Abstract

Pectin is an essential polysaccharide that is normally found in the peels of various fruits and vegetables. It acts as a gelling agent and stabilizer in many foods and pharmaceutical industries. The current study was focused on the potential of mango peel as a source of pectin. The pectin was isolated from mango (Mangifera Indica) peels powder in the hot water bath at five different extraction conditions viz. temperatures (60, 70, 80, 90 and 100 °C), pH (1.0, 1.5, 2.0, 2.5 and 3.0) and time (60, 80, 100, 120 and 140 min). At different extraction conditions, the yield of pectin ranged between 14.60 and 28.42%. The highest yield condition was achieved (28.06%, 28.42% and 28.06%) at the temperature of 90 °C, 1.5 pH, and the extraction time of 120 min. The quality parameters of pectin such as equivalent weight (450.45 to 1324.24 g), methoxyl content (5.15 to 7.90%), anhydrouronic acid content (48.93 to 74.62%), and degree of esterification (43.28% to 77.14%), were found in satisfactory level. In contrast, the soluble sugar content was higher (12.43 to 23.49%), the anhydrouronic acid (AUA) content was low as compared to the existing data for various pectin sources. This is an indication of the existence of protein in the extracted pectin. The mango peel powder was applied in the jelly formulation at different concentrations (0.5%, 1.0%, and 1.5%) to identify the quality and the sensory characteristics. The sensory attributes (e.g., color, taste, appearance and flavor) was highly appreciable at 1% pectin concentration compared to other concentration of pectin. The created polynomial model efficiently accounted for the data fluctuation and accurately captured the actual correlation between the independent and dependent variables. The extraction temperature, pH, and time had a substantial impact on the yield and quality of the extracted pectin, according to the results of both single factor studies and RSM. The optimal conditions were determined from the optimization research to be 88.86 °C, pH 1.36, and 79.61 min, which produced 23.31% pectin. Lastly, the manufacturer will be able to get information regarding the quality of mango peel pectin. It can be utilized as an important source of pectin for application in food and pharmaceutical industries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Mango is the most common and attractive fruit because of its physical appearance and as a rich source of precious components (polyphenols, carotenoids, dietary fiber, Vitamin C, Vitamin E and pectin) comprised in the peel. In the total composition of the fruit, at least 20% peel is assumed as a waste product, responsible as a hazardous problem at the time of disposal in the environment [1]. Mango (Mangifera indica L.), the family of Anacardiaceae sometimes is called the “king of fruits” produced in different (tropical and subtropical) regions [2]. In 2020, global mango production (including guavas and mangosteens) was 54.83 million metric tons [3]. Commercial production of canned mango, frozen slices, dried mango, purée, nectar, juices and other preserved mango products generate mango waste. Approximately 200,000 tons of biomass are produced during these processes only in Thailand, with peels accounting for up to 24% of the total volume [4]. Byproducts from mango processing account for 35% to 60% of the total fruit mass. Peels, stones, and occasionally perishable pulp pieces make up this portion [5]. According to reports of Dorta et al. [6], the global mango industry creates 75,000 tons of waste per year. Considering mango peels comprise for 15–20% of the fruit's weight, the annual global production of mango waste is estimated to be between 11 to 8.2 million metric tons [7].

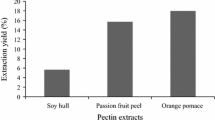

Pectins are compound structural polysaccharides especially found in the middle lamella of the cell wall at the topmost plants. It retains galacturonic acid residue that is connected with α-(1–4) linkages [8, 9]. Pectins are abundant in practically every fruit fraction, including the pulp, peels and kernels [10]. In 2019, the global demand for pectin as a biopolymer was $1 billion, and it is predicted to climb to $1.5 billion by 2025 [11]. Commercial pectin is mostly extracted from apple pomace or citrus peel, which have varying physicochemical functions depending on the availability of pectin esterase in the raw materials [12]. Pectin from apple pomace generates a high-viscosity gel that can be used as a medical polymer, although citrus pectin is preferred in the confectionery industries because of its lighter colour. Industry-grade biopolymer pectin requires a minimum of 65% galacturonic acid on ash and moisture-free materials, limiting other potential new sources of pectin [13]. It has several important multifunctional properties which are applicable in many food industries such as a gelling agent, texturizers, emulsifiers, thickener, and stabilizer properties [14].

Pectin also has a variety of other functional features in the food industry, including the ability to act as potential probiotics and prebiotics [15]. In the food processing industry, as well as in non-food industries, pectin polysaccharides have been widely used as a functional ingredient in packaging materials, cosmetics and pharmaceuticals [16]. Pectin has also played a vital role in physiological and health adequacy [8, 17]. In the present years, pectin is not only used as coating materials in many fruits and vegetables but also rapidly applied as encapsulating agents in the pharmaceutical industry [18].

The most often used method for extracting pectin is the traditional approach, which requires for using hot water (60–100 °C) that has been acidified to a pH of 1.5–3.0 [19, 20] nonetheless, other alternative techniques have been used to maximize the pectin yield. such as enzyme-assisted [21, 22] ultra-high pressure extraction [23], microwave-assisted [24, 25] subcritical fluid [26], moderate electric field extraction [27], ultrasound pulses [22, 25], ultrasound [8, 28], microwaves or a combination of these techniques [29]. Pectin is also isolated from the sample by using the treatment with different minerals and organic acids. Moreover, the characteristics of pectin are affected by the raw material and extraction conditions such as pH, temperature, and extraction time [17]. In order to obtain a higher yield and higher quality of extracted pectin, it is essential to optimize these parameters prior to pectin extraction. A useful technique for developing, statistically modeling, and improving biological processes is called response surface methodology (RSM). It may also be used to find relationships between one or more process variables [30]. Due to fewer experimental runs and the ability to efficiently assess both the individual and interacting impacts of the process variables, optimization using RSM coupled with Box-Behnken design (BBD) has recently gained prominence over older optimization approaches [9].

