Abstract

Wire Arc Additive Manufacturing (WAAM) is a welding process used to build up three-dimensional structures in steel. Like other Additive Manufacturing technologies, it allows for geometrically-complex structures to be fabricated which are otherwise unfeasible to manufacture using traditional methods. This research paper presents an integrated design approach to the use of WAAM in the context of large-scaled applications, focusing on column variants of gradually-increasing geometric complexity as basis for architectural constructions. It combines material behavior and process para-meter research together with a rudimentary digital twin model, with the aim of providing a digital tool to design architectural structures for WAAM. To achieve the desired geometries, necessary welding parameters are stored and applied to the digital twin model. This is complimented by multiple process-control checks, which are implemented during the printing process to ensure that an object is generated as planned. Finally, the structures are manufactured and are subjected to a critical evaluation in order to identify the possible future potential. The challenge of combining geometric complexity with manufacturing for large scale represents a next step in the integration of WAAM in steel constructions for architectural applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction to WAAM

In addition to the classic manufacturing processes of material removal and forming, additive manufacturing (AM) is another process that has emerged in the manufacturing industry. It can be used to serve complex geometric requirements and allows for integrating functionality in areas that cannot be provided by traditional manufacturing processes or only at extremely high cost. Several of these building materials e.g. concrete and their application cases are under research by the construction industry as well and therefore seem to be a prospective tool of this branch. For the steel construction industry the research into Wire Arc Additive Manufacturing (WAAM) has raised attention. WAAM is an additive manufacturing process based on gas shielded metal arc welding (GMAW), in which a welding/filler wire serves as the printing material. To achieve the desired target geometry and properties, various welding wires - both the usual welding wires made of carbon steel, e.g. G3Si1 [1] as well as various stainless steels [2] – are used. The liquid molten pool, which is produced by the electric arc solidifies in lines or spots and forms three-dimensional structures. The selection of the wire electrode significantly determines the material characteristics of the manufactured structure. The shielding gas serves on the one hand to protect the seam from atmospheric influences and impurities, and on the other hand it stabilizes the heat input of the welding process and influences the molten pool [3]. Compared to other metallic additive manufacturing processes, the WAAM is characterized by a 30 to 40-fold higher application rate [4]. At the same time, investment costs for system technology and supplies are significantly lower [5]. Six-axis robotic systems, shown in Fig. 1, for guiding the welding torch offer greater flexibility in the manufacturing of components and are used to ensure production in large installation spaces. With increasing size, accuracy decreases as the distance to the machine origin extends [6]. These aspects make the process attractive for the manufacture of large architectural components like free form columns.

Column Structures

Introduction

The diversified availability of digital design tools and fabrication techniques has allowed architects to realize more expressive and performative structures. This is particularly apparent in the context of additive manufacturing, where standardized structural systems, including floor slabs [7], walls [8] and beams [9] are reimagined as geometrically-complex and structurally-efficient members. The same may also be said for column-type structures; the researchers at Bologna University, together with MX3D, illustrated the potentials of combining digital design tools with additive manufacturing by producing a large-scale lattice-type column structure [2]. Similarly, researchers at ETH Zurich also made use of the creative freedoms that AM had to offer and incorporated these into the design of column structures; The Smart Dynamic Casting (SDC) used an adaptable slip-formwork to gradually build up reinforced concrete columns with varying cross-section [10]. Building on the use of generative design tools to inform architectural systems, the Subdivided Columns by Hansmeyer [11] are a result of generating ornamental textures through a set of pre-defined design rules. As Hansmeyer describes, the architect is placed in the position of developing a set of design rules, particularly, the subdivision of an initial mesh geometry, which may be continuously run to create endless permutations of ornamental column structures; effectively rendering an architect as an orchestrator rather than designer.

Investigated 3d printed column structures

The research presented in this paper lies within the context of combining digital design tools and WAAM to manufacture performative and expressive column structures, which are cost-intensive or impossible to produce using conventional manufacturing processes. The column structures of our choice are shown as scale models in Figs. 2a and f. The transfer to large column structures spanning several meters and adapted wall thicknesses is equally possible, but limited by the radius of action of the robot. In these cases, the entire structure must be manufactured in segments, at the end of which the individual components are welded together either in the factory or on the construction site.

