Abstract

To date, many methods have been suggested to improve the performance of materials in various applications by applying new physical and chemical properties at the nanometer scale in the form of nanodots, nanowires, and nanofilms. However, most of the proposed methods are difficult to apply to industrial settings due to their size limitations. In that sense, the realization of 3D nanostructured materials is significant for practical use of nanotechnology. The continuous 3D nanostructuring insures the maximum utilization of materials efficiency and improves the stability through well-ordered structures. In this respect, 3D nanostructures of materials can be useful for energy conversion applications such as thermoelectric, piezoelectric, and electrocatalytic applications. Herein, we briefly overview 3D nanofabrication methods to convert the materials in the 3D nanostructures, followed by a review on the advantages of 3D ordered nanoelectrodes for high-performance energy conversion applications.

Copyright 2004, The National Academy of Sciences of the USA.)

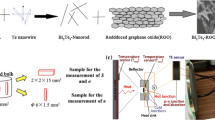

Copyright 2013 The Royal Society of Chemistry.) c Schematic illustration of material conversion of 3D nanostructured materials using electrodeposition. d Corresponding cross-sectional scanning electron microscopy (SEM) images of using electrodeposition. (Reprinted from [40]. Copyright 2018 Elsevier.)

Copyright 2018 The Royal Society of Chemistry.)

Copyright 2017 The Royal Society of Chemistry.)

Copyright 2020 Elsevier.)

Copyright The Royal Society of Chemistry 2018.)

Copyright 2019 Elsevier.)

Copyright 2020 American Chemical Society.)

Copyright 2018 Elsevier.)

Copyright 2020, The National Academy of Sciences of the USA)

Copyright 2019, Wiley–VCH)

Similar content being viewed by others

References

J.H. Holtz, S.A. Asher, Polymerized colloidal crystal hydrogel films as intelligent chemical sensing materials. Nature 389, 829–832 (1997)

J. Qin, Z. Cui, X. Yang, S. Zhu, Z. Li, Y. Liang, Three-dimensionally ordered macroporous La1−xMgxFeO3 as high performance gas sensor to methanol. J. Alloys Compd. 635, 194–202 (2015)

M. Campbell, D.N. Sharp, M.T. Harrison, R.G. Denning, A.J. Turberfield, Fabrication of photonic crystals for the visible spectrum by holographic lithography. Nature 404, 53–56 (2000)

P.V. Braun, R.W. Zehner, C.A. White, M.K. Weldon, C. Kloc, S.S. Patel, P. Wiltzius, Epitaxial growth of high dielectric contrast three-dimensional photonic crystals. Adv. Mater. 13(10), 721–724 (2001)

D.G. Grier, A revolution in optical manipulation. Nature 424, 810–816 (2003)

G.M. Gratson, F. García-Santamaría, V. Lousse, M. Xu, S. Fan, J.A. Lewis, P.V. Braun, Direct-write assembly of three-dimensional photonic crystals: conversion of polymer scaffolds to silicon hollow-woodpile structures. Adv. Mater. 18(4), 461–465 (2006)

Y. Liu, H. Wang, J. Ho, R.C. Ng, R.J.H. Ng, V.H. Hall-Chen, E.H.H. Koay, Z. Dong, H. Liu, C.-W. Qiu, J.R. Greer, J.K.W. Yang, Structural color three-dimensional printing by shrinking photonic crystals. Nat. Commun. 10, 4340 (2019)

S. Jeon, V. Malyarchuk, J.O. White, J.A. Rogers, Optically fabricated three dimensional nanofluidic mixers for microfluidic devices. Nano Lett. 5(7), 1351–1356 (2005)

J.W. Long, B. Dunn, D.R. Rolison, H.S. White, Three-dimensional battery architectures. Chem. Rev. 104(10), 4463–4492 (2004)

H. Zhang, X. Yu, P.V. Braun, Three-dimensional bicontinuous ultrafast-charge and-discharge bulk battery electrodes. Nat. Nanootechnol. 6(5), 277–281 (2011)

J. Park, S. Wang, M. Li, C. Ahn, J.K. Hyun, D.S. Kim, D.K. Kim, J.A. Rogers, Y. Huang, S. Jeon, Three-dimensional nanonetworks for giant stretchability in dielectrics and conductors. Nat. Commun. 3, 916 (2012)

J.H. Pikul, H.G. Zhang, J. Cho, P.V. Braun, W.P. King, High-power lithium ion microbatteries from interdigitated three-dimensional bicontinuous nanoporous electrodes. Nat. Commun. 4, 1732 (2013)

C. Ahn, J. Park, D. Kim, S. Jeon, Monolithic 3D titania with ultrathin nanoshell structures for enhanced photocatalytic activity and recyclability. Nanoscale 5(21), 10384–10389 (2013)

C. Kern, M. Wegener, Three-dimensional metamaterial hall-bar devices. Phys. Rev. Mater. 3(1), 015204 (2019)

C. Crook, J. Bauer, A.G. Izard, C.S. de Oliveira, J.M. de e Silva, J.B. Berger, L. Valdevit, Plate-nanolattices at the theoretical limit of stiffness and strength. Nat. Commun. 11, 1579 (2020)

