Abstract

Climate change mitigation technologies have been a focus in reducing atmospheric carbon levels for the past few years. One such mitigation technology is pyrolysis, where biomass feedstocks are combusted at elevated temperatures for varying durations to produce three main products: biochar, bio-oil, and biogas. While bio-oil and biogas are typically used to produce energy via further combustion, biochar can be used in several different applications. Furthermore, using forest harvest residues as a feedstock for biochar production helps use excess biomass from the forestry industry that was previously assumed unmarketable. In our study, we combined forest carbon analysis modelling with cradle-to-gate life cycle emissions to determine the greenhouse gas emissions of biochar produced from forest harvest residues. We examined three collection scenarios, spanning two harvesting methods in one forest management unit in northern Ontario, Canada. From our analysis, we observed immediate reductions (− 0.85 tCO2eq·tbiochar−1 in year 1) in CO2-equivalent emissions (CO2eq) when producing biochar from forest harvest residues that would have undergone controlled burning, without considering the end use of the biochar. For the forest harvest residues that would remain in-forest to decay over time, producing biochar would increase overall emissions by about 6 tCO2eq·tbiochar−1. Throughout the 100-year timeframe examined–in ascending order of cumulative emissions–scenario ranking was: full tree harvesting with slash pile burn < full tree harvesting with slash pile decay < cut-to-length/tree-length harvesting.

Graphical Abstract

Highlights

-

Cradle-to-gate life cycle analysis for biochar production was evaluated.

-

Forest harvest collection methods influence overall life cycle emissions for biochar.

-

Harvest residues that typically undergo controlled burning are an ideal feedstock.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Climate change mitigation technology needs to be adopted faster and changes to said technology need to accelerate for a timely global transition to low-carbon systems to reduce detrimental anthropogenic effects on the climate (Dhakal et al. 2022). Since coal combustion for energy use accounts for 40% of global carbon dioxide (CO2) emissions (Jakob et al. 2020), focus on reducing coal use has become a priority in climate change mitigation strategies.

Wood has been strategized as a substitute for coal in energy production (Sterman et al. 2018; Sher et al. 2020; Fimbres Weihs et al. 2022). However, wood has a lower energy content and lower combustion and processing efficiencies than coal, which leads to higher CO2 emissions per unit of energy produced (Sterman et al. 2018). While wood can be regrown to offset this initial increase in emissions, the breakeven point (i.e., when emissions from using biomass for energy and foregone sequestration by harvested forest are fully offset by sequestration in regenerating forest) can take up to several decades to achieve (Buchholz et al. 2016; Ter-Mikaelian et al. 2023). This delay can potentially lead to negative and irreversible climate impacts (Sterman et al. 2018), potentially countering the overall goal of climate mitigation: controlling the rise of global average temperature (Searchinger et al. 2009).

Fortunately, combustion efficiencies for wood can be improved and made comparable to those for coal through pyrolysis (Li et al. 2022). Pyrolysis uses high temperature in the absence of oxygen to create three main products: biochar, bio-oil, and biogas. Due to the various combinations of temperature and residence times (for both solids and vapour phases) pyrolysis can be slow (sometimes referred to as carbonization; Fick et al. 2014), moderate, or fast. Other forms of pyrolysis, such as torrefaction (sometimes referred to as mild pyrolysis; Gürel et al. 2022) and flash pyrolysis (Ighalo et al. 2022) are also referenced (Table 1). Typically, slow pyrolysis favours biochar production, moderate pyrolysis favours bio-oil production, and fast pyrolysis favours bio-gas production (Bridgwater 2007).

Feedstocks other than wood that have previously been used for pyrolysis include agricultural residues (Biswas et al. 2017), algae (Sun et al. 2022), animal manure (Tan et al. 2023), and lignin-rich digested stillage from bioethanol production (Ghysels et al. 2019). However, biochar from woody feedstocks has more potential than most other feedstocks as wood is commonly available and the resulting biochar has a high surface area and low ash content (Shaheen et al. 2019) resulting in numerous possible end-uses beyond carbon storage. Likewise, the underutilized parts of the forest sector, e.g., forest harvest residues such as tops and branches (Azzi et al. 2019), wood bark (Lee et al. 2013), pine needles (Das et al. 2021), pine cones (Maaoui et al. 2023), and dead standing trees (Barrette et al. 2015), have been shown to produce beneficial products through pyrolysis. Canada contains 9% of the global total of forest land and is one of the world’s largest forest product manufacturers (Natural Resources Canada 2022). Recent remote sensing data estimated Canada’s available forest harvest residues, including branches and foliage biomass (hereafter referred to as harvest residues) but excluding downed woody debris (DWD), standing dead trees, stumps, and unmerchantable stemwood, at 21 M oven-dry tonnes (odt) per year, or about 26 odt·ha−1 (Barrette et al. 2018).

The Canadian province of Ontario has one of the highest proportions of annual harvesting by area (Barrette et al. 2018), with the total volume of harvested forest above 13 million m3 in 2021 (47.5% of the allowable harvest volume) (Government of Ontario 2022a). Harvest residues in Ontario without DWD and with DWD were estimated to average about 30 and 47 odt·ha−1, respectively, for cut-to-length harvesting and 14 and 32 odt·ha−1, respectively, for full-tree harvesting (Hazlett et al. 2014). Findings from another Ontario study were similar, with cut-to-length harvesting producing about 30 odt·ha−1 of harvest residues (branches, bark, chips, cones, and foliage) and full-tree harvesting nearly 14 odt·ha−1 (Morris et al. 2014). These estimates give Ontario a unique opportunity to become a larger contributor to the bioeconomy.

Currently (2024), no strategic plan is in place to use harvest residues in sectors other than forestry in Ontario. The recommended management practices are (1) to gather harvest residues into slash piles and dispose of them by controlled burning to allow recovery into productive land or (2) to re-distribute harvest residues over the cut area to prevent erosion and nutrient losses (Ontario Ministry of Natural Resources 2010). Large amounts of harvest residues are, therefore, an ideal bio-feedstock in terms of costs and greenhouse gas (GHG) implication for numerous products including wood pellets (Sgarbossa et al. 2020), wood plastic composites (Wang et al. 2021), and biochar (Azzi et al. 2022). The objective of this study was to assess the cradle-to-gate life cycle emissions of biochar production from slow pyrolysis using harvest residues as feedstock. We used a mass balance approach to compare the three forest residue collection scenarios to their respective business-as-usual (BAU) scenarios.

2 Material and methods

A cradle-to-gate (i.e., without including end-use) analysis was conducted for biochar production. This is because there are numerous end-uses for biochar (e.g., soil amendment (Adekiya et al. 2022), wastewater decontamination (Huang et al. 2019), concrete additive (Sirico et al. 2021), and coal substitution (Fick et al. 2014, Safarian 2023)), each drastically altering the overall emissions associated with the cradle-to-grave life cycle. By focusing on cradle-to-gate, we shift the focus to the upstream emissions associated with the production of biochar, for which cradle-to-grave analyses can be developed. We assessed three alternative harvest residue scenarios to compare to the BAU harvest residue management practices (leave to decay or controlled burn), using both full-tree and cut-to-length harvesting operations in one forest management unit (MU) from northern Ontario.

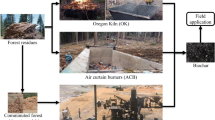

With our emphasis on GHG emissions throughout the cradle-to-gate life cycle, this analysis can be considered a partial carbon footprint of biochar, as outlined in ISO 14067 (ISO 2018). As such, this analysis adheres to the standards outlined by the International Organization for Standardization (ISO). The system boundary for all biochar scenarios (Fig. 1) includes collecting harvest residues (A1 stage), transporting chips to the pyrolysis plant (A2 stage), and producing biochar (A3 stage). The declared unit used to compare all scenarios was 1 tonne of biochar produced (tbiochar).

The cradle-to-gate system boundary for the various harvest residue scenarios presented in this study. The A1 stage encompasses the carbon dioxide equivalent (CO2eq) emissions and forest carbon changes associated with collecting and grinding forest harvest residues. The A2 stage encompasses the carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) emissions associated with transporting the chips to a pyrolysis plant 100 km using 30 tonne biomass trucks. The A3 stage encompasses the CO2, CH4, and N2O emissions from producing biochar, including the emissions associated with electricity use. The A1 stage does not include any upstream processes related to forest harvesting. Likewise, the A3 stage does not include any downstream processes related to packaging, shipping, or using biochar

2.1 Study area

The productive Crown (i.e., publicly-owned) forests managed for timber production in Ontario, Canada, are partitioned into 39 (as of 2023) separate MUs, each with their own 10-year forest management plan (FMP) that “establishes the long-term direction and shorter-term operational goals” (Vermillion Forest Management Company 2020). The effects of biochar production emissions on climate were estimated using the available harvest residues in the Sudbury Forest (Sudbury MU), situated in northeastern Ontario. The latest FMP for the Sudbury MU (2020–2030) was based on projections from the Strategic Forest Management Model (SFMM), which incorporates forest conditions, forest dynamics, finances, wood supply, wildlife habitat, and forest diversity to enable a forest’s development and management objectives to be explored through time (Kloss 2002).

The Sudbury MU covers about 11,000 km2 with an allowable harvest volume of about 600,000 m3 (in 2022), of which 21% was harvested (Government of Ontario 2022a, 2022b, 2022c). It is situated in the Great Lakes-St. Lawrence Forest Region and as such is biologically diverse with dominant species being white pine (Pinus strobus L.), jack pine (P. banksiana Lamb.), and poplar (Populus sp.). The Sudbury MU was chosen due to its proximity to other industries in both southern and northern Ontario with the capacity to introduce biochar as a feedstock in their operations.

