Highlights

-

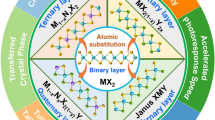

Atomic substitution applied in the synthesis of different dimensional transition metal chalcogenide (TMC) is dissertated.

-

The controllable synthesis and property modification realization with atomic substitution or ion exchange are introduced.

-

The substitution principle and mechanism in different TMCs are concluded.

Abstract

In recent years, low-dimensional transition metal chalcogenide (TMC) materials have garnered growing research attention due to their superior electronic, optical, and catalytic properties compared to their bulk counterparts. The controllable synthesis and manipulation of these materials are crucial for tailoring their properties and unlocking their full potential in various applications. In this context, the atomic substitution method has emerged as a favorable approach. It involves the replacement of specific atoms within TMC structures with other elements and possesses the capability to regulate the compositions finely, crystal structures, and inherent properties of the resulting materials. In this review, we present a comprehensive overview on various strategies of atomic substitution employed in the synthesis of zero-dimensional, one-dimensional and two-dimensional TMC materials. The effects of substituting elements, substitution ratios, and substitution positions on the structures and morphologies of resulting material are discussed. The enhanced electrocatalytic performance and photovoltaic properties of the obtained materials are also provided, emphasizing the role of atomic substitution in achieving these advancements. Finally, challenges and future prospects in the field of atomic substitution for fabricating low-dimensional TMC materials are summarized.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The diversity in types, structures, and properties of transition metal chalcogenides (TMCs) has led to their wide application prospects in devices, energy, and catalysis [1,2,3]. Especially those with reduced dimensions, including zero-dimensional (0D), one-dimensional (1D) and two-dimensional (2D) structures, have attracted significant attention due to their unique properties differing from their bulk counterparts [4,5,6,7,8,9]. To realize the applications of low-dimensional TMC materials in various scientific and technological fields, it is essential for these materials to exhibit well-defined optical, electronic, magnetic, and catalytic properties. Thereby, the synthesis methods that enable the precise control over the structures, morphologies and compositions of TMC materials are highly desired.

In the past few decades, different synthesis strategies for TMC materials have been developed, such as thermal injection and hydrothermal synthesis for 0D and 1D TMCs [10, 11], chemical vapor deposition (CVD) and molecular beam epitaxy (MBE) methods for 2D TMCs [12,13,14,15]. Although TMC materials with different sizes and morphologies have been realized, their qualities and compositions are generally limited [16, 17]. Due to the complex dynamics of reactions that involve multiple components, the controllability of direct synthesis methods is restricted. In contrast, atomic substitution shows great advantages in controlling the shapes, morphologies and compositions of multi-element materials. To date, the synthesis of various TMC structures have been realized by atomic substitution methods, including single binary compounds, doped materials, alloys, heterostructures and others [18,19,20,21,22,23,24,25,26,27].

As a post-processing technique, atomic substitution provides opportunities for precise engineering and customization of the desired properties of multi-element materials, and therefore serves to address the limitations of direct synthesis methods. By this method, great achievements have been made in TMCs synthesis and property modulation. For example, to achieve TMC materials with desired electronic or catalytic properties, ion exchange methods are commonly employed to tune the composition of the transition metal and chalcogens [28,29,30,31,32,33]. Moreover, the substitution reaction has the potential in inducing structural transformation, providing a promising pathway for synthesizing new materials or those are difficult to obtain directly [34,35,36,37,38,39]. For instance, through a moderate expansion of the anion sublattice during the substitution reaction process, it is possible to achieve metastable core@shell heterostructures without the formation of strain-induced defects at the interface, despite of a moderate lattice mismatch between core and shell [40]. These metastable heterostructures can hardly be directly synthesized by conventional growth methods, due to thermodynamically limited [41, 42]. Such controlled structural evolution not only expand the range of accessible materials but also enable the exploration for novel properties and functionalities, which is definitely advances the field of nanoscience.

The fast development of atomic substitution methods has made the precise synthesis of TMC materials with well-controlled properties possible. Here, we reviewed recent progresses in the synthesis and modulation of low-dimensional TMC materials, including 0D, 1D and 2D, achieved by atomic substitution methods. In the 0D section, the principles of atomic exchange in solution are discussed. The synthesis of substituted TMCs through both the cation exchange reactions and anion exchange reactions is presented. Moving to the 1D section, the synthesis of TMC nanorods, nanowires, nanotubes and nanobelts is summarized, highlighting the strategies employed to achieve their controlled growth. In the 2D section, the initiation mechanisms for atomic substitution within TMC films are introduced, which typically originate from vacancies, grain boundaries or edges. The substitution processes for 2D TMCs are discussed, categorized as either complete substitution or partial substitution, depending on the extent of the process. Complete substitution shows great potential in fabricating ultra-thin TMC films that cannot be directly synthesized, whereas partial substitution is widely employed for the synthesis of heterostructure materials, Janus structures, alloys and so on. The improved electrocatalytic and photovoltaic properties of the obtained TMC materials are also presented. Finally, we conclude this review by discussing the limitations and future. This comprehensive review provides valuable insights into the design principles, structural characteristics, and potential applications of low-dimensional TMC materials, which will greatly benefit the development of next-generation TMC devices and technologies.

2 0D TMCs

0D TMC materials refer to structures with all dimensions being in the range of 1 ~ 100 nm, which typically consist of transition metals from Group IB to Group IIB and chalcogens, with a composition ratio of M:X ranging from 1:1 to 1:2 [43,44,45]. Their unique physical and chemical properties make them to be highly promising for photoluminescence [46, 47], photocatalysis [48, 49], photothermal therapy [50, 51], etc. To date, many strategies have been developed to synthesize 0D TMC materials, such as hot injection [52, 53], topological chemical synthesis [54, 55] and solvothermal (or hydrothermal) method [56, 57]. Among them, the topological chemical synthesis approach accompanied with atomic substitution shows great advantages in precisely tailoring the compositions, morphologies and structures of materials [58,59,60]. It is worth noting that for 0D TMC materials, atomic substitute reactions typically take place within solutions containing ionic compounds, known as ion exchange reactions.

Since Alivisatos and coworkers demonstrated the potential of ion exchange in fabricating inorganic nanocrystals with diverse compositions, sizes, shapes and structures [61], this synthesis approach has gained widespread exploration for generating various materials. To date, ion exchange has become as a versatile tool for synthesizing TMC materials. In this section, the principles of ion exchange reactions were discussed, followed by the employment of ion exchange reactions in synthesizing various 0D TMC materials, including single-, doped-, alloyed- and hetero-nanocrystals.

2.1 Principles of Ion Exchange Reactions

Generally, ion exchange reactions are reversible, with the reaction direction dominated by the thermodynamic factors of the reactants and products. Both the Gibbs free energy of reactions (ΔGr) and bond dissociation energies (BDEs) are essential for predicting the thermodynamics of ion exchange reaction [62, 63]. ΔGr determines whether the reaction is thermodynamically favorable or not, and the reaction can proceed spontaneously when ΔGr < 0. BDEs theory suggests that materials with stronger BDEs are more likely to participate in ion exchange reactions, especially when various ions are miscible. BDEs of some common metal chalcogenides are listed in Table 1. The synthesis of tellurides is more challenging compared to sulfides and selenides, owing to the lower BDEs between metal and Te atoms.

The thermodynamics and kinetics of ion exchange reactions can also be effectively mediated by factors like ligands, solvents and crystal structures, etc., which are not taken into account in the above two theories. Currently, Pearson’s hard and soft acid base theory is widely used for assessing the affinity between metal ions and ligands/solvents [64]. It offers a framework to predict the process of ion exchange reactions, with hard acids showing a preference for hard bases and soft acids favoring soft bases. Phosphines as soft Lewis bases are common ligands in ion exchange reactions. Depending on the nature of the R groups, phosphines can form either σ bonding or π back-bonding with metal. In 2015, Zhang’s group intuitively characterized the distinct coordination capabilities between various metal cations and phosphine ligands, providing direct evidence for cation exchange (CE) reactions induced by phosphine ligands [65]. As shown in Fig. 1a, for a thermodynamically unfavorable exchange process (ΔGr > 0), the introduction of phosphine ligands can not only facilitate the solvation and extraction of cations from the reactants but also enhance the desolvation and incorporation of cations into the products. This effectively changed the sign of ΔGr (ΔGr < 0), making the reaction thermodynamically favorable. Based on this finding, a series of metal@semiconductor core@shell nanocrystals were successfully obtained by choosing appropriate phosphine ligands. Solvents also play a crucial role in determining the kinetics of ion exchange reaction. As illustrated in Fig. 1b, Bai et al. synthesized high-quality Ag-doped ZnS quantum dots (QDs) and Au@ZnS core–shell nanocrystals using different solvents [66]. It was found that even utilizing the same thiol ligand, CE reactions in different solvents shows distinct reaction rates, suggesting diverse coordination abilities between metal cations and solvents.

