Abstract

Carbon-based materials (CM) growth techniques include common growth factors for meta-photonics-heterostructure, holographic displays, and lasers. In this article, a review of basic growth using several sources is presented. The solid and gas sources of CVD and PLD techniques are discussed. Additionally, doping types and the fabrication of the CM devices are covered to satisfy the requirements of the light emitters’ functionality in the physics of materials as follows: (a) direct bandgap, (b) UV range of 0.1 μm < λG < 0.4 μm, 12.40 eV < EG > 3.10 eV, and (c) p-n junction formation. Additionally, conversion of injected electrical current into light in the semiconductor materials using the anti-electrons process for creating light emitters is proposed. Therefore, this review study explores the potential of the selected CM sources as an inexpensive and abundantly available renewable natural source for highly crystalline nanolayers. The CM status of epitaxial thin-film growth is introduced as well as device-processing technologies for prediction. Finally, the positron process in direct light conversion is discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Semiconductor-based light emitters are a key component of this century’s technology. Light emitters, which have great historical significance, require continual development to be the optimal energy resource. Yet despite huge progress in efficiency over the centuries, there are physical limits to the wide range of wavelengths. Tracing the invention’s birth with a clear roadmap toward its broader impact and predicting its potential is critical for the future optoelectronic industry. The initial discovery of the light emitter was noted from semiconductor diode as a Russian, Oleg Vladimirovich Losev, realized the light emitter [1]. Zheludev et al. previously indicated the “Losev’s paper facsimile” (see Fig. 1) [1, 2]. Soviet researcher Losev was awarded a Ph.D. at Ioffe Physical-Technical Institute in St. Petersburg, Russia. Losev made several breakthroughs in solid-state optoelectronics, such as the first semiconductor amplifier and generator [3]. With his efforts, major advances in semiconductors came to life. Following that, the father of the semiconductor laser [4], Prof. Zhores Alferov at Ioffe Physical-Technical Institute, alongside Prof. Herbert Kroemer at UCSB Department of Materials, was received the Physics Nobel Prize for developing heterostructures and GaN epitaxial layers growth. Furthermore, after three decades of struggle to produce the elusive blue light emitters diode (LED), Isamu Akasaki and Hiroshi Amano first made a simple GaN-based diode from semiconductors in the late 1980s. Next, Shuji Nakamura discovered the remaining missing layers needed to produce a blue LED in the early 1990s. That led to receiving the Physics Nobel Prize [5].

“One of the historical papers: Losev’s facsimile patent for light emitters” by NIKOLAY ZHELUDEV, Losev pioneered the realization of light emitters potential for telecommunication. Losev awarded a Ph.D. at the Ioffe Institute in 1938 [1, 6, 7]. Reproduced with permission [1]. Copyright 2007, Nature Publishing

In selecting the optimal material to overcome the existing limitations in optoelectronic semiconductors, the wide bandgap diamond is considered a carbon-based material (CM) that can be doped to stimulate p/n-types. Therefore, Aleksov et al. reported the diamond-based bipolar diode fabrication [8] emission realization [9,10,11,12]. Zaitsev et al. discussed the nitrogen-vacancy (NV) defects properties, the prediction of electrically driven single-photon source design is with the diamond electrical [13]. Regarding conductivity, converting material is required. The natural diamond is unable to be selected as p/n-type electrodes due to its high electrical resistivity. The solid source from recycled CM supplied by the production of oil, crude, and coal combustion of coal-fired power plants [14, 15] is a raw waste product comprising a carbon content [16, 17]; therefore, it is necessary to establish a technique for recycling the waste CM into valuable components which could be used for wide-ranging applications in the optoelectronic industrial, and environmental.

Thus, this review study explores the potential of the selected CM solid or gas sources as an inexpensive and abundantly available renewable natural source for highly crystalline nanolayers to create light. That is similar to research into the Destriau effect. French physicist Georges Destriau named the light “Light of Losev” after Russian radio frequency (RF) technician Oleg Losev and his work of inducing the electroluminescence (EL) in 1927 using silicon carbide (SiC) crystals [18]. The roadmap of the proposed process from waste materials to a solid source to the advanced devices is defined. The synthesis of high-quality crystal-based CM is introduced to facilitate such a complicated growth technique. The most relevant directions for further development of light emitter structures include the use of the solid source in pulse laser deposition (PLD) based on the optimizing growth conditions of semiconducting with high-quality n/p-doped crystal diamond. With the diamond’s outstanding properties, it is ‘the ultimate engineering material’ [19].

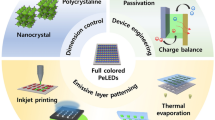

A new semiconductor CM perspective, along with ultra-wide bandgap (UWBG) semiconductors, is essential. CM can provide two basic advantages over such as GaN, namely a high value of Eg and simplicity of epitaxial thin-film growth and bulk wafer production. However, there are few intensive publications on CM for optoelectronic devices compared to (Al, Ga)N compounds, as GaN-based devices are pioneering the markets. Figure 2 indicates the recognition of the implementation of CM for ultraviolet emission from a p-n junction. Also, for the high thermal conductivity, CM is targeted to be incorporated with GaN devices, such as ultraviolet UV-LEDs with a vertically oriented graphene nano-wall buffer layer and in the tunnel junction LED device design for graphene-based transparent conductive electrodes (TCEs) [20,21,22,23].

This review, a roadmap of CM and device technologies, presents CM as an alternative material with the prediction of high performance. It should be noted that there is an attempt to exhaustively review and cover the entire CM work. Also, it should be noted that although there are several implementations of CM into, for example, GaN-based devices, the discussion in this review focuses solely on CM as an emitter device or a component of optoelectronic devices using a solid source from recycled CM. The review is represented: Section 1 introduces the light emitters history for two reasons: (I) to include the early pioneers in an effort to form an understanding of the invention of light emitters, (II) to acknowledge that while various aspects of light emitters are taken for granted, the produce of indirect to direct gap semiconductors can be practically effective.

