Abstract

Biochar is a material derived from biomass pyrolysis that is used in urban applications. The environmental impacts of new biochar products have however not been assessed. Here, the life cycle assessments of 5 biochar products (tree planting, green roofs, landscaping soil, charcrete, and biofilm carrier) were performed for 7 biochar supply-chains in 2 energy contexts. The biochar products were benchmarked against reference products and oxidative use of biochar for steel production. Biochar demand was then estimated, using dynamic material flow analysis, for a new city district in Uppsala, Sweden. In a decarbonised energy system and with high biochar stability, all biochar products showed better climate performance than the reference products, and most applications outperformed biomass use for decarbonising steel production. The climate benefits of using biochar ranged from − 1.4 to − 0.11 tonne CO2-eq tonne−1 biochar in a decarbonised energy system. In other environmental impact categories, biochar products had either higher or lower impacts than the reference products, depending on biochar supply chain and material substituted, with trade-offs between sectors and impact categories. However, several use-phase effects of biochar were not included in the assessment due to knowledge limitations. In Uppsala’s new district, estimated biochar demand was around 1700 m3 year−1 during the 25 years of construction. By 2100, 23% of this biochar accumulated in landfill, raising questions about end-of-life management of biochar-containing products. Overall, in a post-fossil economy, biochar can be a carbon dioxide removal technology with benefits, but biochar applications must be designed to maximise co-benefits.

Article Highlights

-

Multiple life cycle assessments of novel urban biochar applications were performed.

-

Urban biochar use has better climate impact than references, when biochar stability is high and energy is low-carbon.

-

Biochar products lead to some shifts in environmental burdens and will create new types of urban waste.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Several cities in Sweden have set ambitious climate and socio-environmental goals. Climate change goals generally include reaching carbon neutrality between 2030 and 2050, and achieving net-negative emissions thereafter, which will require removal of carbon dioxide from the atmosphere. A major carbon dioxide removal (CDR) technology deemed possible in Sweden is biochar production and use. Biochar, the carbon-rich residue derived from biomass pyrolysis (Lehmann and Joseph 2009), is regarded as having a higher readiness than other CDR technologies as it is already available at small and medium scales, while large-scale reactors are being developed (Nemet et al. 2018). Besides, various actors in Sweden (municipalities, public and private companies) have already invested in biochar production facilities.

1.1 Biochar in urban areas

The increasing interest in biochar production near urban areas is motivated, beyond CDR, by the multiple applications that biochar can have within urban areas and the availability of low-grade biomass for biochar production in these areas (Bolan et al. 2021). The most well-established application of biochar in Sweden is in constructed soils in urban environments. Trees planted in hard-paved areas, suffering from soil compaction, have been re-planted in blends of macadam, biochar and compost since 2012 (Stockholm Stad 2020). Today, biochar-macadam structural soils are used for tree planting and rain-gardens in several Swedish cities, also contributing to storm-water management. Since 2020, biochar has been added to lightweight mineral soils used in extensive green roofs (Pettersson 2020). Several soil manufacturers also now offer landscaping soil containing biochar as part of their standard catalogue (Hasselfors 2021).

In parallel, several new biochar applications are being developed. Adding small biochar fractions to concrete mixes is currently being tested, first for the production of carbon–neutral charcrete elements like garden tiles, tree pits or benches (Vinnova 2021). Biochar for filtering applications is also being investigated (Shaheen et al. 2019; Jayakumar et al. 2021), but commercial applications are not yet common in Sweden. While biochar filters for removal of contaminants such as per- and polyfluoroalkyl substances are currently excluded from commercial applications in Sweden (McCleaf 2020), the use of biochar as a support for biofilm growth and carbon oxidation in water has shown promising results (Perez-Mercado et al. 2018). Other applications, such as biochar-enriched asphalt, biochar-mortar, activated biochar or carbon fillers for electronics, also exist but were not included in the scope of the present work.

While urban applications of biochar are expanding, the potential environmental impacts of these new products have not yet been quantified in life cycle assessment (LCA) studies or benchmarked against current technologies. In addition, the bioeconomy poses the challenge that the climate impact of bio-based products (whether bioenergy, biomaterials, or biorefineries) is usually highly dependent on the type of biomass used, its supply-chain, the time perspective, reference land uses, and modelling choices (Ahlgren et al. 2015; Brandão et al. 2021). In the case of biochar-based products, the type of biomass, the biochar properties, and the design of the biochar product may significantly influence the environmental footprint of the final product. In addition, a common criticism of using biochar for carbon (C) sequestration is that the biochar could instead be used as a fuel (Peters et al. 2015) replacing e.g. the use of coal and coke in the metallurgy industry (Riva et al. 2019) for which projects exist in Sweden (Envigas 2020). Few previous LCA studies have performed comparisons between oxidative and non-oxidative uses of biochar (Peters et al. 2015) or have included the benefits of the use of biochar products in terms of material substitutions (Fryda et al. 2019). Therefore, there is a need to apply LCA to the new urban uses of biochar, considering these effects and the potential variability induced by different biochar supply-chains.