2.2 Harvest residue scenarios

Three harvesting methods are applied in the Sudbury MU: full-tree (FT), tree-length (TL), and cut-to-length (CTL). During FT harvesting, trees are felled and the bole (including stems and branches but excluding the stump and roots) is hauled to the roadside or appropriate landing site for processing (delimbing, topping, and bucking). In TL harvesting, delimbing and topping occur at the stump and the bole is hauled to the roadside for final bucking. Lastly, in CTL harvesting, all processing (delimbing, topping, and bucking) occurs at the stump. These harvesting methods are similar to those described in various studies (Hazlett et al. 2014; Soman et al. 2020; Ameray et al. 2021) but sometimes FT is designated as whole-tree (Hartsough et al. 2001; Han and Han 2020; Akselsson et al. 2021; Clarke et al. 2021; Titus et al. 2021) and TL is designated as stem-only (Braghiroli and Passarini 2020) harvesting. Whole-tree harvesting is similar to FT but also includes the removal of stumps and roots (Government of Nova Scotia 2019), much like the method of whole-tree with forest floor removal methods outlined in other studies (Rousseau et al. 2019; James et al. 2021; Curzon et al. 2022). These term variations could be attributed to differences in regional forestry practices or perhaps language discrepancies. Either way, the definitions outlined above are those applied in the Sudbury MU (Vermillion Forest Management Company 2020).

The harvest residue scenarios we defined include BAU residue scenarios, and their alternative residue collection scenarios for biochar production (Table 2). BAU residue scenarios are dependent on the harvesting method applied, with FT harvest residues stacked by the roadside in slash piles and CTL and TL harvest residues scattered in-forest. Due to the similarities between CTL and TL residue management, we assume that emissions associated with these practices are equal and will therefore represent these methods as one: CTL/TL. Furthermore, when sufficient slash piles have accumulated, the Sudbury MU initiates a burn program to encourage tree regrowth. Not all slash piles are burned, leading to two FT BAU scenarios: one with burning and the other with decay for piles left on-site. Considering the Sudbury MU has low occurrences of annual burning, possibly due to lower harvesting in the past few years, we assume that half of the area covered with slash piles undergoes controlled burning while the other half is left to decay. CTL and TL combined make up about two-thirds of the harvesting practices in the Sudbury MU with the remaining one-third being FT. Due to the large discrepancy in the harvesting practices, we assume that some areas in the Sudbury MU are completely treated via CTL and TL, resulting in an overall 3:1 ratio of total areas treated by CTL/TL and FT.

Under the biochar collection scenarios, slash piles offer the most straightforward collection where they can be directly placed into a grinder/chipper, loaded into a truck, and removed from site. Since the Sudbury MU has 2 FT BAU scenarios, we have a collection scenario for those piles that were intended to undergo burning (denoted as “FT-slash pile burn”) and a collection scenario for those piles intended to remain on site to decay (denoted as “FT-slash pile decay”). Meanwhile, since harvest residues are naturally distributed on the forest floor during CTL/TL practices, additional machinery such as a shovel yarder or a forwarder with a specialized residue grappler (Routa et al. 2016; Premer and Froese 2018) is needed for the alternative collection scenario (denoted as “CTL/TL”). We assumed a forwarder was used to collect harvest residue in the study area, as per the method described by Oneil and Puettmann (2017).

High moisture content (~ 30%) in harvest residues can cause energy overloads in grinders, causing operators to need to slow the system to avoid overheating, which can reduce overall productivity (Klinger et al. 2020). Though chippers have higher productivity and lower energy consumption (Spinelli et al. 2012), grinders can handle more irregular shaped (i.e., branches/limbs) and contaminated (i.e., soil, rocks etc.) feedstock (Bergström and Di Fulvio 2019). Varying degrees of contamination from residues in slash piles (from FT harvesting) or from delayed residue collection after CTL/TL harvesting have led to operators favouring grinders in these instances (Spinelli et al. 2019). Therefore, considering the Sudbury MU does not have an integrated harvesting system in place for harvesting merchantable wood and collecting/processing residues, which can reduce residue contamination (Spinelli et al. 2019), we assumed that the quality of collected residues would favour using a grinder over a chipper. More detailed assumptions about harvest residue collections are outlined in Sect. 2.4.

The amount of biomass available for biochar production was estimated using available harvest areas specified in the 2020–2030 FMP (Vermillion Forest Management Company 2020). As mentioned above, the actual harvest area is usually lower than the allowable one due to factors such as low market demand, harvesting costs, and lack of access to remote stands. Therefore, allowable harvest area was scaled down to reflect historical ratios of actual to available harvest volumes. As described by Ter-Mikaelian et al. (2021), using past actual harvest levels between 1990 and 2018 and calculating the average annual harvest volumes for all consecutive five-year periods and arranging those values in ascending order gave us a median time period of 1995–2014. Calculated over 1995–2014, the historical actual to available harvest volume ratios for the Sudbury MU are equal to 0.6145 and 0.318 for softwood- and hardwood-dominated stands, respectively.

2.3 Analysis framework

We used a global warming potential (GWP)-based mass balance approach, using the analysis framework developed by McKechnie et al. (2011) and Ter-Mikaelian et al. (2015), to assess the total GHG emissions resulting from biochar production via slow pyrolysis of harvest residues during 1 year of operation (one-time harvest residue collection with resulting biochar production). Following this framework, we combined the biochar production life cycle inventory (LCI) analysis and the forest carbon stock change analysis over a 100-year period. The cumulative carbon balance over the study period was calculated using Eq. 1:

where T0 denotes the time of harvest residue collection, GHGTot(T0 + t) is the cumulative total emissions (metric tonne of carbon dioxide-equivalent; tCO2eq) that include forest carbon stock changes at time t after the residue collection and the LCI emissions associated with biochar production, ΔFC(T0 + t) is the change in forest carbon (tCO2eq) due to harvest residue collection, and GHGBio(T0) is the GHG emissions (tCO2eq) associated with the LCI of biochar production.

Using the carbon balance approach, the CO2 emissions from biomass combustion were excluded from the calculation to avoid double counting. To account for the non-CO2 GHG emissions, all emissions are presented as CO2eq values, using the 100-year GWP multipliers outlined in the IPCC’s Sixth Assessment Report (i.e., CH4 = 27.9, N2O = 273; Forster et al. 2021). We also converted forest carbon stock changes (ΔFC) to the same units as the GHG emissions (one tonne of carbon is equivalent to 3.667 tonnes of CO2).

2.4 Forest carbon stock analysis

The change in forest carbon due to harvest residue collection (ΔFC) is the difference between forest carbon stocks after collecting the residues and those in the BAU scenario where residues are not collected:

where FCBAU(T0 + t) is the forest carbon stock (tCO2eq) at time t in the BAU scenario (where residues are either left to decay or burned) and FCres(T0 + t) is the forest carbon stock (tCO2eq) at time t after harvest residue collection at time T0.

For a FT harvest system, the collectable slash pile biomass was calculated using the available biomass equation from Ter-Mikaelian et al. (2023):

where BresFT is the unmerchantable biomass collected for biochar production per unit of harvest area (odt·ha−1), BAg is the total aboveground biomass in forest (odt·ha−1), Fracfol is the ratio of the amount of foliage to the total aboveground biomass, Bstem is the harvested merchantable biomass (including bark) (odt·ha−1), Fracsite is the fraction of unmerchantable biomass left scattered on site, and Fracrecovery is the fraction of unmerchantable biomass from slash piles that can be recovered to produce biochar.

Like Ter-Mikaelian et al. (2023), we used 0.5 for the fraction of unmerchantable biomass left on site (Fracsite) during FT harvesting. This fraction was based on the results by Ralevic et al. (2010), Belleau et al. (2006), Klockow et al. (2013), and Hytönen and Moilanen (2008), who found the fraction of unmerchantable biomass left on site to be between 0.35 and 0.69. Furthermore, we assumed 0.75 was the fraction of recoverable unmerchantable biomass from the slash piles (Fracrecovery) in the FT scenarios, based on the results by Ralevic et al. (2010). For both FT scenarios, the remaining 25% of slash pile residues not collected for biochar production was assumed to be left on site to decay. The unmerchantable biomass scattered in-forest was assumed to decay and release biogenic carbon overtime.

For the collection of residual biomass in the CTL/TL scenario, we used an equation similar to (3) with a minor adjustment to Fracsite:

where BresCTL is the unmerchantable biomass collected for biochar production per unit of harvest area (odt·ha−1) in a CTL/TL harvest system. We assumed Fracsite to be 1 in the CTL/TL scenario, i.e., 100% of the residual biomass is left scattered in-forest. Based on calculations by Thiffault et al. (2016) and Spinelli et al. (2016), the recoverable fraction for biochar production would likely be lower than that in a FT system and therefore we assumed Fracrecovery to be at 0.5. This fraction is also in line with recommendations to keep a proportion of residues in forest for soil recovery (Titus et al. 2021). We assumed all the biomass not collected for biochar production in the CTL/TL harvest system decays in-forest.