H.-F. Wang, C. Tang, Q. Chang, A review of graphene-based 3D van der waals hybrids and their energy applications. Nano Today 25, 27–37 (2019)

K.S. Novoselov, A.K. Geim, S.V. Morozov, D. Jiang, Y. Zhang, S.V. Dubonos, I.V. Grigorieva, A.A. Firsov, Electric field effect in atomically thin carbon films. Science 306(5696), 666–669 (2004)

K.S. Novoselov, D. Jiang, F. Schedin, T.J. Booth, V.V. Khotkevich, S.V. Morozov, A.K. Geim, Two-dimensional atomic crystals. PNAS 102(30), 10451–10453 (2005)

A.P. Tiwari, H.J. Yoo, J.T. Lee, D. Kim, J.H. Park, H. Lee, Prevention of sulfur diffusion using MoS2-intercalated 3D-nanostructured graphite for high-performance lithium-ion batteries. Nanoscale 7, 11928–11933 (2015)

Y. Yoon, A.P. Tiwari, M. Choi, T.G. Novak, W. Song, H. Chang, T. Zyung, S.S. Lee, S. Jeon, K.-S. An, Precious-metal-free electrocatalysts for activation of hydrogen evolution with nonmetallic electron donor: chemical composition controllable phosphorous doped vanadium carbide MXene. Adv. Funct. Mater. 29(30), 1903443 (2019)

B.D. Gates, Q. Xu, M. Stewart, D. Ryan, C.G. Willson, G.M. Whitesides, New approaches to nanofabrication: molding, printing, and other techniques. Chem. Rev. 105(4), 1171–1196 (2005)

G.M. Gratson, M. Xu, J.A. Lewis, Microperiodic structures: direct writing of three-dimensional webs. Nature 428, 386 (2004)

B. Hatton, L. Mishchenko, S. Davis, K.H. Sandhage, J. Aizenberg, Assembly of large-area, highly ordered, crack-free inverse opal films. PNAS 107(23), 10354–10359 (2010)

Y.A. Vlasov, X.-Z. Bo, J.C. Sturm, D.J. Norris, On-chip natural assembly of silicon photonic bandgap crystals. Nature 414, 289–293 (2001)

M. Miyake, M. Suginohara, N. Narahara, T. Hirato, P.V. Braun, Low-temperature hydrothermal synthesis of colloidal crystal templated nanostructured single-crystalline ZnO. Chem. Mater. 29(22), 9734–9741 (2017)

D.-Y. Kang, J.H. Moon, Lithographically defined three-dimensional pore-patterned carbon with nitrogen doping for high-performance ultrathin supercapacitor applications. Sci. Rep. 4, 5392 (2014)

Q. Geng, D. Wang, P. Chen, S.-C. Chen, Ultrafast multi-focus 3-D nano-fabrication based on two-photon polymerization. Nat. Commun. 10, 2179 (2019)

K. Xia, H. Zhan, Y. Gu, Graphene and carbon nanotube hybrid structure: a review. Procedia IUTAM 21, 94–101 (2017)

S. Jeon, J.-U. Park, R. Cirelli, S. Yang, C.E. Heitzman, P.V. Braun, P.J. Kenis, J.A. Rogers, Fabricating complex three-dimensional nanostructures with high-resolution conformable phase masks. PNAS 101(34), 12428–12433 (2004)

S. Jeon, Y.-S. Nam, D.J. Shir, J.A. Rogers, A. Hamza, Three dimensional nanoporous density graded materials formed by optical exposures through conformable phase masks. Appl. Phys. Lett. 89(25), 253101 (2006)

J.H. Moon, S. Yang, Chemical aspects of three-dimensional photonic crystals. Chem. Rev. 110(1), 547–574 (2009)

D.J. Shir, E. Nelson, Y. Chen, A. Brzezinski, H. Liao, P. Braun, P. Wiltzius, K. Bogart, J. Rogers, Three dimensional silicon photonic crystals fabricated by two photon phase mask lithography. Appl. Phys. Lett. 94(1), 011101 (2009)

J.S. King, E. Graugnard, O.M. Roche, D.N. Sharp, J. Scrimgeour, R.G. Denning, A.J. Turberfield, C.J. Summers, Infiltration and inversion of holographically defined polymer photonic crystal templates by atomic layer deposition. Adv. Mater. 18(12), 1561–1565 (2006)

R.K. Grubbs, A. Ellis, A. Sanchez, M. Wiwi, I. El-kady, K. Bogart, M. Su, C. Christodoulou, M. Taha, D.J. Shir, Controlled synthesis of 3D nanostructures using proximity-field nanopatterning lithography and graded temperature ALD. ECS Trans. 16(4), 165–171 (2008)