1.2 Uppsala case study: scaling up LCA results

Some cities in Sweden are expecting population growth and therefore new districts are being planned and built. Urban expansion inevitably involves high energy and material consumption during construction, while the choice of infrastructure sets the emissions during the use phase of the district. In Uppsala, Sweden, the municipality is planning the construction of a new city district for 57,000 residents, to be built between 2025 and 2050. The ambition is to test and deploy new technologies, including biochar, with the aim of reducing the district’s environmental impact. In cooperation with the municipality, the district was selected as a case study to estimate the potential for biochar C sequestration via urban biochar applications. Working at the scale of a district allowed to place LCA results at the product level into perspective. From an industrial ecology perspective, the district scale allowed to complement LCA results with material flow dynamics, which is of interest for both the management of carbon sinks and municipal development planning.

1.3 Aims and objectives

The aim of this study was to assess the environmental life cycle impacts of 5 urban applications of biochar (tree, green roof, landscaping soil, charcrete, biofilm) and one oxidative application (pig iron production). Specific objectives of the LCA were to: (i) evaluate the sensitivity of the LCA results for urban biochar applications with respect to biomass, pyrolysis, or reference land use, (ii) quantify the biochar demand and carbon sequestration potential of each urban biochar application, (iii) identify environmental hotspots in the life cycle of each application and its reference, and (iv) rank the environmental benefits provided by the different urban biochar applications, relative to reference technologies. The Uppsala case study was then used to convert the LCA results to the scale of an actual city district, in order to identify the urban biochar applications with the greatest potential for meeting the municipal climate objectives, and to highlight potential differences between LCA results at the product level and LCA results at the district level.

2 Methods

2.1 Scope definition

The main method applied was LCA (Curran 2017). For each biochar product and supply-chain studied, relevant system boundaries were defined. To describe the life cycle of the products, inventory data were then collected from various sources. Finally, the inventory data were used to calculate environmental impacts and these impacts were interpreted, at both the product level and the district level.

2.1.1 System boundaries

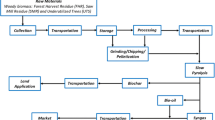

The system boundaries used to describe the 5 urban biochar products, pig iron production, and their references included: production and supply of biochar, production and supply of other materials, manufacture of the biochar product, and its use and disposal (Fig. 1). The production and supply of biochar included biomass production, reference land or biomass use, biomass pyrolysis, and valorisation of the pyrolysis co-products (Fig. 1). The biochar use phase and end-of-life, which are key in assessing biochar carbon sequestration and other side-effects (Azzi et al. 2021), are here part of the lifecycle of the biochar product.

Energy co-production in the biochar supply chain or during disposal of other materials via incineration was handled by substitution. Each of the biochar products was modelled with 7 different biochar supply chains, further described in Sect. 2.2. The impact assessment focused on climate change, characterised using global warming potential with a 100-year time horizon (GWP100), but also included the 15 midpoint impact categories from the International Life Cycle Data (ILCD) system (JRC 2012) relating to resource depletion, human toxicity, and ecotoxicity.

2.1.2 Functional units

Several functional units (FU) were used to answer the research questions. In the sensitivity analysis of type of biochar and its supply chain, the FU was 1 m3 or 1 tonne of biochar produced (cradle-to-gate). For environmental hotspot identification in each product-system, we used 1 unit of product (i.e. 1 tree planted, 1 m2 year of green roof, 1 m3 landscaping soil, 1 concrete tile of dimensions 40 × 40 × 4 cm, 1 m3 water treated, and 1 kg pig iron). For benchmarking biochar applications against each other, the FU selected was: 1 tonne of biochar produced and used. For the Uppsala case study, the FU was set to the amount of final products needed to build and maintain the district over the period 2025–2100 (see Sect. 2.3).