Many studies were revealed that different extraction techniques and extractants used in various types of crops and by-products [31], even in mango peel [32] for the extraction of pectin. The yield obtained from modern extraction techniques (e.g., Microwave-Assisted Extraction) is lower compare to conventional methods [33] and these traditional methods take longer time to extract which is an obstacle for commercial production [34]. The popularity of pectin is also rising gradually because of its industrial purposes and frequent research is needed to find out the special source of pectin at a low cost [35]. In this concern, mango peel can be an important and primary pectin source used in many food and pharmaceutical products. Hence, the present study was conducted to investigate the effects of extraction factors on the yield as well as quality of mango peel pectin, to find optimum extraction conditions which can be favorable for commercial production and to make a value-added product (i.e., Jelly) by using extracted pectin from peel (mango) powder.

2 Materials and methods

2.1 Collection and preparation of sample

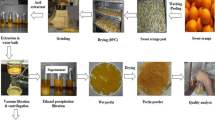

The fresh mangoes were purchased from the local market at Dinajpur, Bangladesh. Mangoes were cleaned with running water and then skinned. The peels were chopped into thin particles and dried in a cabinet dryer at 60 °C for 24 h. The dried peels were ground by using a blender. The powders were packed in high density polyethylene bags. The powder was wrapped and deposited at 4 °C until further use (Fig. 1).

2.2 Extraction of pectin

The extractant was prepared by mixing one part of unbuffered concentrated hydrochloric acid (30% v/v, HCl) with one part of distilled water and used as a stock solution, for preparing the extractants of different pH. The different extractants with pH of 1.0, 1.5, 2.0, 2.5 and 3.0 were prepared by diluting the stock solution of hydrochloric acid solution. These extractants were used for the extraction of pectin from the dried mango peel powder.

The pectin was isolated from the mango peel powder by using water bath according with few modifications as described previously [36]. At first, dried mango peel powder (15 g) was transferred into a beaker (1000 ml) by using extractants with several pH such as 1.0, 1.5, 2.0, 2.5 and 3.0 which mixed with sample to the specific ratio of w/v (1:20). Subsequently, using shaking water bath (Vision Scientific Co. Ltd., Korea) the beaker was consigned and extracted with selected temperature and time such as 60 °C for 60 min, 70 °C for 80 min, 80 °C for 100 min, 90 °C for 120 min and 100 °C for 140 min. The extraction time and temperature was predicted from the pectin extraction condition from other fruit peel sources [37, 38]. The beaker was cooled down at room temperature and filtered through Whatman filter paper No. 1. By using centrifugal machine, the pectin was purified, subsequently added similar volume of ethanol 95% (v/v) to precipitate the supernatant and kept overnight at refrigerator at 4 °C temperature. After washing two times with 95% ethanol (v/v), the viscous quantity of pectin was apart from mono and disaccharides. Afterward, the extracted pectin was dried (50OC) in hot air oven dryer achieving fixed weight.

The pectin yield was then calculated as follows:

Each experiment should be carried out in triplicates and the average results was reported.

2.3 Quality evaluation of pectin

Equivalent weight and methoxyl content were evaluated by the method as described previously [36]. The following derivations were used to measure the Equivalent weight:

By using the values of equivalent weight and the methoxyl content, the anhydrouronic acid (AUA) content was measured by the method as described previously [36].

When molecular unit of AUA (1 unit) = 176 g.

where, z = ml (titre) of NaOH from equivalent weight determination; y = ml (titre) of NaOH from methoxyl content determination.

The degree of esterification (DE) of pectin was deliberate depending upon the methoxyl and AUA content and computed in the following equation [39]:

where, MeO = Value from methoxyl content; AUA = Value from Anhydrouronic acid content.

Anthrone reagent was used to estimate the total soluble sugar (TSS) [40]. Known concentration of pure glucose and total sugar samples were measured from standard curve which computed with the reference of the standard curve.

2.4 Preparation of pineapple jelly

To begin, mature, edible, and fresh pineapples was collected and sorted. The pineapples was washed away with running tap water. Pineapples was peeled and sliced into thin slices after being hulled. After that, the pieces were blended and the liquid will be extracted (juice). Afterwards, 55% of the juice and 45% of the sugar were balanced and mixed. The mixture was steamed to extract 0.5%, 1.0%, and 1.5% pectin, as well as 4 g of citric acid. The jelly was then curdled at 150 °C and the end point was calculated (by bead). After that, any bubble was removed and poured the hot liquid into a sterilized bottle. Finally, chilling, topping, and packing were done at room temperature.

2.5 Sensory test of pineapple jelly

Sensory test of prepared jelly by of the extracted and commercial pectin at three different concentration such as 0.5%, 1.0% and 1.5% were examined such as color, appearance, flavor, taste and overall acceptability by 20 panel members. The jelly prepared from commercial pectin at the same percentage (as standard) also tasted for the same parameters. For statistical analysis of sensory data, three varieties of jellies were further subjected to sensory evaluation. Hedonic ranking test (9-point) was used to test the products degree of acceptability. 20 panel members were offered the parts (three) of each sample coded randomly to point out (9) the hedonic scale (1 = Extremely dislike and 9 = Extremely like).

2.6 Optimization of process conditions

An optimization research has been conducted utilizing the Box-Behnken Design (BBD) of response surface approach based on the early single factor trials (RSM). Pectin yield was chosen as the dependent (response) variable, while the independent variables, temperature (60–100 °C), time (60–140 min), and pH (1.0–3.0), were chosen from the single factor experiments. Based on the experimental design (Table 1), fifteen experiments were carried out. The data collected were then fitted to a second-order polynomial model equation as follows to assess the correlation between the independent and dependent variables.

where Y = response; Xi and Xj = variables, where i and j vary from 1 to k; βo = model intercept; βj, βjj and βij = interaction coefficients, k = independent variables (k = 3 in this work). Design of Expert trial version 13 (Stat-Ease Inc., Minneapolis, USA) was employed to create and evaluate the optimization process.

2.7 Statistical analysis

IBM SPSS Statistics, version 22 (SPSS Inc., Chicago, IL) was used to analyse the obtained data. In the tables, the results were presented as the mean ± standard error of the mean of three replicates. To determine statistically significant differences among the means, one-way analysis of variance (ANOVA) was used at 5% level of significance.

