Abstract

Digital technologies are becoming more pervasive and industrial companies are exploiting them to enhance the potentialities related to Prognostics and Health Management (PHM). Indeed, PHM allows to evaluate the health state of the physical assets as well as to predict their future behaviour. To be effective in developing PHM programs, the most critical assets should be identified so to direct modelling efforts. Several techniques could be adopted to evaluate asset criticality; in industrial practice, criticality analysis is amongst the most utilised. Despite the advancement of artificial intelligence for data analysis and predictions, the criticality analysis, which is built upon both quantitative and qualitative data, has not been improved accordingly. It is the goal of this work to propose an ontological formalisation of a multi-attribute criticality analysis in order to i) fix the semantics behind the terms involved in the analysis, ii) standardize and uniform the way criticality analysis is performed, and iii) take advantage of the reasoning capabilities to automatically evaluate asset criticality and associate a suitable maintenance strategy. The developed ontology, called MOCA, is tested in a food company featuring a global footprint. The application shows that MOCA can accomplish the prefixed goals; specifically, high priority assets towards which direct PHM programs are identified. In the long run, ontologies could serve as a unique knowledge base that integrate multiple data and information across facilities in a consistent way. As such, they will enable advanced analytics to take place, allowing to move towards cognitive Cyber Physical Systems that enhance business performance for companies spread worldwide.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Digital technologies are enabling Prognostics and Health Management (PHM) to become a cornerstone for companies willing to have insights on their shopfloor status [1]. Specifically, PHM allows to evaluate the health state of the physical assets and to predict their future behaviour so to intercept possible deviations from normal conditions [2]. These potentialities have increased over time thanks to the use of several modelling techniques, including physical models, statistical models and artificial intelligence (AI) [3]. Specifically, AI models, in particular Machine and Deep Learning, are promising to improve state detection, health assessment and prognostic assessment performance given their ability to describe and approximate complex dataspaces, where statistical models may stack [4]. As such, PHM could support maintenance management and has a key role also within asset management [5].

Nevertheless, a PHM program to succeed needs to be properly set since the beginning; many are those programs that do not reach optimal performance, for various reasons [6] that are either technical or organisational. Thus, to pave the way for a successful PHM program development, it is important to perform an analysis of available assets to understand on which the modelling efforts must be directed [7]. It is relevant to adequately plan the spending committed in the development of advanced technologies and organizational implications; indeed, investments in PHM, for hardware, software and competencies, should be carefully defined as, otherwise, they may compromise the benefits the PHM itself could bring in terms of performance improvement. In order to make a balanced analysis of costs and opportunities, high-priority assets are typically addressed by PHM programs. The evaluation of the prioritization of the assets is performed by looking at their criticality, assessed from several perspectives depending on specific business requirements [8]. The multiple perspectives extend the traditional machine-narrowed, availability-focused criticality evaluation of assets towards a broader set of characteristics, envisioned to be more sustainability [9] and system level [10] oriented for the coming years. However, extended criticality analyses are not widely spread in industry for various reasons and several shortages exist in the related tools [11].

Indeed, to assess the criticality of an asset it is possible to refer to process hazards analysis (PHA) that includes several techniques, such as, for example, FMEA/FMECA (Failure Modes and Effects Analysis, with eventual Criticality Analysis) and HAZOP (Hazards and Operability analysis) [7]. Amongst them, the multi-attribute criticality analysis, both at asset level and component level is the most widely used [12]. Despite its relevance, the multi-attribute criticality analysis currently suffers of some limitations, mainly related to the unavailability of historical data to evaluate asset performance; this limitation is especially true in the beginning of life (BoL) of the asset, where only qualitative information through a subjective judgment from experts could be extracted if no benchmarking is possible [13]. Furthermore, for companies owning geographically dispersed facilities, the way the multi-attribute criticality analysis is performed may differ and an overall cross-plant evaluation for budget allocation by the headquarter may be challenging, even unfeasible, due to this potential misalignment [14]. Hence, despite the wide adoption and the strategic role the criticality analysis has, several are the pitfalls that affect its correct implementation.

In this work, the application of symbolic AI is explored to cope with the current gaps in criticality analysis. Symbolic AI refers to the application of techniques, like logic programming and semantic modelling [15]. Specifically, an ontology is proposed to i) fix the semantics behind the terms so to have common and agreed-upon meanings between the involved stakeholders and ii) fix the methodology and computations so to have a common way to perform the criticality analysis. These goals are pursued to leverage on a standardization of the criticality analysis to help properly direct the spending committed for the assets, in particular for the application of advanced technologies, in companies owning several plants.

The proposed ontology follows recent ontology development methodologies and best practices. In particular, the realised ontological model is tested in a global manufacturer in the food sector to prioritise the assets in a new plant in order to plan maintenance strategies in advance in its BoL and, thus, to better direct PHM-related investments. This required to identify and establish a common criticality analysis methodology to be adopted, as standard approach, in other plants to make the evaluation uniform. Generally, depending on the criticality value, different maintenance strategies could be engaged: for those assets of high priority, PHM programs are envisioned to take place to support condition-based maintenance (CBM) as well as predictive maintenance; for very high priority values also redesign, i.e., a more asset management related strategy acting on the characteristics of the industrial technology, plant and/or production process, could be also selected.

The structure of the work is as follows: Sect. 2 provides an overview of criticality analysis; Sect. 3 reviews the literature on ontologies used for criticality analysis to understand current gaps; Sect. 4 proposes and describes the MOCA (multi-attribute ontology-based criticality analysis) ontology, which is then tested, as presented in Sect. 5, in the food company case. Finally, Sect. 6 draws some conclusions and paves the way for future research. This article is an extended version of a conference paper [16] presented at the 17th IFAC Symposium on Information Control Problems in Manufacturing INCOM 2021. With respect to the conference paper, the current work proposes a new, extensive literature review adopting a systematic approach to identify the current state of the art in the ontological formalisation of criticality analysis, pinpointing the current gaps. Furthermore, the MOCA ontology is detailed out, clarifying the used methodology for its development, the reason behind the selection of a specific foundational ontology, the choice to go for non-reflexive relationships between concepts, and a thorough description of how MOCA works thanks to its formalised rules.

2 Basics of multi-attribute criticality analysis

The criticality analysis allows to identify and prioritise undesired events [17]. It is a general-purpose technique that found a flourished application in maintenance and asset management domains. As such, it allows to take asset-related decisions [12].

