Abstract

Solar driven carbon dioxide (CO2) recycling into hydrocarbon fuels using semiconductor photocatalysts offers an ideal energy conversion pathway to solve both the energy crisis and environmental degradation problems. However, the ubiquitous presence of carbonaceous contaminants in photocatalytic CO2 reduction system and the inferior yields of hydrocarbon fuels raise serious concerns about the reliability of the reported experimental results. Here in this perspective, we focus on the accurate assessment of the CO2 reduction products, systemically discuss the possible sources of errors in the product quantification, elaborate the common mistakes spread in the analysis of reaction products obtained in 13CO2 labelling experiments, and further propose reliable protocols for reporting the results of these isotopic tracing experiments. Moreover, the challenges and cautions in the precise measurement of O2 evolution rate are also depicted, and the amplification of the concentration of O2 in photoreactors well above the limit of detection is still demonstrated to be the most effective solution to this troublesome issue. We hope the viewpoints raised in this paper will help to assessment the reliability of the reported data in future, and also benefit the beginners that intend to dive in the photocatalytic CO2 reduction area.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Fossil fuels have been powering human society for over 150 years, and currently still supply about 80% of the world’s energy demand [1]. But they are finite resources, will eventually run out, and cannot be replenished for thousands or even millions of years. Meanwhile, the voracious burning of fossil fuels for energy leads to massive carbon dioxide (CO2) emission, the atmospheric concentration of which reached a new record high amount of 412.5 ppm in 2020 [2], artificially amplifying up the natural greenhouse effect and altering the earth’s climate system. Therefore, the exploitation of clean and renewable alternative energy sources and the reduction of worldwide CO2 emission have become the top priority for human society to achieve a sustainable future.

Natural photosynthesis process of green plants capture energy from sunlight to activate the reaction between water (H2O) and CO2 to produce oxygen (O2) and chemical energy stored in glucose (eq. 1), maintaining the carbon-oxygen cycle which is vital for all the lives on earth [3]. Such a fascinating energy conversion pathway with no net CO2 emission offers an ideal solution to both the energy crisis and environmental degradation problems. Hence, technical routes capable of recycling atmospheric CO2 into synthetic fuels using solar energy, also called artificial photosynthesis technologies, have attracted tremendous research interests in recent years [4,5,6,7].

Natural photosynthesis:

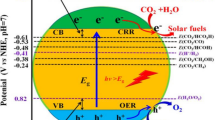

One promising solar driven CO2 recycling technology is the photocatalytic reduction of CO2 into hydrocarbon fuels using semiconductor photocatalysts, wherein CO2 is reduced by energetic electrons generated in semiconductors when they were stimulated by photons with energy larger than their bandgaps (eq. 2) [8, 9]. Owing to its high maximum energy conversion efficiency, moderate reaction condition, as well as great potential of large-scale production, photocatalytic CO2 reduction has been at the forefront of academic research ever since its first report [8, 9], and more recently, witnesses another burst of publications and citations related to this field because of the signing of Paris Agreement [10,11,12,13,14].

Photocatalytic CO2 reduction:

In 2011, the formation of carbon monoxide (CO) with a selectivity exceeding 50% along with the evolution of stoichiometric amounts of O2 was first reported by Kudo group, when an Ag loaded BaLa4Ti4O15 photocatalyst was irradiated by ultraviolet (UV) light under CO2 atmosphere [15]. Following this study, various UV responsive semiconductor photocatalysts, such as, tantalum-based NaTaO3 [16], ZnTa2O6 [17], and Sr2KTa5O15 [18], titanium-based K2Ti6O13 [19], La2Ti2O7 [20], and SrTiO3 [21, 22], and gallium-based Ga2O3 [23], and ZnGa2O4 [24], were found to be active for photocatalytic reduction of CO2 by H2O when they were modified with a universal Ag cocatalyst. However, their solar energy conversion efficiencies have been quite limited, since the UV region only accounts for 4% of the sunlight spectrum. Accordingly, Z-scheme photocatalytic systems, represented by CuGaS2/RGO/TiO2 [25], CuGaS2/RGO/CoOx-BiVO4 [26], (CuGa)1-xZn2xS2/Co-complex/BiVO4 [27], SrTiO3:Rh/BiVO4 [28], and SrTiO3:La,Rh/Au/BiVO4:Mo [29] attract considerable research interests recently, because of the alleviated thermodynamic requirements of the applied photocatalysts which enable the use of visible-light responsive narrow bandgap semiconductors. Moreover, photocatalytic CO2 reduction at the expense of hole scavengers, such as sodium sulfite (Na2SO3) [30, 31] and triethanolamine (TEOA) [32, 33], to bypass the kinetically sluggish H2O oxidation half-reaction, also shows accessibility toward effective CO2 reduction. But this is not economically feasible and wastes the oxidizing power of photogenerated holes. To this end, Wu et al. integrated photocatalytic reduction of CO2 to CO with an oxidative organic synthesis of 1-phenylethanol to pinacols, achieved the simultaneous production of solar fuels and value-added chemicals, opening a new horizon for efficient and cost-effective photocatalytic CO2 reduction [34].

Despite the tremendous efforts devoted to the development of photocatalytic CO2 reduction technology, the state-of-the-art solar-to-fuel conversion efficiency of this process is still much less than 1% [29]. This troublesome situation, as have been discussed in several excellent reviews [35,36,37,38,39,40,41], is closely associated with the multiple challenges spread all over the complex and consecutive physicochemical processes occurred during the photoreduction of CO2, including the low solubility of CO2 in water, the high thermodynamic stability of C=O bonds, the poor solar spectrum response of photocatalysts, the severe recombination of photogenerated charge carriers, the complex and multiple reaction pathways, as well as the diverse reduction products. The incremental advances accumulated upon a large quantity of research focusing on one or several specific scientific problems mentioned above will certainly lead to a further progress of photocatalytic CO2 reduction. However, one important but often overlooked issue that should be solved is the accurate assessment of the catalytic performance of photocatalysts, since the very little product yields (μmol h− 1 gcat− 1) pose a huge challenge in the identification and quantification of the real reduction products [42, 43]. Particularly, it has been reported that both the organic substances involved in the preparation of photocatalysts [44,45,46,47,48] and the decomposition products of sacrificial reagents and/or reaction additives [49,50,51] may decompose to small molecules, such as hydrogen (H2), CO, and methane (CH4), causing the overestimation of catalytic activities or even false positive results. In this regard, isotopic 13CO2 labelling experiments are suggested to verify whether the carbon-containing products are derived from CO2 or carbonaceous impurities [10, 36, 40, 52]. Unfortunately, the lacking of standard reporting protocols has resulted in the accumulation of a vast amount of unconvincing or often misleading data, not only damaging the research community but also causing significant waste of research investment and resources. Moreover, there is increasing literature that demonstrated the stoichiometric production of O2 along with the photoreduction of CO2 under visible or even infrared light irradiation, when using the earth-abundant H2O as a reducing agent recently. This is in sharp contrast to the problem confronted in photocatalytic overall water splitting that many groups failed to confirm the balance between electrons and holes generated by the charge transfer [52,53,54,55], despite the inferior yields of CO2 reduction products, thereby making some of the reported results questionable and further hindering the sustained progress of the photocatalytic CO2 reduction field.