Copyright 2015, John Wiley and Sons. b Schematic of the thiol ligands and solvents combination coordinated CE reactions. Reproduced with permission [66]. Copyright 2019, John Wiley and Sons. c Schematic of CE reaction triggered by surface vacancy engineering. Reproduced with permission [67]. Copyright 2020, Elsevier. d Scheme of partial CE reactions in djurleite Cu1.94S nanodisks and covellite CuS nanodisks. Reproduced with permission [68]. Copyright 2022, RSC Pub

Schematics of ion exchange reaction principles a Thermodynamic scheme of the cation exchange (CE) reactions initiated by the phosphine ligands. Reproduced with permission [65].

The influence of defects and crystal structures of reactants on the process of ion exchange reaction cannot be ignored. Vacancy defects act as vehicles to promote ion diffusion as they can move quickly within the crystal during reactions. As illustrated in Fig. 1c, using engineered CuInX2 nanocrystals with abundant surface vacancies as the reactant, Bai et al. successfully synthesized Cu/In dual-doped CdX (X = S, Se) nanocrystals [67]. The creation of Cu and In vacancies are found to be critical to overcoming kinetic energy barriers and effectively accelerating Cd2+ diffusion process. As for the crystal structure, it mainly affects the diffusion of ion into host materials. In Fig. 1d, due to the similar structures between djurleite Cu1.94S and wurtzite CdS, Cu+ in djurleite Cu1.94S nanodisks can be easily substituted by Cd2+ at a low temperature [68]. It is worth noting that the CE reactions from the top of Cu1.94S nanodisks were kinetically limited due to the absence of vacancies along the < 100 > direction, resulting in the formation of segmented Cu1.94S/CdS nanodisks. In contrast, Cu2+ in covellite CuS were hardly replaced by Cd2+ at a low temperature, due to the high energy barrier for breaking S–S covalent bonds. At a high temperature, S–S bonds underwent reduction, leading to the reorganization of sulfur anion frameworks. As a result, the substitution of Cu2+ in CuS by Cd2+ along the lateral directions became energetically favorable. However, CE reactions starting from the top of the CuS nanodisks were limited because of the large mismatch of S–S distances between CuS (001) and CdS (001), resulting in the formation of CuS@CdS nanodisks.

2.2 Complete Exchange

To date, the ion exchange strategy has been widely used for controllable synthesis of TMC materials with tailored morphologies, structures and hetero-interfaces. Especially, it allows synthesis of TMC materials with unique compositions and morphologies that cannot be obtained by direct seeded growth. For example, metal@semiconductor core@shell heterostructures through ions exchange of semiconductor shells with guest ions showed atomically organized interfaces and high-crystalline semiconductor shells, and such structures can be achieved even there is a large lattice mismatch between metal and semiconductor components [65, 69,70,71]. These structures generally enable efficient injection of hot electrons triggered by surface plasmon resonance, which provides an avenue to promoting the efficiency of photocatalysis, photoelectrochemical cells and photovoltaics.

2.2.1 Syntheses of 0D TMCs via CE Reactions

According to the type of exchanged element, ion exchange reactions can be categorized into the CE reactions and anion exchange (AE) reactions. CE reactions involve the release of cations from the reactant TMC material and the exchange of other cations from the solution into TMC material. After CE reactions, the anion framework can be either preserved or reconstructed [63, 72,73,74]. As shown in Fig. 2a, b, the original S framework can be maintained when the height of Cu1.8S nanocrystals was less than 9 nm, resulting in the formation of wurtzite cobalt sulfide (CoS) [38]. Once the height exceeds 13 nm, structure reconstruction driven by thermodynamics occurred and cubic cobalt pentlandite (Co9S8) nanocrystals was obtained.

Copyright 2021, The American Association for the Advancement of Science. c Schematic showing the kinetic control and thermodynamic control for the CE process of PdTe and Pd20Te7 nanospheres synthesis. EG represents ethylene glycol and DMSO represents dimethyl sulfoxide. d TEM, HRTEM images of PdTe2 and Pd20Te7 nanospheres and corresponding energy-dispersive X-ray spectroscopy (EDS) elemental mapping images. Reproduced with permission [60]. Copyright 2022, Springer Nature

Synthesis and characterizations of 0D TMC materials obtained by CE reactions. a Schematics of height-dependent phase transformation of Cu1.8S nanocrystals during the CE process and b corresponding transmission electron microscopy (TEM) images, X-ray diffraction (XRD) patterns, high-resolution transmission electron microscopy (HRTEM) images. Reproduced with permission [38].

CE reactions have been widely used for the controllable synthesis of M–S and M-Se materials [55, 75,76,77,78,79,80]. However, the transformation of M–Te materials is often accompanied with significant alteration in morphology, making the synthesis of M–Te materials with desired morphologies and structures to be more challenging [63, 81]. Recently, Feng et al. synthesized noble metal tellurides (NMTs) with tailored morphologies (0D, 1D, 2D and 3D), compositions (Pd/Pt/Rh/Ru/Ag/Au-based NMTs) and structures via CE strategy by regulating the interactions between solvents and noble metal cations [60]. As displayed in Fig. 2c, Cu2+ within the CuTe template can be rapidly exchanged by Pd2+ based on the kinetic control, leading to the formation of Te, PdTe2 and PdTe. The products can be further tuned by controlling the thermodynamic process. In dimethyl sulfoxide, Pd2+ formed strong bound with the sulfoxide group, leading to a low content of free Pd2+ in solution for CE reactions. This resulted in the formation of Pd-poor NMTs, specifically PdTe. In contrast, there were more Pd2+ cations available for CE reactions in ethylene glycol due to its much weaker interaction with Pd2+. As a result, a Pd-rich structure characterized as Pd20Te7 was formed. Despite of the reconstruction of anion framework, the original nanosphere shape was retained in Pd20Te7 and PdTe products, showing highly crystalline structures with a uniform element distribution (Fig. 2d). In this strategy, the kinetic control and solvent-dependent thermodynamic control were revealed to be critical for the successful synthesis. This CE reaction provide a feasible and flexible method for the achieving of desired NMTs.

In addition to the synthesis of pure phase of TMCs, CE reactions also provide a promising strategy for fabricating metal–semiconductor heterostructures. In Table 2, representative examples of such heterostructures with varying lattice mismatches are listed. Notably, CE reactions demonstrate a great potential in synthesizing heterostructures with substantial lattice mismatches, which is typically beyond the capability of conventional epitaxial growth methods. In 2010, Zhang et al. reported a synthetic route for metal@semiconductor core@shell heterostructures [69], as exhibited in Fig. 3a, b. Starting from the metal core, an amorphous shell of Ag2X (X = S, Se, Te) was obtained first, serving as a crucial platform for the following reverse CE reactions. Tributylphosphine was then selected as the phase-transfer agent to exchange free cations (Mn+) in solution with Ag+ in the amorphous matrix, in order to obtain Au@MX (X = S, Se, Te) heterostructures. Various core@shell heterostructures were achieved finally, including Au-CdSe, Au-CdTe, FePt-CdS, Au-PbS, Au-ZnS and Pt-CdS. These heterostructures all possessed atomically organized interfaces and monocrystalline shells. The lattice structures of TMC shells were found to be independent of the core metal, suggesting their non-epitaxial relationship. With the development of this reverse CE reaction-facilitated non-epitaxial growth strategy, the size of synthesized high-quality metal@semiconductor heterostructures had reached to 50–100 nm [48], achieving breakthroughs from quantum scale to nanoscale (Fig. 3c). In these studies, the shell growth was guided by its thermodynamic property, and the obtained structure was independent of the core. The CE reaction is beneficial for circumventing the limitations imposed by epitaxial strategies and offers a precise and controllable way in the synthesis of core@shell heterostructures with atomically organized interfaces.

Copyright 2010, The American Association for the Advancement of Science. c TEM images of Au@ CdS heterostructures and high-angle annular dark-field scanning TEM (HAADF-STEM) images with corresponding elemental mapping images. Reproduced with permission [48]. Copyright 2018, Elsevier. d TEM and HAADF-STEM images of Au@CdS/CsPbBr3 heterostructures. Reproduced with permission [71]. Copyright 2022, John Wiley and Sons

Synthesis and characterizations of 0D metal–semiconductor heterostructures obtained by the reverse CE reaction-facilitated non-epitaxial growth strategy. a, b Schematic showing different growth stages of Au@CdS heterostructures and the corresponding HRTEM images. Reproduced with permission [69].

This non-epitaxial growth strategy also shows a great potential in manipulating the compositions and structures of heterostructures [71, 95]. For instance, by maneuvring interfacial strain between metal and semiconductor components, non-concentric Au@CdX heterodimer structures were achieved [70]. The tunable relocations of plasmonic Au to CdX (X = S, Se, Te) in quantum size region allowed for a high degree of tunability in coupling their optoelectronic properties with other structures. By a combined non-epitaxial/epitaxial strategy, Au@CdS/CsPbBr3 ternary heterostructures with atomically organized interfaces were obtained (Fig. 3d). These resulting Au@CdS/CsPbBr3 heteronanocrystals generated remarkably long-lived plasmon-induced charge carriers with lifetime up to nanosecond timescale [71]. This development further expanded the applications of the reverse CE reaction-facilitated non-epitaxial growth strategy.

