Abstract

In this study, we aimed to fabricate nanostarch (NS) reinforced polyaniline/polyvinyl alcohol (PANI-PVA) bionanocomposite of polyaniline-polyvinyl alcohol-nanostarch for skin tissue engineering application. The microstructure of the bionanocomposite was analyzed using TEM and the particle size ranged from 35 to 37 nm. The swelling degree was increased with the increase in the concentration of nanostarch and displayed a greater hydrophilic surface leading to the increase in the absorption. The degradation index analysis was recorded with an increase in the weight loss of the scaffold which attributed to a strong hydrogen bond network. The bionanocomposites exhibited 70% to 82% of cytocompatibility towards L929 cells during the incubation period of day 1, day 4 and day 7. Hence, the novel bionanocomposite with the features of enhanced water-holding capacity, weight loss percentage and cytocompatibility made it suitable for the prospective use in skin tissue engineering applications.

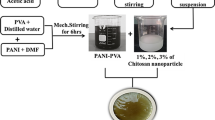

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The regeneration of repaired tissues caused by infections, injuries, tumours, and deformities is a rising problem of the present day. It is the greatest challenge to address the problems associated with treating tissue diseases by conventional therapy. Tissue engineering has emerged as a potential technique to restore the infected tissues by applying a variety of hybrid biomaterials. This approach restores the retention of the damaged tissues to their early stages of tissue growth and allows them to regrow. The natural, synthetic, conductive polymers and the hybrid biomaterials are utilized as synthetic extracellular matrix [1]. At the molecular level, organic biopolymers and nanoparticles are used to fabricate bionanocomposite scaffolds with good mechanical, structural, economic, and environmental properties [2]. Moreover, these biomodulated biomaterials create the physiological environment for tissue repair and regeneration, and the transportation of nutrients and metabolites by controlled release of signal molecules. The fabricated biomaterials act as an extracellular matrix to organize and reconstruct the tissues into three-dimensional architecture [3].

Polyaniline (PANI) is a well-known conductive polymer that has drawn a lot of interest in a variety of industrial and biological applications because of its simple synthesis, low cost, high electrical conductivity, biocompatibility, low toxicity, and environmental stability [4, 5]. They can stimulate biological activity at the polymer-tissue interface, such as cell adhesion, migration, proliferation, differentiation, and protein secretion, in addition to being biocompatible [6, 7]. However, the disadvantages of PANI such as low solubility in the most common solvents, infusibility and weak processability have to be encountered. This has resulted in the advancement of several techniques, such as re-doping with functionalized organic acids, copolymerization with other polymers or PANI derivatives, and the establishment of blends and bionanocomposites using a variety of materials, making it a promising material for both biomedical and industrial applications [8].

The advantages of polyvinyl alcohol (PVA) as a synthetic polymer include its capacity to be generated in a repeatable manner under well-regulated conditions and to be made readily available in practically infinite quantities. It is fabricated with a variety of physical, chemical, and mechanical properties that can be easily adjusted chemically [9, 10]. PVA as a single polymer does not display every desirable trait for biomaterials. As a result, PVA is coupled with natural or synthetic polymers to fabricate the composite material improving the overall physicochemical and biological properties of produced scaffolds that are biocompatible, biodegradable, conducting, and infection resistant to support tissue formation [11, 12].

Nanoscale materials commonly have distinctive characteristics due to their very tiny size and are utilized for a variety of biomedical and biotechnological applications. Nanopolysaccharides are used as reinforcing agents to develop bionanocomposite due to the hydroxyl group at their surface. For the present work, we have taken nanostarch, a natural polymer, that can be tailored to match a defect in a difficult physiological geometry and can be used in tissue engineering for a variety of functions, such as matrix formers, gelling agents, and drug release modifiers. It has been well studied in preclinical investigations using a range of animal models, including primates, and the published work indicated its usefulness in tissue engineering applications [13, 14]. However, starch has low physical stability in fluids because it degenerates quickly under aqueous circumstances. Researchers have asserted that mixing nanostarch with synthetic polymers improves its biocompatibility, water solubility, and degradability to make up this drawback [15, 16]. Collecting the strength and liabilities of all these polymers highlighted above we have decided to prepare a novel bionanocomposite by the reinforcement of nanostarch in PANI-PVA polymer matrix and analysed its physicochemical behaviour and the in-vitro cell culture studies to indicate its promising role as supporting material for skin tissue engineering application.