Notably, indirect gap could be converted into a direct band gap as described by the breakthrough in Ref. [24] of a direct bandgap silicon-based material for optical telecommunications [24]. It is critical to address the nature of the material and the simplified techniques into its implementation to meta-photonics-heterostructure, lasers, and holographic displays. After the introduction in Section 1, Section 2 illustrates the basic physical properties of carbon-based materials (CM) growth. Section 3 provides the epitaxial thin-film growth technologies of CM. In Section 4, the selected device-processing technologies are discussed with the development history of CM. Section 5 introduces the antielectron process theory for the direct conversion towards light, and Section 6 provides a conclusion and a prospective direction.

2 Physical properties of carbon-based materials (CM) growth

The outstanding properties of CMs, such as electrical, optical, mechanical, and magnetic, have attracted substantial consideration. References [25, 26] summarize the relevant material properties for SiC, GaN, and diamond, including the breakdown field, thermal conductivity, drift velocity, and electron mobility. The authors give a good indication of the diamond advantages over its competitors in the semiconductor field. The increase in Eg will cause an enhancement of electric breakdown field to be higher than Si [27, 28]. Therefore, the selected CM has a clear direction, along with the proposed growth methods and designs later introduced.

2.1 Polymorph: carbon-based atom arrangements and bonding physics

CMs are an extensive family of carbon allotropes consisting of 0-D quantum dots, 2D graphene, and 3D nanodiamonds and nanohorns [29,30,31]. All the beneficial properties for the a-C: H arise from the sp3 component of their bonding, and these carbons are often diamond-like carbon (DLC). DLDs are considered by the ternary diagram based on hydrogen content and sp2/sp3 bonding ratio as in [32]. Reference [32] presents the diagram of the DLC structure. However, amorphous carbon a-C, hydrogenated amorphous carbon a-C: H, tetrahedral carbon ta-C, and hydrogenated tetrahedral amorphous carbon ta-C: H are considered as DLC [32], and DLC structure has diamond (sp3-bond) and graphite (sp2-bond) [32].

The control of film properties can be conducted by introducing constituents other than H or C. In a broad sense, DLC films can include films comprising various metals, Si, and/or nitrogen [32,33,34,35]. a-C DLC, the mixture of tetrahedral (sp3) diamond and trigonal (sp2) graphite [36, 37]. Also considered are CMs differences between diamond, graphite, and DLC in terms of hydrogen%, Sp3 %, and bandgap (eV).

2.2 Band structure

Eg values above GaN (3.4 eV) are identified as UWBG semiconductors. AlGaN with high Al content, and diamond are as UWBG. The bandgap determines physical properties; therefore, bandgap engineering is one of the directions to explore novel semiconductors. A promising semiconductor should acquire unsimilar bandgaps energy (Eg) than the materials in the market. As described in this article, the wide-bandgap diamond is for an optoelectronic device in both active, for example, laser diodes (LDs), and passive devices, for example, electrodes, current spreading layers, and Schottky diodes [38]. The diamond band structure with the principal energy gaps of this band structure and theoretical and experimental values for the location of the conduction band minimum and the principal band gaps of the diamond are represented in Ref [39], and the calculation of the energy bands is convergent to − 0.003 Ry. The lattice constant (a) was taken to be 3.57 A [39].

2.3 Electric field breakdown

The diamond leads ahead of other materials is due to such as its high dielectric breakdown strength. Breakdown field Ebr (MV/cm) values are 0.3 Si, 3 SiC, 5 GaN, and 5–10 diamond, as shown in Table 1 [38, 40,41,42]. In Ref [43], a summary of SiC, and GaN relevant material properties is presented. Semiconductors for example GaN, and diamond are projected to dominate the optoelectronic technology. An intrinsic breakdown in semiconductors outcomes from such ionization impact. In contrast, extrinsic breakdown relies on the crystalline status [38]. The diamond shows the highest predicted breakdown field (Ebr), as presented in Table 1 [38, 40, 41].

2.4 Electron mobility

The 80 meV exciton binding energy is allowed room-temperature (RT) UV emission for diodes [44, 45]. However, electron mobility μe (cm2/vs) values are 1500 Si, 800 SiC, 900 GaN, and 2200 diamond [38, 40, 41]. In Ref [46], the RT electron and hole mobility is proportional to the thermal conductivity [46, 47]. The diamond shows the highest predicted electron mobility μe (cm2/vs) of any semiconductor.

2.5 Saturation velocity

The high values of saturation carrier velocity and the breakdown field, Baliga’s figure of merit (BFOM) indicates that has 10 times higher value than GaN [48]. The saturation of charge carrier velocity is at high fields [38]. The saturation velocity vs in Table 1 is

where Eopt is the energy of (k = 0) optical phonon and m* is the effective mass of the charge carriers. The high optical phonon energies thus tend to give a high saturation carrier velocity. The highest optical phonon energy Eopt = 160 meV is for diamond [40]. The experimental values of vs have been indicated as 0.85 − 1.2 × 107 cms−1 and vs = 1.5 − 2.7 × 107 cms−1 for hole and electron. However, diamond has a real advantage in that its saturation velocity is reached in fields of ~ 10 kV/cm, whereas for SiC, the velocity saturates at fields close to its practical electrical breakdown strength. Such high fields can be very difficult to approach in devices [38].