2.2.2 Syntheses of 0D TMCs via AE Reactions

The process of AE reactions refers to exchanging anions in the reactant material with other anions. Compared with cations, the diffusion of anions is much slower within the 0D TMC nanocrystals due to their large ionic radii and large diffusion barrier. Consequently, AE reactions usually require higher reaction temperatures and longer reaction times, which contributes to a more manageable and controllable reaction process. As displayed in Fig. 4a, by performing the AE reactions of S2− by Te2− at 260 °C, the wurtzite CdS nanocrystals can be gradually transformed into zinc blende CdTe [96]. During the AE process, the size of the CdTe phase increased gradually, and spontaneous phase segregation occurred between CdS and CdTe due to their different phase structures. As the reaction continued, the complete transformation to a high-crystalline zinc blende CdTe was achieved at 120 min.

Copyright 2011, American Chemical Society. b Illustrations showing the synthesis of hollow Fe3S4 and solid Fe3S4 nanocrystals and corresponding TEM and HRTEM images. OER represents an oxygen extracting reagent, TMS-ODA represents (Z)-N-trimethylsilyloctadec-9-en-1-amine and TMS2O represents bis-(trimethylsilyl) oxide. Reproduced with permission [97]. Copyright 2020, American Chemical Society. c Illustrations showing the synthesis of MX nanoparticles (M = Cd, Mn; X = S, Se) and corresponding HRTEM image as well as EDS elemental mapping images. Reproduced with permission [98]. Copyright 2019, American Chemical Society

Synthesis and characterizations of 0D TMC materials obtained by the anion exchange (AE) reactions. a Synthesis illustrations of w-CdS/zb-CdTe heterodimers and corresponding TEM and HAADF-STEM images. Reproduced with permission [96].

Besides, AE reactions not only occur between chalcogens but can also take place between other elements. As shown in Fig. 4b, Lim et al. synthesized morphology-conserving Fe3S4 nanocrystals by AE reactions with the aid of oxygen extracting reagents [97]. In the AE process, the extraction of oxygen and subsequent formation of an amorphous phase acted as accelerants for the diffusion of incoming S2− ions, leading to the formation of morphology-conserving Fe3S4 nanocrystals (Fig. 4bii). Conversely, in the absence of oxygen-extraction agents, the formation of hollow Fe3S4 nanocrystals was inevitable, due to the imbalance in the diffusion between outgoing and incoming ions (Fig. 4bi). The oxygen extracting reagents assistant method has a great advantage in the synthesis of designed 0D nanocrystals without voids. This strategy illustrated new possibilities for the synthesis of various TMCs regardless of their shape and crystal structure. Jia et al. found that quasi-linear NCN2− in MNCN (M = Cd, Mn) nanoparticles can also be exchanged by X2− (X = S, Se) in colloidal solution (Fig. 4c). The quasi-linear NCN2− generated open space within the crystal lattice, effectively accommodating internal stress induced by AE reactions. As a result, the morphology and crystallinity were retained throughout the AE process. Besides, the anisotropic lattice of [NCN]2− anions was revealed to be critical in avoiding diffusion rate disparities and lattice collapse that occurred in single-atom anion compounds [98].

2.3 Partial Exchange

Compared with the complete exchange, partial anions/cations exchange process shows great advantages to synthesize doped, alloyed, and heterostructure TMC materials [10, 66, 99,100,101,102,103,104]. These materials have been widely reported due to their enhanced properties and optoelectronic applications [105,106,107]. For example, the deep-site doping enabled by reverse CE reactions can lead to nanocrystals with improved fluorescence quantum yields and lifetimes [100]. Core@shell QDs with continuously graded semiconductor shells prepared by ion exchange reactions show a strain-free interface and well-confined exciton, which are promising in optoelectronic applications of luminescent solar concentrators, light emitting devices and laser [108, 109]. Moreover, the ion exchange reaction provides possibilities for achieving metastable or non-equilibrium nanostructures, which cannot be obtained by conventional hot injection synthesis [42, 110]. In this section, we discuss the status of partial exchange in preparing doped, alloyed and hetero-structured TMC materials. In general, alloyed and doped materials were obtained in the case of reactants and products were miscible; otherwise, multi-domain heterostructures were formed.

2.3.1 Synthesis of 0D Doped TMC Materials

Due to the inherent self-purification effects, the host matrix often exhibits a tendency to expel dopant ions toward the surface of nanocrystals during doping process, especially at high temperatures [100]. Therefore, a delicate balance in precursor reactivity is required for precise control over the incorporation of dopants, which is quite challenging in a direct synthesis process. In contrast, the ion exchange strategy shows great advantages in the synthesis of doped materials, as it allows for the temporal separation of nanocrystal growth from the incorporation of impurities [63]. By controlling the kinetics of partial CE process, it is possible to retain a small quantity of “impurities” within the host matrix, serving as dopant ions. To date, various 0D doped TMC nanocrystals have been reported by direct CE reactions, such as Yb-doped PbIn2S4 nanocrystals [111], Ag-doped CdSe nanoparticles [112], Mn-doped ZnSe QDs [113] and Cu- or Ag-doped Cd1-xZnxSe nanocrystals [114]. All of these materials exhibited a much broader tunable spectrum range and enhanced optoelectronic properties, depending on the concentration of dopants.

Besides, as shown in Fig. 5a, Zhang et al. synthesized M-doped CdX (M = Ag, Cu and X = S, Se, Te) QDs by reverse CE reactions. By controlling CE process of M+ and Cd2+, the deep-site heterovalent doping can be achieved. Transmission electron microscopy (TEM) and high-resolution transmission electron microscopy (HRTEM) images in Fig. 5b, c show that the obtained QDs were monodispersed and highly crystalline. Figure 5d, e confirms that Ag atoms were effectively retained within the center of CdS QDs, suggesting the realization of deep-site heterovalent doping rather than a surface doping [100]. Deep-site heterovalent doping effectively avoided the self-purification process. The efficient energy transfer from the intrinsic conduction band to the deep dopant energy level quenched exciton emission and inspired stable and strong dopant emission (Fig. 5f, g). This synthesis paves the way for the incorporation of dopant ions into specific sites of nanocrystals.

Synthesis and characterizations of 0D doped TMC materials by CE reactions. a Illustrations showing the synthesis process of M-doped CdX (M = Ag, Cu; X = S, Se, Te) nanocrystals. TBP represents tributylphosphine. b TEM image, c HRTEM images, d strain mapping images and e EDS elemental mapping images of Ag-doped CdS quantum dots (QDs). f Room temperature steady-state fluorescence spectra with different Ag-dopant concentrations, and the inset shows a digital photograph of fluorescence under 365 nm ultraviolet irradiation. PL represents photoluminescence. g Kinetic traces at representative wavelengths are also shown (pump laser wavelength: 390 nm). Reproduced with permission [100].

2.3.2 Synthesis of 0D TMC Alloys

In direct synthesis of alloyed TMC materials, a significant challenge arises from the necessity of balancing the reactivities of precursors, which makes it difficult to attain the desired atomic composition. However, the development of CE reactions provides a feasible approach to overcome this challenge. Based on this strategy, binary, ternary and even quaternary alloyed nanocrystals have been realized [18, 106, 115,116,117,118]. As exhibited in Fig. 6a–c, Li et al. synthesized hollow CuInS2 nano-dodecahedrons with a uniform elemental distribution by using Cu2-xS as reactants. The formation of hollow structure was attributed to different rates of Cu+ extraction from Cu2-xS nanocrystals and In3+ incorporation into them [18]. The diffusion kinetics of Cu+ and In3+ can be precisely manipulated by passivating the surface of Cu7S4 nanocrystals. As shown in Fig. 6d–f, with an increased In3+/Cu+ ratio, the surface of Cu7S4 nanocrystals were passivated due to excess In3+ cations. As a result, a series of CuInS2 and Cu7S4@CuInS2 nanocrystals with intricate structures and uniform elemental distribution were obtained, which showed different photocatalytic abilities in singlet oxygen generation [116]. This research not only provides a flexible way to achieve nanocrystals with structural complexity and diversity, but also have an important significance in understanding the reaction kinetics in ion exchange process.

Copyright 2019, American Chemical Society. d The different products derived from In3+—for—Cu+ CE in Cu7S4 nanocrystals at different In: Cu ratio. e, f HRTEM image and the corresponding EDS elemental mapping images for the product in d with the In: Cu ratio of 1: 1. Reproduced with permission [116]. Copyright 2019, Royal Society of Chemistry. g Illustrations showing the synthesis of CuZnxInySe nanocrystals. h HRTEM images and corresponding EDS elemental mapping images of CuZnxInySe nanocrystals. Reproduced with permission [118]. Copyright 2023, American Chemical Society

Synthesis and characterizations of TMC alloys by CE reactions. a TEM images showing the structural evolution from Cu2-xS dodecahedrons to CuInS2 ones. b, c STEM images and corresponding EDS elemental mapping images of CuInS2 dodecahedrons. Reproduced with permission [18].

