Abstract

The present work focuses on the two-step chemical synthesis of Ag/ZnS nanoparticles as core–shell nanoparticles. Various techniques were used to characterize nanoparticles, including UV–Vis spectroscopy, Dynamic Light Scattering, Transmission Electron Microscopy, Fourier Transform Infrared Spectroscopy, and a Solar Simulator. UV–Vis spectral analysis of Ag/ZnS core–shell nanoparticles at 450, 469, and 498 nm reveals broad plasmon resonance bands. The solution of silver nanoparticles was redshifted by increasing its concentration. Core and shell images obtained from each nanoparticle show different contrasts, indicating that the core and shell materials differ. Infrared spectroscopy confirmed the presence of ZnS NPs around AgNPs. Incorporating Ag/ZnS into polycrystalline silicon solar cells has improved efficiency from 13.02 to 14.29%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Developing advanced nanomaterials to accomplish renewable and sustainable energy management has been one of the most challenging research topics in recent years. Enough efforts have been made to integrate nanoscale building blocks into suitable catalytic nano-architectures that can improve energy efficiency and reduce material costs [1, 2]. The potential applications of core–shell nanostructures in photocatalysts, microelectronics, optoelectronics, drug delivery, chemical sensors, catalysis, etc., have much research interest [3,4,5,6,7]. In (CSNPs) materials, properties depend on the composition and arrangement of two components [8]. By modifying the shell material and the ratio of core–shell size, (CSNPs) are also a more flexible way to engineer optical and electronic properties [9]. Several studies have shown that metal and semiconductor nanoparticles and dielectric metal core–shell nanoparticles have unique and tunable surface plasmon resonances [10,11,12,13]. As a multi-component heterostructure nanosystem, metal–semiconductor (CSNPs) have great potential. By interacting at the nanoscale, the disparate core and shell components appear to have more synergistic properties, enhanced tunability, and combined properties [14, 15]. There are two reasons why they are made. It is possible to tune the optical properties of the semiconductor to extend the resonance frequency band to the entire near-infrared region by adjusting the carrier concentration. Metal cores and semiconductor shells have optical properties that support two SPRs in different light regions that differ from dielectric-metal and metal-dielectric (CSNPs) [16]. One of the easiest ways to increase the efficiency of a solar cell is to deposit metallic nanoparticles on its surface. Adding plasmonic metal nanostructures to polycrystalline solar cells can increase the light absorption, ultimately increasing the photocurrent (Jsc). This method will alter neither recombination centers nor solar cell manufacturing procedures [17, 18]. This promising result was achieved by using NPs with different materials and geometries. As a noble metal with high UV–visible absorption, silver (Ag) is a good choice for photoactive applications since its manufacturing cost is lower than those of gold (Au) and platinum (Pt) [9]. Due to the collective oscillation of free electrons in metal nanoparticles or free electrons on planar metal surfaces under visible or near-infrared light, Ag nanoparticles exhibit single or multiple localized surface plasmon resonance (LSPR) characteristics. When the incident light frequency coincides with the surface plasmon resonance, Ag nanoparticles exhibit LSPR characteristics. The plasmon resonance frequency of silver nanoparticles lies in the visible range of the electromagnetic spectrum. Typical plasmonic absorption peaks of Ag nanoparticles are around 450 nm. Due to their LSPR capabilities, Ag nanoparticles have attracted interest for use in optical devices. Light is more efficiently absorbed and scattered by Ag nanoparticles, in particular. On top of solar cells, Ag has also been used as an anti-reflection (A.R.) coating due to its high reflectivity. In addition, the surface plasmon effect enhances light scattering and absorption coefficients by enlarging the local electromagnetic field. In LSPR, electron–hole pairs are produced either radiatively or non-radiatively. There is a finite lifetime for it. Light is scattered into nanostructures during radiative decay, known as far-field decay, or the local electromagnetic field is enhanced, known as near-field decay. A non-radiative decay occurs when electrons are transferred, or plasmon resonant energy is transferred. The plasmon resonance frequency is affected by many factors, including particle size, shape, dielectric properties of the surrounding medium, chemical composition, concentration, aggregation state, and bandwidth. The plasmon resonance frequency was shifted to blue with a reduction in particle size while bandwidth widened. A red shift in resonance frequency can also be observed when the dielectric function of the surrounding medium increases [19,20,21,22]. Metallic nanoparticles can improve solar cells in three main ways: (1) near-field confinement, (2) far-field scattering, and (3) light trapping. In metallic nanoparticles, parasitic absorption losses remain a critical issue. The dominant effect can not be identified merely by solving difficult Maxwell equations or experimenting [23]. A semiconducting, insulating layer must be used to separate metal nanoparticles from the active layer of a solar cell in order to ensure: (i) effective charge recombination at the metal surface; and (ii) chemically protecting the metal core, which prevents nanoparticles from aggregating and oxidizing during the fabrication and operation of devices, especially when they are exposed to air or other chemicals. As a result, the protective shell optical characteristics and thickness should be chosen to reduce light absorption and ensure the closest possible proximity between the NPs and the active layer [9]. As a result of the encapsulated core–shell structure, resonance energy can be transferred from the noble metal to the semiconductor sulfide, effectively suppressing the recombination of electrons and holes. Therefore, the synergy between metal and semiconductors can enhance this hybrid photoelectric conversion efficiency. In addition, there is high carrier mobility and super photo-matter interaction in metal sulfides [19]. It is necessary to separate metal nanoparticles from the active layer with insulating, semiconducting, selected layers for solar cell applications. There are numerous applications for zinc sulfide (ZnS) nanoparticles ranging from dye degradation and antibiotic degradation [24] to photovoltaic devices, solar cells [25], and water purification [26, 27]. Due to its large excitation energy (40 meV) and wide band gap (3.7 eV), ZnS is considered to be a versatile material as it is a chemically stable semiconducting material [28, 29]. The small size and high optical activity of ZnS nanoparticles make them appealing for optoelectronic applications in the UV range [29]. Various core–shell NPs have been synthesized: Au@NiO [30], Ag@ZnO [31], Sn@Al2O3, [32], Au@TiO2 [33], Au@CdS [19]. These NPs exhibit enhanced catalytic or photocatalytic activity, unique optical properties, and gas sensing capabilities. Solar cell efficiency (η) depends on open circuit voltage (Voc), short circuit current (Jsc), and fill factor (FF), which, in turn, are highly dependent on the device construction and the energetics of the materials. Optimizing these characteristics in the polycrystalline silicon solar cell is necessary to increase the short-circuit current to achieve a proper power conversion efficiency. On the other hand, a large bandgap material (e.g., ZnS) can increase the open-circuit voltage [34, 35]. This study aims to utilize both Ag NPs and ZnS advantages. A core–shell structure material, Ag@ZnS, was prepared by the wet-chemical method and then used to enhance the efficiency of polycrystalline silicon solar cells.