Annual changes in forest carbon stocks were calculated similarly to the methods used by Ter-Mikaelian et al. (2023). In short, changes in the forest carbon stocks of the regenerating area under the FT biochar production scenarios and the BAU scenarios were calculated using FORCARB-ON2 (Chen et al. 2018), which is a modified version of FORCARB2 (Heath et al. 2010) that better reflects Ontario forest conditions. Carbon stock changes that occurred in decaying residues were estimated based on a negative exponential function using decay rates calculated by Ter-Mikaelian et al. (2016) (i.e., 0.0171 year−1 and 0.0365 year−1 for conifers and hardwoods, respectively), resulting in a 50% loss of mass by years 34 and 24 for softwood- and hardwood-dominated stands, respectively. Though the decay rates from Ter-Mikaelian et al. (2016) were estimated based on down woody debris, Wright et al. (2017) found decay rates from slash piles in Washington, USA to be similar, with an estimated decay rate of 0.027 year−1. During the combustion of slash piles in the FT scenarios, an 88% combustion efficiency (Hardy 1998) was assumed, with the remaining fraction undergoing decay. We assumed slash pile burning would occur in the late fall/early winter months to reduce wildfire risk. As such, we used the emission factor of 1.85 tCO2eq·odt−1 of wet slash described by Aurell et al. (2017). The rate of black carbon (i.e., the product of incomplete combustion) produced was estimated to be 0.0225 (Ter-Mikaelian et al. 2016), based on estimates by Forbes et al. (2006) and Preston and Schmidt (2006). As per the FMP, the fraction of total harvested area covered by slash piles was estimated at 0.025 and the regeneration rates of areas previously occupied by slash piles was simulated using average post-harvest regeneration rates.

2.5 Life cycle inventory of biochar production

LCI emissions for all residue collection scenarios were estimated for the following activities: forest carbon changes and harvest residue collection and grinding at roadside (A1 stage), biomass transportation to the pyrolysis plant (A2 stage), and biochar production (A3 stage; Table 3). In all scenarios, in-forest emissions associated with normal forest harvesting practices (i.e., site preparation, stem biomass harvesting, forest renewal, and forest road construction) are not accounted for since all harvest residues are considered a waste product of roundwood harvesting and carry no upstream burden (ISO 2006). Emissions associated with biomass collection (including grinding into chips) were based on estimates by Oneil and Puettmann (2017). Biomass was assumed to be transported 100 km (Meil et al. 2009) from the forest to the pyrolysis plant via 30 tonne trucks.

To the authors’ knowledge, biochar is not currently produced in the Sudbury MU; however due to a large, industrialized city located in the centre of the MU, a pyrolysis plant was assumed to have been previously constructed. Therefore, emissions associated with the construction and maintenance of a pyrolysis plant are not included in the analysis. The biochar produced via slow pyrolysis parallels that described by Peters et al. (2015), who simulated the use of poplar wood chips derived from a plantation in Central Spain as their pyrolysis feedstock. In short, the chips from harvest residues are dried to 7% moisture content before entering the pyrolysis reactor, where they undergo slow pyrolysis at 450 °C for about 42 min, yielding 29.0% biochar, 40.8% bio-oil, and 30.2% biogas. In other words, for every odt of harvest residue chips, about 0.29 tonnes of biochar are produced. Peters et al. (2015) describe their biochar as having a carbon content of about 82%, an ash content of about 9%, and a higher heating value (HHV) of 30.77 MJ·kg−1. The bio-oil and biogas are burned in a combustor to generate the heat needed for pyrolysis (including the pre-dry step) as well as excess heat. The CO2 emissions from bio-oil and biogas combustion were not included to avoid double-counting, and CH4 and N2O emissions were not identified by Peters et al. (2015) and were thus ignored in this study. Emissions associated with electricity use were calculated from Canadian emission factors (CO2 = 100 g·kWh−1, CH4 = 0.01 g·kWh−1, N2O = 0.002 g·kWh−1; Government of Canada 2022b).

3 Results

In both FT scenarios (FT-slash pile burn and FT-slash pile decay), the annual harvest area adjusted for historical actual-to-allowed harvest ratio was equal to 591 ha and 122 ha of softwood- and hardwood-dominated stands, respectively, for a total of 713 ha. For each of the two FT scenarios, the total amount of available biomass for biochar production from this harvest area was estimated at 5,575.4 odt, which resulted in a total of 1,623.4 tonnes of biochar produced. In the CTL/TL scenario (where harvest residues are collected from in-forest and moved to roadside), the annual harvest area was equal to 2,015 ha and 351 ha of softwood- and hardwood-dominated stands, respectively, for a total of 2,366 ha. The total amount of biomass collected from this harvest area was estimated as 50,543.4 odt, which can produce 14,716.8 tonnes of biochar. The discrepancy in available biomass between FT and CTL/TL scenarios reflects the Sudbury MU’s difference in harvest residue disposal and recoverable fraction rates between FT and CTL/TL harvesting.

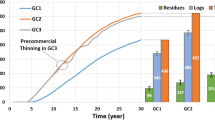

Total cumulative emissions through time (100-year period) per tonne of biochar (tbiochar) for a 1-year operation are presented in Fig. 2. Of the three collection scenarios that were studied, producing biochar from slash piles that would otherwise undergo prescribed burning (FT-slash pile burn scenario) showed immediate CO2eq removals (−0.85 t CO2eq·tbiochar−1) compared to the BAU scenario, with an approximate decrease of 12%. The FT-slash pile burn scenario consistently produced less emissions compared to the BAU scenario for about 76 years, at which time the emissions from decay of the remaining slash surpass those of the BAU scenario resulting in slightly higher emissions (cumulative difference of 0.08 tCO2eq·tbiochar−1 by the year 2120). The FT-slash pile decay and CTL/TL scenarios consistently presented higher emissions throughout the study period compared to their respective BAU scenario.

The total cumulative emissions (tCO2eq·tbiochar−1) for each collection scenario against their respective business-as-usual (BAU) scenarios for 2021–2120: a full tree-slash pile burn (dashed line), b full tree-slash pile decay (dotted line), and c cut-to-length/tree-length (dash-dot line). These emissions represent one full year of operation (i.e., one-time harvest residue collection with resulting biochar production) in the Sudbury Forest management unit in northern Ontario, Canada, and include forest carbon analysis and cradle-to-gate life cycle inventory emissions from biochar production

As expected, the largest difference between the collection scenario and BAU scenario throughout the 100-year timeframe was found in CTL/TL harvesting, followed closely by FT-slash pile decay (Fig. 3). While both CTL/TL and FT-slash pile decay scenarios account for decay rates of the residues, only FT-slash pile decay accounts for forest regeneration in the area where slash piles once occurred whereas regeneration in CTL/TL would be reported during normal stem harvesting. This distinction between the two collection methods results in instantly lower cumulative emissions in FT-slash pile decay (6.44 tCO2eq·tbiochar−1) than in CTL/TL (6.56 tCO2eq·tbiochar−1) when compared to their respective BAU scenarios at year 1. The largest difference in emissions between FT-slash pile decay and CTL/TL is found at year 2065, with 6.34 tCO2eq·tbiochar−1 and 10.27 tCO2eq·tbiochar−1, respectively.

Net cumulative differences in emissions (tCO2eq·tbiochar−1) for all three collection scenarios (full tree-slash pile burn = solid line; full tree-slash pile decay = dotted line; cut-to-length/tree-length = dot-dash line) compared to their business-as-usual scenario, over a 100-year period (2021–2120) in the Sudbury Forest management unit located in northern Ontario, Canada. Negative values indicate CO2eq removals, whereas positive values indicate CO2eq emissions

3.1 Sensitivity analysis

A sensitivity analysis was performed on the following LCI inputs: biomass yield, biochar yield, biochar production emissions, transportation distance, and harvest residue collection emissions. A range of ± 25% was applied to the parameters to assess their effects on the life cycle emissions from the first year of production. As seen in Fig. 4, biochar yield was the most influential parameter on the overall emissions. A 20% decrease and a 33% increase in cradle-to-gate emissions were achieved in all biochar scenarios when biochar yield was increased and decreased by 25%, respectively. Biomass yield was the second most influential parameter in determining the overall emissions during the first year: with emissions from both FT scenarios decreasing and increasing by 0.52% and 0.88% when biomass yield increased and decreased by 25%, respectively. Meanwhile, the emissions from the CTL/TL scenario decreased and increased by 0.84% and 1.4% when biomass yield increased and decreased by 25%, respectively. The parameter that had the least influence on overall cumulative emissions was transportation distance, which showed a 0.07% change in either direction (i.e., overall emissions decreased by 0.07% when the input was decreased by 25%, and vice versa). Harvesting methods (i.e., FT and CTL/TL) appeared to have very little influence over the emissions associated with transportation distance and biochar production, as percent change between the scenarios remained relatively constant when the parameters’ values changed.

Percent change in overall emissions during the first year of production in each biochar scenario when the input parameters were either increased (solid bar) or decreased (hatched bars) by 25%. The biochar scenarios include full-tree harvesting where the harvest residues are collected from slash piles that are burned (FT-slash pile burn; green) or left to decay (FT-slash pile decay; orange) and cut-to-length/tree-length harvesting where the harvest residues are collected from in-forest (CTL/TL; purple). The input parameters that were manipulated include biochar yield, biomass yield, harvest residue collection emissions, biochar production emissions, and transportation distance

4 Discussion

Differences in forest harvesting methods (in particular, the way the resulting harvest residues are managed) affect overall emission factors from biochar production using harvest residues as a feedstock. This study offers unique insight into how differences in BAU harvest residue management influence overall emissions from biochar production. While the emissions of harvesting collection methods have been studied (Johnson et al. 2012; Dias 2014; Oneil and Puettmann 2017; Kühmaier et al. 2022), most biochar life cycle analyses (LCAs) focus on comparing feedstocks (Roberts et al. 2010; Dutta and Raghavan 2014; Rajabi Hamedani et al. 2019), pyrolysis methods (Azzi et al. 2019), production systems (Puettmann et al. 2020; Bergman et al. 2022), biochar applications (Peters et al. 2015; Homagain et al. 2015; Tisserant et al. 2022), or some combination of those (Puettmann et al. 2020; da Costa et al. 2023).