In 2023, Thiel et al. used Cu2-xSe nanocrystals as templates to synthesize CuZnxInySe quaternary alloyed nanocrystals (Fig. 6g). HRTEM images and corresponding energy-dispersive X-ray spectroscopy (EDS) elemental mapping images demonstrated the complete transformation of Cu2-xSe nanocrystals into CuZnxInySe nanocrystals, while maintaining high uniformity in the distribution of Cu, Zn, In and Se elements (Fig. 6h). The photoluminescence test results showed that the synthesized CuZnxInySe nanocrystals exhibited excellent near-infrared photoluminescence, without the need for additional shell growth. This is notable because the most of developed protocols require an additional shell to achieve similar performance. In particular, the full width at half-maximum of their near-infrared photoluminescence was reduced to 150–190 meV, accompanied by an enhancement of photoluminescence quantum yield to 20%. Moreover, precise control over the In/Zn ratio was achieved, and it was observed that increasing the Zn content resulted in an observable blue shift [118]. Up to now, various 0D alloyed TMC materials have been realized by CE reactions, including ZnxCd13-xSe13 magic-size clusters [117], AgInS2 nanoparticles [119] and Au@Ag2ZnSnS4 core–shell nanocrystals [120], etc. This synthesis strategy not only offers a protocol for the precise construction of 0D TMC nanocrystals with desired structures and composition, but also contributes to enhancing the structural complexity and diversity to TMC materials.

2.3.3 Synthesis of 0D TMC Heterostructures

TMC heterostructures have attracted lots of attention due to their capacity to integrate diverse functions stemming from coupling between multiple components. In recent years, partial CE reactions have emerged as a valuable alternative to epitaxial growth for the synthesis of TMC heterostructures at relatively low temperatures [121]. It also shows great advantages in controlling the interface between two components. To date, both segmented heterostructures and core@shell heterostructures have been realized by partial CE reactions. In segmented heterostructures, different materials are arranged in distinct segments or regions, including Janus-like, striped and sandwich-like structures.

For the synthesis of segmented heterostructures, the ion mobility is usually high enough to facilitate the atomic arrangement of transformed domains into the lowest energy configuration. For instance, due to the high mobility of Cu ions, Cu2-xS reactants have been extensively employed for producing Cu2-xS/MS (M = Cd, Zn, Pb) segmented heterostructures. In Fig. 7a, Fenton et al. used different shaped Cu1.8S nanoparticles as templates in CE process. By adjusting reaction time, the extent of CE reactions involving Cu+ with Cd2+ or Zn2+ can be controlled [122]. As a result, various types of Cu1.8S/CdS or Cu1.8S/ZnS heterostructures were achieved successfully, including particles that contain asymmetric, patchy, porous, and sculpted nanoarchitectures. These heterostructures exhibited clear segmentation pattern and distinct internal interfaces (Fig. 7b–d), as confirmed by TEM images and corresponding EDS elemental mapping images [25]. This modular and divergent synthetic strategy enables the design and synthesis of complex nanoparticle systems. These researches have illustrated the reaction time is essential for the control of heterostructure with different morphology. These intricate colloidal nanoarchitectures have diverse potential applications, such as semiconductor–semiconductor interfaces for the controllable separation or confinement of excitons, precision integration of semiconductors and catalysts for light-driven chemical transformations, etc.

Copyright 2020, American Chemical Society. TEM images and corresponding EDS elemental mapping images of Cu1.8S b spheres, c rods and d hexagonal plates. Reproduced with permission [25]. Copyright 2018, The American Association for the Advancement of Science

Synthesis and characterizations of the segmented heterostructures obtained by CE reactions. a Synthesis illustrations of Cu1.8S/CdS and Cu1.8S/ZnS segmented heterostructures. Reproduced with permission [122].

During the synthesis of core@shell heterostructures, CE reactions follow an isotropic-like exchange, without the generation of a significant strain between the two components. One of the extensively studied examples is PbX@CdX (X = S, Se, Te) core–shell heterostructures, where the core and shell have immiscible crystalline structures and a slight lattice mismatch. In 2008, Pietryga et al. applied CE reactions to prepare PbX@CdX QDs. As shown in Fig. 8a, PbSe QDs were exposed to a Cd-containing precursor, the partial substitution of Pb2+ by Cd2+ resulted in the formation of PbSe@CdSe QDs. The small lattice mismatch (∼1%) between the rock-salt PbSe and zinc-blende CdSe led to a relatively defect-free interface (Fig. 8b–d). The obtained PbSe@CdSe core@shell QDs exhibited significantly enhanced stability, thereby extending their operational temperature range [123]. In 2012, applying the similar strategy to PbSe nanocrystals of star, cube, and rod shapes, Casavola et al. achieved PbSe@CdSe core–shell heterostructures with corresponding shapes [83]. It was revealed that CE reactions proceeded dominantly in the (111) crystallographic direction, regardless of the shape of the initial PbSe QDs. This facilitated the formation of the Pb(111)—Se(111)—Cd(111) sandwich structure, resulting in a stress-free interface. Moreover, Pietryga et al. reported that a higher reaction temperature resulted in a thicker shell [124]. The thickness of CdSe shell up to 4 nm was achieved at a temperature of 200 °C, which displayed an additional infrared emission channel aside from the common visible range. The obtained heterostructures are a unique class of tuneable, dual-emitting, dispersible fluorophores, holding great potentials for labeling and photoluminescence microscopy. The critical factor of the core@shell heterostructure formation is to overcome the strain at interface resulting from lattice mismatch.

Copyright 2008, American Chemical Society. e Cu2Se@PbSe heterostructures and f–h corresponding HRTEM images as well as corresponding EDS elemental mapping images. Reproduced with permission [40]. Copyright 2017, American Chemical Society

Synthesis and characterizations of the core–shell heterostructures obtained by CE reactions. a Synthesis illustrations of PbSe@CdSe QDs. Ph2O represents phenyl ether, TOP represents trioctylphosphine, Et2Zn represents diethyl zinc and TMS2S represents hexamethyldisilathiane. b Low-resolution image of 6.1 nm PbSe cores with 1.4 nm CdSe shells. c Low-resolution image of the same area as b, but tilted by 12° to enhance the diffraction contrast. d High-resolution image of PbSe@CdSe QDs, showing a relatively defect-free interface. Reproduced with permission [123].

Precise control over the kinetics of CE reactions allows for the synthesis of core–shell heterostructures with a moderate lattice mismatch. However, these obtained core–shell heterostructures are usually metastable and prone to transform into more stable configurations, especially under conditions of elevated temperatures or intense light irradiation [80, 125,126,127]. For example, by performing partial Cu+ ions exchange with Pb2+ or Sn2+ within Cu2-xTe nanocubes, metastable Cu2-xTe@PbTe or Cu2-xTe@SnTe heterostructures were synthesized. The rapid and non-selective CE reactions took place on all facets of Cu2-xTe nanocubes, owing to abundant vacancies on the surface and high diffusion rate of Cu+ ions. Due to the significant deviation in lattice constants from that of Cu2-xTe, the formed PbTe or SnTe shells were polycrystalline. These metastable core@shell heterostructures transformed into stable Janus-like heterostructures when annealed at 200 °C in vacuum [42]. Additionally, it is possible to achieve core@shell heterostructures without the formation of strain-induced defects at the interface through a moderate expansion of the anion sublattice, even when there is a moderate lattice mismatch between core and shell. As shown in Fig. 8e, cubic Cu2Se nanocrystals were employed as host materials in CE reactions, and Cu2Se@PbSe heterostructures with a small expansion of the Se sublattice (∼6%) was formed by partially substituting surface Cu+ with Pb2+ [40]. The low diffusivity of Pb2+ ions into Cu2Se lattice and the absence of preferred entry positions in cubic Cu2Se led to the formation of a face-centered cubic Se anion sublattice, which was consistent with the host Cu2Se nanocrystals. During reaction, the moderate expansion of the Se sublattice was revealed to be critical in reducing strain and defects at the interface (Fig. 8f–h).

Moreover, CE and AE can be combined to synthesize high-quality heterostructures. Yin et al. reported the synthesis of quaternary kesterite Cu2ZnSnS4-Cu2ZnSnSe4 (CZTS-CZTSe) heterostructures by a combining CE and AE strategy, in which Cu, ZnO and SnO2 were chosen as precursors (Fig. 9a). The small lattice mismatch between Cu9S5 and CZTS nanocrystals allowed a transformation from Cu9S5 to CZTS with minimal changes in the S2− framework. This not only facilitated the incorporation of Zn and Sn but also helped to preserve the morphology of Cu9S5 nanocrystal (Fig. 9b). The pristine CZTS nanocrystals then served as a template for subsequent AE. HRTEM images in Fig. 9c show that Se treatment triggered the substitution of S2− within kesterite CZTS surface by Se2− during the AE process, and sandwich CZTS-CZTSe nano-heterostructures were obtained [128]. Compared with direct synthesis of pure kesterite CZTSSe nanoparticles, sandwich CZTS-CZTSe nano-heterostructures containing quaternary and quinary phases are more promising in promoting electron–hole separation in solar cell devices. Meanwhile, AE reactions overcame the energy barrier and energy difference between polycrystalline states that cannot be ignored in direct synthesis of CZTSSe nanocrystals.