Single-attribute and multi-attribute criticality analysis are available and the selection of how many attributes depend on the dimensions worth to consider [18] and the unit of analysis, being the asset or the failure mode. The traditional application of the criticality is based on the evaluation of the RPN (Risk Priority Number), which quantifies the criticalities and allows to prioritise assets and/or related failure modes. The RPN is closely related to the FMEA/FMECA methods as expressed in the IEC 60812 [19]. In single-attribute FMECA-like criticality analysis, occurrence, severity and detectability are usually equally weighted and the final RPN defines the final rank. The way RPN is calculated could consider also uncertainties by means of fuzzy logic approaches [20]. To associate a scale to the parameters and relative thresholds there exists some standards, like SAE (link) that merges several criteria to consider, like availability, safety, and quality. In Fig. 1, a scale for severity taken from Bowles [21] is reported, where it is possible to see that a severity value is associated with more criteria.

Example of severity value definition based on multiple criteria (adapted from [21])

The multi-attribute criticality analysis goes beyond the evaluation of RPN and introduces more parameters rather than occurrence, severity and detectability only, like expected cost of failure [18]. In so doing, it is possible to prioritise assets and failure modes in a more precise way given that the weights to the parameters are determined by maintenance experts; a sensitivity analysis is also useful if objective weights cannot be established. The result is a list of assets and failure modes ranked and prioritized according to their criticality.

Once available this information, it is possible to better plan the maintenance strategies. At asset level, for low criticality assets, corrective maintenance still remains the best option; when the criticality increases, it is possible to implement time- or age-based preventive maintenance, condition-based maintenance with or without prognosis, and redesign as last option, beyond the scope of maintenance and more within that of asset management. The criticality thresholds to identify the best maintenance strategy could be defined through a cost-benefit analysis considering the available budget. Figure 2 reports an example of how to allocate maintenance strategies by considering occurrence and severity.

In spite of the long-lasting history behind criticality analysis, its relevance is still increasing due to CBM [22], which enables diagnostics and prognostics actions framed within the PHM discipline. However, not all assets require CBM/PHM to be put in place since the investment in monitoring systems, both in terms of hardware and software, may not be economically advantageous. This is particularly true for companies owing multiple plants in which investments may be heavy and where there is not consistency to perform criticality analysis, so that budget planning and allocation may be erroneous based on misleading information. Also, to optimise the operational expenditure during the usage phase of the assets (alias, the middle of life of the assets, i.e., MoL), it is important to plan maintenance strategies in advance with respect to the commissioning of the assets and their operation [23]. However, prior to the installation, thus in the BoL, operational data are not available if not coming from tests, benchmarks, data banks or simulations. These sources of information could be helpful to set a first draft planning of the maintenance strategies, but the conditions in which the assets were tested, simulated, benchmarked, or reported in data banks, could be (very) different from the actual ones. Anyway, planning maintenance strategies in the BoL could be of great advantage [24]. Thus, integrating the available sources at BoL phase, considering both quantitative and qualitative data, is vital to succeed in establishing the criticality analysis. As qualitative data are usually due to experts’ knowledge, it is important to manage their knowledge, and related subjective evaluation, to achieve homogeneity in the analysis.

In the specific context of large companies with a global footprint due to the worldwide spread facilities, the criticality analysis could be carried out taking advantage of the collective knowledge available from experts on field. Nevertheless, there may be the risk that the underlying meaning of terms could change, thus leading to incompatible results between production sites. This, in turn, may affect the optimisation of maintenance and asset management strategies since criticality may be affecting other plans, also related to the spare parts management [25] and investment/reinvestment appraisal [23]. Therefore, a careful consideration should be kept in order to assure the homogeneity of criticality analysis and asset-related decision-making.

In this regard, ontologies are showing potentialities to identify the most suitable maintenance strategies by selecting and assessing machine criticality [26, 27]. In particular, ontologies, models related to symbolic AI, are used in the scientific literature and industry to set up common and agreed-upon terminologies between stakeholders. Furthermore, their reasoning capabilities offer support in the automatic allocation of maintenance strategies to proper assets, and its related components, also combining information coming from diagnostics, for which ontologies are already established, powerful state-of-art means [28]. Nonetheless, as the following Sect. 3 describes through an extensive literature review, some gaps still exist regarding ontology modelling of multi-attribute criticality analysis, especially from the semantic perspective.

3 Review of ontological modelling of criticality analysis in industry

To define the state of art of ontology modelling for criticality analysis, a systematic literature review is performed. The considered databases are Scopus, Web of Science and IEEE Xplore and the research protocol includes:

-

Keywords: ontolog* AND criticality analysis

-

Eligibility criteria:

-

Limitation to journal and conference papers only.

-

Only English written documents.

-

No predefined timespan.

-

The identified documents are screened to assess if they fit with the current goal and only documents relating to the industrial domain are kept. Then, a snowball analysis is performed so to integrate additional scientific works. Figure 3 summarises the step-by-step results obtained in the searching process. The final set is composed of 7 eligible documents, which are analysed to depict the state of art in modelling criticality analysis through ontologies in industry.

Defèr et al. [29] focused on the criticality analysis as a relevant tool to cope with increasing complexity of today production systems. In their work, the authors proposed an ontology for high-level mapping of concepts that overall describe the risk management in complex production systems; furthermore, a lot of effort is put on the identification of relevant data that are needed to be collected from information systems so to suitably carry out the criticality analysis. Ali and Hong [30] studied the criticality analysis in the context of CPS (Cyber Physical System) and position the ontology in the cognition level of the 5C architecture [31]. The developed ontology is able to carry out the criticality analysis according to the traditional FMECA approach; the application shows that the ontology is able to identify the most critical components in a condition monitoring system. In line, also Zhou et al. [28] developed an ontology for advanced FMECA analysis in the context of wind turbines. Both research [28, 30] introduced SWRL (Semantic Web Rule Language) to improve reasoning performance and provide output to the decision-maker; in both cases, the attention is given to failures that affect the availability attribute, thus embracing the traditional approach of FMECA. Castet et al. [32] ontologically modelled both the FMECA and the FTA (Failure Tree Analysis) by defining the main concepts and the relationships between them. The application to two simplified cases, a rover for night-time operations and a NASA habitable spacecraft, shows that the models allow for a deep understanding of the physical decomposition of the asset, the failure modes in evolution and possible failure causes that are affecting the current functioning of the asset. Rehman and Kifor [33] used ontology to model the PFMEA (process FMEA). In their work, the ISO 15926 [34] is used as reference ontology to support modelling all needed concepts that relate to the traditional approach of criticality analysis based on the evaluation of the RPN. Finally, the last eligible paper is a very recent work published in 2021 by Wu et al. [35]. In this work, the FMEA in manufacturing is reviewed so to understand the different approaches and methods that could be used to support criticality analysis in complex industrial environments and at different indenture levels. Especially, the authors summarised the several contributions ontologies bring to FMECA, like specification of semantics, knowledge reuse and reasoning, and improved knowledge management.