2.6 Doping types

There are techniques for converting diamond to be conducive through doping diamond materials. The undoped and non-conductive diamond with resistivities is in the order of 1020 ohm.cm. The converting of the insulating diamond to a conductor is through such as rapid thermal annealing (RTA) with N2 flow. In terms of CM growth, the initial development was the single-crystal realization. The second development is doping realization. Doping of the diamond layers are conducted using the gas flow doping during plasma-enhanced CVD growth or gas doping flow during the post-annealing process.

The mass production demand, low-defect, single-crystal diamond substrates has decreased device concept realization. Previously, several techniques established to enable low defects (< 105 cm−2) substrates and new synthesis approaches for substrates mass production. Single-crystal diamond with scales greater than 1 × 1 cm2 can be fabricated by high-growth-rate CVD on (100) crystal orientation; these are commercialized [44]. The dopants introduced in diamond as Table 2. For p/n-doping types, CMs are prepared by various techniques, such as CVD and PLD. To attain final devices, one needs to control the doping of CM by CVD and ion implantation. The n-type with five valence electrons dopants is phosphorous. The p-type with three valence electrons dopants is boron. Doping may occur by flowing the gas over the crystalline material. Therefore, the potential barriers design of the surface or at the semiconductor and a metal contact interface or two semiconductors is achievable [49].

Table 2 represents p-type and n-type dopability with their associated ionization energies [50]. For LDs, p/n- types of doping are required, along with high substrate quality [50]. However, the focus of this article is on the recycled CM solid source for diamond, and its growth techniques, as the highest known thermal conductivity is in the diamond. That is particularly important because it addresses heat removal in power electronics and optoelectronics applications’ device operation.

2.6.1 n-type doping

The fabrication of n-doping region can be through using phosphorus [51, 52] (activation energy 0.6 eV), nitrogen [52, 53] (1.6–1.7 eV), and sulfur [52, 54]. However, the nanostructure fabrication is a factor in introducing the conductivity, initiating sp2 and mid-gap states [51,52,53,54]. Koizumi et al. reported obtaining “n-type diamond employing diamond substrates” [55]. Low n-type dopants activation in diamond causes the challenging in obtaining conduction band masses [56].

2.6.2 p-type doping

The boron doped diamond, a low charge carrier of the 0.37 eV activation energy, produces a p-type. The heavily boron-doped CVD diamond introduces superconducting properties [57, 58]. Boron introduces mid-gap states for conductivity and electron-transfer improvement [59, 60].

2.7 Figure of merit

Semiconductor suitability for specific applications is assessed by merit (FOMs) device figures. Baliga’s FOM (BFOM) and Johnson’s FOM (JFOM). BFOM is employed for evaluation semiconductor capability, and diamond shows high BFOM. For the high saturation carrier velocity and high breakdown field, Baliga’s BFOM for diamond is 10 times higher than GaN [48]. Previously, the demonstration of high power is on the single crystalline diamond [48, 61,62,63,64]. The BFOM is based on the theory that the activated doped impurities are at RT; however, in diamond, deeper impurity levels lead to the low dielectric constant. Consequently, the RT carrier activity is less than 10% [65]. Various semiconductors (normalized to silicon) figure of merit of Johnson (Ebr. vsat/2π2) is 2540 for the C-Diamond, and the figure of merit of Baliga (\({E}_{br}^3\)εr. μe) is 3770 for the C-Diamond [48, 64, 65].

2.8 Thermal conductivity

One of the important parameters is thermal conductivity, which impacts the performance of high power electronic and optoelectronic devices by limiting the dissipation capacity of the heat generated. Diamond has a higher thermal conductivity compared to such as GaN. Thermal conductivity is 253–319 AlGaN/AlN, 4.9 β-Ga2O3, and 2290–3450 (W m−1 K−1) diamond. The major aspect is avoiding the low thermal conductivity to enhance the device reliability. However, the diamond shows the highest thermal conductivity value.

3 Growth of carbon-based materials (CM)

3.1 UV of p-n junction CM

The diamond Eg (5.5 eV) at 225 nm. That opens the window for the diamond to be a promising and attractive candidate for optoelectronic since it allows the deep ultraviolet (DUV) emitters. Even though the indirect band gap diamond, photoluminescence (PL) showed UV [12].

Table 3 shows the diamond, graphite, and DLC of synthesized CM into the selected phase. Moreover, growing mono- or hetero-crystal structures of different colors is challenging, and semiconductor materials with different crystal structures are needed to span the entire spectra. Red emission requires a cubic zinc blende structure, while higher energy wavelengths like green and blue require a hexagonal wurtzite crystal structure [66]. The crystal structures should be selected in alignment with the targeted spectrum and device designs.

On the other hand, diamond possess many luminescence centers throughout the UV, visible, and near-IR [11]. As for silicon to CM crystal structures, the GexSi1-x, with its recent breakthrough, is capable of emitting light; thus, the same concept should be applied to CM as ultimate semiconductors. The structure of graphite is sheets, which tend to slide, the diamond structure is atoms with connections in three directions. Important key achievements are (1) the production of a direct band gap silicon-based material at optical telecommunications; and (2) connecting the findings of the silicon-based devices that emits light, as established with CM light-emitting structures [11]. The diamond, graphite, and DLC, the layout difference with the same atoms explains the properties variances:

-

Conduction of current: graphite is conductive; diamond is an insulator and requires doping to be conductive.

-

Conduction of heat: diamond is an outstanding conductor of heat; graphite is a moderate conductor of heat.

DLC films are in demand for various applications due to their properties [32, 68, 69]. DLCs are fabricated by deposition conditions, and depending on the ratio of sp3, sp2 and hydrogen content, the DLC properties are changed [70, 71]. DLC material characteristics range from graphite-like to diamond-like to polymer-like.