3 Results and discussion

3.1 Evaluation of processing factors on the yield of pectin

3.1.1 Effect of extraction parameters on pectin yield

The percentage of pectin yield at different pH (ranged from 1.0 to 3.0) is shown in Fig. 2 which was extracted from mango peel powder. The isolation was carried out using an aqueous solution containing HCl at the pH of 1.0, 1.5, 2.0, 2.5, and 3.0, as well as a constant isolated duration and temperature of 90 °C and 120 min, respectively. The pectin yield was varied between 14.60–28.42%, with the maximum and minimum pH being 1.5 and 2.5, respectively (Fig. 2). Similar findings were reported for pectin from pumpkin by-products and passion fruit peel, respectively, by Kulkarni and Vijayanand [41] and Lalnunthari et al. [42] respectively. One of the most crucial parameters in the pectin extraction process is pH [43, 44]. The yield of pectin was found to be between 14.60% and 28.42%, with the maximum yield at pH 1.5 and the lowest yield at pH 2.5 (Fig. 2). When the pH was increased, the amount of pectin production increased significantly (p < 0.05). It was continued up to pH 1.5, although increasing the pH further reduce the pectin output (Fig. 2). The hydrolysis of protopectin has been accelerated by the presence of a high concentration of hydrogen ions in the solvent [45]. Protopectin is a compound made up of cellulose molecules and pectin molecules. Ionization of the carboxylate groups is repressed at low pH when the hydrogen ion concentration of the solution increases, i.e., the highly hydrated carboxylate group is transformed into hydrated carboxylic acid groups. The loss of carboxylate groups reduces polysaccharide molecule repulsion, promoting pectin gelation qualities and resulting in more precipitated pectin at lower pH [46]. This observation agreed with Canteri-Schemin et al. [47]. and Yapo et al.’s [31] work who extracted pectin from apple pomace and sugar beet pulp where the yield increased with increasing acid strength. Nevertheless, the solubility and breakdown of pectic substances as well as neutral sugar side chains (i.e., glycosidic bonds) at higher pH is low, which might decrease the pectin extraction rate [48].

Time is most important factor for isolating the pectin from mango peel. The pectin has been extracted by using separated time duration such as 60 min, 100 min, 120 min, 140 min based on condition ‘HCl-NaOH buffer. It has been showed that the yield was separated from 20.17 to 28.06% depending upon the time. The uppermost pectin yield was gained at 120 min whereas the lowermost at 60 min (Fig. 3). Pectin yields varied between 20.17 to 28.06% in this study. The amount of pectin yielded increased significantly (p < 0.05) as the extraction time was increased. After 120 min of extraction time, the maximum yield of pectin was recorded (Fig. 3). Previous research has shown that extraction time has a significant impact on pectin yield [41]. Under constant pH and temperature, the higher the pectin obtained the longer the extraction time [49]. This is because pectin, a carbohydrate polymer made up of (1, 4) linked galacturonic acid units, requires time to soften its structure before being extracted. At the start of the extraction, the pectin yield increased with time since longer periods allow for greater reaction time. However, after 120 min, pectin yield decreased, probably due to the influence of acid, which may have broken the glycoside and ester bonds of pectin, resulting in lesser yield [50]. However, other investigations have shown that the best pectin yield can be achieved in as little as 60 min of extraction [41].

The yield of pectin is greatly influenced by its isolated temperature which represented as Fig. 4. The different temperature such as 60 °C, 70 °C, 80 °C and 100 °C were used to extract pectin from peel at pH (1.5), ratio (1:20) and isolation period (120 min). The pectin was ranged from 14.40 to 28.16% according to its origin of temperature. The yield has been increased (28.06%) at 90 °C temperature and decreased temperature 60 °C at 14.40% (Fig. 4). Pectin extraction was carried out at various temperatures with a peel to extractant ratio of 1:20 (w/v), extractant pH of 1.5, and an extraction time of 120 min, as shown in Fig. 4. The results showed that as the temperature increases, the production of pectin increased considerably (p < 0.05). It was continued up to a temperature of 90 °C, however when the temperature was increased more, the pectin output declined (Fig. 4). It is illustrated in the figure that at 60 °C, the total production of pectin was lowest (14.19%). The production of pectin increased as the extraction temperature increased, with the highest pectin yield of 28.16 percent reported at 90 °C. Gragasin et al. [51] observed similar findings for dried mango peels of several varieties, and Kulkarni and Vijayanand [41] reported similar findings for passion fruit peel. According to earlier research [41, 52], separation duration significantly affects pectin yield, which keeps rising with time at a constant temperature and pH. This could be because the solute (in this case, sweet orange peel) has enough time to extract pectin from solvent [53]. However, thermal degradation occurs at higher temperatures and lower pH after the optimal time has passed, which may result in a decline in the quality of the extracted pectin [48].

3.2 Effect of processing factors on the quality of pectin

3.2.1 Effect on equivalent weight

Equivalent weight (EW), the factor which affected the quality of pectin is shown in Tables 2, 3 and 4. The extractant of pH was greatly affected by the quality of pectin that was observed to vary between 450.45 to 1324.24 g. The pH 1.0, 1.5, 2.0, 2.5 and 3.0 at different extractant ratio (1:20), temperature (90 °C) and time (120 min) were presented 450.45, 980.39.1015.23, 1124.29 and 1324.24 g equivalent weight of pectin. The value was identified 471.69 to 979.39 g and 769 to 980.39 g depends on extraction time and temperature. The highest EW was 979.39 g at 120 min whereas lowest EW was 471.69 at 100 min (Table 3). The topmost and lowermost values (Tables 2, 3, 4) were found at 3.0 and 1.0 pH, 90 °C and 100 °C temperature and time 100 and 120 min. The total quantity of free galacturonic acid (not esterified) in the molecular chains of pectin is the equivalent weight of pectin [54]. Table 2 shows the equivalent weight of pectin extracted from mango peel powder using hydrochloric acid in this study. Table 4 shows that, depending on the extractant pH, the equivalent weight of pectin ranged from 450.45 to 1324.24. This value varies from 471.69 to 979.39 depending on the extraction time (Table 3). The equivalent weight was observed to vary between 769.23 and 980.39 based on extraction temperature (Table 4). This finding is similar to the findings of Nahar et al. [55], who reported that the equivalent weight of mango peel powder pectin ranged from 506.58 to 2142 depending on extraction conditions. Table 2 shows that increasing pH resulted in a significant (p < 0.05) increase in equivalent weight. On the other hand, it was discovered that when time and temperature increased, the value of EW increased significantly (p < 0.05) (Tables 3, 4). The influence of these factors might vary greatly depending on the manner and composition of citrus fruits utilized, as well as the amount of free acid present in pectin powder, as found in this study [56, 57]. Pectin with a higher equivalent weight may have a larger gel-forming capacity, while pectin with a lower equivalent weight may have a stronger partial degradation effect [58].