3.1 Concluding remarks

The eligible documents allow to state some remarks about the employment of ontologies to model criticality analysis for industrial assets and their related failure modes:

-

1.

all the proposed models confirm that the RPN and the failure mode criticality are the two agreed-upon indicators to prioritise assets and failure modes;

-

2.

ontologies are seen as a way to extract information and infer possible failure modes that are occurring to the asset or possible failure causes that initiate a failure mode;

-

3.

all the proposed ontology-based criticality analyses do consider availability as main attribute, that is, physical (a breakdown) or functional (loss of functionality) failures impacting availability are introduced and prioritised thanks to RPN computation;

-

4.

each of the proposed ontological model relies on its own physical decomposition of the asset, i.e., number of considered indenture levels, and there is no consensus on this matter.

Overall, the analysis of the literature shows that criticality analysis is increasingly related to the ontological modelling. Nonetheless, difference are the holdbacks that are worth to investigate. Firstly, none of the analysed document explicitly states the use of a reference foundational ontology except in one case where the ISO 15926 is used. Secondly, the analysed papers do not advocate, at least from the manuscripts content, the use of methodologies to develop ontological models. Thirdly, none of the eligible documents explicitly uses ontologies as a way to guarantee semantic alignment between stakeholders, but mainly use them for reasoning capabilities. Finally, the availability is the main considered attribute, also safety is worth to mention; nevertheless, it is evident the limited potentiality offered by the criticality analysis in prioritising assets/failure modes in light of additional attributes and, thus, a broader scope of asset-related characteristics. Therefore, this research aims at coping with some of the pitfalls emerged from the systematic literature review. The proposed ontology, named MOCA (Multi-attribute Ontology-based Criticality Analysis) focuses on the description of the multi-attribute criticality analysis based on a reference foundational ontology and by introducing additional attributes as described in Sect. 4.

4 Proposed ontology for multi-attribute criticality analysis

The ontological modelling of MOCA considers a multi-attribute criticality analysis for asset prioritisation that includes quality and energy, which are additional relevant attributes to be considered, besides availability. The main goal of the realised model is the ontological formalisation of concepts as well as the standardization and uniformity of the methodology to evaluate asset criticality. Indeed, the proposed ontology does not outperform the numerical results obtained through already available multi-attribute criticality analysis methods, given that the underlying operations are the same, whereas MOCA is focused on the semantic formalisation and definition of relevant concepts and relationships so to establish a common background and semantic alignment between stakeholders.

Before presenting the ontological modelling, Sect. 4.1 describes the adopted methodology for ontology development, shedding lights on the main design choices with attention towards the selection of the reference foundational ontology; then, Sect. 4.2 proposes the MOCA ontology for the multi-attribute criticality analysis integrating availability, quality, and energy.

4.1 Ontology development methodology and design choices

The methodologies to develop ontologies are varied and over the years several ones have been proposed. Time by time, the methodologies have become more and more structured, clearly fixing the steps to follow to manage the entire ontology lifecycle. In this work, the AMODO methodology proposed by Polenghi et al. [36] is adopted. To the best of authors’ knowledge, AMODO is the only methodology for ontology modelling specifically referring to the maintenance field. Furthermore, it is consistent with advanced general methodologies, namely NeOn [37] and DOGMA [38], and it integrates most of IOF (Industrial Ontologies Foundry) guidelines [39]; finally, AMODO provides a compendium of ontologies in the field of maintenance and asset management, which is useful not to start from scratch. The methodology entails four main phases, which are hereinafter summarised (please refer to the original work for more information):

-

1.

Specification. The step includes the definition of the domain, purpose and scope of the ontology, the identification of appropriate competency questions, and the selection of foundational ontology and implementation language.

-

2.

Knowledge elicitation. This phase looks after additional ontological and non-ontological resources to be integrated in the developed ontology.

-

3.

Conceptualisation. The step relates to classes, relationships, and properties summary, accompanied by appropriate definitions and axioms.

-

4.

Formalisation & Implementation. The ontology is implemented so to be verified against the defined competency questions and finally deployed.

The specification represents the most critical phase since the main design choices are here taken. Apart from the domain and scope, which depends on the current application (in this case, the domain is maintenance, and the scope is the multi-attribute criticality analysis), the selection of a suitable reference foundational architecture is particularly critical. The foundational ontologies formalise very general entities and could potentially be used to describe every domain of discourse, from medicine to industry. Several are the ontologies that are labelled as foundational: BFOFootnote 1 (Basic Formal Ontology) [40], DOLCEFootnote 2 (Descriptive Ontology for Linguistic and Cognitive Engineering) [41] and SUMOFootnote 3 (Suggested Upper Merged Ontology). All foundational ontologies have different commitment, conciseness and also intended use [42]. Nevertheless, BFO is the most concise [43] and this property eases its adoption.

From a philosophical perspective, BFO embraces realism when representing entities. As such, ontology modellers seek to represent “directly” entities in the reality they want to describe rather than concepts or mental artifacts persons have about those entities [44]. The implications the adoption of ontological realism have are multiple. Mainly, realist ontologies have an intrinsic capability of fostering intra- and inter-enterprise data integration [45]. This happens because modelled entities do have counterparts in the real world, that is the domain of interest. Therefore, assertations introduced in the ontology should adhere with what happens in the real world and, if false, must be corrected. It is worth to mention that “real world” does not specifically refer to physical entities, but everything upon which an agreement has been reached, e.g., physical laws. Despite partially overlapping with BFO [46], DOLCE instead does not embrace a strong ontological realism, that is, the modelled entities could be merely putative and speculative. Indeed, in DOLCE, entities belonging to fiction of mythology are welcome; this leaves floor for interpretation since assertations could not find proofs in the reality, but modelled entities refer to concepts that persons create in their mind about a certain thing that could possibly exist. According to the scope of research work within the maintenance domain in industry, BFO fits better. Lastly, SUMO is excluded from the options since it could be hardly labelled as a foundational ontology in the sense intended in this work (that is, an ontology that could serve for a downward population that specifies entities of specific domains). Indeed, SUMO already propose biology-related terms.

The selection of BFO as reference foundational ontology also stems from the current trend of ontological modelling in industry. Firstly, the ISO 21838 [47] specifies the BFO as the reference top-level (a synonymous of foundational, also said formal) ontology to be used when developing a new ontology. Secondly, BFO is the reference foundational ontology of the IOF and CHAMP (Coordinated Holistic Alignment of Manufacturing Processes) initiatives, which are structuring industry-related relevant knowledge as extension from BFO.