While model (a) consists of an additively manufactured column with an octagonal cross-section, which gradually twists as height increases, showcasing some of the possibilities for expressive architectural shapes (Figs. 2b and c), the column (f) is manufactured as a structure with an ellipsoid cross-section (d) of varying width. It forms the basis for the manufacturing of a column shape shown in Fig. 2e, whose cross-sectional dimensions are maximum in the center column height and tapered in the area of the supports. The designed column shapes can correspond to varying force distributions and still be architecturally appealing. In this case, the structure is given a smaller cross-sectional area at the base and top, where bending moments are expected to be less due to a hinged bearing, and a larger cross-sectional area in the center.

Although the structures are relatively simple in terms of geometry (Figs. 2a and f), they are intended to serve as the first iteration into more geometrically-complex columns defined by material deposition limitations such as maximum overhangs, minimum cross-sectional areas and wall thicknesses. This approach of manufacturing could be combined with other design factors such as shape optimization in order to maximize load carrying capacity. Column (f), which is not intended for load bearing capacity tests, forms the basis of this paper, where mainly the feasibility for additively manufactured columns, with highly variable cross sections - stronger than for (f) - will be investigated. Moving forward we will also focus on the "design to production" workflow for additive manufacturing of the structure.

Design to Production Workflow

One of the common misconceptions in additive manufacturing is that it is a “plug-and-play” process, in which a 3D model is divided into layers (slicing), which are then converted into motion instructions, or g-code which is uploaded to a printer. With such a setup, the flow of information between the digital model and the printed geometry stops there; and the ability to adaptively update the position of a 3D printer in response to the printed geometry is lost. In reality, there are often differences, especially in WAAM, some of which may be quite significant, between a design geometry and what is actually printed. These variances may include, but are not limited to, discrepancies in layer heights or distortion of the printed structure during printing. Therefore, the ability to adjust robotic motion paths, layer-heights and welding parameters is critical to ensure a stable printing process.

In response, this research establishes a workflow from design to production (Fig. 3). The digital model, generated with the design tool Rhinoceros 3d, contains information on process and input parameters, welding layer geometries and material properties. The weld paths are generated by means of parametric robot programming (PRP), a coordinate determination based on mathematical functions (see chapter Parametric Robot Programming). A feedback of information from the column in production with the digital model by the robot controller enables adaptive updating of the weld paths according to the required production.

During manufacturing, data like welding, cooling, measuring and movement times, as well as the measured layer heights of the manufactured structure are recorded for each layer. The final evaluation of the recorded data, supplemented by 3D scanning for a target/actual comparison, is used to generate welding and milling trajectories for a surface finish, which is not part of this article, as well as to determine, for example, optimized movement sequences or cooling and measuring processes. All stored information results in a rudimentary Digital Twin within the design tool. This was essential in ensuing proper process control as it allowed for a partially real-time feedback of information between the initial 3D geometry and data generated during the printing process.

Process and input parameters

A layer deposition under a stable welding process depends significantly on the selected welding and input parameters, which influence the geometric dimensions of a weld layer and the subsequent material properties [12]. The material deposition is decisively controlled by the defined travel speed (TS), the wire feed speed (WFS) and the CMT process regulation [13]. Fronius offers the "CMT Cycle Step", a welding process in which the ratio of material application (CMT cycles) to the predefined pause interval for the solidification of the melt can be selectively controlled. This targeted control is essential for the additive manufacturing of free-formed column structures with overlaying layer deposition, for which dripping of the molten material (Fig. 6) must be prevented. Table 1 lists the welding parameters for a Fronius CMT Advanced 4000 R welding source with a CMT Cycle Step characteristic and relevant process parameters.

To prevent the weld metal from dripping a cooling, explained in detail in chapter Process Sequence Parameters, is set after each welding so the structures can cool down.

Material characteristics

To determine the load-bearing capacity of an additively manufactured structure, the material properties were first determined. Table 2 lists the minimal material properties of the wire electrodes Weko 2 G3Si1 and Weko 2 G4Si1 which serve as a reference [14]. Then the measured average material characteristics and standard deviation for each tensile specimen sample line – consisting of three samples each - according to DIN 50125 - E [15] are given. They were recorded in tensile tests on a universal testing machine of the Institute for Steel Construction and Materials Mechanics of the Technical University of Darmstadt with a maximum tensile or compressive force of 100 kN. The specimens samples 1Seam-milled-45 and 1Seam-milled-90 were milled out of cantilevered wall structures (shown in Fig. 4d). They consist of one welding seam per layer with an inclination of 45° and 90° to a vertical material deposition. More detailed information can be found in [16]. The specimens of 2Seams-as built-0 (b) and 2Seams-milled-0 (c) were printed vertically with two welding seams in each layer (a), providing milled and as built surfaces.