S.-G. Park, T.Y. Jeon, H.C. Jeon, S.-M. Yang, J.-D. Kwon, C.-W. Mun, B. Cho, C.S. Kim, D.-H. Kim, Fabrication of 3D ZnO hollow shell structures by prism holographic lithography and atomic layer deposition. J. Mater. Chem C 2(11), 1957–1961 (2014)

S. Cho, C. Ahn, J. Park, S. Jeon, 3D nanostructured N-doped TiO2 photocatalysts with enhanced visible absorption. Nanoscale 10(20), 9747–9751 (2018)

K. Kim, J. Park, S. Hong, S.H. Park, S.G. Jeon, C. Ahn, J.Y. Song, S. Jeon, Anomalous thermoelectricity of pure ZnO from 3D continuous ultrathin nanoshell structures. Nanoscale 10(6), 3046–3052 (2018)

Y.-E. Na, D. Shin, K. Kim, C. Ahn, S. Jeon, D. Jang, Emergence of new density-strength scaling law in 3D hollow ceramic nanoarchitectures. Small 14(44), 1802239 (2018)

H. Park, C. Ahn, H. Jo, M. Choi, D.S. Kim, D.K. Kim, S. Jeon, H. Choe, Large-area metal foams with highly ordered sub-micrometer-scale pores for potential applications in energy areas. Mater. Lett. 129, 174–177 (2014)

S. Kim, C. Ahn, Y. Cho, G. Hyun, S. Jeon, J.H. Park, Suppressing buoyant force: new avenue for long-term durability of oxygen evolution catalysts. Nano Energy 54, 184–191 (2018)

J. Bong, C. Ahn, T. Lim, J.H. Park, S.K. Kwak, S. Jeon, S. Ju, Controlled three-dimensional interconnected capillary structures for liquid repellency engineering. RSC Adv. 6, 61909–61914 (2016)

S.K. Kuk, Y. Ham, K. Gopinath, P. Boonmongkolras, Y. Lee, Y.W. Lee, S. Kondaveeti, C. Ahn, B. Shin, J.-K. Lee, S. Jeon, C.B. Park, Continuous 3D titanium nitride nanoshell structure for solar-driven unbiased biocatalytic CO2 reduction. Adv. Energy Mater. 9(25), 1900029 (2019)

S. Araki, Y. Ishikawa, X. Wang, M. Uenuma, D. Cho, S. Jeon, Y. Uraoka, Fabrication of nanoshell-based 3D periodic structures by templating process using solution-derived ZnO. Nanoscale Res. Lett. 12, 419 (2017)

H. Yan, Y. Yang, Z. Fu, B. Yang, L. Xia, S. Fu, F. Li, Fabrication of 2D and 3D ordered porous Zno films using 3D opal templates by electrodeposition. Electrochem. Commun. 7(11), 1117–1121 (2005)

G.M. Zarkadas, A. Stergiou, G. Papanastasiou, Influence of citric acid on the silver electrodeposition from aqueous AgNO3 solutions. Electrochim. Acta 50(25), 5022–5031 (2005)

X. Yu, Y.-J. Lee, R. Furstenberg, J.O. White, P.V. Braun, Filling fraction dependent properties of inverse opal metallic photonic crystals. Adv. Mater. 19(13), 1689–1692 (2007)

Y. Xu, X. Zhu, Y. Dan, J.H. Moon, V.W. Chen, A.T. Johnson, J.W. Perry, S. Yang, Electrodeposition of three-dimensional titania photonic crystals from holographically patterned microporous polymer templates. Chem. Mater. 20(5), 1816–1823 (2008)

R. Beica, C. Sharbono, T. Ritzdorf, in Through Silicon via Copper Electrodeposition for 3D Integration. 58th Electronic Components and Technology Conference IEEE pp 577–583 (2008).

K.A. Arpin, M.D. Losego, P.V. Braun, Electrodeposited 3D tungsten photonic crystals with enhanced thermal stability. Chem. Mater. 23(21), 4783–4788 (2011)

M. Heim, S. Reculusa, S. Ravaine, A. Kuhn, Engineering of complex macroporous materials through controlled electrodeposition in colloidal superstructures. Adv. Funct. Mater. 22(3), 538–545 (2012)

D. Santiago, G.G. Rodríguez-Calero, A. Palkar, D. Barraza-Jimenez, D.H. Galvan, G. Casillas, A. Mayoral, M. Jose-Yacamán, L. Echegoyen, C.R. Cabrera, Platinum electrodeposition on unsupported carbon nano-onions. Langmuir 28(49), 17202–17210 (2012)

S. Hrapovic, Y. Liu, G. Enright, F. Bensebaa, J.H.T. Luong, New strategy for preparing thin gold films on modified glass surfaces by electroless deposition. Langmuir 19(9), 3958–3965 (2003)

Y. Chen, M. Cao, Q. Xu, J. Zhu, Electroless nickel plating on silicon carbide nanoparticles. Surf. Coat. Tech. 172(1), 90–94 (2003)