3.2 The methods of CM growth

Whatever the methods of CM growth, the reactor chamber condition should involve the pyrolysis furnace for the steam pyrolysis of hydrocarbons. Figure 3 shows methods of PLD and CVD in terms of the carbon-based source type [60, 72]. The CM can be used for the development of semiconductor applications such as power electronics, lasers, and sensors. The synthesis routes implementing solid, or gas sources have allowed the selected properties. Importantly, the UV-LEDs based CMs has been realized [12]. The solid source from recycled CM is supplied by the production of oil, crude, and coal combustion of coal-fired power plants [14, 15]. This raw waste product comprises a carbon content [16, 17]. In Fig. 4, a roadmap is defined of the proposed process from waste materials of carbon-rich materials as a solid source to the advanced devices.

The considered sources of carbon-rich materials: a CVD, either solid source or gases; b PLD [73]

Method of growing a transparent and conductive DLC thin film which can be employed as an alternative to the conventional TCO with comparable performance to recycled carbon as a waste material [73]

This review presents research on the possibility of alternative techniques and resources to produce carbon films for the mass production. Therefore, we consider the implementation advantage of the coal fly ash (CFA) source, which is waste materials produced using a fuel in power plants [74]. Using carbon as a catalyst and precursor for CM by the CVD or as a solid source for the PLD method is critical. The method has been proven effective in developing a large-scale production [75]. The CM synthesis is still costly considering their raw materials, such as a high purity graphite target (99.999%) [76]. Moreover, proposed techniques have been introduced to employ fly ash, thus decreasing the waste in landfills and preventing environmental challenges [77,78,79,80].

3.3 CVD with conditions of adjusting pressure and temperature

In 1962, Eversole [72] realized that deposition of CMs on a substrate from a hydrocarbon gas or gas mixture including CO2 by means of CVD. Eg and a are modified by changing the composition within such as the group III-V semiconductors and within the hexagonal III-nitrides. Accordingly, different light colors may be produced. However, the wavelength is determined by the laser crystal in diode-pumped solid state (DPSS) lasers. For GaN-based devices, the indium concentration varies in order to produce light emitters with the selected emission wavelengths. That is a similar functionality to GaAs-based devices. For example, to fabricate LED of different colors within one device, semiconductors with different crystal structures are needed; thus, red LED requires a cubic zinc blende structure while higher energy wavelengths like green require a hexagonal wurtzite crystal structure [66].

3.4 Epitaxial growth modes

The thin film growth modes are the Volmer-Weber mode (island), the Frank-van der Merwe mode (layer-by-layer), and the Stranski-Krastanov mode (layer plus island). Moreover, (I) three-dimensional (3D) islands are considered the island mode growth; (II) the adatoms of monolayers for two demotions growth on the surface is considered layer-by-layer mode growth; and (III) layer plus island mode growth forms [5, 73, 81].

3.5 Substrate selection for diamond growth

Silicon substrate and Sapphire substrates with a high melting point, high availability, and high thermal conductivity are employed for the fabrication of the GaN-based blue LEDs. Compared to other substrates often used for diamond heteroepitaxy, such as Ni or Pt, sapphire offers the advantage of a higher melting point and much lower incorporation of gases into its crystal structure [82].

3.6 Diamond growth initiation and future potential implementation

Diamond semiconductors, including the type of diamond a-C and their alloys, have been under active investigation and development. That has resulted in the maturing of the diamond system to be adopted into diamond-based optoelectronic devices. Diamond technology is implemented in a wide range of devices, including visible and UV-LEDs, photodetectors (PDs), and laser diodes (LDs). Device designs of such p-type growth methods with only the holes are needed due to the deficiency in the n-type dopant [38]. That is a completely opposite system than (In, Al) GaN-based device system. In 1991, Nakamura developed the p-type GaN using thermal annealing and discovered a mechanism of hydrogen passivation with p-doping high enough for LEDs. Moreover, in GaN-based devices, it is difficult for the p-type contact layer to reach ohmic as n-type because of the challenge of reaching a high doping deep level of Mg acceptor on p-type GaN. Addressing the p-type issue led to GaN being directed toward several new commercial products with the potential to make revolutionary high-efficiency devices. In 1996, Nichia Corp. commercialized white LED using InGaN DH blue LED [83]. On the other hand, the diamond potential is based on the simplified proposed growth techniques besides the diamond’s ultimate properties that requires the development of fabrication methods.

Intrinsic design factors are Structure ➔ Properties ➔ Processing (synthesis, growth) ➔ Performance ➔ Characterization ➔ Application are represented for mapping the necessary elements to address the issues with p/n type growth methods, as well as the issues with material properties. CM research is moving toward changing the lifespan and functionality of many future optoelectronic devices if doped with a controlled level of impurity based on the concept of life cycles introduced in this research. The issues were covered that have long prevented the CM devices progress and represent the overcome in utilizing the recycled CM supplied by the production of oil, crude, and coal combustion of coal-fired power plants [14, 15].

4 Device-processing technologies

4.1 Light-emitting diamond-based materials

Issues with GaN-based devices pose major challenges due to their physical limits at all wavelengths. In contrast, the potential of the existing technologies to produce diamond p-n structures, such as CVD epitaxy, and various modifications of liquid-phase epitaxy, is covered. Alternatively, the diamond development for light emitters was the result of the homo-junction device emitting light in 1994 as diamond-based materials for light-emitting diodes. In addition, Burchard and co-authors reported a method of fabricating practical devices with a working mechanism of obtaining the laser emission for the first time [11]. There is a need for the continued progress of diamond-based light emitters for efficient results in the revolution of illumination by utilizing materials with abundant resources.