2 Experimental

2.1 Materials

Polyvinyl alcohol (MW = 85,000–1,24,000 g/mol with 98% of the degree of hydrolysis) and waxy maize starch (MW = 828.718 g/mol) were purchased from Sisco Research Laboratories Pvt. Ltd. Mumbai, India and were used as received. Double distilled aniline (MW = 93.13 g/mol), Ammonium Persulphate, Hydrochloric acid, Dodecylbenzene Sulfonic acid, Dimethylformamide, Sulphuric acid, deionised water and the other chemicals of analytical grade reagents were purchased from Spectro chemicals Pvt. Ltd. Mumbai, India.

2.2 Synthesis of PANI-PVA-NS bionanocomposite

NS was synthesized by promoting the acid hydrolysis of waxy maize powder with sulfuric acid. PANI was prepared by chemical oxidative polymerization of aniline using hydrochloric acid as a dopant, DBSA as a surfactant and ammonium persulphate as an oxidant. The PANI-PVA mixture was incorporated with various proportions of NS (1%, 2%, and 3%) for the synthesis of PANI-PVA-NS bionanocomposites. The resulting product was then magnetically stirred for 6 h at room temperature before being poured into Petri dishes and allowed to dry at room temperature for three days to yield thin films [17].

2.3 Characterization of PANI-PVA-NS Bionanocomposite

2.3.1 Microstructural characterization

The dispersion of nanostarch in PANI-PVA polymer matrix and its microstructure was examined by Transmission electron microscopy (TEM, Philips CM 200 model).

2.3.2 Swelling degree

In order to study swelling behaviour, a known weight of dry scaffold (W0) was immersed for two hours in a beaker containing 50 mL of 0.1 M PBS at a pH of 7.4 at 32 °C. The samples were then taken out of the beaker, placed between filter paper and was pressed gently for 1 min to drain excess water, which was then weighed (W1). The weight of swollen scaffold at every 2 h for 4 times was found as a fraction of the dry weight using the formula,

where Ws is the weight of the wet scaffold (g), W0 is the weight of the dry scaffold (g).

2.3.3 In-vitro degradation percentage profile

In-vitro degradation of the samples was studied in phosphate buffer solution (PBS) under pH 7.4 at 37 °C. The developed sample of size 10 mm × 10 mm was incubated in test tubes containing 15 ml PBS. The tubes were stored in a water bath at 37 °C for 50 days. The pH value of PBS was measured every ten days total for a total of 50 days and then the percentages of weight loss (%Wt loss) of the samples were calculated using the formula

where W0 is the original weight of dry scaffold and Wt is the weight of the scaffold at time t.

2.4 Cell experiment

2.4.1 Cell line culture

The L929- fibroblast cells were incubated in a regular growth medium containing Dulbecco’s modified eagle medium (DMEM) with 10% fetal bovine serum, 1% penicillin and streptomycin. The cells were then seeded at a density of 2 × 104 cells/mL onto the PANI-PVA-NS (1%, 2% and 3%) scaffolds. The cell-scaffold constructs were incubated in an incubator with 5% CO2 at 37o C, and the medium was changed every 2 days. The fibroblast cells in a regular growth medium without the scaffolds served as the control group.

2.4.2 Cell seeding

To determine the cytocompatibility of PANI-PVA-NS scaffolds, circular scaffolds (ɸ = 15 mm) were plated in 24-well plates and subsequently immersed in a DMEM medium containing 10% fetal bovine serum, 1% penicillin and streptomycin. L929 fibroblast cells were then seeded at a density of 2 × 104 cells/mL onto the scaffolds. The cell-scaffold constructs were incubated in an incubator with 5% CO2 at 37 °C. The medium was changed every 2 days.

2.4.3 Cell viability using MTT assay

The MTT cell viability test was used as an indicator to evaluate the cell compatibility of the scaffolds. The cell viability of L929 fibroblast cells on the surface of the scaffold was determined quantitatively using 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) which is a soluble yellow dye. It makes a mitochondrial reductase in living cells to reduce into an insoluble purple dye called formazan [(E,Z)-5-(4,5-dimethylthiazol-2-yl)-1,3-diphenylformazan]. The dye remains inside the cells until being extracted by DMSO. The PANI-PVA with different proportions of NS (1%, 2% and 3%) was dispersed in 24-well plates. L929 fibroblast cells were then seeded at a density of 2 × 104 cells/ml onto the scaffolds. The scaffolds were incubated at 37 °C with 5% CO2 for 3 h. DMEM containing 10% fetal bovine serum (Invitrogen), penicillin (50unit/ml) and streptomycin (50 unit/ml) were added and incubated with 5% CO2 at 37 °C. This medium was utilized to grow L929 fibroblast cells and were quantified by MTT assay. The medium was changed every 2 days and the scaffolds were observed under a microscope. One of the wells without the scaffold was used as the control. After 1, 4 and 7 days of culture the cell viability was measured quantitatively by MTT assay, which is a colorimetric technique to determine the number of viable cells. The cell extracts from the scaffold were mixed with MTT solution and the absorbance at 550 nm was measured on a microplate reader.