F. Hanna, Z.A. Hamid, A.A. Aal, Controlling factors affecting the stability and rate of electroless copper plating. Mater. Lett. 58(1–2), 104–109 (2004)

A. Radke, T. Gissibl, T. Klotzbücher, P.V. Braun, H. Giessen, Three-dimensional bichiral plasmonic crystals fabricated by direct laser writing and electroless silver plating. Adv. Mater. 23(27), 3018–3021 (2011)

C.-F. Cheng, H.-Y. Hsueh, C.-H. Lai, C.-J. Pan, B.-J. Hwang, C.-C. Hu, R.-M. Ho, Nanoporous gyroid platinum with high catalytic activity from block copolymer templates via electroless plating. NPG Asia Mater. 7, e170 (2015)

T.A. Schaedler, A.J. Jacobsen, A. Torrents, A.E. Sorensen, J. Lian, J.R. Greer, L. Valdevit, W.B. Carter, Ultralight metallic microlattices. Science 334(6058), 962–965 (2011)

N. Xu, Y. Zhang, T. Zhang, Y. Liu, J. Qiao, Efficient quantum dots anchored nanocomposite for highly active ORR/OER electrocatalyst of advanced metal-air batteries. Nano Energy 57, 176–185 (2019)

K. Kim, A.P. Tiwari, G. Hyun, T.G. Novak, S. Jeon, Improving electrochemical active area of MoS2 via attached on 3D-ordered structures for hydrogen evolution reaction. Int. J. Hydrog. Energy 44(52), 28143–28150 (2019)

F. Song, W. Li, J. Yang, G. Han, P. Liao, Y. Sun, Interfacing nickel nitride and nickel boosts both electrocatalytic hydrogen evolution and oxidation reactions. Nat. Commun. 9, 4531 (2018)

A.P. Tiwari, K. Lee, K. Kim, J. Kim, T.G. Novak, S. Jeon, Conformally coated nickel phosphide on 3D, ordered nanoporous nickel for highly active and durable hydrogen evolution. ACS. Sustain. Chem. Eng. 8(46), 17116–17123 (2020)

D.J. Shir, S. Jeon, H. Liao, M. Highland, D.G. Cahill, M.F. Su, I.F. El-Kady, C.G. Christodoulou, G.R. Bogart, A.V. Hamza, J.A. Rogers, Three-dimensional nanofabrication with elastomeric phase masks. J. Phys. Chem. B 111(45), 12945–12958 (2007)

J. Ahn, C. Ahn, S. Jeon, J. Park, Atomic layer deposition of inorganic thin films on 3D polymer nanonetworks. Appl. Sci. 9(10), 1990 (2019)

K. Lee, H. Yoon, C. Ahn, J. Park, S. Jeon, Strategies to improve the photocatalytic activity of TiO2: 3D nanostructuring and heterostructuring with graphitic carbon nanomaterials. Nanoscale 11, 7025–7040 (2019)

L.E. Bell, Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 321(5895), 1457–1461 (2008)

G. Chen, M. Dresselhaus, G. Dresselhaus, J.-P. Fleurial, T. Caillat, Recent developments in thermoelectric materials. Int. Mater. Rev. 48(1), 45–66 (2003)

K.P. Ong, D.J. Singh, P. Wu, Analysis of the thermoelectric properties of n-type ZnO. Phys. Rev. B 83(11), 115110 (2011)

M. Ohtaki, Recent aspects of oxide thermoelectric materials for power generation from mid-to-high temperature heat source. J. Ceram. Soc. Jpn. 119(1395), 770–775 (2011)

T. Tsubota, M. Ohtaki, K. Eguchi, H. Arai, Thermoelectric properties of Al-doped ZnO as a promising oxidematerial for high-temperature thermoelectric conversion. J. Mater. Chem. 7, 85–90 (1997)

E. Guilmeau, P. Díaz-Chao, O.I. Lebedev, A. Rečnik, M.C. Schäfer, F. Delorme, F. Giovannelli, M. Košir, S. Bernik, Inversion boundaries and phonon scattering in Ga: ZnO thermoelectric compounds. Inorg. Chem. 56, 480–487 (2016)

X. Qu, W. Wang, S. Lv, D. Jia, Thermoelectric properties and electronic structure of Al-doped ZnO. Solid State Commun. 151(4), 332–336 (2011)

Y. Kinemuchi, M. Mikami, K. Kobayashi, K. Watari, Y. Hotta, Thermoelectric properties of nanograined ZnO. J. Electron. Mater. 39(9), 2059–2063 (2010)

L. Shi, J. Chen, G. Zhang, B. Li, Thermoelectric figure of merit in Ga-doped [0001] ZnO manowires. Phys. Lett. A 376(8), 978–981 (2012)

M. Ruoho, T. Juntunen, I. Tittonen, Large-area thermoelectric high-aspect-ratio nanostructures by atomic layer deposition. Nanotechnology 27(35), 355403 (2016)