4.2 Carbon-based semiconductors for light emitters

CM intrinsic properties create the enhancement for growing market beyond scope of Si technology. In Fig. 5, Wang et al. described devices of ultraviolet emission from heteroepitaxial diamond film [22], and Koizumi et al. described “UV-LED by a diamond p-n junction” [11, 12, 84]. The carrier concentration of Boron-doped and phosphorous-doped layers was approximately 1.5 × 1016 and 2.2 × 1017 cm−3, respectively [22]. Enhancing the emission productivity for the UV light emitters requires concentration increment, and reduction in the impurity.

Diagram of the fabricated diamond LEDs: a p+-i-p+; b M -i -p+ (with metallization). Reproduced with permission [11], Copyright 1994, Elsevier Publishing

4.3 The establishment of CM in the form of active devices (ADs) and passive devices (PDs)

Metal-semiconductor contacts, and growth techniques development allow for further realization. We outline the factors of such as junctions and contacts that enabled LD-based lighting breakthroughs through the initiation of the growth of diamond LDs. The awarded Physics Nobel Prize is a result of many factors including device-quality GaN epitaxial layers advancement, heterostructures, and p-type doping. On the other hand, the diamond-based light-emitting structure is similar to that of advanced GaN-based light-emitters. In addition, light emitter aspects are taken for granted as the indirect bandgap semiconductors are un-ability to generate emission [24].

4.4 Meta-photonics-heterostructure for lasers and holographic displays

The CM in the form of passive or active components is part of the field of meta-surface holography. The meta-surfaces capability the light propagation control through the scattering behavior design of the high spatial resolution ultrathin planar elements, thus making them suitable for holographic beam-shaping elements. The holography-based techniques have been used to achieve three-dimensional (3D) displays [85]. Butt et al. realized binary amplitude holography by the scattering of carbon nanotubes. For meta-surface holography, materials with high refractive indexes are implemented, such as Ge, GaAs, TiO2, and diamond [85].

5 From the theory of electrons and holes to positrons (anti-electrons)

One of the fundamental concepts in semiconductor is converting the electrons process in an electrical current for creating emission. Positron theory and Antielectron process? The antielectron process is for converting the electrical current directly into light towards new fields of research for semiconductor. A positron is a subatomic particle with an equal electron mass. While numerically equal, it is a positively charged particle. The existence of the antiparticle of the electron, the positron, was predicted by Dirac in 1928, and its first experimental observation came in 1932 by Carl Anderson [86, 87].

The process of the antiparticle of the electron (positron) and the antiparticle of holes (the absence of positron) is realized but not yet implemented into the semiconductor industry. A positron is an anti-electron as an antiparticle and an actual particle. On the other hand, a hole is just the lack of an electron, not an anti-particle or a particle. Thus, the absence and lack of positron should be anti-positron. If the device is injected with the current of a positron, how will this impact the device performance? Notably, there is an opportunity to create low emittance muon beams by the collisions of electron positron [88]. The system called “Muonic Electromagnetic Generator” relates generally to the generation of power, and more particularly to an apparatus and a method for the generation of electricity from the decay of muons created in the upper atmosphere from cosmic particles called pions. Free electrons and positrons are frequently sourced from thermionic cathode ray tubes.

On a smaller scale and with minor effort, the positrons were produced by means of a setup of laser-driven particle acceleration for electron and positron generation as reported in Ref. [89]; this is proposed for electrical injection of the LD structure as shown in Fig. 6 [89,90,91,92,93].

InGaN-based light emitter of the epitaxial layers. Reproduced with permission [92], Copyright 2016, AIP Publishing; the electric current exists whenever the charges move, and the current-injected device is based on “positron electricity” and “anti-electron electricity.” The positrons are the same as electrons for carrying a charge [89, 90, 92, 93]

6 Conclusion and future work

The historical development of CM synthesis is described to shape the future direction of optoelectronic devices. Three main threads are as follows: (1) The overall goal is to provide a scientific basis for CVD and PLD CM synthesis that incorporates the solid source from recycled carbon-rich fly ash. (2) Carbon-based semiconducting is investigated for light emitters toward overcoming shortcomings related to fundamental material properties, which is the deficiency in the n-type dopant. (3) Anti-electron process for creating light-emitters is introduced. Moreover, CM, an outstanding heat conductor, is crucial materials being used in optoelectronics where thermal management is challenging. Thus, the use of diamond in optoelectronics is as a passive component and high-power active device. However, based on the current CM devices, the indication is that the technology is still immature, and so much effort is required to introduce CM into marketplaces with its highest potential. The continued efforts on the selected CM sources as an inexpensive and abundantly available natural source for a highly crystalline nanolayer toward device manufacturing will lead to technological advancement.

Availability of data and materials

All data and figures presented in this article are based on the materials available through the corresponding references with their permissions.

References

N. Zheludev, The life and times of the LED—a 100-year history. Nat. Photon. 1(4), 189–192 (2007)

O.V. Losev, Luminous carborundum detector and detection effect and oscillations with crystals. Phil. Mag. 6, 1024–1044 (1928)

A. Zhores, in International Year of Light and Light-Based Technologies, from the Opening Ceremony of the International Year of Light at the UNESCO Building in Paris France, 19-20 January. Efficient light conversion and generation (2015)

S. Ivanov, Remembering Zhores Alferov. Nat. Photon. 13(10), 657–659 (2019)

L.H. Schwartz et al., U.S. Assessment of the New Diamond Technology in Japan. NIST Special Publication 807 (Materials Science and Engineering Laboratory National Institute of Standards and Technology, Gaithersburg, 1991), p. 20899

O.V. Losev, Soviet Patent 12191 (1929)