According to the embraced philosophical perspective and the recent trends in ontology development, BFO is selected as reference foundational ontology to develop MOCA. This represents the main ontology design choice of this research work and is a relevant difference with respect to extant criticality analysis works related literature since foundational ontologies are not exploited and used.

As such, the modelling approach is top-down, that is, starting from the ground formalisation of reality in very general terms downwards to the needed concepts for the application of interest [48]. This way guarantees semantic consistency through levels, at the cost of being burdensome.

To complete the overview of design choices, the proposed ontology is developed in OWL (Web Ontology Language) and natural language definitions are adopted. This because the formalised knowledge is new, or it is not fixed and agreed-upon between already available models and standards. For examples, the physical decomposition is differently expressed by several standards, like the ISO 14224, ISO 15926, and IEC 62264, used to develop AAS (Asset Administration Shell). However, it is already demonstrated that the maintenance-related terms urge effort to be syntactically and semantically consistent [36, 49]. Thus, MOCA extensively relies on BFO-compliant ontologies, and, in case of missing or contradicting formalisations, a look to international standards is given; ultimately, a look towards the vocabulary already used by the food company in which the ontology is verified is given to resolve incompliances. Amongst those ontologies relevant to reuse, general enough to be applied to every domain, there are CCO (Common Core Ontologies) [50] and IAO (Information Artifact Ontology) [51], from which MOCA extends.

4.2 Description of MOCA

In the remainder of the document, the final version of MOCA is proposed. This because the development is an iterative process and the conceptualisation, formalisation and implementation phases of AMODO were repeated more times. The implementation is described in Sect. 5.

The domain to which the MOCA ontology refers to is the one of maintenance, with the goal of modelling the multi-attribute criticality analysis for asset prioritisation as a support to PHM programs. The developed ontology is particularly thought for asset in the discrete manufacturing sector, where authors’ experience is concentrated. Apart from the selection of BFO as reference foundational ontology and OWL as modelling language, it is important to define the competency questions that drive the ontology development. Some competency questions are hereinafter presented:

-

What is the criticality value of the asset?

-

What is the value of the detectability for the availability attribute for a certain asset?

-

What is the specific criticality value of energy for a certain asset?

Indeed, the multi-attribute criticality analysis includes three main attributes, which are: availability, quality, and energy. Thus, the competency questions also refer to quality and its parameters that are not shown here for shortness, because they have the same questions structure as for availability and energy.

The backbone of MOCA is the physical decomposition of the asset. Indeed, this is one of the most debated modelling choices in ontological modelling for industrial applications:

-

Some models propose different physical decomposition based on the industry needs or industrial standards advocated as reference (see the works in the literature of Sect. 3). Generally, the asset (a single machine or equipment) is decomposed from the second up to the fifth indenture level. This is compliant with the ISO 14224 [52] that is a reference for both process and discrete manufacturing industries. Worth also noting that in some cases, also the “asset” concept has a blurred meaning, since asset could be either a single machine, a line or department or an entire plant.

-

Some models instead resolve the physical decomposition complexity by introducing reflexive relationships at the “component” level. In so doing, the ontological model is flexible since it can accommodate different needs regarding the indenture level. However, this may create semantic inconsistency since a “component” could have as part other component/s.

Figure 4 summarises how the physical decomposition in maintenance-related works could be modelled in ontologies. The picture is drawn using the UML (Unified Modelling Language) class diagram.

In the proposed ontology, the decision is to use a three-level physical decomposition since, according to authors’ experience, is the most used. Figure 5 reports how the decomposition is modelled in MOCA.

Except from the upper-level concepts in BFO, the physical decomposition extends from CCO:artificat that is defined as “an object that was designed by some agent to realize a certain function” [53] and from BFO:object_aggregate defined as that is a BFO:material_entity consisting of a plurality of BFO:object(s) as continuant parts [54]. In MOCA, asset plant, that is the entire plant or facility composed of all systems to realise a product transformation, and the asset system, that is a part of the asset plant that is in charge of realising a specific set of transformation processes on the product, are formalised as MOCA:asset_plant and MOCA:asset_system, respectively. They extend from the BFO:object_aggregate. Other concepts related to the physical decomposition extend from CCO:artifact. Namely, asset, functional_unit, and component are inheritance of CCO:artifact and are all disjoint classes. They are related each other’s via the has_part relationships with cardinality as shown in Fig. 5. Since this physical decomposition could not fit with other industrial needs and applications, in MOCA the physical decomposition problem is solved by introducing the maintainable_item concept by ROMAIN [55] (the modelled concept is MOCA:maintainable_item). A maintainable_item is the physical entity that is the target of a specific maintenance strategy; also, it is not disjoint with the concepts “on the other branch”, which are asset, functional_unit, and component. In so doing, the physical decomposition could be changed and customised according to specific needs, but the multi-attribute criticality analysis is anyhow valid since it is linked with the maintainable_item.

In MOCA, the multi-attribute criticality analysis is formalised, whose main concepts extend from the ICE (IAO:information_content_entity) and from CCO, namely, the Information Entity Ontology, as reported in Fig. 6. As anticipated, MOCA formalises three dimensions of the multi-attribute criticality analysis, which are availability, quality and energy.

On the side of the CCO:directive_information_content_entity, the maintenance_strategy_type is introduced and its sub-concepts are related to the main strategies considered, that are: corrective_maintenance_strategy, preventive_maintenance_strategy, condition_based_maintenance_strategy, and predictive_maintenance_strategy, as in Fig. 7.

Once the maintenance strategies are modelled, it is necessary to define what are the main parameters to be considered in accordance with the FMECA standard (IEC 60812). The parameters considered are the occurrence, severity, and detectability. These criticality_parameter are defined as follows (to be noted that the IEC 60812 provides unique definitions for severity only):

-

Occurrence is defined as “relative ranking of likelihood of happening of a failure or a fault”. Even the literature does not provide an agreed-upon definition for occurrence but they generally merge the meaning of “frequency” with “occurrence” [26, 33]. It is worth underlining that frequency could be used as a proxy to define the occurrence. Therefore, the two should be distinguished. Indeed, an occurrence value could be defined even though there is no information about the frequency of the failure, but relying only on maintenance operator’s expertise, e.g., in BoL.

-

Severity is defined as “relative ranking of potential or actual consequences of a failure or a fault” by the IEC 60812 [56]. Worth adding that the consequence of a failure should be measured at both local and global scale to embrace the systemic orientation of maintenance and asset management.

-

Detectability is defined as “relative ranking of the potentiality to intercept the failure or fault before its happening”. Even in this case the IEC does not provide support since it defines the “detection method” only. The detectability parameter is very broad and actually much effort is put in more formally defining it through detection methods and measurement techniques formalisation [57]. It connects to the potentiality offered by current technologies in monitoring specific signals characteristics of a failure mode, leading to diagnostic and prognostic capabilities.