In addition to the yield strength Re and the ultimate strength fu, the elongations at fracture were determined according to DIN EN ISO 6892-1 eq. 6. However, the focus of these investigations is on the ultimate strength.

The results show, that the minimum yield strength and the minimum ultimate strength are almost equal or slightly above (except 1Seam-milled-45) the wire manufacturer's specifications within the range of the standard deviation. The same applies to the measured elongation at fracture. The consistent results allow using the material properties of the wire electrode as parameters for the rudimentary digital twin while they should be supplemented by means of further tensile tests.

Parametric Robot Programming

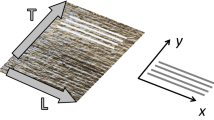

Central to the ability to update welding paths according to recorded information is the use of Parametric Robot Programming (PRP). This process, which has already been illustrated in [17], differs from conventional robot programming in that coordinates are generated by means of mathematical functions which are defined by information recorded during the printing process. Due to the fact that in conventional slicing (Fig. 5a), every single coordinate has to be precalculated and sent as a line of code, the data files generated by PRP (Fig. 5b) are, in most cases, far smaller than conventional ones. In PRP, a series of loops are used to define each layer and equations (right) illustrate how an ellipsoid with varying cross-section can be defined by two loops using Cosine and Sine angles.

The manufactured columns are characterized by a layer deposition with continuously changing transverse offset which influences the layer height. Fig. 6a schematically illustrates the material deposition in vertical orientation and for different overhang angles αt shown in Fig. 6b to d. Up to a horizontal offset of about 10 % of the weld thickness t, a stable process results with angles αt and in layer heights h depending on the selected offset (Fig. 6e)

Above α0.25t, the molten material starts to drip off under neutral torch position [16, 18], so that an unforeseen loss of material and height occurs. In addition, the contact tip to work distance (CTWD) which describes the distance between the contact tip of the welding gun and the work piece changes. In case of significant deviations, this has an influence on the layer width and height to be applied, which would further cause an unplanned manufacturing of the column geometry and could lead to an interruption of the welding process. The PRP prevents this error development during the manufacturing process by dynamically adjusted weld paths through permanent monitoring of the geometric height development of the column structure.

Process Sequence Parameters

WAAM offers various possibilities of building structures. The manufacture of each individual layer is determined by the process sequence parameters. These are shown in Fig.7. First, the x and y coordinates of the 150 weld path coordinates are calculated as a function of the height that has already been manufactured.

It includes a slight change of the starting welding point of each layer (shown in Fig. 8c (left)) because at a constant speed, welds are higher at the starting point and lower at the end-point than in the rest area [19]. In addition the welding seam thickness at the start point is increased. To prevent a punctual error propagation of the layer height, the starting point of each layer was changed by an additional rotation angle. The layer than can be welded with the welding and input parameters given above while welding data and time consumption is saved to the twin.

To ensure an interpass layer temperature of less than 150 °C and a reduction of the cooling time, the columns are cooled for at least 25 s with an automated compressed air cooling system with additional water mixture. The control was carried out with a pyrometer at the upper last applied welding layers. A converted minimum quantity lubrication system with water was used for the purpose of cooling. The water evaporates on the surface of the column, extracting the heat from the body faster than it would for pure compressed air. No negative influences on the metallurgical properties and microstructures were detected for this cooling method [20].

The touch sensing method – a tactile measuring method – is used to measure the current z-height of the structure. For this process the filler wire is automatically cut by a wire cutting station to a defined length and a small voltage is applied. While slowly moving the wire vertically onto the workpiece the respective coordinates of the wire touching the surface are recorded by the robot. These coordinates can now be used to calculate the corresponding layer height. This is executed automatically by the program code so the CTWD stays on a constant value.

Similar to the welding parameters, characteristics influencing the measurement were examined in preliminary investigations to enable a precision of 0.2 mm accuracy. These included the CTWD, the motion and acceleration profile of the robot, the orientation of the welding torch to the target surface and the distance at the start of the tactile measurement. Fig. 8c (right) shows the results of 18 points from every 10th measured layer. These are used to determine a layer height by section. Erroneous measurements outside of a tolerance range of ±1.5 mm to the expected layer height (caused by welding slags for example) are firstly remeasured and then not taken into account in case they still consist.