2 Experimental section

2.1 Materials

The polyvinylpyrrolidone (PVP) (C6H9NO)n was bought from Acros, and the ascorbic acid and silver nitrate (AgNO3) were purchased from BDH. Sodium hydroxide (NaOH) and zinc acetate dihydrate (Zn(CH3COO)2·2H2O) were purchased from Sigma-Aldrich, while ammonium nitrate (NH4NO3) and sodium sulfide (Na2S) were obtained from AVONCHEM and Merck, respectively. All experimental processes were carried out using distilled water. There are 52 mm × 52 mm polycrystalline solar cells were used.

2.2 Synthesis of PVP capped AgNPs

To prepare AgNPs, 2.4 g of PVP (stabilizer) were added to 240 ml of (5 × 10−4 mol/L) ascorbic acid for 15 min. A solution of 4.2 ml (0.1 M) NaOH was then added and stirred for five minutes. After 15 min of vigorous stirring in a 30 °C water bath, 2.4 ml of (0.1 M) AgNO3 was added to the solution under vigorous stirring for 30 min at 80 °C. A TEM and ultraviolet–visible spectroscopy were performed on the obtained solution and the formation of an Ag/ZnS core and shell.

2.3 Synthesis of Ag@ZnS (CSNPs)

In 50 ml of D.W., zinc acetate dihydrate was dispersed at a concentration of 0.04 gm. In the next step, 0.11 gm of NH4NO3 was added under constant stirring. To prepare S2, S3, and S4 samples, 0.19 g of PVP and 70 ml, 80 ml, and 90 ml of AgNPs colloid were added. Next, for 5 min under stirring, 1.8 ml of Na2S (0.2 M) was added dropwise at one drop/s speed. The final step was to add 3.8 ml of (0.1 M) ascorbic acid and keep about 10 ml for TEM analysis and ultraviolet–visible spectroscopy. Afterward, the Ag/ZnS nanoparticles were centrifuged at (15,500 rpm) for 30 min and dried at 40 \(\mathrm{^\circ{\rm C} }\) for 50 h. As a result of the powder being obtained.