In this context, we herein focus on the accurate identification of the real products in photocatalytic CO2 reduction, systemically discuss the possible sources of errors in the quantification of reduction products, specify the common mistakes spread in the analysis of the reaction products obtained in 13CO2 labelling experiments, and further propose reliable reporting protocols for these isotopic tracing results. Moreover, the challenges and cautions in the precise measurement of O2 evolution rate is also elucidated, as well as the possible feasible solutions to this difficulty. The viewpoints raised in this perspective will help to improve the reliability of the reported data in future, benefitting the beginner that intend to dive in the photocatalytic CO2 reduction area.

2 Possible sources of false positive results

2.1 Degradation of carbonaceous contaminants on the surface of or contained in photocatalysts

The current trend of controllable growth of catalytic nanomaterials with great precision necessitates the employment of many organic substances as solvents, reactants, or surfactants in synthetic chemistry, frequently leaving carbonaceous residues in the final products [56]. Moreover, organic micropollutants in the laboratory atmosphere can easily be adsorbed onto the surface of air exposed samples, resulting in the formation of an adventitious carbonaceous layer which is commonly used as a charge reference for X-ray photoelectron spectra analysis [57]. These carbonaceous contaminants have been found to be involved in the CO2 photoreduction process and decompose to small molecules such as CO and CH4, interfering the assessment of catalytic activities [44,45,46, 48]. And, the amount of carbon containing products formed from the carbonaceous residues could be far greater than many reported values attributed to the photoreduction of CO2, if 0.1 g of photocatalyst containing 1% carbonaceous residues by weight was irradiated [43]. That is, the carbonaceous residues on the surface of and/or contained inside catalytic materials are probably the biggest source of false positive results in photocatalytic CO2 reduction (Scheme 1a).

Possible sources of false positive results in photocatalytic CO2 reduction (a) Degradation of carbonaceous contaminants on the surface of or contained in photocatalysts; (b) Light induced decomposition of sacrificial reagents and/or reaction additives as well as UV disinfection caused bond scission of organic micropollutants in water or on glassware; (c) Accelerated release of carbon-containing products from carbonaceous contaminants at eleveated reaction temperature when choosing the gas-solid reaction mode

The adverse effects of carbonaceous impurities on photocatalytic CO2 reduction have been investigated by a number of research groups. Plenty of efforts, such as high temperature calcination in air [47], prolonged exposure to ultraviolet (UV) irradiation [44], repetitive illumination in flowing humid helium (He) [48], and ozonation treatment [58], are already made to remove these carbonaceous residues. Nonetheless, the complete remove of these carbonaceous contaminants remains an intractable problem even after tens of hours exposure to light irradiation [48]. Therefore, an extra high degree of meticulousness is still desperately required when applying carbon-containing or high-surface-area photocatalysts synthesized at low temperature without post annealing treatments for photocatalytic CO2 reduction, before the emerging of an effective decarbonization strategy.

2.2 Light induced decomposition of sacrificial reagents and/or reaction additives

H2O is the most promising reducing reagent in photocatalytic CO2 reduction, which provides both the electrons and hydrogen atoms necessary for hydrocarbon fuel production from CO2 [52]. But it still remains challenging to reduce CO2 by pure water, because of the sluggish kinetics of H2O oxidation reaction which proceeds at millisecond to second timescale [59]. Therefore, sacrificial hole acceptors, like Na2SO3 [30, 31] and TEOA [32, 33, 60], have been widely applied in photocatalytic CO2 reduction, to scavenge photogenerated holes and promote the performance of photocatalysts. Furthermore, the solubility of CO2 in water is as low as 0.033 mol L− 1 at 25 °C, greatly limiting the diffusion of CO2 molecules from vapor phase to the surface of photocatalysts in liquid-solid reaction systems [39]. Various chemical additives, including acetonitrile (CH3CN) [60, 61], bicarbonate (HCO3−) [62], and NaOH [63], thus are adopted to improve the solubility of CO2 in H2O, ensuring a sufficient supply of CO2 molecules to the reactive sites. However, despite the effectiveness of these sacrificial reagents and/or chemical additives in improving the reaction efficiency, little attention has been paid to the possible influence of these chemical reagents on the quantification of CO2 reduction products (Scheme 1b) [50, 51].

Sebastian C. Peter group recently investigated the effects of solvents on the product selectivity and activity of catalyst during photocatalytic CO2 reduction, and demonstrated that the photolysis of CH3CN, ethyl acetate (EAA), TEA, and TEOA under UV-visible light irradiation without the presence of any catalysts can produce CO, CH4, ethylene (C2H4), and H2, resulting in the overestimation of catalytic activities or even false positive results [49]. Notably, care must be taken when choosing chemical additives and/or hole scavengers for photocatalytic CO2 reduction research (Fig. 1). Further information regarding this subject can be found in their work published in ACS Energy Letters [49].

Usability of different solvents and sacrificial agents under different energies of light irradiation. Figure reproduced with permissionfrom ref. [49]. Copyright 2021 American Chemical Society

2.3 UV disinfection caused bond scission of organic micropollutants in water or on glassware

The exposure of photocatalytic reactors and/or reaction solvents to air atmosphere will inevitably lead to the adsorption of trace amount of organic micropollutants [64]. Meanwhile, deionized water, a type of purified water used for most laboratory applications, such as preparing solutions, calibrating equipment, or cleaning glassware, could contains bacteria or pathogens, although it has had all of the ions removed [65]. The molecular bonds of these organic contaminants could be broken by UV-C (200–300 nm) light via a process known as UV disinfection [66], leading to the release of small carbon containing molecules and probably interfering the quantification of CO2 reduction products (Scheme 1b).

To investigate the effect of this UV disinfection process, we exploited the gaseous products evolved in photocatalytic reactors without the presence of catalyst under the irradiation of traditional (300 ~ 2400 nm) or UV enhanced (260 ~ 2400 nm) xenon (Xe) lamps (Fig. 2a and b, see supporting information for experimental details). It is evident in Fig. 2c that H2 and CO are produced in the reaction system with the incidence of UV-C light, the evolution rates of which are comparable or even larger than many reported values attributed to the photoreduction of CO2 when they were divided by the regular amounts of photocatalysts employed in literature (several tens to one hundred of milligram), regardless of the presence of water, CO2 and NaHCO3 additive or not. Here we consider the generation of H2 and CO under the irradiation of UV enhanced Xe lamp reasonable, since the molecular bonds of the organic contaminants on the inner wall of photoreactors and/or in the reaction solvents could be broken by UV disinfection effects, which is similar to the light induced decomposition and/or oxidation of hole scavengers during the photocatalysis process, resulting in the release of small molecules [49, 51]. While in contrast, gas products can hardly be found when the reaction is carried out under the irradiation of traditional Xe lamp (Fig. 2d). Hence, light sources with their emission spectra containing UV-C wave bands must be used with cautions in photocatalytic CO2 reduction research. While for the decreased evolution rates of gaseous products in CO2 atmosphere when water is absent, it should be attributed to the decrease in the temperature of the reaction system since water is a good heat sink. Moreover, CO2 might react with the small active species released from the UV-C induced decomposition reaction of organic contaminants, resulting in the higher amounts of gaseous products in CO2 atmosphere than those in Ar when empty reactors were employed.