Evaluation

For the 52.2 cm high scaled column model, shown in Fig. 8a, 400 welding layers were applied. This corresponds to an average layer height of 1.304 mm. The ellipse had maximum major and minor radii of 150 mm and 100 mm respectively and a minimum cross sectional dimension of 32 mm. Fig. 8b shows the evaluation of the manufacturing process and the result of the target/actual comparison.

It shows one side of the target/actual comparison of the digital model and the scanned solid model determined by means of the FARO Freestyle 2 handheld scanner (left) and the rendered surface (right). The deviations are homogeneous, and range between 0.0 to 0.3 mm from the lower to the upper part, with a maximum of 0.8 mm at the upper edge of the column.

At this point, the scan result shows a lower accuracy. This is highlighted by the dot-like dark grey areas of the rendered scan of the right half of the column, which are not shown in Fig. 8a.

Fig. 8c (left) shows the progression of the coordinate points and their changing horizontal distance, ∆d, for each layer. In the section of the tapered cross-section between layers 200 to 300, the distance decreases below the limit value to be processed by the robot controller. In this area, only every fifth weld path coordinate has to be approached due to the weld path density. The geometry of the column is not unexpectedly affected by this. Illustrated in Fig. 8c (right) the evaluation of the tactile height measuring for every 10th layer over one half of the column is given. The vertically significantly deviating measurement shown in the enlargement – the measured height is in the existing structure – is erroneous and was not taken into account in the averaged height determination consisting of 18 recorded values. The small number of faulty deflections illustrates the reliability of the information generated by the touch-sensing method for the rudimentary digital twin.

Fig. 8d shows the time spent for the manufacturing of the column divided into welding time (continuous line), cooling time (dotted line) and measuring time (crosses) for the tactile detection of the layer heights. The 10 fluctuations of the red curve, especially up to layer 100, indicate interruptions in the welding process, e.g. due to wire stuck, which led to an interruption of the material deposition. The applied mass of 5.12 kg was deposited within 3.35 hours of pure welding time, which corresponds to a deposition rate of 1.52 kg/h. The red curve shows a variation in the course of the cooling time. The different lengths of the tactile measurement processes are the result of faulty measurements, which meant that measurements had to be repeated.

All evaluated data are stored in the rudimentary digital twin. They can serve as reference values for a reproduction and the manufacture of an upscaled column structure.

Conclusion

This paper described the manufacturing of scaled columns using WAAM. The process follows a design-to-production workflow that results in a rudimentary digital twin in addition to the physical structure. The selected process parameters, in conjunction with parametric robot programming and frequent touch-sensing, guarantee a stable manufacturing process with simultaneous high geometric correspondence between the nominal and real models. The material properties determined in preliminary tensile tests show no significant deviations to the minimum required properties given by the manufacturer. Two columns were manufactured using the presented workflow while for the cross section changing ellipsoid detailed information about the collected data were given in this paper. In a further step the rudimentary digital twin could be combined with a shape optimization in order to maximize the load-carrying capacity. An evaluation of the recorded measuring data, stored in the digital twin, provides the basis for a post-processing of the surfaces and the improvement of the manufacturing process.

References

Williams S, Martina F, Addison AC et al (2016) Wire + Arc Additive Manufacturing. Mater Sci Technol 32:641–647. https://doi.org/10.1179/1743284715Y.0000000073

Laghi V, Palermo M, Gasparini G et al (2020) Computational design and manufacturing of a half-scaled 3D-printed stainless steel diagrid column. Additive Manuf 36:101505. https://doi.org/10.1016/j.addma.2020.101505

Kampffmeyer D, Wolters M (2015) Moderne Schutzgase zum MAG-Schweißen von unlegierten Stählen. In: DVS-Berichte, vol 315. DVS Media GmbH, Düsseldorf, pp 249–253

Bergmann JP, Henckell P, Reimann J et al. (2018) Grundlegende wissenschaftliche Konzepterstellung zu bestehenden Herausforderungen und Perspektiven für die Additive Fertigung mit Lichtbogen: Studie im Auftrag der Forschungsvereinigung Schweißen und verwandte Verfahren e.V. des DVS. DVS-Berichte, Band 345. DVS Media GmbH, Düsseldorf