2.4.4 Cell proliferation

The viability of the scaffolds was evaluated by fluorescent staining of live cells in green (by 200 mM calcein–AM, in Invitrogen) and dead cells in red (by 400 mM ethidium, Invitrogen). After being proliferated for 1, 4 and 7 days the cells were washed three times with PBS and stained by calcein-AM and ethidium in the dark. The cells cultured on the scaffold were analyzed with an inverted fluorescence microscope after the addition of dye in the incubator with 5% CO2 at 37 °C.

3 Results and discussion

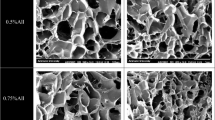

3.1 Microstructural existence

The microstructure of PANI-PVA-NS (1%, 2% and 3%) was examined using a Transmission electron microscope. The microstructural images exhibited the lamellar structure consisting of a stack of elongated elements of the nanostarch in the PANI-PVA matrix as we have reported in our previous study [18]. The TEM images in Fig. 1 display the homogeneous dispersion of nanostarch in PANI-PVA-NS (1%, 2% and 3%) bionanocomposite [19]. The uniform dispersion of the nanoparticles confirms the absence of agglomeration of NS in the bionanocomposite which can be attributed to the existence of an efficient bond between PANI-PVA and nanostarch. The increase in the concentration of NS leads to the increased surface area of the porous scaffold and encourages nutrition delivery, better protein absorption, neovascularization, cell adhesion and cell survival at the site of tissue regeneration.

3.2 Swelling degree and in-vitro degradation profile

The swelling degree of the prepared samples is presented in Fig. 2a. Reinforcement of nanostarch significantly altered the swelling capacity of PANI-PVA-NS (0%, 1%, 2% and 3%) with the most significant increase in PANI-PVA-NS3%. The reason for the higher swelling rate of bionanocomposite is due to the presence of hydrogen bonding between the water molecules and the free OH group present in NS. The hydrophilic nature of PVA and NS might be a major factor that impacts the enhanced swelling of the PANI-PVA matrix. As we have previously reported [17] the swelling degree of all bionanocomposites increased with time up to 300 min, reached a maximum, and then decreased over the next 300 min. We have extended the examination of the swelling degree for the next 2 h which displayed a continuous decrease in the swelling concerning extended time. Thus, considering the results of the swelling degree, all samples were suitable to be used as a skin tissue engineering scaffold.Figure 2b displays the comparison in the percentage weight loss rate of bionanocomposite immersing in PBS and the results are recorded every ten days total for a total of 50 days. It prescribes information on the PBS intake property of the scaffold which is typically substantial in applications where the scaffold must come into contact with a fluid, such as tissue engineering applications [20]. The quantitative measures of the scaffold indicate that the introduction of NS into the PANI-PVA matrix significantly accelerates the percentage of degradation. It can be noticed that PANI-PVA resulted in a lower percentage and swelling when compared with the NS reinforced bionanocomposite of PANI-PVA-NS (1%, 2% and 3%). It was in the range of 0.032, 0.025, 0.023 and 0.021 g/10 days which was in good agreement with our previous report [17]. The biodegradation of PANI-PVA-NS 3% was attributed to the increase in the number of hydroxyl groups causing the hydrophilicity which was an essential requirement in the degradation of any material. The homogenous microstructure, water-holding capacity and the large surface area of the bionanocomposites allow the degradation and absorption at the same proportion as new tissues originates during the regeneration process. Therefore the results suggest that the developed scaffold can be a supportive material for a tissue engineering application.