It is worth noting that the above definitions suffer of the traditional approach to criticality analysis where the perspective was the one of availability only [28]. Instead, in the criticality analysis formalised in this work, failure is considered in its broad view as a deviation from the expectations and requirements in different characteristics. In so doing, MOCA aims to express the parameters, e.g., occurrence, for the three considered attributes that are availability, quality and energy as target asset-related characteristics.

In particular, an occurrence_ availability is as an occurrence measured in terms of asset not able to perform its function (also called failure) leading to unavailability (due to production stoppages). The occurrence_quality is an occurrence measured in terms of product whose quality is far from the expected specification; the related quality threshold may depend on customers’ requirements. The occurrence_ energy is an occurrence measured in terms of energy requirements of the asset. Then, each of these parameters could in turn be defined more precisely depending on the practical case, depending on the quantitative and qualitative sources that are at hand.

For example, regarding the availability attribute, the following definition may apply: frequency of asset failures for the occurrence_ availability; weighted average of local and global effects leading to production stoppages for the severity_ availability; capability to detect a failure based on available in-house technologies for detectability_availability.

Then, the specific_criticality_value is the RPN assessed for each of the attribute, and so its subclasses are energy_criticality_value, availability_criticality_value, and quality_criticality_value. The multiplication of all subclasses of specific_criticality_value generates the criticality_value of the asset that is the weighted average of the specific ones. The asset is related to these ICE subclasses via data properties like has_criticality for the criticality_value, has_ener_criticality for the energy_criticality_value (analogously for quality and availability), and has_ener_det_param for the detectability_energy (analogously for quality and availability).

Figure 8 briefly reports how the criticality analysis in MOCA works. The ACV is the instance of the availability_criticality_value and has_value the ACVv (the range of the data property has_value) and has_weight the ACVWv (the range of the data property has_weight). Analogously for energy and quality.

Through SWRL, the criticality_value is elaborated, namely, the CVv (the range of the data property has_value) and associated with the asset of interest. The SWRL rules are summarised in Table 1.

By establishing a range of criticality value for which a certain maintenance strategy is better than the other (e.g., the axiom for predictive_maintenance_strategy: maintainable_item and (has_criticality_value some xsd:decimal[\({>}{=}45\)]) it is possible to associate a maintenance strategy to each specific asset.

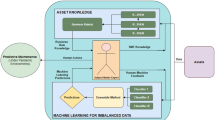

To summarise how MOCA works, Fig. 9 depicts the functioning model by highlighting the asserted and inferred knowledge formalised and derived in OWL and the SWRL rules, how the rules work and the results they provide. The four main steps are represented by the four SWRL rules:

-

1.

Evaluate the RPN for each of the three attributes (availability, energy, quality), based on occurrence O, severity S, and detectability D:

$$\begin{aligned}& RPN_{i} = O_{i} \times S_{i} \times D_{i}, \\& \quad \forall i=\{availability, energy, quality\}. \end{aligned}$$ -

2.

Evaluate the weighted RPN for each attribute given the weights w:

$$\begin{aligned}& RPN_{w,i} = w_{i} \times RPN_{i}, \\& \quad \forall i=\{availability, energy, quality\}. \end{aligned}$$ -

3.

Evaluate the weighted RPN for the asset:

$$\begin{aligned}& RPN_{asset} = \sum_{i} RPN_{w,i}, \\& \quad i=\{availability, energy, quality\}. \end{aligned}$$ -

4.

Associate the obtained RPN (criticality value to the maintainable item).

-

5.

Associate the maintenance strategy, done through axioms, as the one of predictive_maintenance_strategy expressed before.

Indeed, the MOCA ontology is able to relate the asset with the corresponding strategy through reasoning. This is demonstrated by the application described in Sect. 5.

5 Application of MOCA in a food company

The developed MOCA ontology is applied in a food company, which has a twofold objective:

-

1.

Define a common methodology that facilitates and homogenises how the criticality analysis is performed in multiple geographically dispersed facilities. This is urgently required by the company since they are pursuing the centralisation of the maintenance strategies definition in the headquarter and they need that all assets are prioritised with the same criteria.

-

2.

Identify the most critical assets in a new plant in the BoL so to establish the most suitable maintenance strategies to each asset before the operative/MoL phase. More precisely, special attention is given to high-priority asset, for which the company could develop PHM programs for diagnostic and prognostic activities.

The project could be seen as action research since researchers and industrial practitioners, namely the asset manager of the food company, work together to come up with the final artifact. To be effective, several data and information are collected by the research team and elaborated so to properly understand the production plant at hand and related characteristics and then feed the multi-attribute criticality analysis: production plant P&ID (Process and Instrumentation Diagram), several extractions from their ERP (Enterprise Resource Planning) so to have the complete list of assets together with their characteristics, suggested maintenance activities by the Original Equipment Manufacturers, and a first draft of a single-attribute criticality analysis that was already performed.

Figure 10 provides the general scheme of the multi-attribute criticality analysis where availability, quality and energy are modelled and related occurrence, severity and detectability are filled in.

For each specific parameters some rules have been defined that are not shown here for privacy issues. Anyway, whenever quantitative data are not directly available, interviews with experts are put in place. Especially, the former ones allow to cope with missing information for the occurrence parameters while the latter ones mainly suit with the detectability parameters. Overall, 380 assets are present in the plant, but at this stage only a PoC (Proof of Concept) is realised including a few of assets to test the ontological formalisation of criticality analysis.

5.1 MOCA implementation

The implementation includes both ontology verification and validation. The former allows to assess if the ontology is rightly produced, while the latter is focused on whether the produced ontology is the right one [55]. Ontology verification is the first step to be performed; verifying the ontology means that the definitions of concepts are properly stated, and it is able to correctly answer to the competency questions, thus it can suitably represent the knowledge in the domain of interest. Validation instead requires testing if the ontology properly represent the intended meanings. To this end, the industrial dataset provided by the food company is used, and the results are shown below.

Practically, the MOCA ontology is implemented in OWL and populated via the Protégé editor, which allows also to verify that MOCA answers to the competency questions by using several plugins. Specifically, SPARQL query plugin is used to interrogate the asserted MOCA knowledge base, but also the Snap SPARQL query plugin is used, which allows to interrogate the inferred knowledge.

One of the main advantages of MOCA, is that the physical decomposition could be easily customised since the criticality refers to the maintainable_item. In the food company case, the maintainable_item is the asset due to the pursued objective (prioritisation of assets from maintenance strategies planning).