N. Farrell, Russianpatentsblog.patentsfromru.com. Russian Patents Blog » You’d better not ignore Russian Prior Art search – says New Scientist magazine: http://russianpatentsblog.patentsfromru.com/2007/04/12/youd-better-not-ignore-russian-prior-art-search-says-new-scientist-magazine (2007)

A. Aleksov et al., Diamond diodes and transistors. Semicond. Sci. Technol. 18, S59 (2003)

A.A. Melnikov et al., Electrical and optical properties of light-emitting p–i–n diodes on diamond. J. Appl. Phys. 84, 6127 (1998)

X.B. Liang, L. Wang, X.Y. Ma, P.L. Chen, D.R. Yang, Room temperature electroluminescence from a nanocrystalline diamond/Si heterojunction. Diamond Relat. Mater. 16, 306 (2007)

B. Burchard et al., Diamond based light emitting structures. Diamond Relat. Mater. 3, 947 (1994)

S. Koizumi, K. Watanabe, M. Hasegawa, H. Kanda, Ultraviolet emission from a diamond pn junction. Science 292(5523), 1899–1901 (2001)

A.M. Zaitsev, A.A. Bergmann, A.A. Gorokhovsky, M. Huang, Diamond light emitting diode activated with Xe optical centers. Phys. Status Solidi A 203, 638 (2006)

A. Fernandez, Saudis Burned 45% More Crude in Power Plants in March (arabianbusiness: https://www.arabianbusiness.com/saudis-burned-45-more-crude-in-power-plants-in-march-458477.html, 2012)

C. Digges, Russian Parliament Adopts Law Aimed at Limiting Greenhouse Gasses (Bellona.org: https://bellona.org/news/climate-change/2021-06-russian-parliament-adopts-law-aimed-at-limiting-greenhouse-gasses, 2022)

N.A. Salah, Method of Forming Carbon Nanotubes from Carbon-Rich Fly Ash. Appl. N.: 13/247, 588, US Patent (2011)

A. Yasui et al., Synthesis of Carbon Nanotubes on Fly Ashes by Chemical Vapor Deposition Processing (Institute of Electrical Engineers of Japan, Published by John Wiley & Sons, Inc., 2009). https://doi.org/10.1002/tee.20481.

A. Ritter, in Smart Materials in Architektur, Innenarchitektur und Design, Band 3. Lichtemittierende smart materials (2007), pp. 110–141. https://doi.org/10.1007/978-3-7643-8266-7-6

K. Tanaka, Nanotechnology towards the 21st century. Thin Solid Films 341(1-2), 120–125 (1999)

H. Ci et al., UV light-emitting diodes: enhancement of heat dissipation in ultraviolet light-emitting diodes by a vertically oriented graphene nano wall buffer layer. Adv. Mater. 31(29), 1970211 (2019)

M. Malakoutian, M. Laurent, S. Chowdhury, A study on the growth window of polycrystalline diamond on Si3N4-coated N-Polar GaN. Crystals 9(10), 498 (2019)

W. Wang et al., Ultraviolet electroluminescence at room temperature from a p-n junction of heteroepitaxial diamond film by CVD. Diam. Relat. Mater. 12(8), 1385–1388 (2003)

L. Wang et al., Graphene-based transparent conductive electrodes for GaN-based light emitting diodes: challenges and countermeasures. Nano Energy 12, 419–436 (2015)

E. Fadaly et al., Direct-bandgap emission from hexagonal Ge and SiGe alloys. Nature 580(7802), 205–209 (2020)

N. Donato, N. Rouger, J. Pernot, G. Longobardi, F. Udrea, Diamond power devices: state of the art, modelling, figures of merit and future perspective. J. Phys. D Appl. Phys. 53(9), 093001 (2019)

C. Xie et al., Ultrawide-bandgap semiconductors: recent progress in solar-blind deep-ultraviolet photodetectors based on inorganic ultrawide bandgap semiconductors. Adv. Funct. Mater. 29(9), 1970057 (2019)

Evincetechnology.com, Technology – Evince: http://www.evincetechnology.com/whydiamond.html (2021)

Evolvediamonds.com, Electronic Properties of Diamond – Evolve Diamonds: https://www.evolvediamonds.com/electronic-properties-of-diamond/ (2022)

K. Ariga, M. Li, G.J. Richards, J.P. Hill, Nanoarchitectonics for mesoporous materials. J. Nanosci. Nanotechnol. 11(1), 1–13 (2011)

G.A.M. Ali, M.M. Yusoff, Y.H. Ng, N.H. Lim, K.F. Chong, Potentiostatic and galvanostatic electrodeposition of MnO2 for supercapacitors application: a comparison study. Curr. Appl. Phys. 15(10), 1143–1147 (2015)

J. Jeevanandam, A. Barhoum, Y.S. Chan, A. Dufresne, M.K. Danquah, Review on nanoparticles and nanostructured materials: history, sources, toxicity and regulations. Beilstein J. Nanotechnol. 9(1), 1050–1074 (2018)

J. Robertson, Diamond-like amorphous carbon. Mater. Sci. Eng. R. Rep. 37, 129–281 (2002)

H. Tachikawa, Technical Issues on Tribology and DLC Coating in Automotive Industry. Surface Technology. 2008;59 (7):437.

K. Bewilogua et al., DLC based coatings prepared by reactive d.c. magnetron sputtering. Thin Solid Films 447–448, 142–147 (2004)

J. Fontaine, C. Donnet et al. Tribology of Diamond-like Carbon Films Fundamentals and Applications. New York: Springer; 2008; pp. 139–154.