Synthesis and characterizations of 0D TMC heterostructures obtained by a combining CE and AE strategy. a TEM and HRTEM images of synthesis Cu2ZnSnS4-Cu2ZnSnSe4 (CZTS-CZTSe) nano-heterostructure process. b TEM images of CZTS nanocrystals and fast Fourier transform (FFT) patterns of overlay, domain I (red), domain II (green), and domain III (blue). c TEM and high-resolution scanning TEM (HR-STEM) images of CZTS-CZTSe heterostructures and corresponding STEM-EDS elemental mapping images as well as corresponding FFT pattern of CZTS-CZTSe nanocrystals. Reproduced with permission [128].

In summary, the ion exchange in 0D TMCs is a reversible reaction, in which both the kinetic control and thermodynamic control play essential roles in regulating the overall process. By the complete cation substitution, the synthesized core@shell heterostructure with substantial lattice mismatches exhibits atomically organized interface. The independence of shell from the core is beneficial for overcoming the strain at the interface imposed by epitaxial strategy. During the anion exchange, the adding of extra reagents provides new possibilities for the synthesis of desired nanocrystals. In partial ion exchange, the realization of controllability is a crucial point in achieving TMCs with exceptional properties. Numerous studies have demonstrated that by preciously controlling the reaction time and reactant concentration, it is possible to obtain heterostructures and alloys with desired compositions and morphologies. These studies also pave the way for controllable doping.

3 1D TMCs

Due to their adjustable quantum confinement effects, 1D TMC nanostructures hold great potential in applications of photonics and thermoelectricity [28, 129]. Compared with the conventional vapor–liquid-solid methods, atomic substitution offers an alternative route to create 1D TMC materials with intricate structures and notable compositional diversity [39, 101]. Similar to the case of 0D materials, low-cost colloidal methods are commonly employed for synthesizing 1D TMC materials. In this section, the development of ion exchange reaction in preparing nanorods, nanowires and nanotubes, is summarized.

3.1 Synthesis of 1D Nanorods

1D nanorods refer to nanostructures with one dimension much larger than the other two, exhibiting a distinct rod-like shape. This specific geometry enables the fine-tuning of their properties by varying the aspect ratios. To explore their fundamental properties and potential applications, great efforts have been dedicated to manipulate the morphologies and compositions of nanorods [28, 129,130,131,132].

The substitution between atoms in nanorods is demonstrated to be selective, which plays an important role in determining the structure of products. For example, Sadtler et al. studied the partial transformation of CdS nanorods through CE reactions, as shown in Fig. 10a–g [131, 133]. In the case of Cu+–Cd2+exchange, the reaction started preferentially from either one or both ends of CdS nanorod, depending on Cu+/Cd2+ratio. This led to the growth of one or two Cu2S domains inward from the tip region. As a result, segmented Cu2S/CdS heterostructures were formed, in which the two subunits shared a flat interface perpendicular to the axial direction (Fig. 10a–c). The reason behind the selective nucleation and growth of Cu2S within CdS nanorods is the exceptional stability of formed CdS-Cu2S interfaces. In the case of Ag+-Cd2+exchange, the reaction occurred non-selectively and the formed Ag2S regions are randomly distributed within CdS nanorod. During the CE process, multiple Ag2S segments spanned the diameter of nanorod with a uniform size (Fig. 10d–g). The non-selective nucleation of Ag2S in CdS nanorod was ascribed to the negative chemical formation energies of CdS-Ag2S interface. However, as Ag2S regions extended within the nanorods, the influence of elastic energy became dominant, driving the ripening process of Ag2S regions and resulting in the reduction of interfacial area. The randomly distributed Ag2S regions finally evolved into a periodic pattern. The distinctions between CdS–Cu2S and CdS–Ag2S systems arise from differences in both the chemical favorability of bond formation and the elastic distortions at the interfaces. This offers an opportunity to manipulate the spatial configuration of components within heterostructures, and further control their chemical and physical properties.

Copyright 2009, American Chemical of Society. e, f TEM images of the pristine CdS nanorods and obtained CdS-Ag2S nanorods. g TEM images of CdS-Ag2S nanorods with inset showing histogram of Ag2S segment spacing (center-to-center). Reproduced with permission [131]. Copyright 2007, The American Association for the Advancement of Science. h HAADF-STEM image of CdS/Pd4S hybrid nanorods. Reproduced with permission [134]. Copyright 2015, American Chemical Society. i Tip growth of Pd4S on CdS nanorods with a diameter of 5.9 nm. j The extensive growth of Pd4S on CdS nanorods with a broad size distribution. k Close-up of the sample shown in i. l HRTEM of a single CdS-Pd4S nanorod from the sample shown in j. Reproduced with permission [11]. Copyright 2011, John Wiley and Sons

Synthesis of hetero-nanorods by ion exchange process. a The morphology of CdS-Cu2S nanorods by CE reactions. b, c TEM image and color-composite energy-filtered transmission electron microscopy (EFTEM) image of the obtained CdS-Cu2S nanorods. d Illustration of CdS-Ag2S nanorods produced by CE methods. Reproduced with permission [133].

The CdX/PbX system (X = S, Se, Te) has also been widely studied due to their excellent photoelectric property and chemical stability. Because PbX and CdX are immiscible, the exchange between Cd2+ and Pb2+ generally results in separated CdX/PbX heterostructures. Lee et al. demonstrated that the exposure of CdSe to Pb2+ ions lead to the transformation of wurtzite CdSe into rock-salt PbSe [134]. As shown in Fig. 10h, the replacement of Cd2+ ion was found to occur anisotropically, starting from the tips of nanorods and leading to the formation of interfaces parallel to the (0001) plane of nanorods. This is similar to the CdS/Cu2S case depicted in Fig. 10b [133]. Moreover, the Cd-to-Pb exchange was facet-selective and two tips of nanorods showed significant differences during transformation, because the (000 \(\overline{1}\)) facet of CdSe nanorods is more active than the (0001) one. Explorations in this area enable precise control at the atomic level for CE, which could expand the possibility for designing CdX/PbX heterostructures. Under the similar reaction conditions, Zhang et al. prepared CdS/PbS and CdSe/PbSe Janus-like heterostructures by partial CE reactions [135]. The obtained structure exhibited excellent optoelectronic properties that can be customized for potential applications of various fields. By exposing CdS nanorods to Pd2+ containing solution, Shemesh et al. realized the synthesis of CdS/Pd4S segmented nanorods [11]. Similarly, the formation of Pd4S started from either one or both tips of CdS nanorods, resulting in the synthesis of segmented CdS/Pd4S structures with planar interfaces (Fig. 10i–l). These planar interfaces are critical in reducing interface energy and strain, thereby ensuring the stability of the structure.

3.2 Synthesis of 1D Nanowires

By CE reactions, Zhang et al. synthesized CdS@Cu2S core@shell nanowires with diameters of 30–40 nm and lengths of ~ 10 μm, as exhibited in Fig. 11 [129]. It was found that Cu+–Cd2+ exchange reaction occurred simultaneously at both side facets (Fig. 11a, b) and tips (Fig. 11c, d) of CdS nanowires, with a notable preference at the tips. The calculated transformation energy for nucleation from side facets was approximately seven times higher than that at tips [133]. Furthermore, solid-state diffusion enabled the penetration Cu ions into the inner regions of the CdS nanowires. This diffusion process resulted in the formation of core@shell nanowires, and the thickness of the shell increased as the reaction continued. Besides, the composition of resulting core@shell nanowire was found to be dependent on the Cu+/Cd2+ ratio. As shown in Fig. 11e, f, CdS@Cu2-xS nanowires were achieved under a Cu+/Cd2+ ratio of 0.5:1, while CdS@Cu2S nanowires with a thicker shell were formed under a Cu+/Cd2+ ratio of 1:1. Similar with the ion exchange reaction in 0D TMC alloys (Fig. 6d–f), by regulating the reactant concentration, this research provides a method for precisely control over the structure, composition, and crystal phases of nanowires, holding a promising prospect in various applications.

Synthesis and characterization of CdS@Cu2-xS nanowires by ion exchange process. a-d EDS element mapping images for Cd (in green) and Cu (in red) and corresponding STEM images. a, b Images showing the substitution started at the side surface of nanowires. c, d Images showing the substitution started at the tips of nanowires. e, f HRTEM images of CdS@Cu2–xS core@shell nanowires. e A core@shell nanowire obtained with a 0.5:1 Cu+/Cd2+ ratio, f a core@shell nanowire with increasing shell thickness obtained with a 1:1 Cu+/Cd2+ ratio. Reproduced with permission [129].