We found that during a 1-year operation (i.e., one-time harvest residue collection) of biochar production, emissions were immediately avoided when using harvest residues from slash piles that, under normal circumstances, undergo prescribed burning. These results are similar to those reported by Puettmann et al. (2020). Although removal of slash piles via prescribed burns is meant to increase the area of productive forest and in theory is thought to reduce wildfire risk by removing surface fuel loads (Johnson et al. 2013), research has demonstrated possible negative ecological effects of slash pile burning. In a recent review, Mott et al. (2021) found slash pile burning had negative effects on surface vegetation, litter layer, and soil composition/nutrients. Meanwhile, Pierobon et al. (2022) illustrated possible increases in ambient particulate matter concentrations that surpass the Environmental Protection Agency’s air quality standard after burning an additional 30% of harvest residues compared to their BAU scenario. Therefore, using harvest residues that would otherwise be burned as a feedstock for biochar may be advantageous to the overall landscape and surrounding environment.

While we used harvest projections from the Sudbury FMP to calculate total availability of biomass and in turn the amount of biochar that can be produced, the aim of this study was to estimate emissions per tonne of biochar for each scenario. In our study, the A1 stage (regardless of harvesting method) was the highest emitting stage (1.85 tCO2eq·odtbiomass−1 or 6.32 tCO2eq·tbiochar−1 and 1.88 tCO2eq·odtbiomass−1 or 6.44 tCO2eq·tbiochar−1 for the FT and CTL/TL scenarios, respectively), mainly due to the changes in forest carbon. Forest carbon accounted for 99% of the emissions associated with the A1 stage, and indeed 98% of the whole cradle-to-gate life cycle for all scenarios. This shows the importance of including forest carbon changes in the analysis, including biomass loss, decay, and regeneration. Assuming automatic net carbon neutrality for forest biomass oversimplifies the effects of an LCA on climate change (Head et al. 2019). For example, Fehrenbach et al. (2022) show that GHG emission savings decrease significantly when considering forest carbon changes when producing a variety of wood products. Specifically, the timing of carbon sinks and emissions should be taken into account (Helin et al. 2013). Throughout our study period, the largest single emission occurs in the biochar scenarios when the harvest residue biomass loss in forest is considered (i.e., year 1). Fluctuations in cumulative emissions are then shown based on regeneration (in the FT scenarios only) and decay rates (in both FT and CTL/TL scenarios) throughout the study period. In the FT scenarios, the cumulative carbon removals from regeneration in the small area occupied by the slash piles in the 100-year study period are not enough to offset the carbon losses from biomass removal in the first year. Furthermore, though the annual emissions from decay are consistently lower in the CTL/TL scenario compared to its BAU scenario (due to the decreased amount of biomass), the net cumulative emissions by the end of the study period is higher in the CTL/TL scenario than its BAU scenario due to the loss of forest harvest residue biomass in the first year.

From our analysis, using harvest residues from FT harvesting resulted in lower emissions than that from CTL/TL harvesting. While it seems intuitive to switch forest harvesting practices to 100% FT harvesting to maximize emission reductions via biochar production, a key challenge of removing harvest residues is the removal of soil nutrients, specifically nitrogen, phosphorus, and potassium (Helmisaari et al. 2011), which can affect subsequent tree growth (Achat et al. 2015). This retention of nutrients in-forest is a key argument for the increase in CTL/TL harvesting in the Sudbury MU (Scott McPherson, Vermillion Forest Management Company, personal communication). When all the harvest residues are distributed across the forest floor during CTL/TL, soil nutrient concentrations were higher (Clarke et al. 2021) and soil compaction was reduced (Ampoorter et al. 2007; Han et al. 2009), compared to FT harvesting. To limit nutrient removal, sustainable forest management guidelines often include recommendations that a fraction (15–66%) of residues remain in-forest (Titus et al. 2021). For our study, we assumed that 50% of total residues remained in-forest for both the FT and CTL/TL harvest systems. These estimates are above those recommended in U.S. southeast and northeast (25–33% retention) though similar to those indicated in the U.S. Pacific Northwest (30–50% retention) and the UK (50–66% retention) (Titus et al. 2021).

In our study, the emissions associated with the process of collecting harvest residues were higher in the CTL/TL scenario (0.056 tCO2eq·tbiochar−1) compared to both FT scenarios due to the extra machinery needed to gather the residue biomass from in-forest and haul it to roadside. However, removing the harvest residues from in-forest could be easier said than done in most cases. Nance (2023) surveyed forest professionals in the Canadian province of British Columbia, outlining the many challenges they face for secondary uses of harvest residues, including limited market access, long transportation distances, and cut blocks that are inaccessible to biomass trucks. Meanwhile, Kons et al. (2022) highlighted the issue of biomass storage pre-pyrolysis. While our analysis did not focus on the economic or technical aspects of biochar production, these challenges are worth mentioning. For example, in the Sudbury MU where we estimated an average 100 km distance between the forest and the pyrolysis plant (based on estimates from Meil et al. 2009), it was assumed that all cut blocks were accessible to the 30 tonne biomass trucks. Realistically, accessibility to all cut blocks via biomass trucks is unknown as no attempts have been made to retrieve the biomass. As for the bioeconomy, biochar facilities are gaining a stronghold in Ontario though to the authors’ knowledge, biochar has yet to be a key driver in the Canadian market. Numerous factors influence the overall economics of biochar, including regional labour costs, technology used to produce biochar, energy consumption and sources for biochar production, biochar feedstock, and the end-use of biochar (Maroušek and Trakal 2022). A recent analysis by Keske et al. (2020) explains that the profitability of biochar from black spruce in Canada is dependent on its end use, as biochar as a soil amendment for beets was shown to be profitable but not for potatoes. Though earlier studies show that the economic viability is dependent on the feedstock (Roberts et al. 2010), cost of pyrolysis, and the value of carbon offsets (Dutta and Raghavan 2014).

The A3 stage (biochar production) was the second highest emitting stage with 0.015 tCO2eq·odtbiomass−1, or 0.052 tCO2eq·tbiochar−1. This value is considerably lower than the values presented by Puettmann et al. (2020), who found production emissions from in-forest pyrolysis to be 0.178–0.211 tCO2eq·tbiochar−1. Our smaller value could be in part due to our pyrolysis system being self-reliant (i.e., the bio-oil and biogas produced were burned for power/heat and with minimal electricity needed) whereas the system in Puettmann et al. (2020) required burning additional wood chips to produce power.

Studies on the mitigation potential of biochar production are numerous (Patel et al. 2021; Shakoor et al. 2021; Lehmann et al. 2021; Hagenbo et al. 2022), and current estimates of GHG emissions reduction potential of biochar produced from globally available biomass residues from agriculture and forests are 6–12% (Woolf et al. 2010; Lefebvre et al. 2023). Biochar is considered a negative emissions technology (Smith et al. 2016) though further studies are required to fully understand it’s role (Genesio et al. 2016; Ravi et al. 2016). As part of the Canadian Net-Zero Emissions Accountability Act, Canada has committed to achieving net-zero emissions by the year 2050 (Government of Canada 2021). As seen from our study, the FT-slash pile burn scenario was the only scenario to have lower emissions compared to their BAU scenario by 2050 (a cumulative net difference of − 0.34 tCO2eq·tbiochar−1 by 2050). However, the FT-slash pile decay scenario also shows better emission reductions than the CTL/TL scenario, with about 27% lower cumulative emissions by 2050.

Transportation distances are often a relevant logistical component to biochar LCAs, where less distance between forest and pyrolysis plant is preferred (Ahmed et al. 2012). Similar to other biochar LCAs (Dutta and Raghavan 2014; Peters et al. 2015; Tisserant et al. 2022), transportation in our analysis resulted in the fewest emissions compared to the other life cycle stages; contributing to about 0.3% of the overall emissions. A noteworthy aspect of current biochar research is the examination of portable pyrolysis systems, which are mobile units that can be deployed in-forest to produce the biochar directly at the landing. Reductions in overall emissions of these portable systems compared to slash pile burning were found by Puettmann et al (2020) and Thengane et al. (2020). Meanwhile, Ayer and Dias (2018) found that using bio-oil and biochar produced from mobile pyrolysis units using forest harvest residues as a feedstock contributed to significant reductions in overall emissions during cement production. Perhaps high cost (Sahoo et al. 2019; Bergman et al. 2022) is causing portable pyrolysis systems to remain in their infancy as demonstrated by the shortage of relevant literature. Nevertheless, future research into this technology would be beneficial for both the technoeconomic and environmental aspects of biochar production.

5 Limitations and uncertainties

Various limitations and uncertainty exist in this study, most notably that all data were collected from several published sources. As such, certain assumptions were required in each stage of the system boundary.

Due to the cradle-to-gate nature of our analysis, further mitigation analysis is needed as we do not consider climate-affecting factors of possible end-use applications of biochar. Biochar has many end-uses, each carrying their own climate-mitigating potential. For example, as a soil ameliorant biochar has the potential to store carbon in the soil for over a century (Wang et al. 2016) and reduce N2O and CH4 emissions (Azzi et al. 2019). Unfortunately, biochar seems to have little to no effect on crop yields (Sorensen and Lamb 2016; Ye et al. 2020), though Jeffrey et al. (2017) did show an increase in yields from tropical latitudes. If used as a coal substitute, biochar can help reduce GHG emissions from large industries (Fick et al. 2014). Even the process of producing biochar (i.e., pyrolysis) can enhance additional substitution effects, as Tisserant et al. (2022) found that the climate change mitigation potential of biochar increased by 65% when the bio-oil and biogas were used to generate heat and electricity and increased by 120% when the bio-oil is instead sequestered into geological deposits.