2.2 Life cycle inventory data

2.2.1 Biochar supply chains

In total, 7 biochar supply chains were considered combining 4 biomass types and 3 pyrolysis reactors (Table 1). The 4 biomass types and their reference land or biomass use (RLBU), considered for their relevance in a Swedish context, were: (i) urban garden waste (GW), otherwise combusted for district heat production; (ii) wood pellets (WP), from residues of the wood processing industry, otherwise combusted for district heating; (iii) logging residues (LR), from tops and branches, otherwise left to decay in the forest (Hammar et al. 2015; Azzi et al. 2019); and (iv) short-rotation coppice willow woodchips (WL), cultivated on previously fallow land (Hammar et al. 2014).

Supply of GW included short transportation (10 km in waste collection trucks and private cars) and chipping at the pyrolysis site. WP production was represented by the eponym ecoinvent activity, edited to reflect Swedish energy conditions, and 150 km of regional transportation to site of use was added. Cultivation and harvesting of LR and WL were modelled as in Hammar (2014, 2015), with LR sourced from the region (150 km transport) and WL cultivated on nearby agricultural land (50 km transport). All transport assumptions are presented in Supporting Information (SI). Biomass moisture during transport was set to 50% except for WP, for which it was 10%. For LR, partial drying in the forest was neglected. Biomass was dried before pyrolysis to 10% moisture, using heat from the pyrolysis and external electricity.

Three pyrolysis reactors were considered: syngas-heated reactors with district heat production (i.e. representative of Pyreg and BioMaCon reactors), electricity-heated reactors with district heat production (BioGreen) and mobile syngas-heated reactors without energy recovery (Earth Systems). The reactor type was assumed not to influence biochar yield (set to 25% in all supply chains) or the biochar properties (here, only influenced by the biomass type). The reactor type influenced other part of the LCA, including heat co-production (also influenced by biomass moisture content), electricity input, start-up fuel, quenching water, and reactor manufacturing, supply and disposal (Table 1 and SI). The same direct air emissions from pyrolysis were included for all reactors, based on data from Sørmo et al. (2020); (SI).

Biochar carbon content and bulk density data were taken from laboratory analysis reports provided by VegTech AB for WP pyrolysed in a BioMaCon reactor, by Stockholm Waste and Water AB for GW in a Pyreg reactor, by Hjälmsäter Gård AB for LR in a BioMaCon reactor, and from the literature for WL (Perez-Mercado et al. 2018). Two biochar stability levels were distinguished depending on the final application: 80% for all soil applications, in line with previous works (IPCC 2019), and 95% for charcrete, which is more conservative than the 100% stability recommended in the European Biochar Certificate (EBC) C sink voluntary guidelines (Schmidt et al. 2020). All biochars were assumed to meet the EBC toxicity requirements for use in urban environments (EBC 2012).

2.2.2 Other material production and supply

Apart from biochar, the biochar products and their reference applications consumed other materials, such as Portland cement, gravel, sand, clay, clay granules, macadam in different size fractions, crushed rock, horticultural peat, pumice, compost, horticultural fleece, geotextiles, steel and concrete elements, water and fertilisers. LCA data for production of these materials were taken from the ecoinvent database (version 3.6, cut-off system-model) (Wernet et al. 2016). When relevant, direct heat and electricity inputs were edited to reflect Swedish conditions (see Sect. 2.2.3). Data on macadam production were taken from Erlandsson (2010). For peat, it was assumed that the reference land use was “no harvesting of peatland”. Compost was assumed to be produced from the treatment of park residues and was therefore taken as burden-free. Assumptions for transport to and within Sweden for each material are summarised in SI. Characterised impacts for production and supply of these materials, per m3 and per tonne, are presented in SI. Mass and volume contents of materials in each product studied were calculated based on equations and material data presented in SI. Finally, all ecoinvent activities used without edition, for background modelling, are listed in SI.

2.2.3 Energy system assumptions

In the foreground system, all energy inputs assumed to be consumed in Sweden (electricity, heat, transportation) were replaced by customised activities. This allowed a switch between two configurations: Σavg, representing Swedish average conditions, and Σfossil, representing a fossil-based system (Table 2). Results for both energy system configurations were computed in sensitivity analysis, also expanding the representativeness of the results beyond Sweden. For Σavg, the share of biofuel in the diesel mix was set to 30% and modelled based on rapeseed biofuel from ecoinvent. For Σfossil, electricity conversion losses from high to low voltage were neglected.

2.2.4 Biochar applications

Inventory data for the biochar products were collected through personal communication with companies, city organisations and researchers listed in SI, and taken from the literature. Descriptions and key assumptions made for each biochar product and its reference are presented below.