Tan et al. realized the controllable synthesis of multiple p-n segmented heterojunctions by a two-step CE strategy, as illustrated in Fig. 12a. Using single-crystal CdS nanowires as reactants, Cu2S nanowires with face-centered cubic (fcc) crystal structure were obtained after the complete exchange of Cd+ by Cu+. Figure 12b, c shows that there are abundant twin planes perpendicular to axial direction [28]. These twin boundaries offered active sites for the following exchanging between Cu+ and Ag+. The newly formed Ag2S segments were found to be parallel to the twin planes and elongate along the axial direction with the reaction proceeded, as shown in Fig. 12d–h. This suggests that the morphology of regular Ag2S–Cu2S heterojunctions can be well controlled by terminating CE process at a precise reaction time. This work highlights the significance of crystal structure and orientation of twin plane in determining the regularity and pattern of the resulting Cu2S–Ag2S heterostructures. As a comparison, irregular patterning was observed after Cu+–Ag+ exchange reaction in monoclinic Cu2S nanowires with twin planes not perpendicular to axial direction (Fig. 12i). These explorations provide two effective methods to control the morphology of nanowires by regulating the reactant concentration and reaction time, respectively. In addition, the ion exchange rate demonstrates noticeable location selectivity in both of the above studies.

Synthesis and characterizations of Cu2S-Ag2S heterostructure nanowires. a Illustration shows the formation process of Cu2S-Ag2S superlattice nanowires. b TEM image of a Cu2S nanowire transformed from a CdS nanowire. The twin planes are the (11̅1) planes. c Dark-field TEM image of a single Cu2S nanowire viewed along the [109] zone axis and presented by selecting the (11̅1) diffracted beam. The green arrows indicate locations of the (11̅1) twins. d-h HAADF-STEM images of the Cu2S-Ag2S nanowires formed. Reaction times are d 0 s, e 6 s, f 24 s, g 48 s, h 60 s. i HAADF-STEM image of Ag2S/Cu2S nanowires after CE reactions in monoclinic Cu2S structure. Reproduced with permission [28].

3.3 Synthesis of 1D Nanotubes

By taking advantage of large volume change during a certain CE reaction, Moon et al. realized the transformation of nanowires to nanotubes, as shown in Fig. 14 [39]. Ultra-thin Ag2Te nanowires were chosen as reactants, and were converted into CdTe nanowires in a Cd+ containing solution. During this process, the single crystalline structure of nanowires was preserved and the volume change was slight (Fig. 13a). Afterward, these CdTe nanowires were exposed to Pt4+ ions, and PtTe2 nanotubes with a wall thickness of 1–2 nm were formed. During this process, the mechanical stress caused by CE accumulated continuously, inducing the creation of voids in products. As a result, the single crystalline nanowires were transformed into polycrystalline PtTe2 nanotubes (Fig. 13b, c). This research illustrates the important effect of stress in the morphology transformation and is valuable for understanding the shape transformations in nanostructured materials under large stress.

Synthesis of PtTe2 nanotubes via the shape evolution in Cd+-Pt4+ exchanging process. a TEM image of CdTe nanowires, b TEM image of PtTe2 nanotubes derived from CdTe nanowires through CE reactions. c HRTEM image of a PtTe2 nanotube indexed as the hexagonal phase with lattice spacing of 0.28 nm along the [100] direction. The inset shows the Fourier transformed ring pattern of PtTe2 nanotubes. Reproduced with permission [39].

3.4 Synthesis of 1D Nanobelts

In 2020, Sim et al. introduced a novel approach for designing TMC heterojunctions by Metal Organic CVD [136]. Single-crystalline WTe2 nanobelts were adopted as the base structures and then sulfurized, as schematically shown in Fig. 14a. Depending on sulfurization temperature, Te atoms were replaced by S to different extents and various structures were formed, including non-curled WTe2/WS2, curled WTe2/WS2, curled WS2, and porous/curled WS2 as illustrated in Fig. 14b. At low temperatures, the substitution of Te by S predominantly started from edges, and the single-crystalline structure was maintained. At high temperatures, the conversion resulted in structurally deformed WS2 throughout the entire layers of nanobelt. Figure 14c shows the obtained curled WTe2/WS2 at 600 °C. The presence of an atomically ordered interface in Fig. 14d, e indicates that the lattices of two subunits were maintained in a coherent manner across the transition region, suggesting the heteroepitaxial stacking of WTe2/WS2 hybrids despite of their large lattice mismatch (≈8.8%). Figure 14f presents the as-prepared curled WS2 under 700 °C, despite many pores and deformed layers were observed throughout the entire area, the shape of nanobelt remained intact. Remarkably, the obtained 1D heterojunctions showed enhanced performance in the hydrogen evolution reaction as well as the long-term durability for electrocatalytic reactions, owing to the increased effective surface area and reduced electron-transfer resistance. Though the specific mechanism is not clear, the temperature effect in this research provides great reference for the exploration of the transformation between 1D TMCs.

Structure diagram and characterizations of TMC nanobelts by atomic substitution process. a The temperature-dependent synthesis of nanobelts via the substitution of chalcogen. NC-WTe2/WS2 represents non-curled WTe2/WS2, C-WTe2/WS2 represents curled WTe2/WS2 and C-WS2 represents curled WS2. b Schematic showing controlled conversion process at different temperatures. c HAADF-STEM image (scale bar: 30 nm) of the curled WTe2/WS2 grown at 600 °C. d, e Atomic-Resolution STEM image (scale bar: 1 nm) and atomic configurations showing the interface structure of the curled WTe2/WS2 heterostructure. f Plan-view Atomic-Resolution STEM image (scale bar: 2 nm) and atomic model showing the WS2 layer was deformed. Reproduced with permission [136].

Similar to the cases of 0D TMCs, the ion exchange method in 1D TMCs have illustrated the effects of temperature, reactant concentration and reaction time on both the composition and morphology, providing valuable references for controllable synthesis. Additionally, strain, surface energy and interfacial energy also show noticeable influences on the structural evolution during the substitution process. Moreover, both the exchange rate and initiation sites exhibit significant location dependence during the reaction.

4 2D TMCs

2D TMCs predominantly have a chemical formula of MX2, where M represents transition metals from Group IVB to Group VIIIB. In a 2D TMC structure, atoms within the same layer are chemically bonded, while those between layers interact through weak van der Waals force [9, 137, 138]. Depending on their compositions and phase structures, 2D TMCs display various electronic properties [139,140,141,142,143,144,145], showing great potential in applications of electronic devices, quantum devices, energy catalysis [146,147,148,149], etc.

In recent years, atomic substitution has been widely used in regulating the compositions and structures of 2D TMCs, and various materials have been obtained, including binary compounds, doped materials, alloys and heterojunctions [20,21,22,23, 150, 151], etc. Unlike the solution methods that are widely employed in 0D and 1D TMCs, CVD techniques are very popular for implementing atomic substitution process in 2D TMCs.

4.1 Initiation of Atomic Substitution

Owing to the ultra-thin structure, 2D TMCs provide a unique platform for studying the real-time process of atomic substitution. It is revealed that crystal defects, such as vacancies, grain boundaries (GBs), surfaces and edges, serve as starting points for the substitution process.

4.1.1 Vacancy-Initiated Substitution

By sulfurizing sub-centimeter scale single crystalline 2H-MoTe2 thin film, Liu et al. achieved a corresponding single crystalline MoS2/MoTe2(1-x)S2x/MoS2 sandwich structure and proposed a Te vacancy-initiated and S diffusion-mediated transformation mechanism (Fig. 15a, b) [152]. The S substitution process started at Te vacancies in the top and bottom layers, and then progressed into the middle layers. Though the rate of substitution in the middle layers is limited by cross-layer diffusion of S atoms, the complete transformation is possible with the continuation of the process. Density functional theory (DFT) calculations also confirmed the role of Te vacancy, and found that there is no energy barrier for the occupation of S at Te vacancy site (Fig. 15c). In comparison, the energy barriers for the 1st and 2nd substitutions of Te in perfect MoTe2 structure are ~ 2.3 and 1.8 eV, respectively (Fig. 15d, e). It was noted that the substitution process is thermodynamically favorable. The lower energy barrier of the 2nd substitution was attributed to the strain field induced by the 1st substitution, as evidenced by the force mapping analysis (Fig. 15f). The compression caused by the initial substitution of S was beneficial for reducing the energy barrier of subsequent substitutions (Fig. 15g). This work provides an efficient way to acquire large-scale high-quality TMC films and heterostructures. Similarly, Taghinejad et al. realized the fabrication of MoS2xSe2(1-x) alloy via sulfurizing MoSe2 films. It was revealed that the driving force of substitution is much lower in CVD-grown MoSe2 films with abundant vacancies than that in exfoliated films with fewer vacancies [153].