3.2.2 Effect of methoxyl content (MeO)

Tables 2, 3 and 4 represents the methoxyl content of mango peel pectin. The values were contained about 5.25%, 5.46%, 6.38%, 6.94 and 7.90% but in Table 3 the methoxyl content attained 7.65%, 6.95%, 6.57%, 5.46% and 5.17% at the time of 60 °C, 80 °C, 100 °C, 120 °C and140 min. The methoxyl content ranged from 7.25%, 7.07%, 6.94%, 5.46% and 5.15% with the temperature of 60, 70, 80, 90, and 100 °C temperature (Table 4). The methoxyl content increased at 60 °C temperature, pH 3.0 and 60 min whereas it was decreased at 100 °C temperature, pH 1.0 and time 140 min (Table 4). The methoxyl content of pectin extracted from mango peel powder using hydrochloric acid increased significantly (p < 0.05) when the pH of the extractants increased from 5.25 to 7.90% (Table 2), with pH 3.0 being the highest and pH 1.0 being the lowest [59]. The methoxyl content (which ranged from 5.17 to 7.65%) varied significantly (p < 0.05) depending on the extraction times. It indicates that as extraction time was extended, methoxyl concentration decreased significantly (p < 0.05) [60]. Table 4 shows that methoxyl content varied between 5.15 and 7.25%, and that it decreased significantly as extraction temperature increased [61]. These results were greater than those reported for dragon fruit pectin [62], which ranged from 2.98 to 4.34%, and passion fruits (5.25%) [41]. This could be due to pectin's partial breakdown.

3.2.3 Effect of anhydrouronic acid (AUA)

The anhydrouronic acid content ranged from 68.88%, 58.16%, 55.08% and 48.93% for pH 1.0, 1.5, 2.0, 2.5 and 3.0, respectively (Table 2). This value was changed at 49.83%, 56.16%, 74.62%, 69.84% and 73.62% to a specific time 60, 80, 100, 120 and 140 min (Table 3). Conversely depending upon the temperature this value was obtained 48.93%, 57.73%, 60.60%, 66.52% and 52.10% (Table 4) at different fixed temperature such as 60, 70, 80, 90 and 100 °C, respectively. It was investigated that the extracted mango peel pectin had highest amount of methoxyl content at appropriate pH 1.0, 120 min and 90 °C temperature, while the lowest amount found at pH 3.0, 60 min, 60 °C temperature. Table 1 shows the anhydrouronic acid (AUA) content of pectin extracted from mango peel powder in this investigation. Mango peel with the highest anhydrouronic acid (AUA) value was achieved at pH 1.0, time 120, and 90 °C temperature. Anhydrouronic acid content was significantly (p < 0.05) different at various pH, time, and temperature levels. Extraction pH was decreased, anhydrouronic acid levels increased significantly (p < 0.05), which is almost identical to Rehman et al. [63] where AUA was 66.73% to 68.72% for mango peel pectin at the same pH levels.

3.2.4 Effect of degree of esterification

In a hydrochloric acid (HCl) extraction method, the effects of pH on Degree of Esterification were investigated. For pH 1.0, 1.5, 2.0, 2.5, and 3.0, the values of degree of esterification (DE) of pectin were 43.28%, 63.31%, 67.62%, 71.58%, and 77.14%, respectively (Table 2). The DE value derived based on extraction time was 63.31%, 62.19%, 49.99%, 52.01% for durations 60, 80, 100, 120, 140 min (Table 3). Again, the DE value reached 68.29%, 67.62%, 66.67%, 63.30%, and 56.09% depending on extraction temperature of 60, 70, 80, 90, and 100 °C (Table 4). The maximum degree of esterification was obtained at pH 1.0, 60 min, and 60 °C temperature, while the minimum degree of esterification was obtained at pH 1.0, 60 min, and 100 °C temperature. The degree of esterification was lowest (43.28%) at low pH (1.0) and highest (77.14%) at high pH (3.0) (Table 2). DE increased significantly (p < 0.05) with increasing pH, which was consistent with the findings of Woo et al. [64]. The degree of esterification ranged from 49.99 to 63.31%, (Table 3) and when the extraction time was increased, the degree of esterification decreased significantly (p < 0.05), with the exception of the temperature 100 °C which decreased slightly. The degree of esterification varied significantly at different extraction temperatures, ranging from 56.09–68.29%, and the degree of esterification decreased significantly (p < 0.05) as the extraction temperature was increased. When the extraction conditions are kept constant, the DE decreases as the temperature increases (Table 4). Because the pectin extraction and de-esterification processes are influenced by the high acid concentration and temperature at the same time [65]. The degree of esterification reported in this study corresponds to Azad et al. [66] for citrus maxima (76.30%) and D'Addosio et al. [67] for passion fruit peels (69.7%). Because the degree of esterification (DE) was greater than 50% at optimum conditions, the produced pectin was categorized as high methoxyl pectin in this study. It can form gels in aqueous systems with high soluble solids content and a low pH value as a high methoxyl pectin. For soft drinks, high methoxyl pectin viscofiers are appealing. In the food industry, only pectin with a degree of esterification greater than 60% is usually used [68].

3.2.5 Effect of soluble sugar content

The anthrone reagent technique was used to calculate the soluble sugar concentration. The soluble sugar content of mango pectin were 14.49%, 16.31%, 23.17%, 23.04%, and 23.49% at pH ranged from 1.0 to 3.0 while other parameters such as time and temperature were maintained constant at 120 min and 90 °C (Table 4). The value of soluble sugar increased significantly (p < 0.05) with increasing extraction pH, but there was no significant difference was observed in pectin's sugar content when time and temperature were taken into account (Tables 3 and 4). The soluble sugar content of pectin obtained in this study was found to be slightly above average. This is because the peels of overripe and matured fruits contain more soluble sugar than those of premature or unripe fruits [66]. The neutral sugar content of citrus pectin ranged from 15.45 to 19.40% in a previous study [69]. The amount of soluble sugar in plants varies depending on the source of the plants and the extraction method used [70].