2.4 Characterization techniques

A UV–Vis spectrometer model Thermo (Evolution 220) was used primarily to confirm the presence of AgNPs and (AgNPs/ZnS) (CSNPs). Deionized water was used as a reference. A Malvern Zetasizer Nano S model was used to measure the particle size distribution using Dynamic Light Scattering (DLS). Transmission electron microscopy (JEM-1400) was used to study the shape, core shells, and distribution of (AgNPs/ZnS) (CSNPs). Images were taken using a voltage of 200 kV. An ImageJ program was used for calculating particle sizes. Infrared spectroscopy analysis was performed using the FT-IR instrument model IRAFFINITY-1S. Under simulated sunlight illumination (100 mw/cm2), the LED Solar Simulator (VeraSol-2) was used to measure the photocurrent and voltage of the cell.

3 Results and discussion

3.1 UV–Vis absorption spectra

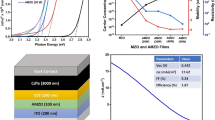

Figure 1 illustrates the UV–visible absorption spectra of AgNPs (S1) and silver-zinc sulfide nanoparticles (S2-S4). Ag/ZnS (CSNPs) were prepared using a variety amounts of AgNPs (S1). Based on the spectra, it is evident that the sample (S1) exhibits the plasmon band at 408 nm, indicating that AgNPs were formed. S2–S4 spectra were interpreted as being zinc sulfide nanoparticles from the small bands at 290 nm. Surface plasmon resonance of silver/zinc sulfide core–shell nanoparticles displayed broad bands at 450 nm for Ag/ZnS (CSNPs) S2, 469 nm for Ag/ZnS (CSNPs) S3, and 498 nm for Ag/ZnS (CSNPs) S4. Figure 2 illustrates how the surface plasmon resonance shifted to a higher wavelength (redshift) due to the increased AgNPs(S1). Due to the lower distribution of the core–shell nanoparticles, the bands widen with increasing AgNPs(S1) molar ratio. It is the formation of ZnS on the surface of AgNPs that causes the change in surface plasmon adsorption, which implies the successful production of core–shell Ag/ZnS composite nanoparticles. Because of the nucleation layer and accumulation of ZnS on the surface of the Ag nanocore, the surface plasmon resonance of the samples (S2–S4) became wider than that of (S1).

3.2 Transmission electron microscopy (TEM) analysis

Figure 3a–c shows silver/zinc sulfide core–shell nanoparticles synthesized with a different quantity of Ag nanoparticles (S1). Image (a) of sample S2 indicates that the Ag/ZnS (CSNPs) have a spherical shape. According to the results, the particle looks like a dark spherical nanoparticle (core) surrounded by a shiny shell. Zinc sulfide nanoparticles are represented by the shiny shell, while the dark color represents silver nanoparticles. Each sample's core–shell nanoparticle size was calculated using ImageJ software. It is estimated at approximately 27 nm in size. Figure 3b clearly shows different sizes forming in sample Ag/ZnS sample S3. There is a difference in image contrast between each nanoparticle’s core and shell composition, suggesting that the core and shell are made of different materials. Furthermore, well-distributed core–shell Ag/ZnS (CSNPs) were observed. Nanoparticle shells have an average thickness of 18 nm, and their core diameters are 46 nm. ZnSNPs(S3) were analyzed using ImageJ software at 81 nm to estimate particle sizes (core and shell). Figure 3c shows a TEM image of the Ag/ZnS (S4) core–shell structure. The as-synthesized particles have dark contrast zinc sulfide shells and a light contrast silver core, indicating that the zinc sulfide shell successfully coated the silver nanoparticle surface uniformly. There is an estimated thickness of 33 nm for the nanoparticle shell. The average diameter of the core is 98 nm. Particles have an average size of 177 nm. Compared to these samples, the particle size increased as AgNPs(S1) quantity increased. UV–Vis results are consistent with these results.