M. Yoshikawa, G. Katagiri, H. Ishida, A. Ishitani, T. Akamatsu, Raman spectra of diamondlike amorphous carbon films. J. Appl. Phys. 64, 6464 (1988)

N. Yasumaru, K. Miyazaki, J. Kiuchi, Glassy carbon layer formed in diamond-like carbon films with femtosecond laser pulses. Appl. Phys. A 79(3), 425–427 (2004)

C. Wort, R. Balmer, Diamond as an electronic material. Mater. Today 11(1-2), 22–28 (2008)

W. Saslow, T. Bergstresser, M. Cohen, Band structure and optical properties of diamond. Phys. Rev. Lett. 16(9), 354–356 (1966)

A.M. Zaitsev, Optical Properties of Diamond: A Data Handbook (Springer-Verlag, 2001). https://doi.org/10.1007/978-3-662-04548-0

M. Geis. Mat. Res. Soc. Symp. Proc. Growth of Device-Quality Homoepitaxial Diamond Thin Films. 162,15–22 (1989). https://doi.org/10.1557/PROC-162-15.

A. Oyekunle, Diamond Keeps Growing as a WBG Material for High-Power and Frequency Electronics (allaboutcircuits: https://www.allaboutcircuits.com/news/diamond-keeps-growing-wideband-gap-material-for-high-power-and-frequency-electronics/, 2022)

P.D. Taylor et al., Industrial Diamond Review (2000), p. 19

M. Schreck, J. Asmussen, S. Shikata, J. C. Arnault & N. Fujimori. Large-area high-quality single crystal diamond. MRS Bull 39, 504 (2014).

T. Makino et al., Enhancement in emission efficiency of diamond deep-ultraviolet light emitting diode. Appl. Phys. Lett. 99, 061110 (2011)

R.S. Balmer, J.J. Wilman, S.M. Woollard, Chemical vapour deposition synthetic diamond: materials, technology and applications. J. Phys. Condens. Matter 21, 364221 (2009). https://doi.org/10.1088/0953-8984/21/36/364221

J. Isberg et al., High carrier mobility in single-crystal plasma-deposited diamond. Science 297, 1670–1672 (2002)

B.J. Baliga, Power semiconductor device figure of merit for high-frequency applications. IEEE Electron Device Lett. 10, 455 (1989)

L. Esaki, Highlights in semiconductor device development. J Res. Natl. Bur. Stand. 86(6), 565 (1981)

J. Tsao et al., Ultrawide-bandgap semiconductors: research opportunities and challenges. Adv. Electron. Mater. 4(1), 1600501 (2017)

M. Nesladek, Conventional n-type doping in diamond: state of the art and recent progress. Semicond. Sci. Technol. 20, R19–R27 (2005)

S.C. Eaton, A.B. Anderson, J.C. Angus, Y.E. Evstefeeva, Y.V. Pleskov, Co-doping of diamond with boron and sulfur. Electrochem. Solid-State Lett. 5, G65–G68 (2002)

Haenni W, Rychen P, Fryda M, Comninellis C. Industrial application of diamond electrodes. In: Nebel, C. (Ed.), Thin-Film Diamond II. Semiconductors and Semimetals Series. Oxford: Academic Press, Elsevier; 2004, p. 149 2004.

S. Vaddiraju, S. Eaton-Magana, J.A. Chaney, M.K. Sunkara, UPS of boron-sulfur Co-doped, n-type diamond. Electrochem. Solid-State Lett. 7, G331–G334 (2004)

S. Koizumi, M. Kamo, Y. Sato, H. Ozaki, T. Inuzuka, Growth and characterization of phosphorous doped {111} homoepitaxial diamond thin films. Appl. Phys. Lett. 71, 1065 (1997)

H. Löfås, A. Grigoriev, J. Isberg, R. Ahuja, Effective masses and electronic structure of diamond including electron correlation effects in first principles calculations using the GW-approximation. AIP Adv. 1(3), 032139 (2011)

V.A. Sidorov, Superconductivity in boron-doped diamond. Diam. Relat. Mater. 14, 335 (2005)

Y. Takano et al., Superconductivity in diamond thin films well above liquid helium temperature. Appl. Phys. Lett. 85, 2851 (2004)

A.T. Collins, P.J. Dean, E.C. Lightowler, W.F. Sherman, Acceptor-impurity infrared absorption in semiconducting synthetic diamond. Phys. Rev. 140, A1272–A1274 (1965)

J. Luong, K. Male, J. Glennon, Boron-doped diamond electrode: synthesis, characterization, functionalization and analytical applications. Analyst 134(10), 1965 (2009)

J.E. Butler, Exceptionally high voltage Schottky diamond diodes and low boron doping. Semicond. Sci. Technol. 18, S67 (2003)

W. Ebert et al., High-voltage Schottky diode on epitaxial diamond layer. Diam. Relat. Mater. 6, 329 (1997)

S.J. Rashid et al., Modelling of single-crystal diamond Schottky diodes for high-voltage applications. Diam. Relat. Mater. 15, 317 (2006)

H. Umezawa et al., Characterization of leakage current on diamond Schottky barrier diodes using thermionic-field emission modeling. Diam. Relat. Mater. 15, 1949 (2006)

H. Umezawa, K. Ikeda, R. Kumaresan, S. Shikata, High temperature characteristics of diamond SBDs. Mater. Sci. Forum 645–648, 1231–1234 (2010)

Patent Yogi LLC, NASA Grows Multi-Color LEDs on Single Wafer (Patent Yogi LLC, 2019) https://patentyogi.com/latest-patents/nasa-grows-multi-color-leds-single-wafer/

J.C. Angus, C.C. Hayman, Low-pressure, metastable growth of diamond and “diamondlike” phases. Science 241, 913 (1988)