3.3 Sensory characteristics of prepared jelly

The three distinct varieties of jelly with various concentration such as 0.5%, 1.0% and 1.5% were used to analyze the hedonic ranking test among 20 panel members (Fig. 5). Tables 5 and 6 present the results of three different types of jelly (extracted mango peel pectin) which compared to normal jelly prepared with the same concentration as commercial grade (Fig. 6).

3.4 Color

Color is one of the most crucial quality detective factors. The extracted mango pectin values were determined to be 7.20, 7.60, and 6.85 at the concentrations of 0.5, 1.0, and 1.5% whereas the commercial pectin was 7.70, 7.10 and 6.90%. The color of isolated and commercial mango pectin jelly had maximum scores of 7.60 and 7.70 at 1.00% and 0.50% pectin concentrations, and minimum scores of 6.85 and 6.90% at 1.50% pectin concentrations (Tables 5 and 6).

3.5 Appearance

Product identification varies depending on its appearance. The extracted mango pectin values were determined to be 6.95, 7.50, and 6.75 at the concentrations of 0.5, 1.0, and 1.5%. It can be seen that the color of isolated and commercial mango pectin jelly had the highest scores of 7.50 and 7.60 at 1% and 0.5% pectin concentrations, and the minimum scores of 6.75 and 7.0% at 1.5% pectin concentration.

3.6 Taste

Taste is a key component that affects a product's acceptance and has the greatest influence on the product's commercial performance. At the concentrations of 0.5%, 1.0%, and 1.5%, the taste values of extracted mango pectin jellies were nearly identical to those of commercial pectin (Tables 5 and 6).

3.7 Flavour

There was no significant difference in flavor among jelly produced with varied pectin concentrations, according to sensory analysis (Tables 5 and 6). The sensory analysis for flavor revealed that the scores obtained of jelly formulated with extracted mango peels pectin were very similar to those obtained of jelly prepared with commercial pectin at 0.5%, 1.0%, and 1.5% concentrations, respectively.

3.8 Overall acceptability

Overall acceptability, which is an important parameter in organoleptic assessment, has a wide range of implications. The total acceptance score achieved with extracted mango peels pectin at concentrations of 0.5%, 1.0%, and 1.5% was 7.10, 7.50, and 7.05, respectively (Table 5). On the other hand, the overall acceptability of jelly prepared with commercial pectin at concentrations of 0.5%, 1.0%, and 1.5% was 7.65, 7.30, and 7.10, respectively (Table 6). The highest overall acceptance scores (7.50) were obtained which formulated with extracted mango peels pectin at 1.0% concentration, while the lowest overall acceptability scores (7.05) were obtained from jelly; formulated with 1.5% pectin concentration (Table 5). In contrast, the highest overall acceptability value (7.65) was obtained at a concentration of 0.5% commercial pectin, while the lowest appearance scores (7.10) were obtained at a concentration of 1.5% pectin.

3.9 Analysis of sensory characteristics

Hedonic testing was performed on the three formulated jellies with different pectin concentrations. The results of the sensory evaluation of the three formulations compared to standards are presented in Tables 5 and 6. The findings clearly demonstrated that the amount of pectin added to each formulation has a distinct effect. The J1 formulation scored well in terms of color, taste, and flavor (7.20, 7.50, and 7.55, respectively), but only moderately in terms of appearance and overall acceptability (6.95 and 7.10), which could be due to the use of less pectin in the formulation. J2 was found to be comparable to jelly made with regular pectin. J2 jelly received similar scores for color, appearance, taste, flavor, and overall acceptability (e.g. 7.60, 7.50, 7.75, 7.50, and 7.50, respectively) as standard jelly S1 (7.70, 7.60, 7.65, 7.60 and 7.65 respectively). J3 formulation was the least acceptable; the amount of pectin used in this formulation was the most, which had a significant impact on its sensory evaluation. J3 received the lowest marks of all the preparations because the jelly became harder than normal jellies, affecting its color, appearance, and overall acceptability (6.85, 6.75 and 7.05 respectively). In terms of color, appearance, and overall acceptability, S3 formulation got similar results. The low color, appearance, and overall acceptability scores of formulations J1 and J3 can be attributed to caramelization during cooking as well as pectin hydrolysis [71]. Due to the high amount of pectin used as a thickening agent in the jelly formulation, the color and appearance of J3 and S3 formulations received the lowest scores. As a result, the more pectin in the formulation, the thicker the jelly became, which had an impact on its appearance, color, and spreadability. Higher pectin concentrations seemed to affect flavor and taste as well [72].

3.10 Statistical analysis for model fitness

The data from the experimental runs (Table 1) were fitted to a second-order polynomial equation with linear, interactive, and quadratic factors to describe the connection between independent and response variables. The results of the ANOVA (analysis of variance) approach used to assess the model fitness are shown in Table 7. It is clear that the resulting model can explain the majority of the response's variation and was significant (P < 0.05). Additionally, the majority of the model terms (both individual and interactive) demonstrated the value of the developed model. The established model's high R2 (0.8211) value demonstrated that it accurately captured the relationship between the independent and response variables, which was also reflected in the values of adjusted-R2 (0.6869) and anticipated R2 (0.7735). Additionally, a smaller coefficient of variance (11.57) indicates that the studies were accurate and acceptable [73]. Adequate precision (> 4) denotes the intended model's highest level of accuracy [74, 75].

Additionally, as shown in Fig. 7a–c, numerous diagnostic plots (predicted against actual, normal percentage probability, and internally studentized residuals) were used to assess the model's fitness. The normal percentage probability plot of the residuals for the response and the close proximity of the values predicted by the model to the experimental values to the straight diagonal line indicated appropriate relevance with the actual data (Fig. 7a and b). To help with the model's acceptable fit, an internally studentized residuals graphic was created (Fig. 7c), which states that all of the data points have fallen inside the ± 3δ limits.

Three-dimensional (3D) plots were created from the established model to investigate the interaction influence of process factors on the pectin yield (Fig. 8a–c). The graphs in Fig. 3a and c showed that the pectin production increased to a point eventually dropping down. Figure 8b and c show that extraction duration significantly affects pectin production, which is in accordance with the theory that prolonged exposure to an acidic extractant at a higher temperature may increase pectin output [37].