Mechanism of atomic substitution initiated by vacancies. a Magnification HAADF-STEM cross-sectional image of the sulfurized MoTe2. b Diffusion-mediated substitution mechanism in multilayer MoTe2 (Red: Mo, yellow: S, and blue: Te) c Energy barrier for S substitution at Te vacancy. Insets are the path details. d Energy barriers and e path details for S substitution at Te sites (blue) in the perfect MoTe2 (orange) and after the insertion of first S. f Force map after the replacement of first S. g Diffusion-mediated substitution mechanism in multilayer MoTe2. Reproduced with permission [152].

The present of vacancies also plays an important role in promoting the substitution between metal atoms. By combining DFT calculations and experiments, Liu et al. [154] explored the Co substitution in MoS2 and revealed that the substitution is induced by sulfur vacancies. Chang et al. [155] found that the metal exchange between Sn and W can be promoted by producing S vacancies at high temperatures. To date, many strategies have been developed for vacancies creation to promote substitution processes, such as high temperature, ion beam bombardment and gaseous plasmas [21, 155, 156].

4.1.2 Grain Boundary-Initiated Substitution

GBs have also been demonstrated to be initiation sites for atomic substitution. As shown in Fig. 16a, starting from intrinsic GBs of MoSe2, Zhu et al. obtained ultra-long MoS2 nano-channels successfully [157]. Figure 16b, c displays the pristine MoSe2 monolayer, where lots of active sites in 8|4|4|8 GBs can be observed. The formation process of MoS2 can be divided into three steps: (i) the chemisorption of S atoms near the GBs, (ii) the exchange between S and Se atoms, (iii) the desorption of Se atom. The second step has the highest energy barrier and is considered as the rate-limiting step. The energy barrier for replacing Se atoms at GBs is much lower, owing to the high in-plane tensile strain. The substituted S atoms then act as the nucleation center, leading to the continued growth of MoS2. Near the GB, MoSe2 was completely transformed into MoS2, while mixed structures that one Mo atom coordinates with S2, Se2, or S + Se atoms were formed at the interface of MoS2 and MoSe2, as shown in Fig. 16d, e. This study offers an excellent method for achieving narrow lateral heterostructures and precise control over the spatial scale of heterostructures.

Mechanism exploration in atomic substitution initiated by grain boundary. a Schematic showing growth of MoS2 channels. b, c Annular dark-field scanning transmission electron microscopy (ADF-STEM) images of intrinsic 60° GB (orange dashed line) within pristine monolayer MoSe2 and atomic arrangement of this GB (blue and purple circles: Mo and Se atoms) resembles that in MoS2 nano-channels. d, e ADF-STEM images showing part of MoSe2-MoS2 hybrid winding channel. The red arrows represent the sulfidation direction. Purple arrows mark 2Se atoms and yellow-purple arrows mark S + Se atoms, with line intensity profile showing in the inset. Reproduced with permission [157].

4.1.3 Edge-Initiated Substitution

The enhanced reactivity of TMCs edges, attributed to their unsaturated chemical bonds, makes them more favorable for atomic substitution compared to the less reactive basal plane [136]. As displayed in Fig. 17a–e, Yun et al. converted monolayer MoS2 to MoTe2 in a Te-rich environment with the assistant of NaOH [158]. During the substitution process, Na2Te, which is the most probable Na-Te compound, acted as the driving agent to accelerate the tellurization of MoS2 and the dissipation of gaseous S2 (Fig. 17b). The optical images in Fig. 17c–e show the tellurization progress of MoS2. It is clear that MoTe2 primarily emerged along the edges and GBs, gradually extending toward the central area of MoS2. In contrast, the occurrence of substitution was not limited at edges at high temperatures, leading to random tellurization over MoS2 basal plane. Similarly, Bogaert et al. investigated the effect of temperature on the substitution between W and Mo in as-grown WS2 islands by CVD methods (Fig. 17f) [159]. At a relatively low temperature (650 °C), Mo substitution predominantly took place at WS2 edges. As a result, an in-plane MoS2/WS2 heterostructure with a sharp interface was formed (Fig. 17g). At a relatively high temperature (710 or 680 °C), the entropy contribution to the Gibbs free energy increased and led to the formation of Mo1-xWxS2 alloy. Therefore, it is possible to customize the pathway to form either TMC alloys or lateral heterostructures by controlling the substitution kinetics.

Mechanism of atomic substitution initiated by edge. a Alkali-metal-assisted transformation from MoS2 to MoTe2. b Schematic showing Na-assisted tellurization process. c-e Optical images showing the evolution from MoS2 to MoTe2. Reproduced with permission [158]. Copyright 2017, Springer Nature. f Illustration showing the substitution of W in WS2 by Mo at different temperatures (W atoms are shown in green, Mo atoms are red, S atoms are black). g Optical image of a typical heterostructure revealing a distinct core-ring structure. Scale bar is 5 μm. Reproduced with permission [159].

4.2 Synthesis of 2D TMC Binary Compounds

4.2.1 Substitution Between TMCs

The complete substitution of either transition metal atoms or chalcogen atoms within a TMC shows a great potential in converting the TMC to another type, as illustrated in Fig. 18a. By using exfoliated 2D TMC nanosheets as reactants, Duan et al. explored the feasibility and universality of ion exchange reactions in solution phase [27]. Three reactions were conducted successfully, including converting SnS2 into MoS2, converting MoS2 into MoSe2, and converting MoS2 into WS2. It was revealed that the ion exchange reactions were completely finished without specific adjustment of ion solubility, because the crystal structures and thermodynamic stabilities of the reactants and products were similar. HRTEM images in Fig. 18b–e show that the TMCs obtained by both CE and AE were highly crystalline with a relatively uniform elemental distribution. Compared with traditional CVD method, this work shows atomic substitution strategy as an alternative and flexible way to achieve new TMC materials.

Transformation between different TMCs by atomic substitution. a Schematic showing ion exchange in TMCs. b HRTEM image of a SnS2 nanosheet before CE reactions. c HRTEM and element mapping images of a MoS2 after CE. d STEM and element mapping images of a MoSe2 after AE. e STEM and element mapping images of a WS2 after CE. Reproduced with permission [27].

4.2.2 Oxygen-Chalcogen Substitution

It is very common to prepare TMCs through utilizing chalcogens to reduce transition metal oxides in traditional CVD methods. In the process, transition metal oxides powder usually go through a high-temperature melting phase to yield metal precursors, followed by the nucleation and growth of TMCs. In contrast, the oxygen-chalcogen substitution strategy, based on transition metal oxide films, allows for the avoidance of the melting process. Chen et al. reported the selenization of WO3 thin films to produce WSe2 with the assistance of laser [160]. As shown in Fig. 19a, b, a WO3 film was directly deposited on a SiO2/Si substrate and placed in a vacuum-sealed quartz tube with Se ingots. The quartz tube was then placed on a hot plate to generate homogeneous Se vapor and a continuous wave laser was utilized to trigger the substrate heating. In the presence of selenium gaseous vapor, the amorphous WO3 film underwent a reduction process when the laser was irradiating on it. Layered WSe2 film was successfully achieved, as shown in Fig. 19c, d. Besides, through a process involving the patterning of the WO3 film and subsequent laser irradiation, patternable WSe2 fabrication was realized. Compared with thermal CVD method, the laser assistant substitution can achieve an ultrafast heating on the target part, making the synthesis process to be more controllable. This laser assisted reduction process was also demonstrated to have a great potential in the synthesis of other TMCs, such as MoS2, WS2, WSe2 [161,162,163]. Large area WSe2 have been synthesized by direct selenization of as-deposited WO3 films [164]. As shown in Fig. 19e, the WO3 films were deposited onto substrates via thermal evaporation first and then converted to WSe2 by exposing to dimethyl selenium in a cold wall reactor. As shown in the cross-section TEM image (Fig. 19f), 8–10 layers of WSe2 were generated on the WO3 film. Besides, the thickness of WSe2 can be effectively controlled by the thickness of WO3 film and the depth of selenization. This research proposed an effective route to synthesize TMC films with controllable and highly uniform thickness based on the transition metal oxide.

Copyright 2015, American Chemical Society. e Synthesis process of WSe2 converted from amorphous WO3 and hexagonal stabilized WO3 films. Thermal evaporated WO3 films were annealed via rapid thermal annealing and then converted to WSe2 via cold wall furnace. f TEM image of the obtained layered WSe2 structure and the unconverted WO3 film between sapphire and WSe2. Reproduced with permission [164]. Copyright 2015, IOP Publishing

Synthesis of WSe2 by the oxygen-chalcogen exchange process. a Illustration showing 2 nm-thick WO3 on SiO2/Si and Se ingots was vacuum-sealed together. b Illustration showing the formation of WSe2 when heating up to 250 °C. c Across-sectional TEM image of WSe2. d HMTEM image revealing the interlayer distance of the WSe2. Reproduced with permission [160].