2.4 Potential risks when choosing the gas-solid reaction mode

The traditional liquid-solid photocatalytic CO2 reduction system suffers from an insufficient supply of CO2 molecules to the surface reactive sites of photocatalysts, making the reduction of H2O to H2 standing out as a major competing reaction with CO2 reduction [39]. Hence, in recent years, the gas-solid reaction system which facilitates the mass transport of CO2 becomes more and more prevalent in this research field, because experimental results in several works demonstrate that the formation rate of H2 is suppressed by using this reaction mode, and the formation rates of CH4 and CO are higher than those with the liquid-solid reaction mode [67]. The gas-solid reaction mode thus seems to be more promising for tuning the reaction activity and selectivity in photocatalytic CO2 reduction than the solid-liquid mode.

However, from the experiment results in Fig. 2c, we see that the amounts of CO derived from the carbonaceous contaminants in an empty reactor under CO2 atmosphere, the reaction condition of which is similar to the gas-solid mode, are much higher than those produced in the reactor filled with deionized water. Moreover, according to research experience accumulated in the past several years in the author’s lab, the amounts of carbon containing products produced in the gas-solid mode under CO2 atmosphere are frequently of the same magnitude to those detected in argon (Ar) atmosphere regardless of the surveyed photocatalysts, frequently causing the overestimation of catalytic activities or even false positive results, which is in distinct contrast to the findings in liquid-solid mode (Fig. 3, see supporting information for experimental details). This is reasonable, as the temperature of photocatalysts in the gas-solid mode, benefitting from the reduced heat loss to the surroundings, is much higher than that in liquid-solid reaction system, which will certainly accelerate the release of small carbon containing molecules from the oxidation or decomposition of the carbonaceous contaminants and/or organic micropollutants in the reaction system (Scheme 1c). Such a phenomenon has also been exemplified by the large amounts of carbon-containing molecules released from the photocatalyst under prolonged exposure to UV irradiation [44] and repetitive illumination in flowing humid He [48]. Thus, we recommend the researchers in this field being aware of the potential risks of false positive results when adopting the gas-solid photocatalytic CO2 reduction system.

Formation rates of photocatalytic reaction products obtained in the gas-solid or liquid-solid reaction mode under different atmospheres. (a) C3N4. Gas-solid reaction: photocatalyst, 10 mg; water, 10 μL; pressure 70 kPa; light source, 300 W Xe lamp. Liquid-solid reaction: photocatalyst, 1.5 mg; solvent, 2 mL water + 0.25 mL TEOA + 0.75 mL CH3CN + 0.1 M Cobalt dipyridine; pressure, 1 atm; light source, 300 W Xe lamp. (b) SiC-Co3O4. Gas-solid reaction: photocatalyst, 10 mg; water, 10 μL; pressure 1 atm; light source, 300 W Xe lamp. Liquid-solid reaction: photocatalyst, 10 mg; solvent, 10 mL water + 2 mL TEOA; pressure, 1 atm; light source, 300 W Xe lamp

3 Identifying the source of carbon in photocatalytic reduction products

The ubiquitous presence of carbonaceous contaminants in photocatalytic CO2 reduction system and the inferior yields of hydrocarbon fuels raise serious concerns about the reliability of experimental results. It is thus necessary to confirm whether the carbon-containing reaction products arise from CO2 reduction or the decomposition of carbonaceous residues. Controlled experiments and 13C isotopic tracing, at present, are the two most common methods to verify the source of carbon in photocatalytic CO2 reduction [10, 40, 43, 44, 52]. However, the lacking of standard reporting protocols has resulted in the accumulation of a vast amount of unconvincing or even misleading data.

3.1 Scientific and rigorous design of controlled experiments

Controlled experiments in the absence of light and/or CO2 are the easiest-to-implement and most cost-effective strategy to specify the source of carbon in the reaction products, which has been widely employed in earlier works in photocatalytic CO2 reduction research [10]. The possible contribution from carbonaceous contaminations can be ruled out when the amounts of reaction products obtained in an inert gas environment (N2 or Ar) with and without the presence of light under otherwise identical conditions are at least an order of magnitude lower than that produced in normal photocatalytic CO2 reduction reaction. However, a simple statement of “no CO2 reduction products were obtained when either light or CO2 was absent” without providing any experimental data, which is ubiquitous in literature, is inadequate and also not convincing.

A recommended controlled experiment design can be referred to the works published by Tanaka group [68]. They generally conducted five blank experiments with one component absent in each test, including photocatalyst, light, CO2, cocatalyst, and chemical additive, to investigate the effects of all these components on the yields of reduction products (Fig. 4). Notably, all the five components are necessary to achieve a highly selective conversion of CO2 into CO, whereas no product could be detected without the presence of photocatalyst or light irradiation, and H2 evolved from water splitting is the main reduction product when CO2, cocatalyst, or chemical additive is absent, explicitly implying that CO does come from the photocatalytic reduction of gaseous CO2.

Formation rates of H2 (gray), O2 (white), and CO (black) in the absence of each component in the photocatalytic conversion of CO2 by H2O over Ag/3.0 Yb/Ga2O3. Photocatalyst weight, 0.5 g; CO2 flow, 30 mL min− 1; solution volume, 1.0 L; additive, 0.1 M NaHCO3; light source, 400 W Hg lamp. Figure reproduced with permissionfrom ref. [68]. Copyright 2017 American Chemical Society

3.2 Valid reporting protocols of isotopic 13CO2 labelling experiment results

13C isotopic tracing using 13CO2 to substitute CO2 is the most convincing and credible strategy to investigate the carbon source of the photocatalytic reaction products, and has become an essential step in conducting photocatalytic CO2 reduction research [35, 36, 40]. Mass spectrometry (MS), as an analytical tool for measuring the mass-to-charge ratio (m/z) of one or more molecules present in a sample, is well suited for the measurement of the differences in the abundances of isotopes [69]. However, the fragmentation interferences under certain circumstances may drastically affect quantification or leading to erroneous results. For instance, the mass spectrum of CO2 exhibits peaks with m/z ratios of 44, 28, 12, and 16, corresponding to CO2+, CO+, C+, and O+ ions, while that of CO consists of peaks located at m/z ratios of 28, 12, and 16, which could also be indexed to CO+, C+, and O (Fig. 5) [70]. This makes it virtually impossible to quantify trace amount of CO diluted in CO2 atmosphere using a single MS, which is happened to be the case in photocatalytic CO2 reduction research. Accordingly, gas chromatography-mass spectrometer (GC-MS), an analytical method that combines the features of both gas chromatography (GC) and mass spectrometry (MS) is adopted to identify the different substances within the gas products of CO2 reduction, wherein the compounds can be identified not only by comparing their retention times in the total ion chromatogram (TIC) to a standard, as in conventional GC, but also by the mass spectra of different components included in each point of TIC [71]. However, owing to the lack of understanding on the principle of this technology, mistakes like providing a single mass spectrum with no GC chromatogram, and/or the coexistence of fragment ions of both CO2 and CO in one mass spectrum recorded by a GC-MS, widely exist in the published works.

Standard electron ionization mass spectra of (a) CO2 and (b) CO from NIST Chemistry WebBook [70]

A thorough literature survey reveals that the most popular configuration of GC-MS employed in photocatalytic CO2 reduction area is a CO2 and H2O tolerant capillary column combined with a single quadrupole mass spectrometry, and the common chromatographic column is a bonded polystyrene-divinylbenzene column (also called PLOT Q column) or a carbon-based PLOT column [72,73,74,75]. The TIC of a gas mixture with known composition obtained upon a PLOT Q column is shown in Fig. 6. It is clear that the retention time of CO2 is lagged far behind those of CO. Thus, the fragmentation interferences between CO and CO2 can be completely avoided, but along with a drawback that the peak of CO merges with those of Ar, O2, and N2. CO and N2, as known, are isobaric, both exhibit peaks with m/z ratio of 28 [76]. Thus, the incorporation of trace amount of air will severely interfere the analysis of 13C isotopic tracing experiment result. This is the reason why Ar rather than N2 is recommended as the sweeping gas in 13C isotopic tracing photocatalytic CO2 reduction experiment, and also why a high degree of airtightness is required for the photocatalytic reactors.