3.11 Optimization of process conditions

The method of Derringer's desire function was used to determine the ideal circumstances for the pectin extraction [9] 52. The output variable, or pectin yield, was set at the maximum while the process factors, such as temperature, pH, and extraction time, were maintained in the range of 80–100 °C, 1.0–2.0, and 90–120 min, respectively (since we desired to have the highest yield of pectin). The expert program's design was used to run the solutions in ideal circumstances. Temperature of 88.86 °C, pH of 1.36, and duration of 79.61 min. were the optimum input variables, producing 23.31% pectin with a desirability of 0.251. The optimization process conditions are close to the findings of Kamal et al. [37].

4 Conclusion

The goal of this study was to extract pectin from mango peel powder and see how different extraction parameters affected the yield and quality of pectin. According to the findings of this study, all process variables have a significant impact on pectin yield. The extraction conditions also influenced quality parameters such as equivalent weight, methoxyl content, anhydrouronic acid, and degree of esterification. Except for anhydrouronic acid, which was found to be below the standard limit, all of the quality parameters were found to be within the standard and acceptable limits. The highest pectin yield was obtained at a pH of 1.5, 120 min, and a temperature of 90 °C. The contents of anhydrouronic acid in pectin ranged from 48.93 to 74.62%, which was found to be within acceptable limits. At different conditions, the degree of esterification of extracted pectin ranged from 43.28 to 77.14%. The pectin obtained from mango peel was mostly High Methoxyl pectin, according to the value of degree of esterification (DE) (HMP). The pectin obtained from mango peels also had good quality characteristics, particularly the jelly grade, which is linked to the product's good jelly formation. According to the sensory evaluation, the jelly made with 1.0% extracted mango pectin was excellent and more acceptable than the other pectin concentrations. When compared to other percentages of pectin used in jelly formulation, the color, taste, appearance, flavor, and overall acceptability were all excellent. The extracted pectin could be used in a variety of food and pharmaceutical products.

This study paved the way for further research into extracting pectin using cutting-edge extraction techniques such as microwave, ultrasonic, electromagnetic heating, high hydrostatic pressure, pulse-electric field processing, and other environmentally friendly solvents, as well as characterizing and evaluating the mango peel pectin.

Data availability

The datasets generated during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

Ajila CM, Naidu KA, Bhat SG, Rao UJS. Bioactive compounds and antioxidant potential of mango peel extract. Food Chem. 2007;105:982–8.

Tafolla-Arellano JC, Yi Z, Sun H, Jiao C, Ruiz-May E, Hernández-Oñate MA, González-León A, Báez-Sañudo R, Fei Z, Domozych D, Rose JKC, Tiznado-Hernández ME. Transcriptome analysis of mango (Mangifera indica L.) fruit epidermal peel to identify putative cuticle-associated genes. Sci Rep. 2017;7:1–13.

FAOSTATS. World mango production. 2022. https://www.statista.com/statistics/577951/world-mango-production.

Rojas R, Alvarez-Pérez OB, Contreras-Esquivel JC, Vicente A, Flores A, Sandoval J, Aguilar CN. Valorisation of mango peels: extraction of pectin and antioxidant and antifungal polyphenols. Waste Biomass Valorization. 2020;11(1):89–98.

Larrauri J, Rupérez P, Borroto B, Saura-calixto F. Mango peels as a new tropical fibre: preparation and characterization. LWT-Food Sci Technol. 1996;29:729–33.

Dorta E, Gloria LM, Gonzalez M. Using drying treatments to stabilize mango peel and seed: effect on antioxidant activity. LWT Food Sci Technol. 2012;45:261–8.

Nguyen HDH, Nguyễn HVH, Savage GP. Properties of pectin extracted from Vietnamese mango peels. Foods. 2019;8(12):629.

De Oliveira CF, Giordani D, Lutckemier R, Gurak PD, Cladera-Olivera F, Marczak LDF. Extraction of pectin from passion fruit peel assisted by ultrasound. LWT Food Sci Technol. 2016;71:110–5.

Kamal MM, Ali MR, Hossain A, Shishir MRI. Optimization of microwave-assisted extraction of pectin from Dillenia indica fruit and its preliminary characterization. J Food Process Preserv. 2020. https://doi.org/10.1111/jfpp.14466.

Nguyen HVH, Savage GP. The effects of temperature and pH on the extraction of oxalate and pectin from green kiwifruit (Actinidia deliciosa L.), golden kiwifruit (Actinidia chinensis L.), kiwiberry (Actinidia arguta) and persimmon (Diospyros kaki). Int J Food Sci Tech. 2013;48:794–800.

Freitas CM, Coimbra JS, Souza VG, Sousa RC. Structure and applications of pectin in food, biomedical, and pharmaceutical industry: a review. Coatings. 2021;11:922.

May CD. Industrial pectins: sources, production and applications. Carbohydr Polym. 1990;12:79–99.

Wongkaew M, Chaimongkol P, Leksawasdi N, Jantanasakulwong K, Rachtanapun P, Seesuriyachan P, Phimolsiripol Y, Chaiyaso T, Ruksiriwanich W, Jantrawut P, Sommano SR. Mango peel pectin: recovery, functionality and sustainable uses. Polymers. 2021;13(22):3898.

Güzel M, Akpınar Ö. Valorisation of fruit by-products: production characterization of pectins from fruit peels. Food Bioprod Process. 2019;115(June):126–33.

Yahya HN, Yahaya N, Baihagi K, Ariffin N, Yahya H. Pectin from duckweed (Lemnaceae) as potential commercial pectin and its gelling function in food production: a review. Malay J Sci Health Technol. 2022;8(1): eISSN: 2601-0003.

Millan-Linares MC, Montserrat-dela Paz S, Martin ME. Pectins and olive pectins: from biotechnology to human health. Biology MDPI. 2021;10(9):860.

Korish M. Potential utilization of Citrullus lanatus var. Colocynthoides waste as a novel source of pectin. J Food Sci Technol. 2015;52:2401–7.

Nemiwal M, Zhang TC, Kumar D. Pectin modified metal nanoparticles and their application in property modification of biosensors. Carbohydr Polym Technol Appl. 2021;2: 100164.