3.3 Analysis of dynamic light scattering (DLS)

As a result of Brownian motion, the particle's scattering intensity fluctuates as a laser beam is applied to our prepared samples. An autocorrelation function can be used to calculate the average hydrodynamic diameter of particles. The hydrodynamic diameter of silver/zinc sulfide core–shell nanoparticles prepared with different amounts of AgNPs(S1) is shown in Fig. 4. Ag/ZnS(S2), Ag/ZnS(S3), and Ag/ZnS(S4) have hydrodynamic diameters of 39.04 nm, 127.8 nm, and 48.39 nm, respectively.

3.4 Fourier transform infrared spectroscopy (FT-IR) analysis

Figure 5 presents the FT-IR spectra of Ag/ZnS (CSNPs) synthesized with different amounts of AgNPs(S1). FTIR spectra of Ag/ZnS samples were measured between 4000 and 400 cm−1 to indicate the presence of ZnSNPs as a shell around AgNPs as a core. FT-IR spectra of pure PVP are presented by Patel et al. [36]. According to our observations of Ag/ZnS (CSNPs) absorbance bands, the peaks in PVP spectra shifted from 3434 to 3432 cm−1, 2955 to 2926 cm−1, 1661 to 1630 cm−1, 1424 to 1377 cm−1, 1291 to 1116 cm−1, and 1018 to 1008 cm−1 for Ag/ZnS nanoparticles. Upon surrounding AgNPs (capped by PVP) with ZnS, the band position changed and confirmed the strong interaction between PVP and ZnS. Due to the interaction between Zn and S, the 651 cm−1 absorbance band is attributed to Zn–S vibrations. Table 1 summarizes the main assignments of Ag/ZnS core–shell nanoparticles.

3.5 Solar cell measurements

Figure 6 illustrates the I-V characteristic curve of polycrystalline silicon solar cells and Ag/ZnS(S4) deposited using a spin coater on polycrystalline silicon with an active area (\(52 \, \;{\text{mm}} \times 52\;{\text{ mm}}\)).These curves were recorded at \(AM - 1.5(100 \, \;{\text{mW}}/{\text{cm}}^{2} )\) under simulated sunlight. As seen from the Figure, the current increased as the applied voltage was increased. It is acceptable to observe this behavior as charge carriers and their mobility increase with an increase in applied voltage. Several parameters of the solar cell were calculated, including the \(V_{OC}\)(open-circuit voltage), \(I_{SC}\) (short-circuit current), and \(FF\)(fill factor). We obtained the maximum current \(\left( {I_{m} } \right)\) and voltage \(\left( {V_{m} } \right)\) and summarized them in Table 2. The fill factor was calculated using Eq. (1) [37]:

Also, the efficiency \(\left( \eta \right)\) of the solar cell is measured using Eq. (2).

where \(\left( {P_{in} } \right)\) is the power of incident light equal light intensity/area [38].

The characteristic parameters performance of the cell was improved after Ag/ZnS (CSNPs) deposition on the cell surface. The cell parameter increased as \(V_{OC}\) increase from \(0.31 \, V\) to \(0.33 \, V\), \(I_{SC}\) from \(0.96 \, mA\) to \(1.05 \, mA\), and the power conversion efficiency \(\eta\) from \(13.02 \, \%\) to \(14.29 \, \%\). A core material (silver nanoparticles) coated with shell material (zinc sulfide nanoparticles) over an energy barrier at the electrode interface provides a pathway for interfacial recombination. As a result of this technique, the interfacial recombination between individual core nanoparticles may be reduced, allowing electrons to travel directly between them. Moreover, Ag/ZnS (CSNPs) on the cell surface increases light scattering. As a result, the silicon cell absorbs more light in the visible light region than the original cell. In addition, SPR on Ag surfaces generates more carriers. The results improved the cell parameters, which increased solar cell efficiency by 14.29%. Metal nanoparticles, however, did not appear to improve the performance of conventional photo-deposited silicon solar cells as expected due to their ohmic losses in the visible region. Figure 7 shows a schematic view of the (Al/p-type silicon/AgNPs capped ZnS/Ag) cell structure.