A valid data reporting protocols for the 13C isotopic tracing experiment results obtained upon a 7890B-5977B GC-MS (Agilent Technologies) equipped with a GS Carbon Plot column is presented in Fig. 7 (see supporting information for experimental details) [77]. The TIC consists of two broad peaks, with the former coalescent peak composed of Ar, O2, N2, and 13CO signals, while the latter one being the peak of 13CO2. The mass spectrum at the rear of the coalescent peak after background correction exhibits peaks with m/z ratios of 29, 28, 16, 13, and 12, corresponding to 13CO+, CO+, O+, 13C+, and C+ ions, wherein the abundance of 13CO+ ions is dominated over that of CO+, implying that CO product does come from the reduction of CO2. Here it should be also emphasized that the peaks with m/z ratios of 32 and 28 could be the background contaminant O2+ and N2+ ions which are originated from the trace amount of leaked air.

Analytical data of 13C isotopic tracing photocatalytic CO2 reduction experiment recorded by a Agilent 7890B-5977B GC-MS. (a) TIC Scan; (b) 13CO mass spectrum; (c) 13CO2 mass spectrum. Reaction condition: photocatalyst, 0.05 g Cd0.2Zn0.8S; solution volume, 50 mL; sacrifical reagent, 0.1 M Na2SO3; atmosphere, 1 atm; light source, 300 W Xe lamp

Tanaka group employed a different GC-TCD-MS configuration, which introduces the sampling gas into a mass spectrometer after the separation of different components by a gas chromatography equipped with a thermal conductivity detector (TCD), wherein the permanent gases including H2, O2, N2, CH4, and CO is separated from each other by a packed molecular sieve column [22, 68]. As shown in Fig. 8, separated peaks corresponding to H2, O2, and CO are observed in the GC-TCD chromatogram, and the peaks attributable to CO are detected at the same retention time in both the GC chromatogram and mass spectrum, along with the principal reaction product being 13CO (m/z = 29), verifying that CO evolved over the photocatalyst definitely originates from CO2 in the gas phase. This GC-TCD-MS configuration achieves an efficient separation of H2, O2, N2, CH4, and CO, seems to be more suitable for the investigation of the origin of carbon containing production in photocatalytic CO2 reduction than the aforementioned GC-MS equipped with a GS Carbon Plot column.

Gas chromatogram and mass spectra (m/z = 28 and 29) in the photocatalytic conversion of 13CO2 by H2O over Ag/3.0 Yb/Ga2O3 after 2 h. Photocatalyst weight, 0.5 g; CO2 flow, 30 mL min− 1; solution volume, 1.0 L; additive, 0.1 M NaHCO3; light source, 400 W Hg lamp. Figure reproduced with permissionfrom ref. [68]. Copyright 2017 American Chemical Society

Synchrotron vacuum ultraviolet photoionization mass spectrometry (SVUV-PIMS) has been also employed in several works to verify the origination of CO in photocatalytic CO2 reduction [78]. The wide tunability and high energy resolution of photoionization energy of this technology, as reported, could facilitate the identification of the difference in the ionization thresholds of CO and CO2. Thus, a delicate selection of photoionization energy can effectively eliminate the release of 13CO (m/z = 29) fragment ions from 13CO2, elegantly circumventing the fragmentation interference problem between CO and CO2 (Fig. 9a) [80,81,82]. According to Fig. 9b, peaks with m/z ratios of 45 and 29 corresponding to 13CO2+ and 13CO+ ions can be found in one mass spectrum, but the 13CO+ here is originated from the ionisation of 13CO rather than the fragments ions of 13CO2, affirming the reduction of CO2 into CO via photocatalytic process. Here we recommend researchers being aware of the difference between this technology and traditional electron impact mass spectrometry, which suffers a severe fragmentation interference between CO and CO2.

(a) Photonionization cross sections of CO+ ions derived from CO and CO2 from Photonionization Cross Section Database [79]. (b) SVUV-PIMS spectrum of the products after 13CO2 photoreduction for the CuS atomic layers at photoionization energy of 14.5 eV. Figure reproduced with permissionfrom ref. [80]. Copyright 2019 American Chemical Society

Apart from CO, many other chemicals could also be present in the CO2 reduction products, ranging from CH4 to higher alkanes in the gas phase, and oxygenates in the liquid phase, like methanol (CH3OH), and ethanol (C2H5OH) [43]. The existence of isotopes in these carbon-containing products can also be verified by using GC-MS technology, wherein a shift in the m/z value which depends on the number of carbon atoms contained in the fragment ions could be found in the 13C labelled compounds, despite their retention times being the same as those of the non-labelled compounds. The standard mass spectra of CH4, C2H6, C2H4, CH3OH, and C2H5OH as well as H2O are shown in Fig. 10 for reference [70]. Notably, background correction is necessary and important for analysing the origin of CH4 product in photocatalytic CO2 reduction, due to the fragmentation interference between the background contamination OH+ ion derived from H2O and the 13CH4+ ion of 13CH4, both of which have a m/z value of 17.

Standard electron ionization mass spectra of (a) CH4, (b) H2O, (c) C2H6, (d) C2H4, (e) CH3OH and (f) C2H5OH from NIST Chemistry WebBook [70]

Besides, techniques including nuclear magnetic resonance (NMR) [83, 84] and Fourier transform infrared spectroscopy (FTIR) [44], in addition to the above-mentioned GC-MS, have also been employed in the analysis of 13C isotopic tracing experiment results to investigate the origin of the reaction products, such as formic acid (HCOOH). However, due to the high caseloads as well as our limited knowledge, these are not included in the current work.

4 Challenges and cautions in quantifying the amount of O2

The use of the earth-abundant H2O as a reducing reagent represents the best possible scenario for photocatalytic CO2 reduction to mimics plant photosynthesis [52]. One of the necessary conditions to verify the reduction of CO2 by H2O is the balance between photogenerated electrons and holes [70]. Thus, in recent years, there is an increase in literature that demonstrated the stoichiometric production of O2 along with CO2 photoreduction under visible or even infrared light irradiation. This is in distinct contrast to the problem confronted at the early stage of photocatalytic overall water splitting research, that many research groups failed to confirm the consumption balance between the generated electrons and holes, i.e., the ratio between the amount of the reduction (H2) and oxidation (O2) products is always deviated from 2:1 [53,54,55], despite that the two processes share similar fundamental principles and a common H2O oxidation half reaction, and the product yields of photocatalytic CO2 reduction is much lower than that of water splitting. These distinct phenomena found in the two reactions thus makes some of the reported results in photocatalytic CO2 reduction field questionable.