P. Jood, R.J. Mehta, Y. Zhang, G. Peleckis, X. Wang, R.W. Siegel, T. Borca-Tasciuc, S.X. Dou, G. Ramanath, Al-doped zinc oxide nanocomposites with enhanced thermoelectric properties. Nano Lett. 11(10), 4337–4342 (2011)

X.A. Zhang, A. Bagal, E.C. Dandley, J. Zhao, C.J. Oldham, B.I. Wu, G.N. Parsons, C.H. Chang, Ordered 3D thin-shell nanolattice materials with near-unity refractive indices. Adv. Funct. Mater. 25(42), 6644–6649 (2015)

S.I. Kim, K.H. Lee, H.A. Mun, H.S. Kim, S.W. Hwang, J.W. Roh, D.J. Yang, W.H. Shin, X.S. Li, Y.H. Lee, Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 348(6230), 109–114 (2015)

S. Hong, J. Park, S.G. Jeon, K. Kim, S.H. Park, H.S. Shin, B. Kim, S. Jeon, J.Y. Song, Monolithic Bi1.5Sb0.5Te3 ternary alloys with a periodic 3D nanostructure for enhancing thermoelectric performance. J. Mater. Chem. C. 5, 8974–8980 (2017)

Y.-Y. Choi, T.G. Yun, N. Qaiser, H. Paik, H.S. Roh, J. Hong, S. Hong, S.M. Han, K. No, Vertically aligned P(VDF-TrFE) core-shell structures on flexible pillar arrays. Sci. Rep. 5, 10728 (2015)

J. Ryu, H. Jeong, Y. Chen, C. Oh, J. Kim, H. Kim, S. Cho, K. No, Y.-H. Park, S. Park, S. Hong, Flexible piezoelectric liquid volume sensor. Sensors Actuat. A: Phys. 276, 219–225 (2018)

Z. Li, Y. Wang, Z.-Y. Cheng, Electromechanical properties of poly(vinylidene-fluoride-chlorotrifluoroethylene) copolymer. Appl. Phys. Lett. 88(6), 062904 (2006)

Y. Chen, Y. Zhang, F. Yuan, F. Ding, O.G. Schmidt, A flexible PMN-PT ribbon-based piezoelectric-pyroelectric hybrid generator for human-activity energy harvesting and monitoring. Adv. Electron. Mater. 3(3), 1600540 (2017)

Z. Yu, C. Ang, R. Guo, A.S. Bhalla, Piezoelectric and strain properties of Ba(Ti1−xZrx)O3 ceramics. J. Appl. Phys. 92(3), 1489–1493 (2002)

K. Wang, J.-F. Li, J.-J. Zhou, High normalized strain obtained in Li-modified (K, Na)NbO3 lead-free piezoceramics. Appl. Phys. Express 4(6), 061501 (2011)

D. Jang, L.R. Meza, F. Greer, J.R. Greer, Fabrication and deformation of three-dimensional hollow ceramic nanostructures. Nat. Mater. 12(10), 893–898 (2013)

L.R. Meza, S. Das, J.R. Greer, Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345(6202), 1322–1326 (2014)

X. Li, H. Gao, Smaller and stronger. Nat. Mater. 15(4), 373–374 (2016)

H. Mirzaei, M. Darroudi, Zinc oxide nanoparticles: biological synthesis and biomedical applications. Ceram. Int. 43(1), 907–914 (2017)

B. Yin, Y. Qiu, H. Zhang, J. Lei, Y. Chang, J. Ji, Y. Luo, Y. Zhao, L. Hu, Piezoelectric performance enhancement of ZnO flexible nanogenerator by a NiO-ZnO p-n junction formation. Nano Energy 14, 95–101 (2015)

J. Hong, H. Wagata, K.-I. Katsumata, N. Matsushita, Low Temperature solution-processed ZnO film on flexible substrate. Mater. Sci. Semicond. Process. 47, 20–24 (2016)

H. Kim, S. Yun, K. Kim, W. Kim, J. Ryu, H.G. Nam, S.M. Han, S. Jeon, S. Hong, Breaking the elastic limit of piezoelectric ceramics using nanostructures: a case study using ZnO. Nano Energy 78, 105259 (2020)

J. Schneider, M. Matsuoka, M. Takeuchi, J. Zhang, Y. Horiuchi, M. Anpo, D.W. Bahnemann, Understanding TiO2 photocatalysis: mechanisms and material. Chem. Rev. 114(10), 9919–9986 (2014)

X. Chen, S.S. Mao, Titanium dioxide nanomaterials: synthesis, properties, modifications, and applications. Chem. Rev. 107(7), 2891–2959 (2007)

M.S. Dresselhaus, I.L. Thomas, Alternative energy technologies. Nature 414, 332–337 (2001)

Y. Hou, B.L. Abrams, P.C.K. Vesborg, M.E. Björketun, K. Herbst, L. Bech, A.M. Setti, C.D. Damsgaard, T. Pedersen, O. Hansen, J. Rossmeisl, S. Dahl, J.K. Nørskov, I. Chorkendorff, Bioinspired molecular Co-catalysts bonded to a silicon photocathode for solar hydrogen evolution. Nat. Mater. 10, 434 (2011)

