and biotechnology perspective. Appl Biochem Biotechnol. 2023. https://doi.org/10.1007/s12010-023-04674-9.

Sarkar T, Salauddin M, Paul A, Choudhury T, Chakraborty R, Imran F. The essence of Bengal’s ethnic sweetmeats: an exploratory journey through history, tradition, and culture. J Food Qual. 2023;2023:1–23. https://doi.org/10.1155/2023/5008420.

Krondl M. Sweet invention: a history of dessert. Chicago: Chicago Review Press; 2011.

Muralidharan K, Jayashree A. Value addition, product diversification and by-product utilization in coconut. Indian Coconut J. 2011;7:4–10.

Doll NM, Ingram GC. Embryo–endosperm interactions. Annu Rev Plant Biol. 2022;73:293–321.

Kumar KD, Gautam RK, Ahmad I, Roy SD, Sharma A. Biochemical, genetic and molecular basis of the novel and commercially important soft endosperm Makapuno coconut-a review. J Food Agric Environ. 2015;14:61–5.

Huang AHC. Oil bodies and oleosins in seeds. Annu Rev Plant Biol. 1992;43:177–200.

Mathanghi SK. Shelf - life extension of tender endosperm of Palmyra palm ( Borassus flabellifer ) through retort processing. Appl Nat Sci Found. 2022;9411:77–84.

Rahman SS, Chowdhury SN, Hosen Z, Karim R, Rouf SMA. Comparative studies on nutrient content and antidiabetic effects of sugar palm ( Borassus flabellifer ) fruit pulp & endosperm on rats. Endocr Metab Sci. 2021;5:100113. https://doi.org/10.1016/j.endmts.2021.100113.

Behera S. Phytochemical constituents and nutritional potential of palmyra palm: a review. Rev Contemp Sci Acad Stud. 2022. https://doi.org/10.55454/rcsas.2.12.2022.003.

Vengaiah PC, Murthy GN, Sattiraju M, Maheswarappa HP. Vale added food products from palmyrah palm (Borassus Flabellifer L). J Nutr Heal Sci. 2017. https://doi.org/10.15744/2393-9060.4.105.

Panda A, Nanda S, Panda AK, Nanda S. Working capital financing and corporate ,profitability of indian manufacturing firms. Manag Decis. 2018. https://doi.org/10.1108/MD-07-2017-0698.

Siju S, Sabu KK. Genetic resources of Asian palmyrah palm (Borassus flabellifer L.): a comprehensive review on diversity, characterization and utilization. Plant Genet Resour Charact Util. 2020;18:445–53. https://doi.org/10.1017/S1479262120000477.

Jana H, Jana S. Palmyra palm: importance in Indian agriculture. Rashtriya Krishi. 2017;12:35–40.

Elangovan SM, Muthu Kumar S, Sindhu V, Mahendiran B, Muthusamy S, Krishnakumar GS. Extraction, characterization and biological activity of Galactomannan rich endosperm of Borassus flabellifer (Linn.) suitable for biofabrication of tissue scaffolds. Int J Biol Macromol. 2023;251:126397. https://doi.org/10.1016/j.ijbiomac.2023.126397.

Bourne MC. Chapter 1—texture, viscosity, and food. In: Bourne MC, editor. food science technology. London: Academic Press; 2002. p. 1–32.

Sadhukhan P, Sarkar A. A study on the acceptability, nutrient composition and shelf life of ‘ Sandesh ’, a Bengali sweetmeat, developed from soymilk and enriched with finger millet and sesame seeds. Int J Home Sci. 2017;3:6–9.

Bandyopadhyay M, Chakraborty R, Raychaudhuri U. A process for preparing a natural antioxidant enriched dairy product (Sandesh). LWT Food Sci Technol. 2007;40:842–51. https://doi.org/10.1016/j.lwt.2006.05.007.

Indian Standard Institution, IS: 2785. Specification for natural cheese, processed cheese and processed cheese spread and soft cheese., Manak Bhavan, New Delhi: Indian Standards Institution, 1979.

Sarkar T, Salauddin M, Kumar Hazra S, Chakraborty R. A novel data science application approach for classification of nutritional composition, instrumental colour, texture and sensory analysis of bael fruit (Aegle marmelos (L) correa). Int J Intell Netw. 2020;1:59–66. https://doi.org/10.1016/j.ijin.2020.07.003.