Climate-affecting factors such as albedo or radiative fluxes were also not considered. For instance, biochar’s dark colour can reduce it’s mitigation potential by 10–30% when used as a soil ameliorant, but the amount can be lessened in areas with dense, year-round vegetation cover (Meyer et al. 2012; Verheijen et al. 2013; Bozzi et al. 2015). As highlighted by Moreau et al. (2022), “climate change mitigation strategies need to be tailored to the ecosystem dynamics and initial characteristics”. This need is evident in the study by Kalu et al. (2022) where they observed no significant fluxes of CH4 or N2O emissions in agricultural fields treated with biochar but did observe significant correlation between emissions and soil properties including soil type and soil microbial activity.

Though GHG emissions were our focus, additional analysis is required to assess the environmental impacts from biochar production that were not reported in this study. These environmental impacts include ozone depletion potential, acidification potential, eutrophication potential, and abiotic depletion potential. Furthermore, the geographical scope of our study was quite limited. However, our approach (i.e., GWP-based mass balance approach using forest carbon stock changes and LCI analysis) is easily adaptable to other geographical regions. Indeed, the mass balance approach is required in LCAs, and the principle has been applied previously to account for forest carbon changes in other regions (Fehrenbach et al. 2022; Leinonen 2022).

6 Conclusion

We used forest carbon analysis along with LCI emissions to quantify the GHG emissions associated with the cradle-to-gate life cycle of biochar produced from forest harvest residues during a 1-year operation. In our analysis, we showed immediate reduction in emissions when producing biochar from forest harvest residues that would undergo controlled burning in the absence of collection for biochar production. Within year 1, the production of biochar emitted 0.85 tCO2eq·tbiochar−1 less than what was emitted by slash piles during burning. Meanwhile, producing biochar from harvest residues that would be left to decay over time (either in-forest or in slash piles) emitted an additional 6.24–6.28 tCO2eq·tbiochar−1 within the first year. Of the three residue scenarios, a ranking of total cumulative emissions during the 100-year timeframe is as follows: FT-slash pile burn < FT-slash pile decay < CTL/TL. To no surprise, the A1 stage (collecting harvest residues) from FT harvesting operations produced less emissions than the A1 stage from CTL/TL harvesting operations. And lastly, transportation from the forest to the pyrolysis plant (in all scenarios) resulted in the lowest emissions compared to the other life cycle stages. Our study shows that biochar production in Ontario (under the assumptions described) can be used as a potential product to support Canada’s net-zero goal.

Data availability

Not applicable.

References

Achat DL, Deleuze C, Landmann G, Pousse N, Ranger J, Augusto L (2015) Quantifying consequences of removing harvesting residues on forest soils and tree growth—a meta-analysis. For Ecol Manag 348:124–141. https://doi.org/10.1016/j.foreco.2015.03.042

Adekiya AO, Adebiyi OV, Ibaba AL, Aremu C, Ajibade RO (2022) Effects of wood biochar and potassium fertilizer on soil properties, growth and yield of sweet potato (Ipomea batata). Heliyon 8(11):e11728. https://doi.org/10.1016/j.heliyon.2022.e11728

Ahmed S, Hammond J, Ibarrola R, Shackley S, Haszeldine S (2012) The potential role of biochar in combating climate change in Scotland: an analysis of feedstocks, life cycle assessment and spatial dimensions. J Environ Plann Manag 55(4):487–505. https://doi.org/10.1080/09640568.2011.608890

Akselsson C, Kronnäs V, Stadlinger N, Zanchi G, Belyazid S, Karlsson PE, Hellsten S, Karlsson GP (2021) A combined measurement and modelling approach to assess the sustainability of whole-tree harvesting—a Swedish case study. Sustainability. https://doi.org/10.3390/su13042395

Allman M, Dudáková Z, Jankovský M, Merganič J (2021) Operational parameters of logging trucks working in mountainous terrains of the Western Carpathians. Forests 12(6):718. https://doi.org/10.3390/f12060718

Ameray A, Bergeron Y, Valeria O, Montoro Girona M, Cavard X (2021) Forest carbon management: a review of silvicultural practices and management strategies across boreal, temperate and tropical forests. Curr Forest Rep 7(4):245–266. https://doi.org/10.1007/s40725-021-00151-w

Ampoorter E, Goris R, Cornelis WM, Verheyen K (2007) Impact of mechanized logging on compaction status of sandy forest soils. For Ecol Manag 241(1):162–174. https://doi.org/10.1016/j.foreco.2007.01.019

Aurell J, Gullett BK, Tabor D, Yonker N (2017) Emissions from prescribed burning of timber slash piles in Oregon. Atmos Environ 150:395–406. https://doi.org/10.1016/j.atmosenv.2016.11.034

Ayer NW, Dias G (2018) Supplying renewable energy for Canadian cement production: Life cycle assessment of bioenergy from forest harvest residues using mobile fast pyrolysis units. J Clean Prod 175:237–250. https://doi.org/10.1016/j.jclepro.2017.12.040

Azzi ES, Karltun E, Sundberg C (2019) Prospective life cycle assessment of large-scale biochar production and use for negative emissions in Stockholm. Environ Sci Technol 53(14):8466–8476. https://doi.org/10.1021/acs.est.9b01615

Azzi ES, Karltun E, Sundberg C (2022) Life cycle assessment of urban uses of biochar and case study in Uppsala, Sweden. Biochar 4(1):18. https://doi.org/10.1007/s42773-022-00144-3

Barrette J, Thiffault E, Saint-Pierre F, Wetzel S, Duchesne I, Krigstin S (2015) Dynamics of dead tree degradation and shelf-life following natural disturbances: can salvaged trees from boreal forests ‘fuel’ the forestry and bioenergy sectors? Forestry 88(3):275–290. https://doi.org/10.1093/forestry/cpv007

Barrette J, Paré D, Manka F, Guindon L, Bernier P, Titus B (2018) Forecasting the spatial distribution of logging residues across the Canadian managed forest. Can J for Res 48(12):1470–1481. https://doi.org/10.1139/cjfr-2018-0080

Belleau A, Brais S, Paré D (2006) Soil nutrient dynamics after harvesting and slash treatments in boreal aspen stands. Soil Sci Soc Am J 70(4):1189–1199. https://doi.org/10.2136/sssaj2005.0186

Bergman R, Sahoo K, Englund K, Mousavi-Avval SH (2022) Lifecycle assessment and techno-economic analysis of biochar pellet production from forest residues and field application. Energies 15(4):1559. https://doi.org/10.3390/en15041559

Bergström D, Di Fulvio F (2019) Review of efficiencies in comminuting forest fuels. Int J for Eng 30(1):45–55. https://doi.org/10.1080/14942119.2019.1550314

Biswas B, Pandey N, Bisht Y, Singh R, Kumar J, Bhaskar T (2017) Pyrolysis of agricultural biomass residues: comparative study of corn cob, wheat straw, rice straw and rice husk. Biores Technol 237:57–63. https://doi.org/10.1016/j.biortech.2017.02.046

Bozzi E, Genesio L, Toscano P, Pieri M, Miglietta F (2015) Mimicking biochar-albedo feedback in complex Mediterranean agricultural landscapes. Environ Res Lett 10(8):084014. https://doi.org/10.1088/1748-9326/10/8/084014

Braghiroli FL, Passarini L (2020) Valorization of biomass residues from forest operations and wood manufacturing presents a wide range of sustainable and innovative possibilities. Current Forestry Reports 6(2):172–183. https://doi.org/10.1007/s40725-020-00112-9

Bridgwater T (2007) Biomass pyrolysis. IEA Bioenergy

Buchholz T, Hurteau MD, Gunn J, Saah D (2016) A global meta-analysis of forest bioenergy greenhouse gas emission accounting studies. GCB Bioenergy 8(2):281–289. https://doi.org/10.1111/gcbb.12245

Chen J, Ter-Mikaelian MT, Ng PQ, Colombo SJ (2018) Ontario’s managed forests and harvested wood products contribute to greenhouse gas mitigation from 2020 to 2100. For Chron 94(03):269–282. https://doi.org/10.5558/tfc2018-040

Clarke N, Kiær LP, Janne Kjønaas O, Bárcena TG, Vesterdal L, Stupak I, Finér L, Jacobson S, Armolaitis K, Lazdina D, Stefánsdóttir HM, Sigurdsson BD (2021) Effects of intensive biomass harvesting on forest soils in the Nordic countries and the UK: a meta-analysis. For Ecol Manage 482:118877. https://doi.org/10.1016/j.foreco.2020.118877

Curzon MT, Slesak RA, Palik BJ, Schwager JK (2022) Harvest impacts to stand development and soil properties across soil textures: 25-year response of the aspen Lake States LTSP installations. For Ecol Manage 504:119809. https://doi.org/10.1016/j.foreco.2021.119809

da Costa TP, Murphy F, Roldan R, Mediboyina MK, Chen W, Sweeney J, Capareda S, Holden NM (2023) Technical and environmental assessment of forestry residues valorisation via fast pyrolysis in Ireland. Biomass Bioenerg 173:106766. https://doi.org/10.1016/j.biombioe.2023.106766

Das SK, Ghosh GK, Avasthe RK, Sinha K (2021) Compositional heterogeneity of different biochar: Effect of pyrolysis temperature and feedstocks. J Environ Manage 278:111501. https://doi.org/10.1016/j.jenvman.2020.111501