Dao TAT, Webb HK, Malherbe F. Optimization of pectin extraction from fruit peels by response surface method: conventional versus microwave-assisted heating. Food Hydrocolloids. 2021;113: 106475.

Cui J, Ren W, Zhao C, Gao W, Tian G, Bao Y, et al. The structure–property relationships of acid-and alkali-extracted grapefruit peel pectins. Carbohydr Polym. 2020;229: 115524.

Cui J, Zhao C, Zhao S, Tian G, Wang F, Li C, et al. Alkali+ cellulase-extracted citrus pectins exhibit compact conformation and good fermentation properties. Food Hydrocolloids. 2020;108: 106079.

Abou-Elseoud WS, Hassan EA, Hassan ML. Extraction of pectin from sugar beet pulp by enzymatic and ultrasound-assisted treatments. Carbohydr Polym Technol Appl. 2021;2: 100042.

Guo X, Han D, Xi H, Rao L, Liao X, Hu X, Wu J. Extraction of pectin from navel orange peel assisted by ultra-high pressure, microwave or traditional heating: a comparison. Carbohyd Polym. 2012;88(2):441–8.

Dranca F, Vargas M, Oroian M. Physicochemical properties of pectin from Malus domestica ‘Fălticeni’apple pomace as affected by non-conventional extraction techniques. Food Hydrocolloids. 2020;100: 105383.

Karbuz P, Tugrul N. Microwave and ultrasound assisted extraction of pectin from various fruits peel. J Food Sci Technol. 2021;58(2):641–50.

Mao G, Wu D, Wei C, Tao W, Ye X, Linhardt RJ, et al. Reconsidering conventional and innovative methods for pectin extraction from fruit and vegetable waste: targeting rhamnogalacturonan I. Trends Food Sci Technol. 2019;94:65–78.

de Oliveira CF, Giordani D, Gurak PD, Cladera-Olivera F, Marczak LDF. Extraction of pectin from passion fruit peel using moderate electric field and conventional heating extraction methods. Innov Food Sci Emerg Technol. 2015;29:201–8.

Xu Y, Zhang L, Bailina Y, Ge Z, Ding T, Ye X, Liu D. Effects of ultrasound and/or heating on the extraction of pectin from grapefruit peel. J Food Eng. 2014;126:72–81.

González-Rivera J, Spepi A, Ferrari C, Duce C, Longo I, Falconieri D, et al. Novel configurations for a citrus waste based biorefinery: from solventless to simultaneous ultrasound and microwave assisted extraction. Green Chem. 2016;18(24):6482–92.

Shishir MRI, Taip FS, Aziz NA, Talib RA, Sarker MSH. Optimization of spray drying parameters for pink guava powder using RSM. Food Sci Biotechnol. 2016;25(2):461–8.

Yapo BM, Robert C, Etienne I, Wathelet B, Paquot M. Effect of extraction conditions on the yield, purity and surface properties of sugar beet pulp pectin extracts. Food Chem. 2007;100:1356–64.

Alcantara-Marte YY, Ramirez-Benitez JE, Arias-Lara GN, Velazquez-Vizcaino ND, Alcantara-Marte YY. Effect of extraction pH and temperature on the physicochemical properties and pectin yield from mango peel (Mangifera indica L.). AGRO Productividad. 2021;14(12):51–9.

Wongkaew M, Sommano SR, Tangpao T, Rachtanapun P, Jantanasakulwong K. Mango peel pectin by microwave-assisted extraction and its use as fat replacement in dried Chinese sausage. Foods. 2020;9(4):450.

Patience NA, Schieppati D, Boffito DC. Continuous and pulsed ultrasound pectin extraction from navel orange peels. Ultrason Sonochem. 2021;73: 105480.

Ciriminna R, Fidalgo AMA, Delisi R. Pectin production and global market. Agro Food Industry Hi Technol. 2016;27(5):17–20.

Ranganna S. Hand book of analysis and quality control for fruits and vegetable products. 2nd ed. New Delhi: McGraw Hill publishing Co., Ltd.; 1995. p. 33–43.

Kamal M, Kumar J, Mamun M, Hamid A, Ahmed M, Uddin N, et al. Extraction and characterization of pectin from Citrus sinensis peel. J Biosyst Eng. 2021;46(1):16–25.

Arioui F, Ait Saada D, Cheriguene A. Physicochemical and sensory quality of yogurt incorporated with pectin from peel of Citrus sinensis. Food Sci Nutr. 2017;5(2):358–64.

Owens HS, McCready RM, Shepard AD, Schultz TH, Pippen EL, Swenson HA, Miers JC, Erlandsen RF, Maclay WD. Methods used at Western Regional Research Laboratory for extraction of pectic materials. USDA Bur Agric Ind Chem. 1952. P.P. 9.

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith FA. Colorimetric method for the determination of sugars. Nature. 1991;168:167.

Kulkarni V. Effect of extraction conditions on the quality characteristics of pectin from passion fruit peel (Passiflora edulis f. flavicarpa L.). Int J Food Sci Technol. 2010;43:1026–31.

Lalnunthari C, Devi LM, Badwaik LS. Extraction of protein and pectin from pumpkin industry by-products and their utilization for developing edible film. J Food Sci Technol. 2019;57:1807–16.

Naik L, Mamatha J, Bhargavi J, Nayomi T, Hema B. Extraction of pectin from orange peels and optimization of process parameters. Int J Comput Sci Eng. 2019; https://doi.org/10.26438/ijcse/v7i6.16.

Kanse NG, Chirag S, Vishal S. Effects of operating parameters on extraction of pectin from orange peel’s. Int J Eng Technol Sci Res. 2018;5(4):981–7.

Kertesz ZJ. The pectic substances. New York: Inter science Publishers Interscience. 1951;432(441), 45 462.

BeMiller JN. An introduction to pectins: structure and properties. Chemistry and function of pectin. American Chemical Society. Washington, America; 1986. pp 2–12.

Canteri-Schemin MH, Fertonani HCR, Waszczynskyj N, Wosiacki G. Extraction of pectin from apple pomace. Braz Arch Biol Technol. 2005;48(2):259–66.

Fakayode OA, Abobi KE. Optimization of oil and pectin extraction from orange (Citrus sinensis) peels: a response surface approach. J Anal Sci Technol. 2018;9(1):1–16.