Pathare PB, Opara UL, Al-said FA. Colour measurement and analysis in fresh and processed foods : a review. Food Bioprocess Technol. 2013;6:36–60. https://doi.org/10.1007/s11947-012-0867-9.

Hsu C, Chen W, Weng Y, Tseng C. Chemical composition, physical properties, and antioxidant activities of yam flours as affected by different drying methods. Food Chem. 2003;83:85–92. https://doi.org/10.1016/S0308-8146(03)00053-0.

Sarkar T, Salauddin M, Pati S, Sheikh HI, Chakraborty R. Application of raw and differently dried Pineapple (Ananas comosus) pulp on Rasgulla (sweetened Casein Ball) to enhance its phenolic profile, shelf life, and in-vitro digestibility characteristics. J Food Process Preserv. 2021. https://doi.org/10.1111/jfpp.15233.

Ray S, Saha S, Raychaudhuri U, Chakraborty R. Preparation of okra-incorporated dhokla and subsequent analysis of nutrition, antioxidant, color, moisture and sensory profile. J Food Meas Charact. 2017;11:1–12. https://doi.org/10.1007/s11694-016-9433-x.

Kalisz S, Oszmiański J, Kolniak-Ostek J, Grobelna A, Kieliszek M, Cendrowski A. Effect of a variety of polyphenols compounds and antioxidant properties of rhubarb (Rheum rhabarbarum). LWT. 2020;118:108775. https://doi.org/10.1016/j.lwt.2019.108775.

Grobelna A, Kalisz S, Kieliszek M. The effect of the addition of blue honeysuckle berry juice to apple juice on the selected quality characteristics, anthocyanin stability, and antioxidant properties. Biomolecules. 2019. https://doi.org/10.3390/biom9110744.

Boxi M, Rajesh Y, Kumar VR, Mangamma BPK. Extraction, phytochemical screening and in-vitro evaluation of anti-oxidant properties of commicarpus chinesis (aqueous leaf extract). Int J Pharma Bio Sci. 2010;1:537–47.

Harborne AJ. Phytochemical methods, a guide to modern techniques of plants analysis. 3rd ed. Dordrecht: Springer; 1973.

Kumar S, Sarkar T, Salauddin M, Sheikh HI, Pati S, Chakraborty R. Heliyon characterization of phytochemicals, minerals and in vitro medicinal activities of bael ( Aegle marmelos L.) pulp and differently dried edible leathers. Heliyon. 2020;6:e05382. https://doi.org/10.1016/j.heliyon.2020.e05382.

Reshma MV, Jacob J, Syamnath VL, Habeeba VP, Kumar BSD, Lankalapalli RS. First report on isolation of 2,3,4-trihydroxy-5-methylacetophenone from palmyra palm (Borassus flabellifer Linn.) syrup, its antioxidant and antimicrobial properties. Food Chem. 2017. https://doi.org/10.1016/j.foodchem.2017.02.043.

Chafer A, Pascual-Martí MC, Salvador A, Berna A. Supercritical fluid extraction and HPLC determination of relevant polyphenolic compounds in grape skin. J Sep Sci. 2005;28:2050–6. https://doi.org/10.1002/jssc.200500128.

Zhang A, Wan L, Wu C, Fang Y, Han G, Li H, Zhang Z, Wang H. Simultaneous determination of 14 phenolic compounds in grape canes by HPLC-DAD-UV using wavelength. Molecules. 2013;18:14241–57. https://doi.org/10.3390/molecules181114241.

Saleh E-S, Bazaid S, Shohayeb M. RP-HPLC-UV-ESI-MS phytochemical analysis of fruits of Conocarpus erectus L. Chem Pap. 2014. https://doi.org/10.2478/s11696-014-0570-6.

Konan M, Janat Akhanovna M-B, Bakalara N, Virieux D, Pirat J-L, Bekro Y-A. hplc analysis and cytotoxicity of n-Butanol extract from glyphaea brevis roots against C6 glioma cells. Sci Pharm. 2014;82:171–6. https://doi.org/10.3797/scipharm.1307-08.