The concentration of O2 in a gas mixture is generally quantified by GC-TCD, with a limit of detection of around 50 ~ 100 ppm when choosing He as the carrier gas [85]. It is right on the same level as that of the O2 evolved in a photocatalytic CO2 reduction, which is about 100 ppm if 0.02 g photocatalyst with a moderate CO2 reduction activity, for instance, a CO evolution rate of 10 μmol g− 1 h− 1, is irradiation for 1 h in a photoreactor with a free volume of 20 mL. This, therefore, makes the accurate quantification of O2 evolved during the photocatalytic reaction process very challenging. Although the accumulation of O2 in classical batch reactors with the extension of reaction time will certainly lead to a monotonic increase in its concentration, facilitating the quantification process [12, 86, 87], the air leakage problem in batch reactors and the inevitable incorporation of air when sampling using a gas-tight syringe, will make the quantification of the O2 molecules produced from H2O oxidation very difficult [87]. The amount of O2 originated from air sometimes can be calibrated via exploring the variation in the concentration of N2 in the reaction system, considering the fixed concentration ratio of N2 to O2 in air. But this method carries a large margin of error, cannot be applied for the accurate quantification of O2 yield. Flow reactors in combination with on-line automatic product analysis, wherein air leakage rarely happens, have also been employed in the photocatalytic CO2 reduction research [12, 85, 86]. But the key issue is that the continuous flow of the carrier gas will lead to a continuous dilution of the evolved O2 in the sampling gas, making its quantification also very challenging.

Apparently, an essential precondition for the detection of O2 generated in photocatalytic CO2 reduction is to eliminate the interference from air leakage. The most common solution to date is the development of a gas-tight reaction system equipped with an on-line analysis equipment, while recently another option is proposed by K. Domen group to conduct the photocatalytic CO2 reduction experiment in an anaerobic glove box, which has been proven to be effective in their recently published works [29]. As for the accurate quantification of O2, the feasible solution is to maximize the concentration of O2 in the reactor well above the limit of detection of GC-TCD via increasing the dosage of photocatalyst, decreasing the free volume of reactor, and/or amplifying the incident light intensity, or perhaps to employee a GC equipped with a barrier ionization discharge (BID) detector which has a sensitivity greater than 100 times that of a TCD [88].

5 Conclusion and perspective

Photocatalytic CO2 reduction by H2O mimics the photosynthesis process of natural plants, provides an ideal pathway to solve both the energy crisis and environmental pollution problems. A great deal of efforts is worthy to be done to promote the development of this technology from laboratory level to practical application in the future. However, multiple challenges that spread all over the complex and consecutive physicochemical processes occurred during the photoreduction of CO2 are still unsolved at the current stage, leading to the inferior yields of hydrocarbon fuels. Moreover, carbon contaminants in the photocatalytic reaction system have been proven to decompose to small molecules under light irradiation, the amount of which could be far greater than many reported values attributed to the photoreduction of CO2, causing the overestimation of catalytic activities or even false positive results. Therefore, the accurate identification and quantification of the real reduction products becomes a critical issue that have to be solved before the further development of this technology.

Here in this perspective, we systemically discuss the possible sources of errors in the product quantification of photocatalytic CO2 reduction. The researchers in this area are recommend to be aware of the possible contribution from the decomposition products of the carbonaceous contaminants on the surface of or contained inside photocatalysts and the sacrificial reagents and/or chemical additives in reaction medium, to the final products, and also be cautious when using light sources with their emission spectra containing UV-C wave bands, because UV disinfection will lead to the release of small molecules from the micropollutants in deionized water and/or adsorbed on the reactor walls. In addition, the potential risk in the gas-solid reaction mode is also alerted, since the strong photothermal effect will accelerate the decomposition of carbonaceous contaminants.

We further elaborate the current approaches employed in the verification of the carbon source of photocatalytic products. Taking one of the CO2 reduction products, CO, as an example, the common mistakes spread in the analysis of 13CO2 labelling experiments are specified, and the reliable reporting protocols for the isotopic tracing results are prosed. Then, the challenges and cautions in the precise measurement of O2 evolution rate is elaborated, and maximizing the concentration of O2 in the reactor well above the limit of detection is proposed to be a feasible solution to mitigate this troublesome issue.

We hope the viewpoints raised in this work will help the beginners engaged in the photocatalytic CO2 reduction area to improve the reliability of the reported data, thereby benefitting the sustainable progress of this technology in future.

Availability of data and materials

Not applicable.

Abbreviations

- Ar:

-

argon

- BID:

-

barrier ionization discharge

- CH4 :

-

methane

- C2H4 :

-

ethylene

- C2H6 :

-

ethane

- CH3CN:

-

acetonitrile

- CH3CH2OH:

-

ethanol

- CH3OH:

-

methanol

- CO2 :

-

carbon dioxide

- CO:

-

carbon monoxide

- EAA:

-

ethyl acetate

- FTIR:

-

Fourier transform infrared spectroscopy

- GC:

-

gas chromatography

- GC-MS:

-

gas chromatography-mass spectrometry

- H2 :

-

hydrogen

- HCOOH:

-

formic acid

- H2O:

-

water

- MS:

-

mass spectrometry

- m/z:

-

mass to charge ratio

- N2 :

-

nitrogen

- Na2SO3 :

-

sodium sulfite

- NMR:

-

nuclear magnetic resonance

- O2 :

-

oxygen

- SVUV-PIMS:

-

synchrotron vacuum ultraviolet photoionization mass spectrometry

- TEOA:

-

triethanolamine

- TEA:

-

triethylamine

- TIC:

-

total ion chromatogram

- TCD:

-

thermal conductivity detector

- UV:

-

ultraviolet

- Xe:

-

xenon

References

International Energy Agency (2021) Global energy review 2021. IEA Publications, Paris. https://www.iea.org/reports/global-energy-review-2021

Butler J, Montzka S (2021) The noaa annual greenhouse gas index (AGGI). NOAA Global Monitoring Laboratory https://gml.noaa.gov/aggi/aggi.html

Hall DO, Rao KK (1999) Photosynthesis, 6th edn. Cambridge University Press, Cambridge, pp 214.

Shih CF, Zhang T, Li J, Bai C (2018) Powering the future with liquid sunshine. Joule 2(10):925–1949. https://doi.org/10.1016/j.joule.2018.08.016

He J, Janáky C (2020) Recent advances in solar-driven carbon dioxide conversion: expectations versus reality. ACS Energy Lett 5(6):1996–2014. https://doi.org/10.1021/acsenergylett.0c00645

Adamu A, Russo-Abegão F, Boodhoo K (2020) Process intensification technologies for CO2 capture and conversion-a review. BMC Chem Eng 2(1):2. https://doi.org/10.1186/s42480-019-0026-4

Romano V, D'Angelo G, Perathoner S et al (2021) Current density in solar fuel technologies. Energy Environ Sci 14(11):5760–5787. https://doi.org/10.1039/d1ee02512k

Halmann M (1978) Photoelectrochemical reduction of aqueous carbon dioxide on p-type gallium phosphide in liquid junction solar cells. Nature 275(5676):115–116. https://doi.org/10.1038/275115a0

Inoue T, Fujishima A, Konishi S et al (1979) Photoelectrocatalytic reduction of carbon dioxide in aqueous suspensions of semiconductor powders. Nature 277(5698):637–638. https://doi.org/10.1038/277637a0

Wu JH, Huang Y, Ye W, Li Y (2017) CO2 reduction: from the electrochemical to photochemical approach. Adv Sci 4(11):1700194. https://doi.org/10.1002/Advs.201700194

Sun ZY, Talreja N, Tao HC, Texter J, Muhler M, Strunk J, Chen J (2018) Catalysis of carbon dioxide photoreduction on nanosheets: fundamentals and challenges. Angew Chem Int Ed 57(26):7610–7627. https://doi.org/10.1002/anie.201710509