Tree in hard-surface area

Tree in hard-surface area refers to establishment of a new tree in a structural soil, with or without biochar, as described in Stockholm City’s handbook for urban greening (Stockholm Stad 2020). The product is 1 tree planted, including a 2-year establishment period, with a soil volume of 15 m3, covering a pavement area of about 10 m2. The manufacturing step included production of various parts (steel water inlet, geotextiles, concrete tree pit, nursery tree), provision of macadam-biochar-soil substrate, excavation of former soil and terracing works, machinery use during installation, transportation of materials to site, and watering and fertilising during the tree establishment period.

The main difference between the biochar and reference tree planting techniques was the composition of the structural soil. The main layer of the reference structural soil was made of 80%bvp (bulk volume parts) macadam 32–64 mm and 20%bvp of landscaping B soil (65%bvp sand and 35%bvp horticultural peat), with a bulk density of 1790 kg m−3 (including average moisture at delivery). In the biochar structural soil, the main layer was made of 80%bvp macadam 32–64 mm and 20%bvp biochar-compost mix in equal parts, with a final bulk density of the mixed product of 1700 kg m−3.

The use phase was not explicitly modelled. In particular, potential biochar effects such as reduced fertiliser use, stormwater treatment or improved tree growth were neglected. Due to their lifetime of several decades, disposal of constructed soils is unknown. Discussions with landscaping contractors revealed that constructed soil may become clogged over time, thus requiring maintenance or complete renovation (Fridell 2020). Thus, disposal was modelled as the landfilling of the constructed soil in inert landfill after 50 years.

Extensive green roof

The biochar and reference green roofs modelled were inspired by VegTech AB’s biochar-based sedum mats, which the company started to sell in 2020 (Pettersson 2020). These extensive green roofs have a total thickness of about 6 cm and are made up of two layers: a water-holding base layer made of synthetic material (1 cm) and a mineral soil layer (3 cm) planted with sedum (2 cm) 2 years prior to installation. The sedum mats are cultivated on a bearing layer made from geotextile and plastic netting. The manufacturing stage included production of the base layer from recycled and virgin fibres in Lithuania, open-field cultivation of sedum mats in Sweden (including machinery for sowing and harvesting, fertiliser, irrigation), production of mineral soil substrate, and transport to the installation site. Other components used during installation of the roof, such as border elements in wood and steel, were excluded, as well as energy use for lifting the material onto the roof.

The only difference between the biochar and reference green roofs was the composition of the mineral soil. The reference mineral soil had a bulk density of 1250 kg m−3 (wet weight) and was made up of horticultural peat, sand, crushed rock, scoria granulates, and clay granulates. The biochar mineral soil had similar bulk density, and was made up of horticultural peat, sand, crushed rocks, scoria granulates, clay granulates, green compost and biochar. The biochar content was set to 2.5% bvp, which was the amount used by VegTech AB in its product at the time of the study.

The lifetime of both roofs was set to 50 years. During the use phase, application of fertiliser was assumed to take place annually for the reference roof, and biannually for the biochar roof, following the manufacturer’s recommendations. Disposal was modelled as transport to inert landfill for mineral soil, composting for organic materials, and incineration for plastics.

Landscaping soil

Several types of landscaping soil are used in urban environments and are usually categorised by sieving profile and clay and organic matter content. Here, only one type of landscaping soil was modelled (type A), adapted for planting of trees and bushes or grass lawn (Hasselfors 2020). The reference soil had a bulk density of 1250 kg m−3 and was made up of sand (35% bvp), peat (35% bvp) and clay (30% bvp). In the biochar soil, peat was replaced by 20% bvp biochar and 15% bvp compost, leading to a soil mix with a bulk density of around 910 kg m−3 (varying with biochar type). Inclusion of 20% biochar by volume is the upper limit recommended for soil mixes (Stockholm Stad 2020). Transport distance to site of use was set to 50 km, but no explicit use or disposal phase was included. The soil was assumed to remain at the site where applied.

Charcrete elements

Charcrete is made by mixing biochar, sand, gravel, cement and water in different proportions. In 2020–2021, Ecotopic AB developed several charcrete recipes that yielded a product with adequate properties for urban vegetation systems, e.g. floor tiles and tree-pit foundations (Vinnova 2021). In this study, a charcrete developed by Ecotopic AB was modelled but its composition cannot be fully described due to non-disclosure agreements. The modelled charcrete had a bulk density of around 2300 kg m−3 (similar to normal concrete) and a biochar to cement mass ratio within the range 0.15–1. Reference concrete was modelled via the ecoinvent process ‘unreinforced concrete production, with cement CEM II/A, geography CH’, with a bulk density of 2370 kg m−3. The cast product was assumed to be 40 cm × 40 cm × 4 cm floor tiles for urban vegetation systems. Transport distance to site of use and disposal to landfill was set to 50 km in both cases. No explicit use phase or differences in lifetime were modelled.