Dhakal S, Minx JC, Toth FL, Abdel-Aziz A, Figueroa Meza MJ, Hubacek K, Jonckheere IGC, Kim Y-G, Nemet GF, Pachauri S, Tan XC, Wiedmann T (2022) Chapter 2: Emissions trends and drivers. In: Shukla PR, Skea J, Slade R, Al Khourdajie A, van Diemen R, McCollum D, Pathak M, Some S, Vyas P, Fradera R, Belkacemi M, Hasija A, Lisboa G, Luz S, Malley J (eds) IPCC, 2022: Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge, UK and New York, NY, USA, pp 215–294

Dias AC (2014) Life cycle assessment of fuel chip production from eucalypt forest residues. Int J Life Cycle Assess 19(3):705–717. https://doi.org/10.1007/s11367-013-0671-4

Dutta B, Raghavan V (2014) A life cycle assessment of environmental and economic balance of biochar systems in Quebec. Int J Energy Environ Eng 5(2):106. https://doi.org/10.1007/s40095-014-0106-4

Fehrenbach H, Bischoff M, Böttcher H, Reise J, Hennenberg KJ (2022) The missing limb: including impacts of biomass extraction on forest carbon stocks in greenhouse gas balances of wood use. Forests. https://doi.org/10.3390/f13030365

Fick G, Mirgaux O, Neau P, Patisson F (2014) Using biomass for pig iron production: a technical, environmental and economical assessment. Waste Biomass Valor 5(1):43–55. https://doi.org/10.1007/s12649-013-9223-1

Fimbres Weihs GA, Jones JS, Ho M, Malik RH, Abbas A, Meka W, Fennell P, Wiley DE (2022) Life cycle assessment of co-firing coal and wood waste for bio-energy with carbon capture and storage—New South Wales study. Energy Convers Manag 273:116406. https://doi.org/10.1016/j.enconman.2022.116406

Forbes MS, Raison RJ, Skjemstad JO (2006) Formation, transformation and transport of black carbon (charcoal) in terrestrial and aquatic ecosystems. Sci Total Environ 370(1):190–206. https://doi.org/10.1016/j.scitotenv.2006.06.007

Forster P, Storelvmo T, Armour K, Collins W, Dufresne J-L, Frame D, Lunt DJ, Mauritsen T, Palmer MD, Watanabe M, Wild M, Zhang H (2021) The Earth’s energy budget, climate feedbacks, and climate sensitivity. In Climate change 2021: The physical science basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change [Masson-Delmotte, V., P. Zhai, A. Pirani, S.L. Connors, C. Péan, S. Berger, N. Caud, Y. Chen, L. Goldfarb, M.I. Gomis, M. Huang, K. Leitzell, E. Lonnoy, J.B.R. Matthews, T.K. Maycock, T. Waterfield, O. Yelekçi, R. Yu, and B. Zhou (eds.)]. Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA

Genesio L, Vaccari FP, Miglietta F (2016) Black carbon aerosol from biochar threats its negative emission potential. Glob Change Biol 22(7):2313–2314. https://doi.org/10.1111/gcb.13254

Ghysels S, Ronsse F, Dickinson D, Prins W (2019) Production and characterization of slow pyrolysis biochar from lignin-rich digested stillage from lignocellulosic ethanol production. Biomass Bioenerg 122:349–360. https://doi.org/10.1016/j.biombioe.2019.01.040

Government of Canada (2021) Canadian Net-zero Emissions Accountability Act

Government of Canada (2022a) Canada’s Official Greenhouse Gas Inventory - Environment and Climate Change Canada Data. Table A6.1-14 Emission factors for Energy Mobile Combustion Sources. https://data.ec.gc.ca/data/substances/monitor/canada-s-official-greenhouse-gas-inventory/D-Emission-Factors/?lang=en

Government of Canada (2022b) Canada’s Official Greenhouse Gas Inventory - Environment and Climate Change Canada Data. Table A13-1 Electricity Generation and GHG Emission Details for Canada. https://data.ec.gc.ca/data/substances/monitor/canada-s-official-greenhouse-gas-inventory/C-Tables-Electricity-Canada-Provinces-Territories/?lang=en

Government of Nova Scotia (2019) Full- and whole-tree harvesting policy on Crown lands

Government of Ontario (2022a) Report on forest management: annual summary of Ontario’s forest management activities. Harvest Volume | Volume de recolte. https://open.canada.ca/data/en/dataset/6889a142-7a14-4998-9095-5332bac40703/resource/4fb8aa5b-b974-4ccd-b89d-e3b7c43a5756

Government of Ontario (2022b) Report on forest management: annual summary of Ontario’s forest management activities. Harvest Volume - Undersized | Volume de recolté - Sous-dimensionné. https://open.canada.ca/data/en/dataset/6889a142-7a14-4998-9095-5332bac40703/resource/06cffebe-cf32-4fea-993f-cc775b2dde16

Government of Ontario (2022c) Report on forest management: annual summary of Ontario’s forest management activities. Allowable Area and Volume | Superficie et volume autorisés. https://open.canada.ca/data/en/dataset/6889a142-7a14-4998-9095-5332bac40703/resource/addcbea9-b811-41b4-9c3f-a2fb25057987

Gürel K, Magalhães D, Kazanç F (2022) The effect of torrefaction, slow, and fast pyrolysis on the single particle combustion of agricultural biomass and lignite coal at high heating rates. Fuel 308:122054. https://doi.org/10.1016/j.fuel.2021.122054

Hagenbo A, Antón-Fernández C, Bright RM, Rasse D, Astrup R (2022) Climate change mitigation potential of biochar from forestry residues under boreal condition. Sci Total Environ 807:151044. https://doi.org/10.1016/j.scitotenv.2021.151044

Han S-K, Han H-S (2020) Productivity and cost of whole-tree and tree-length harvesting in fuel reduction thinning treatments using cable yarding systems. For Sci Technol 16(1):41–48. https://doi.org/10.1080/21580103.2020.1712264

Han S-K, Han H-S, Page-Dumroese DS, Johnson LR (2009) Soil compaction associated with cut-to-length and whole-tree harvesting of a coniferous forest. Can J for Res 39(5):976–989. https://doi.org/10.1139/X09-027

Hardy CC (1998) Guidelines for estimating volume, biomass, and smoke production for piled slash. U.S. Department of Agriculture, Forest Service, Pacific Northwest Research Station, Portland, OR, USA

Hartsough BR, Zhang X, Fight RD (2001) Harvesting cost model for small trees in natural stands in the Interior Northwest. Forest Prod J 51(4):54–61

Hazlett PW, Morris DM, Fleming RL (2014) Effects of biomass removals on site carbon and nutrients and jack pine growth in boreal forests. Soil Sci Soc Am J 78(S1):S183–S195. https://doi.org/10.2136/sssaj2013.08.0372nafsc

Head M, Bernier P, Levasseur A, Beauregard R, Margni M (2019) Forestry carbon budget models to improve biogenic carbon accounting in life cycle assessment. J Clean Prod 213:289–299. https://doi.org/10.1016/j.jclepro.2018.12.122

Heath LS, Nichols MC, Smith JE, Mills JR (2010) FORCARB2: An updated version of the U.S. Forest Carbon Budget Model. U.S. Department of Agriculture, Forest Service, Northern Research Station, Newton Square, PA, USA

Helin T, Sokka L, Soimakallio S, Pingoud K, Pajula T (2013) Approaches for inclusion of forest carbon cycle in life cycle assessment—a review. GCB Bioenergy 5(5):475–486. https://doi.org/10.1111/gcbb.12016

Helmisaari H-S, Hanssen KH, Jacobson S, Kukkola M, Luiro J, Saarsalmi A, Tamminen P, Tveite B (2011) Logging residue removal after thinning in Nordic boreal forests: long-term impact on tree growth. For Ecol Manage 261(11):1919–1927. https://doi.org/10.1016/j.foreco.2011.02.015

Homagain K, Shahi C, Luckai N, Sharma M (2015) Life cycle environmental impact assessment of biochar-based bioenergy production and utilization in Northwestern Ontario. Canada J Forest Res 26(4):799–809. https://doi.org/10.1007/s11676-015-0132-y

Huang Q, Song S, Chen Z, Hu B, Chen J, Wang X (2019) Biochar-based materials and their applications in removal of organic contaminants from wastewater: state-of-the-art review. Biochar 1(1):45–73. https://doi.org/10.1007/s42773-019-00006-5

Hytönen J, Moilanen M (2008) Short-term effects of whole-tree harvesting on nutrition of Scots pine on drained peatlands. In: Proceedings of the 13th International Peat Congress. Tullamore, Ireland, pp 8–13

Ighalo JO, Iwuchukwu FU, Eyankware OE, Iwuozor KO, Olotu K, Bright OC, Igwegbe CA (2022) Flash pyrolysis of biomass: a review of recent advances. Clean Technol Environ Policy 24(8):2349–2363. https://doi.org/10.1007/s10098-022-02339-5

[ISO] International Organization for Standardization (2006) ISO 14044:2006 Environmental management - life cycle assessment - requirements and guidelines.

[ISO] International Organization for Standardization (2018) ISO 14067:2018 Greenhouse gases - carbon footprint of products - requirements and guidelines for quantification.