The last step includes the identification of the best criticality value thresholds to let MOCA differentiate between the various maintenance strategies and allocate them properly. The thresholds have been defined together with the asset manager, which embraces a conservatory position as understandable from Table 2. The maximum reachable criticality value is 125 since each parameter O, S, and D has a scale ranging from 1 to 5.

As notable from Table 2, the assessment of predictive or condition-based maintenance will be done later in the project since the feasibility of a predictive maintenance approach should be carefully assessed considering asset characteristics. The decision to go for a condition-based approach without extending to predictive will be decided during the PHM program development in the future depending on the availability of data and other factors, like selected indenture level and available technological architecture.

Once all values related to occurrence, severity, and detectability are inserted together with the criticality value thresholds, the Pellet reasoner is used to let MOCA infer the best maintenance strategy to be associated to specific maintainable_item, i.e., asset. The association of the values is performed automatically by the ontology via SWRL rules, while the retrieval of the inferred knowledge is done through the Snap SPARQL query as follows:

PREFIX owl: <https://www.w3.org/2002/07/owl#>

PREFIX rdf: <https://www.w3.org/1999/02/22-rdf-syntax-ns#>

PREFIX rdfs: <https://www.w3.org/2000/01/rdf-schema#>

PREFIX MOCA: <https://www.semanticweb.org/user/ontologies/2020/09/MOCA#>

SELECT ?asset ?mStrat

WHERE {

?mStrat rdfs:subClassOf MOCA:maintenance_strategy_type.

?asset rdf:type ?mStrat }

In the above query, ?asset is a proxy for maintainable_item and ?mStrat is a proxy for maintenance_strategy_type. The output is shown in Fig. 11.

For the PoC, the three attributes, i.e., availability, quality and energy, are equally weighted 0.33 each. Indeed, how to better tune this is an open issue and many options are available, like using ANP (Analytic Network Process) [58, 59], but it is outside the scope of this research.

The obtained results allow the asset manager to better set the maintenance strategies before the assets are in their operational phase. Moreover, the project unveils the highly critical assets for which a condition-based and/or predictive maintenance should be put in place. The development of such strategies underneath the wider implementation of PHM as data acquisition and manipulation are cornerstones that must be faced beforehand. Indeed, the company could establish a campaign aimed to install monitoring systems without interrupting the production. As such, costs are reduced since i) the proper maintenance strategies are established for assets according to their criticality and ii) the production suffers of no interruption since monitoring systems are installed before the operating phase of the plant. This PoC also serves to demonstrate, in the food company, the possibility to set a unique methodology for criticality analysis consistent with the strategic values that the centralised Asset Management function pursues. Therefore, the methodology could be spread worldwide so that machine criticalities from various plants will be consistent. Besides consistency, this approach also provides the capability of an efficient integration of the cross-plant knowledge, which may open to different benefits, such as e.g., periodic re-assessment of criticalities and strategies, or intra- and inter-plant comparison based on the cumulative knowledge base.

6 Conclusions

This research work investigates how to model the multi-attribute criticality analysis through ontologies. This is driven by the relevance that this kind of analysis has in current industrial context since PHM program must be directed to those assets that have high criticality. Companies with world-wide dispersed plants could suffer of criticality analysis performed differently, and investments may be misdirected since the information about asset criticality is not evaluated in the same way. It is a relevant challenge that the present work considers since its beginning.

Extant scientific literature on the topic shows that several holdbacks exist: a reference foundational ontology is barely considered, structured ontology development methodologies are not followed, there is no focus on the underlying semantics of concepts and the semantic alignment between stakeholders, but only on reasoning capabilities, and availability is the only considered attribute in the criticality analysis. Therefore, this work proposes the MOCA ontology. MOCA is built considering a structured methodology specifically grounded on the selection of a reference foundational ontology. For this reason, BFO is considered as top-level ontology to provide to the ontology a strong and agreed-upon backbone. Also, MOCA describes a multi-attribute criticality analysis, where not only availability is modelled, but also energy and quality. In addition to the strong semantic perspective adopted, MOCA is able to infer the best maintenance strategy allocation to assets, also thanks to SWRL rules. Hence, for highly critical machines, a PHM program development could be put in place.

The developed ontology is tested in a food company that is pursuing a twofold objective. Firstly, the company wants a homogeneous methodology to develop criticality analysis for the assets in its geographically dispersed facilities. Secondly, the multi-attribute criticality analysis needs to guide the allocation of maintenance strategies to a new plant before its operational phase. Thus, MOCA represents an answer to the goals pursued by the food company and demonstrates its capability in fixing the semantic behind concepts and in helping the maintenance strategies planning activity. As such, several assets have been identified as potential targets of PHM programs.

The main limitations concerning the proposed ontology refer to its restriction to the three availability, quality and energy attributes. Even though other ones could be manually introduced, MOCA is not able to accommodate automatically other attributes. Also, MOCA has been tested only at asset, or related components, level (i.e. maintainable items); as such, additional concepts to prioritise failure modes are missing at the current state of the developed ontology.

Envisioned future works relate to multiple aspects. Firstly, the syntactic and semantic consistency of terms for criticality analysis needs to be pursued through an extensive review of available models, standards, dictionaries etc.; in the long run this will contribute to an agreed-upon formalisation. Secondly, additional attributes related to sustainability and system-oriented performance are to be introduced in order to improve machine criticality analysis in line with the current trends. Thirdly, it is worth to extend the application to other cases so to enlarge the industrial datasets and the introduction of failure modes related concepts in the MOCA ontology. Furthermore, additional work should be done on exploiting quantitative and qualitative data; reasoning capabilities should be improved so that the ontology automatically evaluates the value of each parameter based on a wide and diversified set of information. This will result in an automatic assessment of the criticality of assets and/or related failure modes that stems from numerical data from the asset operation, simulated data, data from similar assets through benchmarking and experts’ opinion. As such, PHM program could be easily directed to the high priority assets and the ontology could also serve as storage from which PHM-purposed algorithm could be fed. In the long run, a unique knowledge base that integrates multiple aspects could promote the application of advanced algorithms towards cognitive CPS for smart factories.

Availability of data and materials

Not applicable.

Code availability

Not applicable.

Notes

Basic Formal Ontology (BFO)—https://basic-formal-ontology.org/.

Descriptive Ontology for Linguistic and Cognitive Engineering (DOLCE)—http://www.loa.istc.cnr.it/dolce/overview.html.

Suggested Upper Merged Ontology (SUMO)—http://www.ontologyportal.org/.