Carri F. A standardised static in vitro digestion method suitable for food – an international consensus†. Food Funct. 2014. https://doi.org/10.1039/c3fo60702j.

Calvo-lerma J, Forn V, Heredia A, Andr A. In vitro digestion of lipids in real foods : influence of lipid organization within the food matrix and interactions with nonlipid components. J Food Sci. 2018;83:2629–37. https://doi.org/10.1111/1750-3841.14343.

Bandyopadhyay M, Chakraborty R, Raychaudhuri U. Effect of carrot on quality improvement of sweet syrupy cheese ball (Rasgulla). Int J Dairy Technol. 2008;61:290–9. https://doi.org/10.1111/j.1471-0307.2008.00412.x.

Witte C, Bailey E. A new extraction method for determining 2-thiobarbituric acid values of pork and beef during storage. J Food Sci. 1970. https://doi.org/10.1111/j.1365-2621.1970.tb04815.x.

Juárez-Barrientos JM, de Montserrat Tejeda-Paz M, de Jesús Ramírez-Rivera E, Aguirre-Cruz A, Rodríguez-Miranda J, Martínez-Sánchez CE, Herman-Lara E. Use of quantitative descriptive analysis (QDA) coupled with multivariate statistical methods to detection and discrimination of adulterated fresh cheeses. J Sens Stud. 2019;34:e12479. https://doi.org/10.1111/joss.12479.

Singh B, Khamrui K, Debnath A, Lodh J, Gupta H, Prasad W. Sensory and colour profile of milk-coconut sweet as a function of ingredients. Indian J Dairy Sci. 2017;70:497–507.

Singh B, Khamrui K, Lodh J, Debnath A, Prasad W. Selection of levels of ingredients for the preparation of milk-coconut sweet based on sensory and instrumental colour attributes Selection of levels of Ingredients for the preparation of milk-coconut sweet. Asian J Dairy Food Res. 2017. https://doi.org/10.18805/ajdfr.v36i02.7952.

Khan MA, Chitrashekarachar M, Semwal AD, Sharma GK. Studies on the optimization and storage stability of virgin coconut meal incorporated instant sooji halwa mix. Food Nutr Sci. 2012;3:1092–9.

Srivastava Y, Semwal AD, Sharma GK, Bawa AS. Utilization of Virgin Coconut Meal (VCM) in the production of ready-to-eat indian traditional sweet meat using response surface methodology. Food Nutr Sci. 2011;2:214–21. https://doi.org/10.4236/fns.2011.23029.

Bourne M. Food texture and viscosity: concept and measurement. Amsterdam: Elsevier; 2002.

Sarkar T, Salauddin M, Hazra SK, Chakraborty R. Comparative classification efficiency of self-organizing map, principal component analysis, and hierarchical cluster analysis for normal dairy and differently pineapple fortified rasgulla. ES Food Agrofor. 2020;1:94–105. https://doi.org/10.30919/esfaf1115.

Tudorica CM, Kuri V, Brennan CS. Nutritional and physicochemical characteristics of dietary fiber enriched pasta. J Agric Food Chem. 2002;50:347–56.

Devi A, Khatkar BS. Effects of fatty acids composition and microstructure properties of fats and oils on textural properties of dough and cookie quality. J Food Sci Technol. 2018;55:321–30.

Phonphoem W, Sinthuvanich C, Aramrak A, Sirichiewsakul S. Nutritional profiles, phytochemical analysis, antioxidant activity and DNA damage protection of makapuno derived from thai aromatic coconut. Foods. 2022;11:3912. https://doi.org/10.3390/foods11233912.

Rice-Evans C, Miller N, Paganga G. Antioxidant properties of phenolic compounds. Trends Plant Sci. 1997;2:152–9.

Prakash U, Kannaian N, Brighty J, Rajagopal V, Nannu S, Srinivasan B. Phytochemical composition and antioxidant activity of coconut cotyledon. Heliyon. 2020;6:e03411. https://doi.org/10.1016/j.heliyon.2020.e03411.

Moonrungsee N, Jakmunee J, Peamaroon N, Boonmee A, Kasemsuk T, Seeda S, Suwancharoen S. Phytochemical and xanthine oxidase inhibitory activity in nypa fruticans wurmb. Fruit Extracts. Trends Sci. 2022;19:2583. https://doi.org/10.48048/tis.2022.2583.