P. Ascarelli, E. Cappeli, D.M. Trucchi, G. Conte, CVD diamond dosimetric response evaluated by X-ray absorbers method. Diam. Relat. Mater. 12, 691 (2003)

S. Gastelum, E. Cruz-Zaragoza, R. Melendrez, V. Chernov, M. Barboza-Flores, γ radiation thermoluminescence performance of HFCVD diamond films. Nucl. Instr. Meth. Phys. Res. B 248, 103 (2006)

J. Laurikaitienė et al., Electrical properties of the diamond like carbon films irradiated with high energy photons. J. Phys. Conf. Ser. 100(7), 072036 (2008)

A. Grill, Electrical and optical properties of diamond-like carbon. Thin Solid Films 355–356, 189 (1999)

W.G. Eversole, Union Carbide Corporation, U.S. Patent (1962), p. 3030187

S. Ogugua, O. Ntwaeaborwa, H. Swart, Latest development on pulsed laser deposited thin films for advanced luminescence applications. Coatings 10(11), 1078 (2020)

K. Rambau, N. Musyoka, N. Manyala, J. Ren, H. Langmi, M. Mathe, Preparation of carbon nanofibers/tubes using waste tyres pyrolysis oil and coal fly ash derived catalyst. J. Environ. Sci. Health Part A 53(12), 1115–1122 (2018)

N. Salah, A. Al-ghamdi, A. Memic, S. Habib, Z. Khan, Formation of carbon nanotubes from carbon-rich fly ash: Growth parameters and mechanism. Mater. Manuf. Process. 31(2), 146–156 (2015)

F. Stock, F. Antoni, L. Diebold, C. Chowde Gowda, S. Hajjar-Garreau, D. Aubel, N. Boubiche, F. Le Normand, D. Muller, UV laser annealing of diamond-like carbon layers obtained by pulsed laser deposition for optical and photovoltaic applications. Appl. Surf. Sci. 464, 562–566 (2019)

J. Li, X. Zhuang, O. Font, N. Moreno, V.R. Vallejo, X. Querol, A. Tobias, Synthesis of merlinoite from Chinese coal fly ashes and its potential utilization as slow release K fertilizer. J. Hazard. Mater. 265, 242–252 (2014)

S.S. Habib, Naturally endowed oxide nanoparticles from carbon ash in Saudi Arabia. Int. J. Nano Biomater. 2, 437–441 (2009)

V.L. Markad, K.M. Kodam, V.S. Ghole, Effect of fly ash on biochemical responses and DNA damage in earthworm, Dichogaster curgensis. J. Hazard. Mater. 215–216, 191–198 (2012)

G.R. Qian, J. Shi, Y.L. Cao, Y.F. Xu, P.C. Chui, Properties of MSW fly ash–calcium sulfoaluminate cement matrix and stabilization solidification on heavy metals. J. Hazard. Mater. 152, 196–203 (2008)

P.H. Le, C.W. Luo, Thermoelectric and topological insulator bismuth chalcogenide thin films grown using pulsed laser deposition. in Applications of Laser Ablation—Thin Film Deposition, Nanomaterial Synthesis and Surface Modification (ed. Yang, D.) 55–84 (InTech, 2016). https://doi.org/10.5772/65898.

M. Yoshimoto et al., Epitaxial diamond growth on sapphire in an oxidizing environment. Nature 399(6734), 340–342 (1999)

Shuji Nakamura – Nobel Lecture, NobelPrize.org. Nobel Prize Outreach AB 2022 (2022) https://www.nobelprize.org/prizes/physics/2014/nakamura/lecture/

P. John, Toward diamond lasers. Science 292, 1847 (2001)

L. Huang, S. Zhang, T. Zentgraf, Metasurface holography: From fundamentals to applications. Nanophotonics 7(6), 1169–1190 (2018)

Carl D. Anderson – Facts, NobelPrize.org. Nobel Prize Outreach AB 2022 (2022) https://www.nobelprize.org/prizes/physics/1936/anderson/facts/

L. Sodickson, W. Bowman, J. Stephenson, R. Weinstein, Single-quantum annihilation of positrons. Phys. Rev. 124(6), 1851–1861 (1970)

J. M. Byrd, M. Antonelli, T.E. Browder, et al. High Intensity Electron and Positron Beams, Conveners, Community Planning Study: Snowmass. KDKA SuperKEKB (2013). ccac6d0006efb42c39f48d7f5cf8da0c (cern.ch).

D. Johnson, The spin torus energy model and electricity. Open J. Appl. Sci. 09(06), 451–479 (2009)

W. Bostick, Mass, charge and current: the essence and morphology. Phys. Essays 4, 45–59 (1991)

N. Butto, A new theory for the essence and nature of electron charge. J. High Energy Phys. Gravit. Cosmol. 07(03), 1190–1201 (2021)

D. Becerra et al., Measurement and analysis of internal loss and injection efficiency for continuous-wave blue semipolar (20-2-1) III-nitride laser diodes with chemically assisted ion beam etched facets. Appl. Phys. Lett. 108(9), 091106 (2006). https://doi.org/10.1063/1.4943143

L. Kuritzky et al., Chemically assisted ion beam etching of laser diode facets on nonpolar and semipolar orientations of GaN. Semicond. Sci. Technol. 31(7), 075008 (2006). https://doi.org/10.1088/0268-1242/31/7/075008

Acknowledgements

Not applicable.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

The author read and approved the final manuscript as this review is written by the single author whose name is given in the article.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The author declares that she has no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abbas, A.S. Ultrawide-bandgap semiconductor of carbon-based materials for meta-photonics-heterostructure, lasers, and holographic displays. AAPPS Bull. 33, 4 (2023). https://doi.org/10.1007/s43673-022-00073-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43673-022-00073-0