Mollea C, Chimampo F, Conti R. Extraction and characterization of pectin from cocoa husks: a preliminary study. Food Chem. 2008;107:1353–6.

Rolin C, Whistler RL, BeMiller JN. Pectin In: Industrial gums, New York Academic Press. (eds), 3rd edn. 1993.

Gragasin MCB, Ligisan AR, Torres RC, Estrella R. Utilization of Mango Peels as Source of Pectin. PHilMech Technical Bulletin Vol. 4 No.1. Philippine Center for Postharvest Development and Mechanization. Science City of Muñoz, Nueva Ecija. 2012. 20pp.

Maran JP, Sivakumar V, Thirugnanasambandham K, Sridhar R. Optimization of microwave assisted extraction of pectin from orange peel. Carbohyd Polym. 2013;97(2):703–9.

Liew SQ, Chin NL, Yusof YA. Extraction and characterization of pectin from passion fruit peels. Agric Agric Sci Procedia. 2014;2:231–6.

Ranganna S. Manual of analysis of fruit and vegetable products. New Delhi: McGraw Hill; 1977.

Nahar K, Haque MZ, Nada K, Uddin MN, Abdullah M, Mansur A, Khatun N, Jabin SA. Pectin from ripe peels of mango cultivars. Bangladesh J Sci Ind Res. 2017;52(3):229–323.

Nazaruddin R. Effect of ammonium oxalate and acetic acid at several extraction time and pH on some physicochemical properties of pectin from cocoa husks (Theobroma cacao). Afr J Food Sci. 2011;5(5):790–8.

Yadav SR, Khan ZH, Kunjwani SS, Mular SM. Extraction and characterization of pectin from different fruits. Int J Appl Res. 2015;1(9):91–4.

Rose PAE, Abilasha D. Extraction and characterization of pectin from lemon peel. Int J Adv Sci Res. 2016;1(12):12–5.

Srirangarajan AN, Shrikhande AJ. Technical note: comparative aspects of pectin extracted from the peels of different varieties of mango. J Food Sci Technol. 1979;14(5):539–41.

Madhav A, Pushpalatha PB. Characterization of pectin extracted from different fruit wastes. J Trop Agric. 2002;40:53–5.

Ranajit KS, Yoga NAP, Punichelvana, Asrul A. Optimized extraction condition and characterization of pectin from Kaffir Lime (Citrus hystrix). Res J Agric For Sci. 2013;1(2): 1–11.

Ismail NSM, Ramli N, Hani NM, Meon Z. Extraction and characterization of pectin from dragon fruit (Hylocereus polyrhizus) using various extraction conditions. Sains Malays. 2012;41:41–5.

Rehman Z, Salariya A, Habib F, Shah WH. Utilization of Mango peels as a source of Pectin. J Chem Soc Pak. 2004;26:73–6.

Woo K, Chong YY, Li Hiong SK, Tang PY. Pectin extraction and characterization from red dragon fruit (Hylocerus polyrhyzuz): a preliminary study. J Biol Sci. 2010;10:631–6.

Chan S, Choo W. Effect of extraction conditions on the yield and chemical properties of pectin from cocoa husks. Food Chem. 2013;141:3752–8.

Azad AKM, Ali MA, Akter MS, Rahman J, Ahmed M. Isolation and characterization of pectin extracted from lemon pomace during ripening. J Food Nutr Sci. 2014;2(2):30–5.

D’Addosio R, Pa’ez G, Marı’n M, Ma’rmol Z, Ferrer J. Obtainment and characterization of pectin since of the peel of passion fruit (Passiflora edulis F. Flavicarpa Degener). Faculty Agronomy J—LUZ. 2005;22, 240–249.

Ptichkina NM, Markina OA, Rumyantseva GN. Pectin extraction from pumpkin with the aid of microbial enzymes. Food Hydrocolloids. 2008;22:192–5.

Georgiev Y, Ognyanov M, Yanakieva I. Isolation, characterization and modification of citrus pectins. J BioSci Biotechnol. 2012;1(3):223–33.

Hwang J, Pyun YR, Kokini JI. Sidechanins of pectins: some thoughts on their role in plant cell walls. Food Hydrocolloids. 1993;7:39–53.

Fishman G, Jen F. Thickening and gelling Agents for food. 1st ed. London: Public. Blackies Academic and professional; 1986. p. 175.

Broomes J, Badrie N. Effects of low-methoxyl pectin on physicochemical and sensory properties of reduced- Calorie Sorrel/ Roselle (Hibiscus sabdariffa L.) Jams. Open Food Sci J. 2010;4:48–55.

Aronhime S, Calcagno C, Jajamovich GH, Dyvorne HA, Robson P, Dieterich D, et al. DCE-MRI of the liver: effect of linear and nonlinear conversions on hepatic perfusion quantification and reproducibility. J Magn Resonan Imaging. 2014;40(1):90–8.

Lefsih K, Giacomazza D, Dahmoune F, Mangione MR, Bulone D, San Biagio PL, et al. Pectin from Opuntia ficus indica: optimization of microwave-assisted extraction and preliminary characterization. Food Chem. 2017;221:91–9.

Maran JP, Priya B. Ultrasound-assisted extraction of pectin from sisal waste. Carbohyd Polym. 2015;115:732–8.

Acknowledgements

The authors are grateful to the Laboratory of the Department of Food Processing and Preservation for providing the physical support to conduct the study.

Funding

This study is supported by NST fellowship funded by the Ministry of Science and Technology, Peoples’ Republic of Bangladesh.

Author information

Authors and Affiliations

Contributions

JK: Formal analysis, investigation, writing—original draft; MRR: writing—original draft and editing; FN: original draft, writing—review and editing; MAA: conceptualization, methodology, writing—review and editing; MAS: conceptualization, methodology, formal analysis, investigation, writing—review and editing, supervision, project administration. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The authors conducted the study following by ethical standards.

Competing interests

The authors declare that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sayed, M.A., Kumar, J., Rahman, M.R. et al. Effect of extraction parameters on the yield and quality of pectin from mango (Mangifera indica L.) peels. Discov Food 2, 28 (2022). https://doi.org/10.1007/s44187-022-00029-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44187-022-00029-1