Martina F, Williams S (2015) Wire+arc additive manufacturing vs. traditional machining from solid: a cost comparison. Cranfield University, Cranfield

Bandari Y, Williams S, Ding J et al. (2015) Additive manufacture of large structures: robotic or CNC systems? In: 26th international solid freeform fabrication symposium. Austin, Texas

Jipa M-A, Aghaei Meibodi M, Giesecke R et al. (2018) 3D-Printed Formwork for Prefabricated Concrete Slabs. In: 1st International Conference on 3D Construction Printing, vol 1. ETH Zurich, Digital Building Technologies (ITA), Melbourne, Australia

Hack N, Kloft H (2020) Shotcrete 3D Printing Technology for the Fabrication of Slender Fully Reinforced Freeform Concrete Elements with High Surface Quality: A Real-Scale Demonstrator. In: Bos FP, Lucas SS, Wolfs RJ et al. (eds) Second RILEM International Conference on Concrete and Digital Fabrication, vol 28. Springer International Publishing, Cham, pp 1128–1137

Francesca Moretti (2015) 3d printed concreate beam. https://www.3dwasp.com/en/concrete-beam-created-with-3d-printing/. Accessed 29 Nov 2021

Lloret Fritschi, E. et al. (2017) Smart Dynamic Casting – Slipforming with flexible formwork - inline measurement and control in: Norwegian Concrete Association [Hrsg.] Eleventh High Performance Concrete (11th HPC) and the Second Concrete In-novation Conference (2nd CIC). Tromsø, Norwegen. Oslo: Norwegian Concrete Association. https://doi.org/10.3929/ethz-b-000219663

Michael Hansmeyer - Computational Architecture (2021) Michael Hansmeyer - Subdivided Columns. https://www.michael-hansmeyer.com/subdivided-columns#. Accessed 29 Nov 2021

Almeida PMS (2012) Process control and development in wire and arc additive manufacturing. Dissertation, Cranfield University

Fronius, Bruckner J, Egerland S et al. (2013) Schweißpraxis aktuell: CMT-Technologie : Cold Metal Transfer - ein neuer Metall-Schutzgas-Schweißprozess, März 2013. WEKA MEDIA GmbH & Co. KG., Kissing

Westfälische Drahtindustrie GmbH Abt. Schweisstechnik (2012) Schweisstechnik High Quality Welding Wire: Technisches Handbuch, 3. Edition, Hamm

DIN Deutsches Institut für Normung e. V. (2016) DIN 50125:2016-12: Prüfung metallischer Werkstoffe - Zugproben

Feucht T, Erven M, Waldschmitt B et al. (2021) Einfluss des Schutzgases auf auskragend gefertigte WAAM-Strukturen. In: DVS-Berichte, 1. Auflage 2021, vol 371. DVS Media GmbH, Düsseldorf, pp 301–307

Feucht T, Lange J, Erven M et al (2020) Additive manufacturing by means of parametric robot programming. Construction Robotics 4:31–48. https://doi.org/10.1007/s41693-020-00033-w

Kazanas P, Deherkar P, Almeida P et al (2012) Fabrication of geometrical features using wire and arc additive manufacture. Proc Inst Mech Eng Part B: J Eng Manuf 226:1042–1051. https://doi.org/10.1177/0954405412437126

Zhang Y, Li P, Chen Y et al (2002) Automated system for welding-based rapid prototyping. Mechatronics 12:37–53. https://doi.org/10.1016/S0957-4158(00)00064-7

Feucht T, Lange J, Waldschmitt B et al. (2020) Welding Process for the Additive Manufacturing of Cantilevered Components with the WAAM. In: Da Silva LFM, Martins PAF, El-Zein MS (eds) Advanced Joining Processes, vol 125. Springer Singapore, Singapore, pp 67–78

Acknowledgments

We would like to thank the companies Fronius Deutschland GmbH, Messer Group GmbH, WDI Schweißtechnik GmbH, Comau Deutschland GmbH and DDU of TU Darmstadt for their kind support.

Funding

Open Access funding enabled and organized by Projekt DEAL. This research was funded by the Bundesministerium für Wirtschaft und Energie (Grant Number: 16KN076133).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Waldschmitt, B., Costanzi, C.B., Knaack, U. et al. 3d printing of column structures for architectural applications. Archit. Struct. Constr. 2, 565–574 (2022). https://doi.org/10.1007/s44150-022-00050-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s44150-022-00050-z