Jakob M, Steckel JC, Jotzo F, Sovacool BK, Cornelsen L, Chandra R, Edenhofer O, Holden C, Löschel A, Nace T, Robins N, Suedekum J, Urpelainen J (2020) The future of coal in a carbon-constrained climate. Nat Clim Chang 10(8):704–707. https://doi.org/10.1038/s41558-020-0866-1

James J, Page-Dumroese D, Busse M, Palik B, Zhang J, Eaton B, Slesak R, Tirocke J, Kwon H (2021) Effects of forest harvesting and biomass removal on soil carbon and nitrogen: two complementary meta-analyses. For Ecol Manage 485:118935. https://doi.org/10.1016/j.foreco.2021.118935

Jeffery S, Abalos D, Prodana M, Bastos AC, van Groenigen JW, Hungate BA, Verheijen F (2017) Biochar boosts tropical but not temperate crop yields. Environ Res Lett 12(5):053001. https://doi.org/10.1088/1748-9326/aa67bd

Johnson L, Lippke B, Oneil E (2012) Modeling biomass collection and woods processing life-cycle analysis. Forest Prod J 62(4):258–272. https://doi.org/10.13073/FPJ-D-12-00019.1

Johnson MC, Halofsky JE, Peterson DL (2013) Effects of salvage logging and pile-and-burn on fuel loading, potential fire behaviour, fuel consumption and emissions. Int J Wildland Fire 22(6):757–769

Kalu S, Kulmala L, Zrim J, Peltokangas K, Tammeorg P, Rasa K, Kitzler B, Pihlatie M, Karhu K (2022) Potential of biochar to reduce greenhouse gas emissions and increase nitrogen use efficiency in boreal arable soils in the long-term. Front Environ Sci 10:914766. https://doi.org/10.3389/fenvs.2022.914766

Keske C, Godfrey T, Hoag DLK, Abedin J (2020) Economic feasibility of biochar and agriculture coproduction from Canadian black spruce forest. Food Energy Security 9(1):e188. https://doi.org/10.1002/fes3.188

Klinger J, Carpenter DL, Thompson VS, Yancey N, Emerson RM, Gaston KR, Smith K, Thorson M, Wang H, Santosa DM, Kutnyakov I (2020) Pilot plant reliability metrics for grinding and fast pyrolysis of woody residues. ACS Sustain Chem Eng 8(7):2793–2805. https://doi.org/10.1021/acssuschemeng.9b06718

Klockow PA, D’Amato AW, Bradford JB (2013) Impacts of post-harvest slash and live-tree retention on biomass and nutrient stocks in Populus tremuloides Michx.-dominated forests, northern Minnesota, USA. For Ecol Manage 291:278–288. https://doi.org/10.1016/j.foreco.2012.11.001

Kloss D (2002) Strategic Forest Management Model version 2.0 user guide. Ontario Ministry of Natural Resources; Forest Management Branch; Forest Management Planning Section, Sault Ste. Marie

Kons K, Blagojević B, Mola-Yudego B, Prinz R, Routa J, Kulisic B, Gagnon B, Bergström D (2022) Industrial end-users’ preferred characteristics for wood biomass feedstocks. Energies. https://doi.org/10.3390/en15103721

Kühmaier M, Kral I, Kanzian C (2022) Greenhouse gas emissions of the forest supply chain in Austria in the year 2018. Sustainability. https://doi.org/10.3390/su14020792

Lee Y, Park J, Ryu C, Gang KS, Yang W, Park Y-K, Jung J, Hyun S (2013) Comparison of biochar properties from biomass residues produced by slow pyrolysis at 500°C. Biores Technol 148:196–201. https://doi.org/10.1016/j.biortech.2013.08.135

Lefebvre D, Fawzy S, Aquije CA, Osman AI, Draper KT, Trabold TA (2023) Biomass residue to carbon dioxide removal: quantifying the global impact of biochar. Biochar 5(1):65. https://doi.org/10.1007/s42773-023-00258-2

Lehmann J, Cowie A, Masiello CA, Kammann C, Woolf D, Amonette JE, Cayuela ML, Camps-Arbestain M, Whitman T (2021) Biochar in climate change mitigation. Nat Geosci 14(12):883–892. https://doi.org/10.1038/s41561-021-00852-8

Leinonen I (2022) A general framework for including biogenic carbon emissions and removals in the life cycle assessments for forestry products. Int JLife Cycle Assess 27(8):1038–1043. https://doi.org/10.1007/s11367-022-02086-1

Li C, Sun Y, Zhang L, Li Q, Zhang S, Hu X (2022) Sequential pyrolysis of coal and biomass: Influence of coal-derived volatiles on property of biochar. Appl Energy Combustion Sci 9:100052. https://doi.org/10.1016/j.jaecs.2021.100052

Maaoui A, Ben Hassen Trabelsi A, Ben Abdallah A, Chagtmi R, Lopez G, Cortazar M, Olazar M (2023) Assessment of pine wood biomass wastes valorization by pyrolysis with focus on fast pyrolysis biochar production. J Energy Inst 108:101242. https://doi.org/10.1016/j.joei.2023.101242

Maroušek J, Trakal L (2022) Techno-economic analysis reveals the untapped potential of wood biochar. Chemosphere 291:133000. https://doi.org/10.1016/j.chemosphere.2021.133000

McKechnie J, Colombo S, Chen J, Mabee W, MacLean HL (2011) Forest bioenergy or forest carbon? Assessing trade-offs in greenhouse gas mitigation with wood-based fuels. Environ Sci Technol 45(2):789–795. https://doi.org/10.1021/es1024004

Meil J, Bushi L, Garrahan P, Aston R, Gingras A, Elustondo D (2009) Status of energy use in Canadian wood products sector. Natural Resources Canada, Ottawa, Ontario, Canada

Meyer S, Bright RM, Fischer D, Schulz H, Glaser B (2012) Albedo impact on the suitability of biochar systems to mitigate global warming. Environ Sci Technol 46(22):12726–12734. https://doi.org/10.1021/es302302g

Moreau L, Thiffault E, Cyr D, Boulanger Y, Beauregard R (2022) How can the forest sector mitigate climate change in a changing climate? Case studies of boreal and northern temperate forests in eastern Canada. Forest Ecosystems 9:100026. https://doi.org/10.1016/j.fecs.2022.100026

Morris DM, Kwiaton MM, Duckert DR (2014) Black spruce growth response to varying levels of biomass harvest intensity across a range of soil types: 15-year results. Can J for Res 44(4):313–325. https://doi.org/10.1139/cjfr-2013-0359

Mott CM, Hofstetter RW, Antoninka AJ (2021) Post-harvest slash burning in coniferous forests in North America: a review of ecological impacts. For Ecol Manage 493:119251. https://doi.org/10.1016/j.foreco.2021.119251

Nance E (2023) Slash-pile burning in Bristish Columbia: management challenges, emissions uncertainties, and alternative practices. Master’s Thesis, University of British Columbia

Natural Resources Canada (2022) The state of Canada’s forests—annual report 2022. Natural Resources Canada, Ottawa, Ontario, Canada

Oneil EE, Puettmann ME (2017) Chapter 2: Life cycle assessment of forest residue recovery for small scale bioenergy systems. In: Oneil EE, Comnick JM, Rogers LW, and Puettman ME, eds. Waste to wisdom: Integrating feedstock supply, fire risk and life cycle assessment into a wood to energy framework

Ontario Ministry of Natural Resources (2010) Forest management guide for conserving biodiversity at the stand and site scales. Ontario Ministry of Natural Resources, Toronto, Ontario, Canada

Papari S, Hawboldt K (2015) A review on the pyrolysis of woody biomass to bio-oil: Focus on kinetic models. Renew Sustain Energy Rev 52:1580–1595. https://doi.org/10.1016/j.rser.2015.07.191

Patel MR, Rathore N, Panwar NL (2021) Influences of biochar in biomethanation and CO2 mitigation potential. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-01855-6

Peters JF, Iribarren D, Dufour J (2015) Biomass pyrolysis for biochar or energy applications? A life cycle assessment. Environ Sci Technol 49(8):5195–5202. https://doi.org/10.1021/es5060786

Pierobon F, Sifford C, Velappan H, Ganguly I (2022) Air quality impact of slash pile burns: Simulated geo-spatial impact assessment for Washington State. Sci Total Environ 818:151699. https://doi.org/10.1016/j.scitotenv.2021.151699

Premer MI, Froese RE (2018) Incidental effects of cut-to-length harvest systems and residue management on Populus tremuloides (Michx.) regeneration and yield. Forest Sci 64(4):442–451. https://doi.org/10.1093/forsci/fxx019

Preston CM, Schmidt MWI (2006) Black (pyrogenic) carbon: a synthesis of current knowledge and uncertainties with special consideration of boreal regions. Biogeosciences 3(4):397–420. https://doi.org/10.5194/bg-3-397-2006

Puettmann M, Sahoo K, Wilson K, Oneil E (2020) Life cycle assessment of biochar produced from forest residues using portable systems. J Clean Prod 250:119564. https://doi.org/10.1016/j.jclepro.2019.119564

Rajabi Hamedani S, Kuppens T, Malina R, Bocci E, Colantoni A, Villarini M (2019) Life cycle assessment and environmental valuation of biochar production: two case studies in Belgium. Energies. https://doi.org/10.3390/en12112166

Ralevic P, Ryans M, Cormier D (2010) Assessing forest biomass for bioenergy: Operational challenges and cost considerations. For Chron 86(1):43–50. https://doi.org/10.5558/tfc86043-1

Ravi S, Sharratt BS, Li J, Olshevski S, Meng Z, Zhang J (2016) Particulate matter emissions from biochar-amended soils as a potential tradeoff to the negative emission potential. Sci Rep 6(1):35984. https://doi.org/10.1038/srep35984

Roberts KG, Gloy BA, Joseph S, Scott NR, Lehmann J (2010) Life cycle assessment of biochar systems: estimating the energetic, economic, and climate change potential. Environ Sci Technol 44(2):827–833. https://doi.org/10.1021/es902266r

Ronsse F, van Hecke S, Dickinson D, Prins W (2013) Production and characterization of slow pyrolysis biochar: influence of feedstock type and pyrolysis conditions. GCB Bioenergy 5(2):104–115. https://doi.org/10.1111/gcbb.12018