Khan AA, Tahir M (2019) Recent advancements in engineering approach towards design of photo-reactors for selective photocatalytic CO2 reduction to renewable fuels. J CO2 Util 29:205–239. https://doi.org/10.1016/j.jcou.2018.12.008

Albero J, Peng Y, Garcia H (2020) Photocatalytic CO2 reduction to C2+ products. ACS Catal 10(10):5734–5749. https://doi.org/10.1021/acscatal.0c00478

Wang ZJ, Song H, Liu HM, Ye J (2020) Coupling of solar energy and thermal energy for carbon dioxide reduction: status and prospects. Angew Chem Int Ed 59(21):8016–8035. https://doi.org/10.1002/anie.201907443

Iizuka K, Wato T, Miseki Y, Saito K, Kudo A (2011) Photocatalytic reduction of carbon dioxide over ag cocatalyst-loaded ALa4Ti4O15 (a = ca, Sr, and Ba) using water as a reducing reagent. J Am Chem Soc 133(51):20863–20868. https://doi.org/10.1021/ja207586e

Nakanishi H, Iizuka K, Takayama T, Iwase A, Kudo A (2017) Highly active NaTaO3-based photocatalysts for CO2 reduction to form CO using water as the electron donor. Chem Sus Chem 10(1):112–118. https://doi.org/10.1002/cssc.201601360

Iguchi S, Teramura K, Hosokawa S, Tanaka T (2016) A ZnTa2O6 photocatalyst synthesized via solid state reaction for conversion of CO2 into CO in water. Catal Sci Technol 6:4978–4985. https://doi.org/10.1039/C6CY00271D

Huang Z, Teramura K, Hosokawa S, Tanaka T (2016) Fabrication of well-shaped Sr2KTa5O15 nanorods with a tetragonal tungsten bronze structure by a flux method for artificial photosynthesis. Appl Catal B 199:272–281. https://doi.org/10.1016/j.apcatb.2016.06.039

Zhu X, Yamamoto A, Imai S, Tanaka A, Kominami H, Yoshida H (2019) A silver-manganese dual co-catalyst for selective reduction of carbon dioxide into carbon monoxide over a potassium hexatitanate photocatalyst with water. Chem Commun 55(90):13514–13517. https://doi.org/10.1039/C9CC06038C

Wang Z, Teramura K, Hosokawa S, Tanaka T (2015) Photocatalytic conversion of CO2 in water over ag-modified La2Ti2O7. Appl Catal B 163:241–247. https://doi.org/10.1016/j.apcatb.2014.07.052

Wang S, Teramura K, Hisatomi T, Domen K, Asakura H, Hosokawa S, Tanaka T (2021) Dual ag/co cocatalyst synergism for the highly effective photocatalytic conversion of CO2 by H2O over Al-SrTiO3. Chem Sci 12(13):4940–4948. https://doi.org/10.1039/D1SC00206F

Wang S, Teramura K, Hisatomi T, Domen K, Asakura H, Hosokawa S, Tanaka T (2020) Effective driving of ag-loaded andAl-doped SrTiO3 under irradiation at λ > 300 nm for the photocatalytic conversion of CO2 by H2O. ACS Appl Energy Mater 3(2):1468–1475. https://doi.org/10.1021/acsaem.9b01927

Yoshida T, Yamamoto N, Mizutani T, Yamamoto M, Ogawa S, Yagi S, Nameki H, Yoshida H (2018) Synthesis of ag nanoparticles prepared by a solution plasma method and application as a cocatalyst for photocatalytic reduction of carbon dioxide with water. Catal Today 303:320–326. https://doi.org/10.1016/j.cattod.2017.08.047

Wang Z, Teramura K, Hosokawa S, Tanaka T (2015) Highly efficient photocatalytic conversion of CO2 into solid CO using H2O as a reductant over ag-modified ZnGa2O4. J Mater Chem A 3(21):11313–11319. https://doi.org/10.1039/C5TA01697E

Takayama T, Sato K, Fujimura T, Kojima Y, Iwase A, Kudo A (2017) Photocatalytic CO2 reduction using water as an electron donor by a powdered Z-scheme system consisting of metal sulfide and an RGO-TiO2 composite. Faraday Discuss 198:397–407. https://doi.org/10.1039/c6fd00215c

Iwase A, Yoshino S, Takayama T, Ng YH, Amal R, Kudo A (2016) Water splitting and CO2 reduction under visible light irradiation using Z-scheme systems consisting of metal sulfides, CoOx-loaded BiVO4, and a reduced graphene oxide electron mediator. J Am Chem Soc 138(32):10260–10264. https://doi.org/10.1021/jacs.6b05304

Suzuki TM, Yoshino S, Takayama T, Iwase A, Kudo A, Morikawa T (2018) Z-schematic and visible-light-driven CO2 reduction using H2O as an electron donor by a particulate mixture of a Ru-complex/(CuGa)1−xZn2xS2 hybrid catalyst, BiVO4 and an electron mediator. Chem Commun 54(72):10199–10202. https://doi.org/10.1039/C8CC05505J

Yoshino S, Sato K, Yamaguchi Y, Iwase A, Kudo A (2020) Z-schematic CO2 reduction to CO through interparticle electron transfer between SrTiO3:Rh of a reducing photocatalyst and BiVO4 of a water oxidation photocatalyst under visible light. ACS Appl Energy Mater 3(10):10001–10007. https://doi.org/10.1021/acsaem.0c01684

Wang Q, Warnan J, Rodriguez-Jimenez S et al (2020) Molecularly engineered photocatalyst sheet for scalable solar formate production from carbon dioxide and water. Nat Energy 5(9):703–710. https://doi.org/10.1038/s41560-020-0678-6

Meng X, Yu Q, Liu G, Shi L, Zhao G, Liu H, Li P, Chang K, Kako T, Ye J (2017) Efficient photocatalytic CO2 reduction in all-inorganic aqueous environment: cooperation between reaction medium and cd (II) modified colloidal ZnS. Nano Energy 34:524–532. https://doi.org/10.1016/j.nanoen.2017.03.021

Meng X, Zuo G, Zong P, Pang H, Ren J, Zeng X, Liu S, Shen Y, Zhou W, Ye J (2018) A rapidly room-temperature-synthesized cd/ZnS:cu nanocrystal photocatalyst for highly efficient solar-light-powered CO2 reduction. Appl Catal B 237:68–73. https://doi.org/10.1016/j.apcatb.2018.05.066

Kuriki R, Sekizawa K, Ishitani O, Maeda K (2015) Visible-light-driven CO2 reduction with carbon nitride: enhancing the activity of ruthenium catalysts. Angew Chem Int Ed 54(8):2406–2409. https://doi.org/10.1002/anie.201411170

Lin J, Pan Z, Wang X (2014) Photochemical reduction of CO2 by graphitic carbon nitride polymers. ACS Sustain Chem Eng 2(3):353–358. https://doi.org/10.1021/sc4004295

Guo Q, Liang F, Li X-B, Gao YJ, Huang MY, Wang Y, Xia SG, Gao XY, Gan QC, Lin ZS, Tung CH, Wu LZ (2019) Efficient and selective CO2 reduction integrated with organic synthesis by solar energy. Chem 5(10):2605–2616. https://doi.org/10.1016/j.chempr.2019.06.019