Y. Li, H. Wang, L. Xie, Y. Liang, G. Hong, H. Dai, MoS2 nanoparticles grown on graphene: an advanced catalyst for the hydrogen evolution reaction. J. Am. Chem. Soc. 133(19), 7296–7299 (2011)

A. Tiwari, T. Novak, X. Bu, J. Ho, S. Jeon, Layered ternary and quaternary transition metal chalcogenide based catalysts for water splitting. Catalysts 8(11), 551 (2018)

X. Zou, Y. Zhang, Noble metal-free hydrogen evolution catalysts for water splitting. Chem. Soc. Rev. 44(15), 5148–5180 (2015)

N.P. Dasgupta, C. Liu, S. Andrews, F.B. Prinz, P. Yang, Atomic layer deposition of platinum catalysts on nanowire surfaces for photoelectrochemical water reduction. J. Am. Chem. Soc. 135(35), 12932–12935 (2013)

A.P. Tiwari, D. Kim, Y. Kim, O. Prakash, H. Lee, Highly active and stable layered ternary transition metal chalcogenide for hydrogen evolution reaction. Nano Energy 28, 366–372 (2016)

A.P. Tiwari, D. Kim, Y. Kim, H. Lee, Bifunctional oxygen electrocatalysis through chemical bonding of transition metal chalcogenides on conductive carbons. Adv. Energy Mater. 7(14), 1602217 (2017)

Y. Kim, A.P. Tiwari, O. Prakash, H. Lee, Activation of ternary transition metal chalcogenide basal planes through chemical strain for the hydrogen evolution reaction. ChemPlusChem 82(5), 785–791 (2017)

A.P. Tiwari, A. Azam, T.G. Novak, O. Prakash, S. Jeon, Chemical strain formation through anion substitution in Cu2WS4 for efficient electrocatalysis of water dissociation. J. Mater. Chem. A 6, 7786–7793 (2018)

Y. Yoon, A.P. Tiwari, M. Lee, M. Choi, W. Song, J. Im, T. Zyung, H.-K. Jung, S.S. Lee, S. Jeon, K.-S. An, Enhanced electrocatalytic activity by chemical nitridation of two-dimensional titanium carbide mxene for hydrogen evolution. J. Mater. Chem. A 6, 20869–20877 (2018)

T.G. Novak, O. Prakash, A.P. Tiwari, S. Jeon, Solution-phase phosphorus substitution for enhanced oxygen evolution reaction in Cu2WS4. RSC Adv. 9, 234–239 (2019)

A.P. Tiwari, Y. Yoon, T.G. Novak, A. Azam, M. Lee, S.S. Lee, G. Lee, D.J. Srolovitz, K.-S. An, S. Jeon, Lattice strain formation through spin-coupled shells of MoS2 on Mo2C for bifunctional oxygen reduction and oxygen evolution reaction electrocatalysts. Adv. Mater. Interfaces 6(22), 1900948 (2019)

G. Hyun, S.-H. Cho, J. Park, K. Kim, C. Ahn, A.P. Tiwari, I.-D. Kim, S. Jeon, 3D ordered carbon/SnO2 hybrid nanostructures for energy storage applications. Electrochim. Acta 288, 108–114 (2018)

H. Wang, D. Kong, P. Johanes, J.J. Cha, G. Zheng, K. Yan, N. Liu, Y. Cui, MoSe2 and WSe2 nanofilms with vertically aligned molecular layers on curved and rough surfaces. Nano Lett. 13(7), 3426–3433 (2013)

M. Chhowalla, H.S. Shin, G. Eda, L.-J. Li, K.P. Loh, H. Zhang, The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat. Chem. 5, 263 (2013)

D. Voiry, H. Yamaguchi, J. Li, R. Silva, D.C.B. Alves, T. Fujita, M. Chen, T. Asefa, V.B. Shenoy, G. Eda, M. Chhowalla, Enhanced catalytic activity in strained chemically exfoliated WS2 nanosheets for hydrogen evolution. Nat. Mater. 12, 850 (2013)

M.-R. Gao, J.-X. Liang, Y.-R. Zheng, Y.-F. Xu, J. Jiang, Q. Gao, J. Li, S.-H. Yu, An efficient molybdenum disulfide/cobalt diselenide hybrid catalyst for electrochemical hydrogen generation. Nate Commun. 6, 5982 (2015)

B. Hinnemann, P.G. Moses, J. Bonde, K.P. Jørgensen, J.H. Nielsen, S. Horch, I. Chorkendorff, J.K. Nørskov, Biomimetic hydrogen evolution: mos2 nanoparticles as catalyst for hydrogen evolution. J. Am. Chem. Soc. 127(15), 5308–5309 (2005)

T.F. Jaramillo, K.P. Jørgensen, J. Bonde, J.H. Nielsen, S. Horch, I. Chorkendorff, Identification of active edge sites for electrochemical H2 evolution from MoS2 nanocatalysts. Science 317(5834), 100–102 (2007)