Rousseau L, Venier L, Aubin I, Gendreau-Berthiaume B, Moretti M, Salmon S, Handa IT (2019) Woody biomass removal in harvested boreal forest leads to a partial functional homogenization of soil mesofaunal communities relative to unharvested forest. Soil Biol Biochem 133:129–136. https://doi.org/10.1016/j.soilbio.2019.02.021

Routa J, Asikainen A, Björheden R, Laitila J, Röoser D (2016) Forest energy procurement: State of the art in Finland and Sweden. In: Lund PD, Byrne J, Berndes G, Vasalos IA (eds), Advances in Bioenergy. pp 273–283

Safarian S (2023) To what extent could biochar replace coal and coke in steel industries? Fuel 339:127401. https://doi.org/10.1016/j.fuel.2023.127401

Sahoo K, Bilek E, Bergman R, Mani S (2019) Techno-economic analysis of producing solid biofuels and biochar from forest residues using portable systems. Appl Energy 235:578–590. https://doi.org/10.1016/j.apenergy.2018.10.076

Searchinger TD, Hamburg SP, Melillo J, Chameides W, Havlik P, Kammen DM, Likens GE, Lubowski RN, Obersteiner M, Oppenheimer M, Philip Robertson G, Schlesinger WH, David Tilman G (2009) Fixing a critical climate accounting error. Science 326(5952):527–528. https://doi.org/10.1126/science.1178797

Sgarbossa A, Boschiero M, Pierobon F, Cavalli R, Zanetti M (2020) Comparative life cycle assessment of bioenergy wroduction from different wood pellet supply chains. Forests. https://doi.org/10.3390/f11111127

Shaheen SM, Niazi NK, Hassan NEE, Bibi I, Wang H, Tsang DCW, Ok YS, Bolan N, Rinklebe J (2019) Wood-based biochar for the removal of potentially toxic elements in water and wastewater: a critical review. Int Mater Rev 64(4):216–247. https://doi.org/10.1080/09506608.2018.1473096

Shakoor A, Arif MS, Shahzad SM, Farooq TH, Ashraf F, Altaf MM, Ahmed W, Tufail MA, Ashraf M (2021) Does biochar accelerate the mitigation of greenhouse gaseous emissions from agricultural soil? A global meta-analysis. Environ Res 202:111789. https://doi.org/10.1016/j.envres.2021.111789

Sher F, Yaqoob A, Saeed F, Zhang S, Jahan Z, Klemeš JJ (2020) Torrefied biomass fuels as a renewable alternative to coal in co-firing for power generation. Energy 209:118444. https://doi.org/10.1016/j.energy.2020.118444

Sirico A, Bernardi P, Sciancalepore C, Vecchi F, Malcevschi A, Belletti B, Milanese D (2021) Biochar from wood waste as additive for structural concrete. Constr Build Mater 303:124500. https://doi.org/10.1016/j.conbuildmat.2021.124500

Smith P, Davis SJ, Creutzig F, Fuss S, Minx J, Gabrielle B, Kato E, Jackson RB, Cowie A, Kriegler E, van Vuuren DP, Rogelj J, Ciais P, Milne J, Canadell JG, McCollum D, Peters G, Andrew R, Krey V, Shrestha G, Friedlingstein P, Gasser T, Grübler A, Heidug WK, Jonas M, Jones CD, Kraxner F, Littleton E, Lowe J, Moreira JR, Nakicenovic N, Obersteiner M, Patwardhan A, Rogner M, Rubin E, Sharifi A, Torvanger A, Yamagata Y, Edmonds J, Yongsung C (2016) Biophysical and economic limits to negative CO2 emissions. Nat Clim Chang 6(1):42–50. https://doi.org/10.1038/nclimate2870

Soman H, Kizha AR, Muñoz Delgado B, Kenefic LS, Kanoti K (2020) Production economics: comparing hybrid tree-length with whole-tree harvesting methods. Forestry 93(3):389–400. https://doi.org/10.1093/forestry/cpz065

Sorensen RB, Lamb MC (2016) Crop Yield Response to Increasing Biochar Rates. J Crop Improv 30(6):703–712. https://doi.org/10.1080/15427528.2016.1231728

Spinelli R, Cavallo E, Facello A, Magagnotti N, Nati C, Paletto G (2012) Performance and energy efficiency of alternative comminution principles: chipping versus grinding. Scand J for Res 27(4):393–400. https://doi.org/10.1080/02827581.2011.644577

Spinelli R, Magagnotti N, Aminti G, De Francesco F, Lombardini C (2016) The effect of harvesting method on biomass retention and operational efficiency in low-value mountain forests. Eur J Forest Res 135(4):755–764. https://doi.org/10.1007/s10342-016-0970-y

Spinelli R, Visser R, Björheden R, Röser D (2019) Recovering energy biomass in conventional forest operations: a review of integrated harvesting systems. Current Forestry Reports 5(2):90–100. https://doi.org/10.1007/s40725-019-00089-0

Sterman JD, Siegel L, Rooney-Varga JN (2018) Does replacing coal with wood lower CO2 emissions? Dynamic lifecycle analysis of wood bioenergy. Environ Res Lett 13(1):015007. https://doi.org/10.1088/1748-9326/aaa512

Sun J, Norouzi O, Mašek O (2022) A state-of-the-art review on algae pyrolysis for bioenergy and biochar production. Biores Technol 346:126258. https://doi.org/10.1016/j.biortech.2021.126258

Tan S, Zhou G, Yang Q, Ge S, Liu J, Cheng YW, Yek PNY, Wan Mahari WA, Kong SH, Chang J-S, Sonne C, Chong WWF, Lam SS (2023) Utilization of current pyrolysis technology to convert biomass and manure waste into biochar for soil remediation: a review. Sci Total Environ 864:160990. https://doi.org/10.1016/j.scitotenv.2022.160990

Ter-Mikaelian MT, Colombo SJ, Lovekin D, McKechnie J, Reynolds R, Titus B, Laurin E, Chapman A-M, Chen J, MacLean HL (2015) Carbon debt repayment or carbon sequestration parity? Lessons from a forest bioenergy case study in Ontario. Canada GCB Bioenergy 7(4):704–716. https://doi.org/10.1111/gcbb.12198

Ter-Mikaelian MT, Colombo SJ, Chen J (2016) Greenhouse gas emission effect of suspending slash pile burning in Ontario’s managed forests. For Chron 92(03):345–356. https://doi.org/10.5558/tfc2016-061

Ter-Mikaelian MT, Colombo SJ, Chen J (2021) Harvest volumes and carbon stocks in boreal forests of Ontario. Canada the Forestry Chronicle 97(02):168–178. https://doi.org/10.5558/tfc2021-018

Ter-Mikaelian MT, Chen J, Desjardins SM, Colombo SJ (2023) Can wood pellets from Canada’s boreal eorest reduce net greenhouse gas emissions from energy generation in the UK? Forests. https://doi.org/10.3390/f14061090

Thengane SK, Kung K, York R, Sokhansanj S, Lim CJ, Sanchez DL (2020) Technoeconomic and emissions evaluation of mobile in-woods biochar production. Energy Convers Manage 223:113305. https://doi.org/10.1016/j.enconman.2020.113305

Thiffault E, Béchard A, Paré D, Allen D (2016) Recovery rate of harvest residues for bioenergy in boreal and temperate forests: a review. In: Lund PD, Byrne J, Berndes G, Vasalos IA (eds), Advances in Bioenergy. pp 293–316

Tisserant A, Morales M, Cavalett O, O’Toole A, Weldon S, Rasse DP, Cherubini F (2022) Life-cycle assessment to unravel co-benefits and trade-offs of large-scale biochar deployment in Norwegian agriculture. Resour Conserv Recycl 179:106030. https://doi.org/10.1016/j.resconrec.2021.106030

Titus BD, Brown K, Helmisaari H-S, Vanguelova E, Stupak I, Evans A, Clarke N, Guidi C, Bruckman VJ, Varnagiryte-Kabasinskiene I, Armolaitis K, de Vries W, Hirai K, Kaarakka L, Hogg K, Reece P (2021) Sustainable forest biomass: a review of current residue harvesting guidelines. Energy, Sustainability and Society 11(1):10. https://doi.org/10.1186/s13705-021-00281-w

Verheijen FGA, Jeffery S, van der Velde M, Penížek V, Beland M, Bastos AC, Keizer JJ (2013) Reductions in soil surface albedo as a function of biochar application rate: implications for global radiative forcing. Environ Res Lett 8(4):044008. https://doi.org/10.1088/1748-9326/8/4/044008

Vermillion Forest Management Company (2020) 2020–2030 Sudbury forest management plan. The Vermillion Forest Management Company Ltd.

Wang J, Xiong Z, Kuzyakov Y (2016) Biochar stability in soil: meta-analysis of decomposition and priming effects. GCB Bioenergy 8(3):512–523. https://doi.org/10.1111/gcbb.12266

Wang C, Mei J, Zhang L (2021) High-added-value biomass-derived composites by chemically coupling post-consumer plastics with agricultural and forestry wastes. J Clean Prod 284:124768. https://doi.org/10.1016/j.jclepro.2020.124768

Woolf D, Amonette JE, Street-Perrott FA, Lehmann J, Joseph S (2010) Sustainable biochar to mitigate global climate change. Nat Commun 1(1):56. https://doi.org/10.1038/ncomms1053

Wright CS, Evans AM, Restaino JC (2017) Decomposition rates for hand-piled fuels. Research Note PNW-RN-574. U.S. Department of Agriculture, Forest Service, Pacific Northwest Research Station, Seattle, Washington.