Chang X, Wang T, Gong J (2016) CO2 photo-reduction: insights into CO2 activation and reaction on surfaces of photocatalysts. Energy Environ Sci 9(7):2177–2196. https://doi.org/10.1039/C6EE00383D

Fresno F, Villar-Garcia IJ, Collado L et al (2018) Mechanistic view of the main current issues in photocatalytic CO2 reduction. J Phys Chem Lett 9(24):7192–7204. https://doi.org/10.1021/acs.jpclett.8b02336

Li X, Yu J, Jaroniec M, Chen X (2019) Cocatalysts for selective photoreduction of CO2 into solar fuels. Chem Rev 119(6):3962–4179. https://doi.org/10.1021/acs.chemrev.8b00400

Fu JW, Jiang KX, Qiu XQ, Yu J, Liu M (2020) Product selectivity of photocatalytic CO2 reduction reactions. Mater Today 32:222–243. https://doi.org/10.1016/j.mattod.2019.06.009

Kong TT, Jiang YW, Xiong YJ (2020) Photocatalytic CO2 conversion: what can we learn from conventional COx hydrogenation? Chem Soc Rev 49(18):6579–6591. https://doi.org/10.1039/c9cs00920e

Li K, Peng BS, Peng TY (2016) Recent advances in heterogeneous photocatalytic CO2 conversion to solar fuels. ACS Catal 6(11):7485–7527. https://doi.org/10.1021/acscatal.6b02089

Bo YA, Gao C, Xiong YJ (2020) Recent advances in engineering active sites for photocatalytic CO2 reduction. Nanoscale 12(23):12196–12209. https://doi.org/10.1039/d0nr02596h

Christopher P, Jin S, Sivula K, Kamat PV (2021) Why seeing is not always believing: common pitfalls in photocatalysis and electrocatalysis. ACS Energy Lett 6(2):707–709. https://doi.org/10.1021/acsenergylett.1c00064

Hong JD, Zhang W, Ren J, Xu R (2013) Photocatalytic reduction of CO2:a brief review on product analysis and systematic methods. Anal Methods 5(5):1086–1097. https://doi.org/10.1039/c2ay26270c

Yang CC, Yu YH, van der Linden B, Wu JCS, Mul G (2010) Artificial photosynthesis over crystalline TiO2-based catalysts: fact or fiction? J Am Chem Soc 132(24):8398–8406. https://doi.org/10.1021/ja101318k

Grigioni I, Dozzi MV, Bernareggi M, Chiarello GL, Selli E (2017) Photocatalytic CO2 reduction vs. H2 production: the effects of surface carbon-containing impurities on the performance of TiO2-based photocatalysts. Catal Today 281:214–220. https://doi.org/10.1016/j.cattod.2016.05.040

Yuan L, Lu KQ, Zhang F, Fu X, Xu YJ (2018) Unveiling the interplay between light-driven CO2 photocatalytic reduction and carbonaceous residues decomposition: a case study of Bi2WO6-TiO2 binanosheets. Appl Catal B 237:424–431. https://doi.org/10.1016/j.apcatb.2018.06.019

Yui T, Kan A, Saitoh C, Koike K, Ibusuki T, Ishitani O (2011) Photochemical reduction of CO2 using TiO2: effects of organic adsorbates on TiO2 and deposition of Pd onto TiO2. ACS Appl Mater Interfaces 3(7):2594–2600. https://doi.org/10.1021/am200425y

Mei B, Pougin A, Strunk J (2013) Influence of photodeposited gold nanoparticles on the photocatalytic activity of titanate species in the reduction of CO2 to hydrocarbons. J Catal 306:184–189. https://doi.org/10.1016/j.jcat.2013.06.027

Das R, Chakraborty S, Peter SC (2021) Systematic assessment of solvent selection in photocatalytic CO2 reduction. ACS Energy Lett 6(9):3270–3274. https://doi.org/10.1021/acsenergylett.1c01522

Kamat PV, Jin S (2018) Semiconductor photocatalysis: "tell us the complete story!". ACS Energy Lett 3(3):622–623. https://doi.org/10.1021/acsenergylett.8b00196

Costantino F, Kamat PV (2022) Do sacrificial donors donate H2 in photocatalysis? ACS Energy Lett 7(1):42–246. https://doi.org/10.1021/acsenergylett.1c02487

Teramura K, Tanaka T (2018) Necessary and sufficient conditions for the successful three-phase photocatalytic reduction of CO2 by H2O over heterogeneous photocatalysts. Phys Chem Chem Phys 20(31):20733–20733. https://doi.org/10.1039/c8cp91824d

Kiwi J, Graetzel M (1984) Optimization of conditions for photochemical water cleavage. Aqueous platinum/TiO2 (anatase) dispersions under ultraviolet light. J Phys Chem 88(7):1302–1307. https://doi.org/10.1021/j150651a012

Kudo A, Tanaka A, Domen K et al (1988) Photocatalytic decomposition of water over NiO@K4Nb6O17 catalyst. J Catal 111(1):67–76. https://doi.org/10.1016/0021-9517(88)90066-8

Han K, Kreuger T, Mei BT, Mul G (2017) Transient behavior of Ni@NiOx functionalized SrTiO3 in overall water splitting. ACS Catal 7(3):1610–1614. https://doi.org/10.1021/acscatal.6b03662

Zaera F (2013) Nanostructured materials for applications in heterogeneous catalysis. Chem Soc Rev 42(7):2746–2762. https://doi.org/10.1039/C2CS35261C

Greczynski G, Hultman L (2020) X-ray photoelectron spectroscopy: towards reliable binding energy referencing. Prog Mater Sci 107:100591. https://doi.org/10.1016/j.pmatsci.2019.100591

Ulagappan N, Frei H (2000) Mechanistic study of CO2 photoreduction in Ti silicalite molecular sieve by FT-IR spectroscopy. J Phys Chem A 104(33):7834–7839. https://doi.org/10.1021/jp001470i

Corby S, Rao RR, Steier L, Durrant JR (2021) The kinetics of metal oxide photoanodes from charge generation to catalysis. Nat Rev Mater 6(12):1136–1155. https://doi.org/10.1038/s41578-021-00343-7

Wang Y, Huang NY, Shen JQ, Liao PQ, Chen XM, Zhang JP (2018) Hydroxide ligands cooperate with catalytic centers in metal-organic frameworks for efficient photocatalytic CO2 reduction. J Am Chem Soc 140(1):38–41. https://doi.org/10.1021/jacs.7b10107

Xu Y-F, Yang M-Z, Chen B-X, Wang XD, Chen HY, Kuang DB, Su CY (2017) A CsPbBr3 perovskite quantum dot/graphene oxide composite for photocatalytic CO2 reduction. J Am Chem Soc 139(16):5660–5663. https://doi.org/10.1021/jacs.7b00489

Pang H, Meng XG, Li P, Chang K, Zhou W, Wang X, Zhang X, Jevasuwan W, Fukata N, Wang D, Ye J (2019) Cation vacancy-initiated CO2 photoreduction over ZnS for efficient formate production. ACS Energy Lett 4(6):1387–1393. https://doi.org/10.1021/acsenergylett.9b00711

Jeyalakshmi V, Mahalakshmy R, Krishnamurthy KR, Viswanathan B (2016) Photocatalytic reduction of carbon dioxide in alkaline medium on La modified sodium tantalate with different co-catalysts under UV-visible radiation. Catal Today 266:160–167. https://doi.org/10.1016/j.cattod.2015.09.004