References

A.J. Guillén, A. Crespo, M. Macchi, J. Gómez, On the role of Prognostics and Health Management in advanced maintenance systems. Prod. Plan. Control 27, 991–1004 (2016). https://doi.org/10.1080/09537287.2016.1171920

J. Lee, F. Wu, W. Zhao, M. Ghaffari, L. Liao, D. Siegel, Prognostics and Health Management design for rotary machinery systems—reviews, methodology and applications. Mech. Syst. Signal Process. 42, 314–334 (2014). https://doi.org/10.1016/j.ymssp.2013.06.004

J. Lee, C. Jin, Z. Liu, H. Davari Ardakani, Introduction to data-driven methodologies for Prognostics and Health Management, in Probabilistic Prognostics and Health Management of Energy Systems, ed. by S. Ekwaro-Osire, A.C. Gonçalves, F.M. Alemayehu (Springer, Cham, 2017), pp. 9–32. https://doi.org/10.1007/978-3-319-55852-3_2

Y. Lei, N. Li, L. Guo, N. Li, T. Yan, J. Lin, Machinery health prognostics: a systematic review from data acquisition to RUL prediction. Mech. Syst. Signal Process. 104, 799–834 (2018)

A. Polenghi, I. Roda, M. Macchi, A. Pozzetti, Information as a key dimension to develop industrial asset management in manufacturing. J. Qual. Maint. Eng. (2021). https://doi.org/10.1108/JQME-09-2020-0095

K. Javed, R. Gouriveau, N. Zerhouni, State of the art and taxonomy of prognostics approaches, trends of prognostics applications and open issues towards maturity at different technology readiness levels. Mech. Syst. Signal Process. 94, 214–236 (2017). https://doi.org/10.1016/j.ymssp.2017.01.050

L. Cattaneo, A. Polenghi, M. Macchi, A framework to integrate novelty detection and remaining useful life prediction in Industry 4.0-based manufacturing systems. Int. J. Comput. Integr. Manuf., 1–21 (2021). https://doi.org/10.1080/0951192X.2021.1885062

M. Braglia, M. Frosolini, R. Montanari, Fuzzy TOPSIS approach for failure mode, effects and criticality analysis. Qual. Reliab. Eng. Int. 19, 425–443 (2003). https://doi.org/10.1002/qre.528

M.M. Savino, M. Macchi, A. Mazza, Investigating the impact of social sustainability within maintenance operations. J. Qual. Maint. Eng. 21, 310–331 (2015). https://doi.org/10.1108/JQME-06-2014-0038

O. Durán, P.A. Durán, Prioritization of physical assets for maintenance and production sustainability. Sustainability 11, 4296 (2019). https://doi.org/10.3390/su11164296

M. Gopalakrishnan, A. Skoogh, A. Salonen, M. Asp, Machine criticality assessment for productivity improvement. Int. J. Prod. Perform. Manag. 68, 858–878 (2019). https://doi.org/10.1108/IJPPM-03-2018-0091

A.C. Márquez, P.M.D. Leõn, A.S. Rosique, J.F.G. Fernández, Criticality analysis for maintenance purposes: a study for complex in-service engineering assets. Qual. Reliab. Eng. Int. 32, 519–533 (2016). https://doi.org/10.1002/qre.1769

M. Gopalakrishnan, M. Subramaniyan, A. Skoogh, Data-driven machine criticality assessment–maintenance decision support for increased productivity. Prod. Plan. Control (2020). https://doi.org/10.1080/09537287.2020.1817601

A. Polenghi, I. Roda, M. Macchi, A. Pozzetti, A conceptual model of the IT ecosystem for asset management in the global manufacturing context, in Advances in Production Management Systems. Towards Smart and Digital Manufacturing, ed. by B. Lalic, V. Majstorovic, U. Marjanovic, G. von Cieminski, D. Romero (Springer, Berlin, 2020), pp. 711–719. https://doi.org/10.1007/978-3-030-57997-5_82

M. Flasiński, Symbolic artificial intelligence, in Introduction to Artificial Intelligence, ed. by M. Flasiński (Springer, Cham, 2016), pp. 15–22. https://doi.org/10.1007/978-3-319-40022-8_2

A. Polenghi, I. Roda, M. Macchi, A. Pozzetti, Multi-attribute ontology-based criticality analysis of manufacturing assets for maintenance strategies planning. IFAC-PapersOnLine 54, 55–60 (2021). https://doi.org/10.1016/j.ifacol.2021.08.192

T.R. Moss, J. Woodhouse, Criticality analysis revisited. Qual. Reliab. Eng. Int. 15, 117–121 (1999). https://doi.org/10.1002/(SICI)1099-1638(199903/04)15:2<117::AID-QRE238>3.0.CO;2-I

M. Braglia, MAFMA: multi-attribute failure mode analysis. Int. J. Qual. Reliab. Manag. 17, 1017–1033 (2000)

IEC 60812, Failure modes and effects analysis (FMEA and FMECA), BSI Standards Publication (2018)

F. Jaderi, Z.Z. Ibrahim, M.R. Zahiri, Criticality analysis of petrochemical assets using risk based maintenance and the fuzzy inference system. Process Saf. Environ. Prot. 121, 312–325 (2019). https://doi.org/10.1016/j.psep.2018.11.005

J.B. Bowles, An assessment of RPN prioritization in a failure modes effects and criticality analysis, in Annual Reliability and Maintainability Symposium 2003 (2003), pp. 380–386

G. Niu, B.-S. Yang, M. Pecht, Development of an optimized condition-based maintenance system by data fusion and reliability-centered maintenance. Reliab. Eng. Syst. Saf. 95, 786–796 (2010). https://doi.org/10.1016/j.ress.2010.02.016

I. Roda, M. Macchi, S. Albanese, Building a Total Cost of Ownership model to support manufacturing asset lifecycle management. Prod. Plan. Control 31, 19–37 (2020). https://doi.org/10.1080/09537287.2019.1625079

A.C. Márquez, P.M.D. León, J.F.G. Fernndez, C.P. Márquez, M.L. Campos, The maintenance management framework: a practical view to maintenance management. J. Qual. Maint. Eng. 15, 167–178 (2009). https://doi.org/10.1108/13552510910961110

S. Cavalieri, M. Garetti, M. Macchi, R. Pinto, A decision-making framework for managing maintenance spare parts. Prod. Plan. Control 19, 379–396 (2008). https://doi.org/10.1080/09537280802034471

V. Ebrahimipour, K. Rezaie, S. Shokravi, An ontology approach to support FMEA studies. Expert Syst. Appl. 37, 671–677 (2010). https://doi.org/10.1016/j.eswa.2009.06.033

J.J. Montero Jiménez, R. Vingerhoeds, B. Grabot, S. Schwartz, An ontology model for maintenance strategy selection and assessment. J. Intell. Manuf. (2021). https://doi.org/10.1007/s10845-021-01855-3