4 Conclusions

The present study reports the synthesis of Ag/ZnS (CSNPs). Optical, morphological, and structural analyses demonstrate the presence of silver nanoparticles surrounded by zinc sulfide nanoparticles. Due to the surface charge properties of the ZnS shell material, the Ag core material was well capped with the ZnS shell material in the (CSNPs) formation. UV–Vis spectroscopy was used to study the interaction between plasmonic (Ag) and semiconducting (ZnS) material properties of Ag/ZnS (CSNPs). The crystallinity of the prepared materials was determined by XRD analysis. FT-IR spectra showed a strong interaction between ZnS and PVP, as evidenced by the band position change. CSNPs (Ag/ZnS) enhanced solar cell efficiency by 14.29% by altering cell parameters (\(V_{OC} , \, I_{SC} , \, V_{m} , \, {\text{I}}_{m} ,\) and \(FF\)).

Availability of data and material

All data generated or analyzed during this study are included in this published article.

References

Singh R, Bhateria R (2021) Core–shell nanostructures: a simplest two-component system with enhanced properties and multiple applications. Environ Geochem Health 43(7):2459–2482. https://doi.org/10.1007/s10653-020-00766-1

Peng Z, Wei Q, Chen H, Liu Y, Wang F, Jiang X, Liu W, Zhou W, Ling S, Ning Z (2020) Cs0. 15FA0. 85PbI3/CsxFA1-xPbI3 core/shell heterostructure for highly stable and efficient perovskite solar cells. Cell Rep Phys Sci 1(10):100224. https://doi.org/10.1016/j.xcrp.2020.100224

Solaiyammal T, Murugakoothan P (2018) Green synthesis of Au and Au@ TiO 2 core–shell structure formation by hydrothermal method for dye sensitized solar cell applications. J Mater Sci Mater Electron 29(1):491–499. https://doi.org/10.1007/s10854-017-7938-7

Wang Y, Nishida N, Yang P, Toshima N, Du Y (2009) Synthesis, separation, and characterization of Au@ CdS nanoparticles. J Dispersion Sci Technol 30(8):1175–1181. https://doi.org/10.1080/01932690802701697

Min Y, Song G, Zhou L, Wang X, Liu P, Li J (2022) Silver@ mesoporous anatase TiO2 core-shell nanoparticles and their application in photocatalysis and SERS sensing. Coatings 12(1):64. https://doi.org/10.3390/coatings12010064

Sarma S, Agarwal S, Bhuyan P, Hazarika J, Ganguly M (2022) Resveratrol-loaded chitosan–pectin core–shell nanoparticles as novel drug delivery vehicle for sustained release and improved antioxidant activities. R Soc Open Sci 9(2):210784. https://doi.org/10.1098/rsos.210784

Lee HY, Bang JH, Majhi SM, Mirzaei A, Shin KY, Yu DJ, Oum W, Kand S, Lee ML, Kim SS, Kim HW (2022) Conductometric ppb-level acetone gas sensor based on one-pot synthesized Au@ Co3O4 core-shell nanoparticles. Sens Actuators B Chem 359:131550. https://doi.org/10.1016/j.snb.2022.131550

Senthilkumar N, Ganapathy M, Arulraj A, Meena M, Vimalan M, Potheher IV (2018) Two step synthesis of ZnO/Ag and ZnO/Au core/shell nanocomposites: structural, optical and electrical property analysis. J Alloy Compd 750:171–181. https://doi.org/10.1016/j.jallcom.2018.03.348

Caleffi M, Mariani P, Bertoni G, Paolicelli G, Pasquali L, Agresti A et al (2021) Ag/MgO nanoparticles via gas aggregation nanocluster source for perovskite solar cell engineering. Materials 14(19):5507. https://doi.org/10.3390/ma14195507

Yang G, Luo S, Lai T, Lai H, Luo B, Li Z et al (2022) A green and facile microvia filling method via printing and sintering of Cu-Ag core-shell nano-microparticles. Nanomaterials 12(7):1063. https://doi.org/10.3390/nano12071063

Amrani MA, Alrafai HA, Al-nami SY, Labhasetwar NK, Qasem A (2022) Effect of mixing on nickel tartrate and Ni/NiO core/shell nanoparticles: Implications for morphology, magnetic, optical, dielectric and adsorption properties. Optical Mater 127:112321. https://doi.org/10.1016/j.optmat.2022.112321