Hebig KH, Noedler K, Licha T et al (2014) Impact of materials used in lab and field experiments on the recovery of organic micropollutants. Sci Total Environ 473:125–131. https://doi.org/10.1016/j.scitotenv.2013.12.004

Strom C (2018) Difference between deionized and distilled water. Difference Between Similar Terms and Objects. http://www.differencebetween.net/science/difference-between-deionized-and-distilled-water/

Gray NF (2014) Ultraviolet disinfection. In: Microbiology of waterborne diseases, 2nd edn. Academic Press, London, pp 617–630. https://doi.org/10.1016/B978-0-12-415846-7.00034-2

Xie S, Wang Y, Zhang Q, Deng W, Wang Y (2014) MgO- and Pt-promoted TiO2 as an efficient photocatalyst for the preferential reduction of carbon dioxide in the presence of water. ACS Catal 4(10):3644–3653. https://doi.org/10.1021/cs500648p

Tatsumi H, Teramura K, Huang Z, Wang Z, Asakura H, Hosokawa S, Tanaka T (2017) Enhancement of CO evolution by modification of Ga2O3 with rare-earth elements for the photocatalytic conversion of CO2 by H2O. Langmuir 33(49):13929–13935. https://doi.org/10.1021/acs.langmuir.7b03191

Maher S, Jjunju FPM, Taylor S (2015) Colloquium: 100 years of mass spectrometry: perspectives and future trends. Rev Mod Phys 87(1):113–135. https://doi.org/10.1103/RevModPhys.87.113

National Institute of Standards and Technology Mass Spectrometry Data Center (2021) "Mass spectra" in nist chemistry webbook. In Nist standard reference database number 69., NIST, Gaithersburg MD, 2021

Sparkman OD, Penton Z, Kitson F (2011) Gas chromatography and mass spectrometry: a practical guide, 2nd edition. Academic Press Inc., San Diego, pp 632.

Huang Q, Liu J, Feng L, Wang Q, Guan W, Dong LZ, Zhang L, Yan LK, Lan YQ, Zhou HC (2020) Multielectron transportation of polyoxometalate-grafted metalloporphyrin coordination frameworks for selective CO2-to-CH4 photoconversion. Natl Sci Rev 7(1):53–63. https://doi.org/10.1093/nsr/nwz096

He P, Yang S, Hu W, Lee S, Huang J (2020) Unraveling the intermediate species of Co3O4 hollow spheres for CO2 photoreduction by in situ X-ray absorption spectroscopy. J Phys Chem C 124(11):6215–6220. https://doi.org/10.1021/acs.jpcc.0c00101

Isobe K, Koba K, Ueda S, Senoo K, Harayama S, Suwa Y (2011) A simple and rapid GC/MS method for the simultaneous determination of gaseous metabolites. J Microbiol Methods 84(1):46–51. https://doi.org/10.1016/j.mimet.2010.10.009

Ai G, Zhu J, Dong X, Sun T (2013) Simultaneous characterization of methane and carbon dioxide produced by cultured methanogens using gas chromatography/isotope ratio mass spectrometry and gas chromatography/mass spectrometry. Rapid Commun Mass Spectrom 27(17):1935–1944. https://doi.org/10.1002/rcm.6651

Sayi YS, Radhakrishna J, Yadav CS, Shankaran PS, Chhapru GC (1990) Rapid estimation of carbon monoxide and nitrogen by quadrupole mass spectrometry. Anal Lett 23(11):2049–2062. https://doi.org/10.1080/00032719008052549

Zhu Q, Xuan Y, Zhang K, Chang K (2021) Enhancing photocatalytic CO2 reduction performance of g-C3N4-based catalysts with non-noble plasmonic nanoparticles. Appl Catal B 297:120440. https://doi.org/10.1016/j.apcatb.2021.120440

Li XD, Liang L, Sun YF, Xu J, Jiao X, Xu X, Ju H, Pan Y, Zhu J, Xie Y (2019) Ultrathin conductor enabling efficient IR light CO2 reduction. J Am Chem Soc 141(1):423–430. https://doi.org/10.1021/jacs.8b10692

Li Y, Yang J, Cheng Z (2017) Photonionization cross section database (version 2.0). Hefei, China

Li Y, Qi F (2010) Recent applications of synchrotron VUV photoionization mass spectrometry: insight into combustion chemistry. Acc Chem Res 43(1):68–78. https://doi.org/10.1021/ar900130b

Hitchcock AP, Brion CE, van der Wiel MJ (1980) Absolute oscillator strengths for valence-shell ionic photofragmentations of N2O and CO2 (8–75 ev). Chem Phys 45(3):461–478. https://doi.org/10.1016/0301-0104(80)87015-7

Wight GR, Wiel MJV, Brion CE (1976) Dipole excitation, ionization and fragmentation of N2 and CO in the 10-60 ev region. J Phys B At Mol Phys 9(4):675–689. https://doi.org/10.1088/0022-3700/9/4/017

Lee Y, Kim S, Fei H, Kang JK, Cohen SM (2015) Photocatalytic CO2 reduction using visible light by metal-monocatecholato species in a metal-organic framework. Chem Commun 51(92):16549–16552. https://doi.org/10.1039/C5CC04506A

Kuriki R, Matsunaga H, Nakashima T, Wada K, Yamakata A, Ishitani O, Maeda K (2016) Nature-inspired, highly durable CO2 reduction system consisting of a binuclear ruthenium (II) complex and an organic semiconductor using visible light. J Am Chem Soc 138(15):5159–5170. https://doi.org/10.1021/jacs.6b01997

ASTM (2017) D3612–02: standard test method for analysis of gases dissolved in electrical insulating oil by gas chromatography. ASTM International, West Conshohocken, PA

Qureshi M, Takanabe K (2017) Insights on measuring and reporting heterogeneous photocatalysis: efficiency definitions and setup examples. Chem Mater 29(1):158–167. https://doi.org/10.1021/acs.chemmater.6b02907

Chen Z, Deutsch TG, Dinh HN et al (2013) Hydrogen and oxygen detection from photoelectrodes. In: Photoelectrochemical water splitting: standards, experimental methods, and protocols. Springer, New York, pp 105–113. https://doi.org/10.1007/978-1-4614-8298-7_9

Lopes AF, Fernandes TSM, do Nascimento RF (2021) Barrier discharge ionization detector in gas chromatography: a review on applications. Crit Rev Anal Chem:1–20. https://doi.org/10.1080/10408347.2021.1969885

Acknowledgements

Not applicable.

Funding

The authors acknowledge the financial support for this work from the Basic Science Center Project for Ordered Energy Conversion of the National Natural Science Foundation of China (No. 51888103).

Author information

Authors and Affiliations

Contributions

YX supervised the project. KZ, QG, QZ, ZZ, and JW designed and performed the photocatalytic experiments. KZ, QG, CX, DZ, QZ, ZZ, JW, CL, HY, CS, XL, and YX analyzed and discussed the experimental results. KZ, QG, CX, DZ, and YX drafted and revised the manuscript. The authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

The manuscript has been read and approved by all authors, and all authors agree to the publication of the manuscript.

Competing interests

The authors declare no competing financial interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, K., Gao, Q., Xu, C. et al. Current dilemma in photocatalytic CO2 reduction: real solar fuel production or false positive outcomings?. Carb Neutrality 1, 10 (2022). https://doi.org/10.1007/s43979-022-00011-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43979-022-00011-x