A. Zhou, D. Yu, W. Zhang, A research on intelligent fault diagnosis of wind turbines based on ontology and FMECA. Adv. Eng. Inform. 29, 115–125 (2015). https://doi.org/10.1016/j.aei.2014.10.001

F. Defèr, G. Schuh, V. Stich, Towards a unified reliability-centered information logistics model for production assets, in Advances in Production Management Systems. The Path to Digital Transformation and Innovation of Production Management Systems, ed. by B. Lalic, V. Majstorovic, U. Marjanovic, G. von Cieminski, D. Romero (Springer, Cham, 2020), pp. 11–18

N. Ali, J.-E. Hong, Failure detection and prevention for cyber-physical systems using ontology-based knowledge base. Computers 7, 68 (2018). https://doi.org/10.3390/computers7040068

J. Lee, B. Bagheri, H.A. Kao, A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 3, 18–23 (2015). https://doi.org/10.1016/j.mfglet.2014.12.001

J. Castet, M. Bareh, J. Nunes, S. Okon, L. Garner, E. Chacko, M. Izygon, Failure analysis and products in a model-based environment, in 2018 IEEE Aerospace Conference (2018), pp. 1–13. https://doi.org/10.1109/AERO.2018.8396736

Z. Rehman, C.V. Kifor, An ontology to support semantic management of FMEA knowledge. Int. J. Comput. Commun. Control 11, 507–521 (2016)

ISO 15926-1, Industrial automation systems and integration—integration of life-cycle data for process plants including oil and gas production facilities—part1: overview and fundamental principles, International Organization (2004). https://doi.org/10.1021/es0620181

Z. Wu, W. Liu, W. Nie, Literature review and prospect of the development and application of FMEA in manufacturing industry. Int. J. Adv. Manuf. Technol. 112, 1409–1436 (2021). https://doi.org/10.1007/s00170-020-06425-0

A. Polenghi, I. Roda, M. Macchi, A. Pozzetti, H. Panetto, Knowledge reuse for ontology modelling in maintenance and industrial asset management. J. Ind. Inf. Integr., 100298 (2021). https://doi.org/10.1016/j.jii.2021.100298

M.C. Suárez-Figueroa, A. Gómez-Pérez, M. Fernandez-Lopez, The NeOn methodology framework: a scenario-based methodology for ontology development. Appl. Ontol. 10, 107–145 (2015)

P. Spyns, Y. Tang, R. Meersman, An ontology engineering methodology for DOGMA. Appl. Ontol. 3, 13–39 (2008)

F. Ameri, D. Sormaz, F. Psarommatis, D. Kiritsis, Industrial ontologies for interoperability in agile and resilient manufacturing. Int. J. Prod. Res., 1–22 (2021). https://doi.org/10.1080/00207543.2021.1987553

R. Arp, B. Smith, A.D. Spear, Building Ontologies with Basic Formal Ontology (MIT Press, Cambridge, 2015)

S. Borgo, C. Masolo, Foundational choices in DOLCE, in Handbook on Ontologies (2004). https://doi.org/10.1007/978-3-540-24750-0

V. Mascardi, V. Cordì, P. Rosso, A comparison of upper ontologies, in Woa (2007), pp. 55–64

L. Magee, 9—Upper-level ontologies, in Towards a Semantic Web—Connecting Knowledge in Academic Research, ed. by B. Cope, M. Kalantzis, L. Magee (Chandos Publishing, Oxford, 2011), pp. 235–287. https://doi.org/10.1016/B978-1-84334-601-2.50009-X

B. Smith, W. Ceusters, Ontological realism: a methodology for coordinated evolution of scientific ontologies. Appl. Ontol. 5, 139–188 (2010). https://doi.org/10.3233/AO-2010-0079

B. Smith, Coordinated holistic alignment of manufacturing processes (CHAMP), State Univ. of New York at Buffalo Buffalo (2018)

C. Sousa, A. Soares, C. Pereira, R. Costa, Supporting the identification of conceptual relations in semi-formal ontology development, in Proceedings of ColabTKR (2012)

ISO/IEC DIS 21838-1, Information technology. Top-level ontologies (TLO). Part 1. Requirements, BSI Standards Publication (2019)

L. Zhou, Ontology learning: state of the art and open issues. Inf. Technol. Manag. 8, 241–252 (2007). https://doi.org/10.1007/s10799-007-0019-5

S. Beden, Q. Cao, A. Beckmann, Semantic asset administration shells in Industry 4.0: a survey, in 2021 4th IEEE International Conference on Industrial Cyber-Physical Systems (ICPS) (2021), pp. 31–38. https://doi.org/10.1109/ICPS49255.2021.9468266

CUBRC, CCO—common core ontologies for data integration, data science and information fusion (2020), https://www.cubrc.org/index.php/data-science-and-information-fusion/ontology. Accessed 4 May 2020

W. Ceusters, An information artifact ontology perspective on data collections and associated representational artifacts, in MIE (2012), pp. 68–72

ISO 14224, Petroleum, petrochemical and natural gas industries—collection and exchange of reliability and maintenance data for equipment, BSI Standards Publication (2016). https://doi.org/10.1089/gtmb.2010.1513

CUBRC, An overview of the common core ontologies (2019)

B. Smith, On classifying material entities in basic formal ontology, in Interdisciplinary Ontology: Proceedings of the Third Interdisciplinary Ontology Meeting (Keio University Press, 2012)

M.H. Karray, F. Ameri, M. Hodkiewicz, T. Louge, ROMAIN: towards a BFO compliant reference ontology for industrial maintenance. Appl. Ontol. 14, 155–177 (2019). https://doi.org/10.3233/AO-190208

IEC 60812, Failure modes and effects analysis (FMEA and FMECA), BSI Standards Publication (2018)

A. Al-Shdifat, C. Emmanouilidis, M. Khan, A. Starr, Ontology-based context resolution in Internet of things enabled diagnostics. IFAC-PapersOnLine 53, 251–256 (2020). https://doi.org/10.1016/j.ifacol.2020.11.041

G. Gupta, R.P. Mishra, Identification of critical components using ANP for implementation of reliability centered maintenance. Proc. CIRP 69, 905–909 (2018). https://doi.org/10.1016/j.procir.2017.11.122

A. Silvestri, F. De Felice, A. Petrillo, Multi-criteria risk analysis to improve safety in manufacturing systems. Int. J. Prod. Res. 50, 4806–4821 (2012). https://doi.org/10.1080/00207543.2012.657968

Acknowledgements

None.

Funding

None.

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Polenghi, A., Roda, I., Macchi, M. et al. An ontological modelling of multi-attribute criticality analysis to guide Prognostics and Health Management program development. Auton. Intell. Syst. 2, 2 (2022). https://doi.org/10.1007/s43684-022-00021-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43684-022-00021-7