Treml J, Šmejkal K. Flavonoids as potent scavengers of hydroxyl radicals. Compr Rev Food Sci Food Saf. 2016;15:720–38.

Ngampeerapong C, Chavasit V. Nutritional and bioactive compounds in coconut meat of different sources: Thailand, Indonesia and Vietnam, C. J Nat Sci. 2019;18:562–73.

Prasad N, Yang B, Kong KW, Khoo HE, Sun J, Azlan A, Ismail A, Bin Romli Z. Phytochemicals and Antioxidant Capacity from Nypa fruticans Wurmb. Fruit. Evidence-Based Complement Altern Med. 2020. https://doi.org/10.1155/2013/154606.

Mahayothee B, Koomyart I, Khuwijitjaru P, Siriwongwilaichat P, Nagle M, Müller J. Phenolic compounds, antioxidant activity, and medium chain fatty acids profiles of coconut water and meat at different maturity stages. Int J Food Prop. 2016;19:2041–51.

Wang SY, Zheng W. Effect of plant growth temperature on antioxidant capacity in strawberry. J Agric Food Chem. 2001;49:4977–82. https://doi.org/10.1021/jf0106244.

Rajurkar NS, Hande SM. Estimation of phytochemical content and antioxidant activity of some selected traditional Indian medicinal plants. Indian J Pharm Sci. 2011;73:146–51. https://doi.org/10.4103/0250-474x.91574.

Rumpf J, Burger R, Schulze M. Statistical evaluation of DPPH, ABTS, FRAP, and Folin-Ciocalteu assays to assess the antioxidant capacity of lignins. Int J Biol Macromol. 2023;233:123470. https://doi.org/10.1016/j.ijbiomac.2023.123470.

Mahayothee B, Koomyart I, Khuwijitjaru P, Nagle M, Müller J. Phenolic compounds, antioxidant activity, and medium chain fatty acids profiles of coconut water and meat at different maturity stages phenolic compounds, antioxidant activity, and medium chain fatty acids profiles of coconut water and meat at different maturity stages. Int J Food Prop. 2016;19:2041–51. https://doi.org/10.1080/10942912.2015.1099042.

Helena M, De Vasconcelos A, Leite R, Ubaldino E, Junior T, Augusto V, Dorand M, Sabino K, Tavares L, Sergio A, Ranieri B, De Albuquerque L, Maria A, De Magalh T, Araujo S, Francisco A, De Souza J. Extra virgin coconut oil ( Cocos nucifera L.) exerts anti-obesity effect by modulating adiposity and improves hepatic lipid metabolism, leptin and insulin resistance in diet-induced obese rats. J Funct Foods. 2022;94:105122. https://doi.org/10.1016/j.jff.2022.105122.

Arivalagan M, Roy TK, Yasmeen AM, Pavithra KC, Jwala PN, Shivasankara KS, Manikantan MR, Hebbar KB, Kanade SR. Extraction of phenolic compounds with antioxidant potential from coconut (Cocos nucifera L.) testa and identification of phenolic acids and flavonoids using UPLC coupled with TQD-MS/MS. LWT. 2018;92:116–26. https://doi.org/10.1016/j.lwt.2018.02.024.

Narayanankutty A, Tom J, Moothakoottil A, Sasidharan A, Benil PB, Ramesh V, Farouk M, Rizwana H, El-din MME. Proximate composition, antioxidant, anti-inflammatory and anti- diabetic properties of the haustorium from Coconut (Cocos nucifera L.) and Palmyra palm (Borassus flabellifer L.). J King Saud Univ Sci. 2023;35:102404. https://doi.org/10.1016/j.jksus.2022.102404.

Kim RH, Lee SJ, Lee K, Hwang KT, Kim J. Profiling of phenolic acids, flavonoids, terpenoids, and steroid derivatives in coconut (Cocos nucifera L.) haustorium. Food Sci Biotechnol. 2023;32:1841–50. https://doi.org/10.1007/s10068-023-01300-6.

Li S, Yu X, Zhen Z, Huang M, Lu J. Geographical origin traceability and identification of refined sugar using UPLC-QTof-MS analysis. Food Chem. 2021;348:128701. https://doi.org/10.1016/j.foodchem.2020.128701.