Cheng L, Liu W, Zhang Z, Zhou Y, Li S (2022) Enhanced breakdown strength and restrained dielectric loss of polypropylene/maleic anhydride grafted polypropylene/core-shell ZrO2@ SiO2 nanocomposites. Polym Compos 43(4):2175–2183. https://doi.org/10.1002/pc.26530

Szántó G, Bonyár A, Csarnovics I (2022) Dimers of gold-silver core-shell nanospheres: the effect of interparticle gap on the refractive index sensitivity and extinction spectrum. Photonics Nanostruct Fundamentals Appl 50:101023. https://doi.org/10.1016/j.photonics.2022.101023

Yang A, Li S, Wang Y, Wang L, Bao X, Yang R (2015) Synthesis of Ag@ Cu 2 O core-shell metal-semiconductor nanoparticles and conversion to Ag@ Cu core-shell bimetallic nanoparticles. Sci China Technol Sci 58(5):881–888. https://doi.org/10.1007/s11431-015-5797-0

Guo F, Yang H, Liu L, Han Y, Al-Enizi AM, Nafady A, Ma S (2019) Hollow capsules of doped carbon incorporating metal@ metal sulfide and metal@ metal oxide core–shell nanoparticles derived from metal–organic framework composites for efficient oxygen electrocatalysis. J Mater Chem A 7(8):3624–3631. https://doi.org/10.1039/c8ta11213d

Zhang H, Cao P, Dou J, Cheng L, Niu T, Zhang G (2018) Double-exponential refractive index sensitivity of metal–semiconductor core–shell nanoparticles: the effects of dual-plasmon resonances and red-shift. RSC Adv 8(3):1700–1705. https://doi.org/10.1039/c7ra11981j

Feng L, Niu M, Wen Z, Hao X (2018) Recent advances of plasmonic organic solar cells. Polymers 10:1–33. https://doi.org/10.3390/polym10020123

Chen Y, Du C, Sun L, Fu T, Zhang R, Rong W, Cao S, Li X, Shen H, Daning Shi D (2021) Improved optical properties of perovskite solar cells by introducing Ag nanopartices and ITO AR layers. Sci Rep 11:14550. https://doi.org/10.1038/s41598-021-93914-1

Qin P, Wu T, Wang Z, Xiao L, Ma L, Ye F et al (2020) Grain boundary and interface passivation with core–shell Au@ CdS nanospheres for high-efficiency perovskite solar cells. Adv Funct Mater 30(12):1908408. https://doi.org/10.1002/adfm.201908408

Choudhury BD, Lin C, Shawon SMAZ, Soliz-Martinez J, Huq H, Uddin MJ (2021) A photoanode with hierarchical nanoforest TiO2 structure and silver plasmonic nanoparticles for flexible dye sensitized solar cell. Sci Rep 11(1):1–11. https://doi.org/10.1038/s41598-021-87123-z

Edalati S, Behjat A, Torabi N (2018) Near-field effect of Ag@ SnO2 core-shell on dye-sensitized solar cell performance. Plasmonics 13(6):2215–2219. https://doi.org/10.1007/s11468-018-0740-4

Nevruzoğlu V, Bal Altuntaş D, Tomakin M (2020) Cold substrate method to prepare plasmonic Ag nanoparticle: deposition, characterization, application in solar cell. Appl Phys A 126(4):1–9. https://doi.org/10.1007/s00339-020-3433-8

Hasheminassab SMS, Imanieh M, Kamali A, Emamghorashi SA, Hassanhosseini S (2021) Influence of the shape and size of Ag nanoparticles on the performance enhancement of CIGS solar cells: the role of surface plasmons. Plasmonics 16(1):273–282. https://doi.org/10.1007/s11468-020-01280-x

Munyai S, Mahlaule-Glory LM, Hintsho-Mbita NC (2022) Green synthesis of Zinc sulphide (ZnS) nanostructures using S. frutescences plant extract for photocatalytic degradation of dyes and antibiotics. Mater Res Express 9(1):015001. https://doi.org/10.1088/2053-1591/ac4409

Muzakir SK, Almashgari BKB (2021) The effect of vacuum pressure during fabrication of zinc sulphide thin film using thermal evaporator. Curr Sci Technol 1(1):26–31. https://doi.org/10.15282/cst.v1i1.6396