4.2.3 Iodine-Chalcogen Substitution

Owing to the low-energy-barrier substitution of iodine with other chalcogens, metal iodides are considered as promising reactants for atomic substitution to synthesize TMCs at low temperatures [34, 35]. It also shows a great advantage in growing non-layered TMCs (such as CdS) with an ultrathin thickness. For instance, using layered CdI2 nanosheets as host materials, Zhao et al. realized the synthesis of non-layered CdS nanosheets in a S rich vapor at 280–300 °C (Fig. 20a–d) [35]. The obtained CdS nanosheets possess a submillimeter size and atomic layer thickness of 2 nm, which was the smallest thickness as reported (marked in square region in Fig. 20c). Combining with DFT calculations, the formation process of CdS was proposed as follows: (i) replacement of I atoms by S atoms, (ii) formation of Cd–S chemical bonds, and (iii) lattice compression along the thickness-direction of CdS. In 2023, Zhang epitaxially grew metal iodide on wafer-scale substrates at a temperature below 400 °C, which was much lower than the direct growth of TMCs [34]. This metal iodide was then converted into TMCs by overcoming a small energy barrier of substitution between iodine and other chalcogens, as shown in Fig. 20e. By this two-step method, 17 different high-quality wafer scale TMCs (M = In, Cd, Cu, Co, Fe, Pb, Sn and Bi) were successfully synthesized, including metal sulfides, metal selenides, metal tellurides and metal chalcogenide alloys. Since most metal iodides are layered structures, during the transition to non-layered TMC crystals, the van der Waals gap between the iodide layers disappears, resulting in a reduction in the thickness of TMCs. As shown in Fig. 20f, the thickness of the obtained CdS sheet was almost half of that of the original CdI2 sheet. This method provides a new solution for the fabrication of ultrathin non-layered TMC materials with a large scale. Additionally, the substitutions involving transition metal iodide introduces a novel strategy for the synthesis of 2D TMCs synthesis at temperature below 400 °C.

Copyright 2021, Springer Nature. e Schematic showing the preparation of CdS flakes on mica substrate by chemical sulfurization method. f The thickness of CdI2 and SnI2 flakes after being converted to CdS and SnS2. Reproduced with permission [34]. Copyright 2023, Springer Nature

Chalcogen substituting iodine in the synthesis of TMCs. a Schematic of the substitution and atomic structure of CdS flakes on mica substrate by chemical sulfurization method. b Representative optical microscope images of converted CdI2 thin flake on mica substrates. c Representative optical images of original large-scale CdI2 thin flake and converted CdS thin flake on mica substrates, respectively. d HRTEM image of converted CdS flakes. The inset is the selected area electron diffraction pattern taken along the direction [001] of CdS flakes. Reproduced with permission [35].

4.2.4 Nitrogen-Chalcogen Substitution

Through atomic substitution, layered 2D TMCs can also be converted into non-layered materials with an ultra-thin thickness. As illustrated in Fig. 21a, by using layered MoS2 as reactants, Ling et al. synthesized two phases of molybdenum nitride (Mo5N6 and δ-MoN) at different temperatures [165]. The morphology and 2D feature of host materials were inherited after the substitution of S with N, resulting in non-layered molybdenum nitrides. HRTEM image in Fig. 21b, c shows that the obtained Mo5N6 and δ-MoN were highly crystalline with a thickness of only a few nanometers. These obtained ultra-thin nitrides showed ohmic contacts with Cr/Au electrodes, indicating their promising applications in nanoelectronics.

Synthesis of nitrides by atomic substitution. a Crystal structures of Mo5N6 and δ-MoN. b, c HRTEM images of the obtained Mo5N6 and δ-MoN. Reproduced with permission [165].

4.3 Synthesis of 2D TMC Heterostructures

As one of the most important structures in semiconductor industry, heterostructures are essential in high-speed electronic and optoelectronic devices [166,167,168,169]. The majority of TMC heterostructures are composed of a series of materials in which either the transition metals or chalcogens are different. This allows for the exploration of different material combinations and properties [170,171,172]. Traditional preparation techniques for heterostructure refer to stitching or stacking different TMC components together via a direct growth procedure, such as CVD heteroepitaxial synthesis [173,174,175]. Generally, the designability of components and structures are restricted. In contrast, atomic substitution offers a powerful tool for precisely tailoring the interfaces and optimizing the performance of TMC heterostructures.

By performing layer-selected atomic substitution of MoS2 bilayer, Li et al. realized the synthesis of MoS2-MoS2(1-x)Se2x heterostructures [23]. Both the preparation of MoS2 bilayer and substitution process were performed by CVD, as shown in Fig. 22a–c. The substitution temperature for monolayer was 740 °C, while that for the bilayer was 810 °C (Fig. 22d–e). This makes it possible to control the substitution process by modulating the reaction temperature. Figure 22f shows that the achieved MoS2-MoS2(1-x)Se2x heterostructures were highly crystalline with a sharp interface. The photoluminescence energy and the corresponding Se composition of monolayer and bilayer regions at 750 °C as a function of annealing time is given in Fig. 22g. It was demonstrated that S atoms in the monolayer region underwent gradual substitution by Se atoms, whereas the bilayer region remained highly stable. Therefore, effective control over the temperature and duration of the substitution process allows for well-defined morphology of the synthesized heterostructure. These composition-tannable heterostructures hold great potentials in 2D fundamental physical research as well as the development of functional electronic and optoelectronic devices.

Heterostructure synthesized by chalcogenides substitution. a Schematic diagram of the preparation of MoS2-MoS2(1-x)Se2x heterostructure by the Se substitution in a designed stacking MoS2 nanosheet. b, c Optical images of monolayer and bilayer MoS2 nanosheets after substitution with the corresponding AFM images shown in inset. d, e Bandgap values and compositions of the two sheets as a function of annealing temperature. f, g Optical image, bandgap values and compositions of the obtained MoS2-MoS2(1-x)Se2x heterostructures. Reproduced with permission [23].

Patterned growth is a powerful method for customizing the morphology of heterostructures, which involves patterning the base material with a desired shape and a subsequent selective substitution. Figure 23a depicts the lithography process for the synthesis of lateral TMC heterostructures [176]. To realize selective substitution, a part of the MoSe2 film was protected by SiO2 mask. A MoSe2-MoS2 junction was achieved after well annealing in an S atmosphere. Figure 23b illustrates the optical image of the synthesized heterostructure, and Fig. 23c, d shows the Raman mapping intensity. In comparison, a uniform MoS2xSe2(1-x) alloy was obtained without protection by mask, and the substitution ratio ‘‘x’’ in MoS2xSe2(1-x) alloy could be tuned through controlling the extent of sulfurization. Based on this, alloyed heterostructures could be further synthesized by selectively sulfurizing MoS2xSe2(1-x) to MoS2xSe2(1-x)-MoS2ySe2(1-y) heterostructure, as illustrated in Fig. 23e. Similarly, Mahjouri-Samani et al. introduced an electron beam lithography method to selectively replace Se atoms in a mask-patterned MoSe2 flakes, and MoSe2-MoS2 heterojunction array was obtained under pulsed laser vaporization of sulfur [24]. Such lithography technology offers flexibility and benefits for both the precise device design and subsequent performance regulation. In 2021, Wang et al. realized the selective substitution by laser-induced oxidation without the assistance of masks [177]. As shown in Fig. 23f, monolayer MoS2 was synthesized via CVD and then scanned by a laser. The laser-scanned MoS2 could be oxidized into MoOx and then selenized in an Ar/H2 atmosphere (Fig. 23g). During selenization, the unoxidized region remained intact, because MoOx is easier to be selenized at a lower temperature as compared with MoS2.

Copyright 2020, American Chemical Society. f Schematic illustrations showing the formation process of MoS2-MoSe2 by laser patterning and selective selenization. g Microscopy images after the process illustrated in f. Reproduced with permission [177]. Copyright 2021, American Chemical Society

The selective substitution of TMC heterostructure synthesis. a Schematic showing the heterostructures synthesis protocol based on the sulfurization of patterned MoSe2 monolayers. b Optical image of a representative lateral heterostructure. c, d Mapping intensity of the A1g Raman modes of MoSe2 in (b) at 241 cm–1 and MoS2 at 408 cm–1, respectively. e Schematic showing the realization of an (x, y)-heterostructure with x < y. Reproduced with permission [176].

Metal oxide thin films were also used for the patterned synthesis of TMC heterostructures [178]. As illustrated in Fig. 24a, the MoOx thin film was deposited on the patterned region of SiO2/Si substrates with plasma enhanced atomic deposition, the obtained metal oxide was then sulfurized by thermal treatment. STEM and high-resolution scanning TEM images in Fig. 24b, c confirmed the realization of polycrystalline MoS2 films. Importantly, by using a designed MoOx/WOx heterostructure as the reactant, a lateral MoS2/WS2 heterostructures was obtained after sulfurization (Fig. 24d–f). This research provides an effective pathway for the synthesis of large-area 2D MaX2-MbX2 (Ma and Mb represent different metals) heterostructures.