3.3 L929 cell experiment

3.3.1 Cell viability by MTT assay

It is a fundamental necessity to investigate the cytotoxicity of a scaffold for skin tissue engineering application. It helps to accomplish mitochondrial activity as a measure of viable cells, because only living cells are likely to be able to convert MTT to formazan, the colorimetric byproduct of the quantified reaction. Using the MTT assay, the cell viability test on the fabricated bionanocomposite of PANI-PVA-NS (1%, 2%, and 3%) was evaluated against L929 fibroblast cells. For 7 days, the cells were exposed to the scaffolds with the concentrations of NS (1%, 2% and 3%). The results showed that the biocompatibility was between 70 and 82% [21]. The viability of L929 cells is shown in Fig. 3a following 1, 4 and 7 days of incubation on the scaffolds. A difference in cell growth was seen in the study between PANI-PVA-NS1% (70%), PANI-PVA-NS2% (74.8%), and PANI-PVA-NS3% (82%). The results clearly demonstrated that the higher concentration of NS3% increased the compatibility indicating better cell attachment, spreading and had no negative impact on cell proliferation. This is because nanostarch promotes the large surface area and the combination of PANI and PVA in the matrix must have encouraged cell adhesion to the substrate thereby providing ideal conditions for cell growth.

3.3.2 Live/dead cells by fluorescence image

A cell viability assay was performed on the ratio of live and dead cells. Figure 3b display the fluorescence microscopic observations of L929 fibroblast cells on PANI-PVA-NS (1%, 2% and 3%) scaffolds. The images taken after 1, 4 and 7 days of culture were labeled with live-dead stains where the green fluorescence denoted the live cells and the red fluorescence denoted the dead cells. The presence of green fluorescence on all the culture groups indicated the potential cytocompatibility of the bionanocomposites. This could be attributed to the architecture of the bionanocomposite of PANI-PVA-NS that mimic the ECM nanostructure of the tissues. PANI-PVA-NS3% exhibited low toxicity to the fibroblast cell over a broad range of concentration adequate for potential biomedical applications. Hence the scaffold’s result is an important safe guarantee for their use in further in vivo biomedical applications.

4 Conclusion

The present study demonstrated the characterization of PANI-PVA-NS bionanocomposite by physicochemical and in vitro degradation, cytotoxicity test compared with PANI-PVA scaffolds for skin tissue engineering application. The results confirmed that the uniform dispersion of NS in the polymer matrix promotes the degree of swelling allowing the bionanocomposites to exhibit enhanced degradation in PBS at the highest ratio of NS 3%. The cytotoxicity analysis displayed greater non-toxicity and the viability profile of PANI-PVA-NS 3% was due to the presence of an increased number of hydrophilic groups which promoted cell–matrix interactions providing more binding sites and sufficient biomechanical support for the cells to grow. Thus, given the structural characteristics and in vitro biological assays demonstrated that the PANI-PVA-NS bionanocomposite scaffold could be given significant consideration for skin tissue engineering application.

Availability of data and material

The datasets generated during and/or analyzed during the current study are not publicly available due to the ongoing research project but are available from the corresponding author on reasonable request.

References

Shanmugam BK, Rangaraj S, Subramani K, Srinivasan S, Aicher WK, Venkatachalam R (2020) Biomimetic TiO2-chitosan/sodium alginate blended nanocomposite scaffolds for tissue engineering applications. Mater Sci Eng C 110:110710

Pandit AH, Mazumdar N, Ahmad S (2019) Periodate oxidized hyaluronic acid-based hydrogel scaffolds for tissue engineering applications. Int J Biol Macromol 137:853–869

Zarei M, Samimi A, Khorram M, Abdi MM, Golestaneh SI (2021) Fabrication and characterization of conductive polypyrrole/chitosan/collagen electrospun nanofiber scaffold for tissue engineering application. Int J Biol Macromol 168:175–186

Moutsatsou P, Coopman K, Georgiadou S (2017) Biocompatibility assessment of conducting PANI/chitosan nanofibers for wound healing applications. Polymers (Basel). https://doi.org/10.3390/polym9120687

Bertuoli PT, Ordono J, Armelin E, Pérez-Amodio S, Baldissera AF, Ferreira CA et al (2019) Electrospun conducting and biocompatible uniaxial and coreshell fibers having poly(lactic acid), poly(ethylene glycol), and polyaniline for cardiac tissue engineering. ACS Omega. https://doi.org/10.1021/acsomega.8b03411

Saeb MR, Zarrintaj P, Khandelwal P, Chauhan NPS (2019) Synthetic route of polyaniline (I): conventional oxidative polymerization. Fundamentals and emerging applications of polyaniline. Elsevier, Amsterdam

Nezakati T, Seifalian A, Tan A, Seifalian AM (2018) Conductive polymers : opportunities and challenges in biomedical applications. Chem Rev 118:6766–6843