Gobinath VK, Rajasekar R, Moganapriya C, Sri AM, Raja G, Kumar PS, Jaganathan SK (2021) Surface engineering of zinc sulphide film for augmenting the performance of polycrystalline silicon solar cells. Chalcogenide Lett 18(7):375–384

Sharma K, Raizada P, Hasija V, Singh P, Bajpai A, Nguyen VH et al (2021) ZnS-based quantum dots as photocatalysts for water purification. J Water Process Eng 43:102217. https://doi.org/10.1016/j.jwpe.2021.102217

Shahzad N, Ali N, Ahmad I, Ullah N, Khalid S, Fazal M, Al-Sehemi AG (2020) Surfactant assisted hydrothermal synthesis of zinc sulfide nanoparticles using single source precursors. Chalcogenide Letters 17(9):469–480

Balboul MR, Abdel-Galil A (2019) Fabrication and performance of dye sensitized solar cell based on spin coated ZnS nanoparticles. Appl Phys A 125(12):1–10. https://doi.org/10.1007/s00339-019-3132-5

Majhi SM, Naik GK, Lee HJ, Song HG, Lee CR, Lee IH, Yu YT (2018) Au@ NiO core-shell nanoparticles as a p-type gas sensor: novel synthesis, characterization, and their gas sensing properties with sensing mechanism. Sens Actuators B Chem 268:223–231. https://doi.org/10.1016/j.snb.2018.04.119

Seong S, Park IS, Jung YC, Lee T, Kim SY, Park JS et al (2019) Synthesis of Ag-ZnO core-shell nanoparticles with enhanced photocatalytic activity through atomic layer deposition. Mater Design 177:107831. https://doi.org/10.1016/j.matdes.2019.107831

Yoon JH (2019) Fabrication of Sn@ Al2O3 Core-shell nanoparticles for stable nonvolatile memory applications. Materials 12(19):3111. https://doi.org/10.3390/ma12193111

Pougin A, Dodekatos G, Dilla M, Tüysüz H, Strunk J (2018) Au@ TiO2 core–shell composites for the photocatalytic reduction of CO2. Chemi A Eur J 24(47):12416–12425. https://doi.org/10.1002/chem.201801796

Gonfa BA, Zhao H, Li J, Qiu J, Saidani M, Zhang S et al (2014) Air-processed depleted bulk heterojunction solar cells based on PbS/CdS core–shell quantum dots and TiO2 nanorod arrays. Solar Energy Mater Solar Cells 124:67–74. https://doi.org/10.1016/j.solmat.2014.01.037

Mohammadi MH, Fathi D, Eskandari M (2021) Light trapping in perovskite solar cells with plasmonic core/shell nanorod array: a numerical study. Energy Rep 7:1404–1415. https://doi.org/10.1016/j.egyr.2021.02.071

Patel K, Deshpande MP, Chaki SH (2017) Effect of Ag on structural, optical and luminescence properties of ZnS nanoparticles synthesized by microwave-assisted chemical route. Appl Phys A 123:367. https://doi.org/10.1007/s00339-017-0980-8

Al-Azawi MA, Bidin N, Bououdina M (2016) and Sabah M Mohammad, “Preparation of gold and gold–silver alloy nanoparticles for enhancement of plasmonic dye-sensitized solar cells performance. Sol Energy 126:93–104. https://doi.org/10.1016/j.solener.2015.12.043

Ayalew WA, Ayele DW (2016) Dye-sensitized solar cells using natural dye as light-harvesting materials extracted from Acanthus sennii chiovenda flower and Euphorbia cotinifolia leaf. J Sci Adv Mater Devices 1:488–494. https://doi.org/10.1016/j.jsamd.2016.10.003

Funding

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Contributions

RS: conceived and designed the experiments; analyzed and interpreted the data; wrote the paper; reviewed and editing. SAA: performed the experiments; analyzed and interpreted the data; wrote the paper. SA: contribute to practical experiences, writing the manuscript, and reviewing.

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare(s) that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Seoudi, R., Alghamdi, S.A. & Allehyani, S. Synthesis, structural, and optical properties of (Ag/ZnS) core–shell nanostructures and their applications to polycrystalline silicon solar cells. J.Umm Al-Qura Univ. Appll. Sci. 9, 260–267 (2023). https://doi.org/10.1007/s43994-023-00039-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43994-023-00039-4