Z. Chen, D. Cummins, B.N. Reinecke, E. Clark, M.K. Sunkara, T.F. Jaramillo, Core-shell MoO3-MoS2 nanowires for hydrogen evolution: a functional design for electrocatalytic materials. Nano Lett. 11(10), 4168–4175 (2011)

C.G. Morales-Guio, X. Hu, Amorphous molybdenum sulfides as hydrogen evolution catalysts. Acc. Chem. Res. 47(8), 2671–2681 (2014)

J. Kibsgaard, Z. Chen, B.N. Reinecke, T.F. Jaramillo, Engineering the surface structure of MoS2 To preferentially expose active edge sites for electrocatalysis. Nat. Mater. 11, 963 (2012)

D. Kong, H. Wang, J.J. Cha, M. Pasta, K.J. Koski, J. Yao, Y. Cui, Synthesis of MoS2 and MoSe2 films with vertically aligned layers. Nano Lett. 13(3), 1341–1347 (2013)

J. Hu, B. Huang, C. Zhang, Z. Wang, Y. An, D. Zhou, H. Lin, M.K.H. Leung, S. Yang, Engineering stepped edge surface structures of MoS2 sheet stacks to accelerate the hydrogen evolution reaction. Energy Environ. Sci. 10(2), 593–603 (2017)

Q. Zhang, Z. Xu, B. Lu, Strongly coupled MoS2-3D graphene materials for ultrafast charge slow discharge libs and water splitting applications. Energy Storage Mater. 4, 84–91 (2016)

X. Geng, W. Wu, N. Li, W. Sun, J. Armstrong, A. Al-hilo, M. Brozak, J. Cui, T.-P. Chen, Three-dimensional structures of mos2 nanosheets with ultrahigh hydrogen evolution reaction in water reduction. Adv. Funct. Mater. 24(39), 6123–6129 (2014)

D. Cho, J. Park, J. Kim, T. Kim, J. Kim, I. Park, S. Jeon, Three-dimensionally continuous conductive nanostructure for highly sensitive and stretchable strain sensor. ACS Appl. Mater. Interfaces 9(20), 17369–17378 (2017)

E.J. Popczun, J.R. McKone, C.G. Read, A.J. Biacchi, A.M. Wiltrout, N.S. Lewis, R.E. Schaak, Nanostructured nickel phosphide as an electrocatalyst for the hydrogen evolution reaction. J. Am. Chem. Soc. 135(25), 9267–9270 (2013)

W.-F. Chen, J.T. Muckerman, E. Fujita, Recent developments in transition metal carbides and nitrides as hydrogen evolution electrocatalysts. Chem. Commun. 49, 8896–8909 (2013)

H.B. Wu, B.Y. Xia, L. Yu, X.-Y. Yu, X.W. Luo, Porous molybdenum carbide nano-octahedrons synthesized via confined carburization in metal-organic frameworks for efficient hydrogen production. Nat. Commun. 6, 6512 (2015)

S.J. Sitler, K.S. Raja, I. Charit, Metal-rich transition metal diborides as electrocatalysts for hydrogen evolution reactions in a wide range of pH. J. Electrochem. Soc. 163(13), 1609–1075 (2016)

J. Ren, Z. Hu, C. Chen, Y. Liu, Z. Yuan, Integrated Ni2P nanosheet arrays on three-dimensional Ni foam for highly efficient water reduction and oxidation. J. Energy Chem. 26(6), 1196–1202 (2017)

L. Yu, I.K. Mishra, Y. Xie, H. Zhou, J. Sun, J. Zhou, Y. Ni, D. Luo, F. Yu, Y. Yu, S. Chen, Z. Ren, Ternary Ni2(1–x)Mo2xP nanowire arrays toward efficient and stable hydrogen evolution electrocatalysis under large-current-density. Nano Energy 53, 492–500 (2018)

X. Wang, W. Li, D. Xiong, D.Y. Petrovykh, L. Liu, Bifunctional nickel phosphide nanocatalysts supported on carbon fiber paper for highly efficient and stable overall water splitting. Adv. Funct. Mater. 26(23), 4067–4077 (2016)

X. Wang, W. Li, D. Xiong, L. Liu, Fast fabrication of self-supported porous nickel phosphide foam for efficient, durable oxygen evolution and overall water splitting. J. Mater. Chem. A 4, 5639–5646 (2016)

B. Liu, B. He, H.-Q. Peng, Y. Zhao, Y. Cheng, J. Xia, J. Shen, T.-W. Ng, X. Meng, C.-S. Lee, W. Zhang, Unconventional nickel nitride enriched with nitrogen vacancies as a high-efficiency electrocatalyst for hydrogen evolution. Adv. Sci. 5(8), 1800406 (2018)

L. Yu, S. Song, B. McElhenny, F. Ding, D. Luo, Y. Yu, S. Chen, Z. Ren, A universal synthesis strategy to make metal nitride electrocatalysts for hydrogen evolution reaction. J. Mater. Chem. A 7, 19728–19732 (2019)