Bhandari S (2018) Polyaniline: structure and properties relationship. In: Visakh PM, Pina CD, Falletta E (eds) Polyaniline blends, composites, and nanocomposites. Elsevier, Amsterdam, Netherlands, pp 23–60

Kanimozhi K, Basha SK, Kumari VS, Kaviyarasu K (2018) Development of biomimetic hybrid porous scaffold of chitosan/polyvinyl alcohol/carboxymethyl cellulose by freeze-dried and salt-leached technique. J Nanosci Nanotechnol 18(7):4916–4922

Das A, Uppaluri R, Das C (2019) Feasibility of poly-vinyl alcohol/starch/glycerol/citric acid composite films for wound dressing applications. Int J Biol Macromol 131:998–1007

Kanimozhi K, Basha SK, Kumari VS, Kaviyarasu K, Maaza M (2018) In vitro cytocompatibility of chitosan/PVA/methylcellulose–nanocellulose nanocomposites scaffolds using L929 fibroblast cells. Appl Surf Sci 449:574–583

Christy PN, Basha SK, Kumari VS (2022) Nano zinc oxide and nano bioactive glass reinforced chitosan/poly (vinyl alcohol) scaffolds for bone tissue engineering application. Mater Today Commun 31:103429

Aktürk A, Taygun ME, Güler FK, Goller G, Küçükbayrak S (2019) Fabrication of antibacterial polyvinylalcohol nanocomposite mats with soluble starch-coated silver nanoparticles. Colloids Surf A 562:255–262

Poonguzhali R, Basha SK, Kumari VS (2018) Fabrication of asymmetric nanostarch reinforced Chitosan/PVP membrane and its evaluation as an antibacterial patch for in vivo wound healing application. Int J Biol Macromol 114:204–213

Dara PK, Gk S, Deekonda K, Rangasamy A, Mathew S, Cn R (2021) Biomodulation of poly (vinyl alcohol)/starch polymers into composite-based hybridised films: physicochemical, structural and biocompatibility characterization. J Polym Res 28(7):1–12

Poonguzhali R, Basha SK, Kumari VS (2018) Nanostarch reinforced with chitosan/poly (vinyl pyrrolidone) blend for in vitro wound healing application. Polym-Plast Technol Eng 57(14):1400–1410

Switha D, Basha SK, Kumari VS (2022) A novel, biocompatible nanostarch incorporated polyaniline-polyvinyl alcohol-nanostarch hybrid scaffold for tissue engineering applications. Eur Polymer J 178:111448

Pandi N, Sonawane SH, Gumfekar SP, Kola AK, Borse PH, Ambade SB, Ashokkumar M (2019) Electrochemical performance of starch-polyaniline nanocomposites synthesized by sonochemical process intensification. J Renew Mater 7(12):1279–1293

Gautam V, Srivastava A, Singh KP, Yadav VL (2017) Preparation and characterization of polyaniline, multiwall carbon nanotubes, and starch bionanocomposite material for potential bioanalytical applications. Polym Compos 38(3):496–506

Charoensri K, Rodwihok C, Wongratanaphisan D, Ko JA, Chung JS, Park HJ (2021) Investigation of functionalized surface charges of thermoplastic starch/zinc oxide nanocomposite films using polyaniline: the potential of improved antibacterial properties. Polymers 13(3):425

Cai B, Zou Q, Zuo Y, Li L, Yang B, Li Y (2016) Fabrication and cell viability of injectable n-HA/chitosan composite microspheres for bone tissue engineering. RSC Adv 6(89):85735–85744

Acknowledgements

The authors would like to acknowledge Sophisticated Test and Instrumentation Centre (STIC), Cochin University of Science and Technology, Kochi, Kerala and Sophisticated Analytical Instrumentations Facility (SAIF), IIT Madras and TRI-BIOTECH Trichy for their technical support. The authors are grateful to the management of Auxilium College, Vellore, Tamil Nadu, for providing necessary facilities for the research work.

Funding

No funding was received towards the research work.

Author information

Authors and Affiliations

Contributions

DS: resources, methodology, software, writing, editing and visualization. SKB: validation and reviewing. VSK: conceptualization, supervision and resources.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Switha, D., Basha, S.K. & Kumari, V.S. In vitro cytocompatibility evaluation of nanostarch reinforced polyaniline-polyvinyl alcohol conductive bionanocomposites for skin tissue engineering application. J.Umm Al-Qura Univ. Appll. Sci. 9, 252–259 (2023). https://doi.org/10.1007/s43994-023-00040-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43994-023-00040-x