L. Yu, Q. Zhu, S. Song, B. McElhenny, D. Wang, C. Wu, Z. Qin, J. Bao, Y. Yu, S. Chen, Z. Ren, Non-noble metal-nitride based electrocatalysts for high-performance alkaline seawater electrolysis. Nat. Commun. 10, 5106 (2019)

C. Huang, S. Cheng, L. Yu, W. Zhang, J. Zhou, Y. Zhang, Y. Yu, Electrolyzer with hierarchical transition metal sulfide and phosphide towards overall water splitting. Mater. Today Phys. 11, 100162 (2019)

S.H. Yu, W. Chen, H. Wang, H. Pan, D.H.C. Chua, Highly stable tungsten disulfide supported on a self-standing nickel phosphide foam as a hybrid electrocatalyst for efficient electrolytic hydrogen evolution. Nano Energy 55, 193–202 (2019)

X. Bu, R. Wei, W. Gao, C. Lan, J.C. Ho, A unique sandwich structure of a CoMnP/Ni2P/NiFe electrocatalyst for highly efficient overall water splitting. J. Mater. Chem. A 7, 12325–12332 (2019)

S. Liu, C. Hu, C. Lv, J. Cai, M. Daun, J. Luo, J. Song, Y. Shi, C. Chen, D. Luo, A. Watanabe, E. Aoyagi, S. Ito, Facile preparation of large-area self-supported porous nickel phosphide nanosheets for efficient electrocatalytic hydrogen evolution. Int. J. Hydrog. Energy 44(33), 17974–17984 (2019)

C. Hu, J. Cai, S. Liu, C. Lv, J. Luo, M. Daun, C. Chen, Y. Shi, J. Song, Z. Zhang, A. Watanabe, E. Aoyagi, S. Ito, General strategy for preparation of porous nickel phosphide nanosheets on arbitrary substrates toward efficient hydrogen generation. ACS Appl. Energy Mater. 3(1), 1036–1045 (2020)

C. Haung, L. Yu, W. Zhang, Q. Xiao, J. Zhou, Y. Zhang, P. An, J. Zhang, Y. Yu, N-doped Ni-Mo based sulfides for high-efficiency and stable hydrogen evolution reaction. Appl. Catal. B 276(5), 119137 (2020)

C. Hu, C. Lv, S. Liu, Y. Shi, J. Song, Z. Zhang, J. Cai, A. Watanabe, Nickel phosphide electrocatalysts for hydrogen evolution reaction. Catalysts 10(2), 188 (2020)

C.C.L. McCrory, S. Jung, J.C. Peters, T.F. Jaramillo, Benchmarking heterogeneous electrocatalysts for the oxygen evolution reaction. J. Am. Chem. Soc. 135(45), 16977–16987 (2013)

J. Zhang, J. Liu, L. Xi, Y. Yu, N. Chen, S. Sun, W. Wang, K.M. Lange, B. Zhang, Single-atom Au/NiFe layered double hydroxide electrocatalyst: probing the origin of activity for oxygen evolution reaction. J. Am. Chem. Soc. 140(11), 3876–3879 (2018)

H.-R.M. Jhong, S. Ma, P.J.A. Kenis, Electrochemical conversion of CO2 to useful chemicals: current status, remaining challenges, and future opportunities. Curr. Opin. Chem. Eng. 2(2), 191–199 (2013)

J. Kim, J.T. Song, H. Ryoo, J.-G. Kim, S.-Y. Chung, J. Oh, Morphology-controlled au nanostructures for efficient and selective electrochemical CO2 reduction. J. Mater. Chem. A 6, 5119–5128 (2018)

G. Hyun, J.T. Song, C. Ahn, Y. Ham, D. Cho, J. Oh, S. Jeon, Hierarchically porous Au nanostructures with interconnected channels for efficient mass transport in electrocatalytic CO2 reduction. PNAS 117(11), 5680–5685 (2020)

X. Liu, S. Inagaki, J. Gong, Heterogeneous molecular systems for photocatalytic CO2 reduction with water oxidation. Angew. Chem. Int. Ed. 55(48), 14924–14950 (2016)

P. Zhou, J. Yu, M. Jaroniec, All-solid-state Z-scheme photocatalytic systems. Adv. Mater. 26(29), 4920–4935 (2014)

Acknowledgements

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2020R1I1A1A01071675), Nano-Material Technology Development Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (2017M3A7B4049547), and Creative Materials Discovery Program through the National Research Foundation of Korea (NRF) funded by Ministry of Science and ICT (NRF-2017M3D1A1039558, NRF-2020M3D1A1110522).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, K., Tiwari, A.P., Novak, T.G. et al. 3D ordered nanoelectrodes for energy conversion applications: thermoelectric, piezoelectric, and electrocatalytic applications. J. Korean Ceram. Soc. 58, 379–398 (2021). https://doi.org/10.1007/s43207-021-00113-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-021-00113-9