Biofilm carrier

Moving bed biofilm reactors are a water purification technique that can be used e.g. for carbon oxidation (BOD removal) in drinking water treatment plants. The treatment is performed by microorganisms forming a biofilm attached to carriers floating in the reactor. The reference carrier was assumed to be a K1 Anox Kaldnes carrier, made of extruded virgin high-density polyethylene (specific density 0.96 g cm−3), with a bulk specific surface area of 500 m2 m−3 and a material weight of 145 kg m−3 (McQuarrie and Boltz 2011). A filling rate of 60% (McQuarrie and Boltz 2011) and a reactor size of 1100 m3 for an annual treatment capacity of 7 million m3 water (McCleaf 2020) were assumed. For the biochar carrier alternative, the same reactor volume was assumed to be filled to 100% with raw biochar (McCleaf 2020).

Service lifetime was set to 10 years for both products (McCleaf 2020). Disposal of the spent plastic carrier was incineration (heat and electricity co-generation included), while the biochar carrier was assumed to be landfilled or used in secondary soil applications. Transport distance to site of use and disposal was set to 50 km in both cases.

Pig iron production

Pig iron is the intermediate product of steel manufacturing in a blast furnace. Production of pig iron with biochar was modelled to serve as a benchmark in the trade-off between fossil fuel substitution and carbon sequestration in a Swedish context. Biochar was assumed to replace 100% of the fossil coke and hard coal used in the ‘pig iron production’ process available in ecoinvent 3.6 with rest-of-the-world geography (Classen et al. 2009). The biochar equivalence was calculated based on both carbon and energy content of the materials, and the most conservative outcome (i.e. largest biochar requirement) was selected. The corresponding amount of fossil carbon dioxide emissions was replaced by biogenic carbon. The reference pig iron production process was left unchanged. Transport distance to site of use was set to 50 km, but no explicit use or disposal was modelled.

2.3 City district scenario

2.3.1 Demand for final products

To upscale the LCA results from the product level to the city district level, the total demand for each product was estimated using the 55 parameters listed in SI. The lifecycle of the new city district was divided into a construction phase (2025–2050) and a use & maintenance phase that included some renovation work (2050–2100). The urban construction phase usually has high material and energy intensity, but is constrained in time (Lausselet et al. 2020).

Urban trees were assumed to be planted on both sides along 50 km of road, with an average spacing of 10 m. For each urban tree, a tree pit in charcrete was used. Additional decorative charcrete elements were assumed to be used, at a rate of 0.064 m3 tree−1 (equivalent to 10 tiles with dimensions 40 cm × 40 cm × 4 cm). Green roofs were assumed to be installed on 50% of the 837,800 m2 of roof area, with the remaining roof area being used for photovoltaic panels or simply not usable. Landscaping soil was assumed to be used in both residential yards (i.e. green areas around residential buildings) and public parks. Planted areas of residential yards (437,000 m2) and public parks (184,000 m2) were estimated from Uppsala City’s GIS model of the future district. Soil depths and areas planted with three kinds of planting were taken from Ariluoma (2021). Annual demand for primary drinking water treatment was assumed to increase linearly with residents moving in, reaching 2.9 million m3 year−1 (51 m3 person−1 year−1) in 2050.

Some renovation or replacement of biochar products was included. The structural soil used for urban trees was assumed to have an average lifetime of 50 years (following a normal distribution with a 5-year standard deviation,

~ [50, 5]). Charcrete elements were assumed to have an average lifetime of 100 years (

~ [50, 5]). Charcrete elements were assumed to have an average lifetime of 100 years (

~ [100, 10]) and were therefore replaced only partly during the timeframe of the study. For annual maintenance of the parks and yards, landscaping soil was assumed to be used at a rate of 0.001 m3 year−1 m−2 of planted area. Spent biochar products were assumed to be landfilled, maintaining the carbon sequestration function. In particular, no material cascade was assumed (e.g. spent biofilm carrier could then be used as a soil amendment for constructed soil). Stock-driven material dynamics were calculated using the ODYM python package for dynamic material flow analysis (MFA) (Pauliuk and Heeren 2020).

~ [100, 10]) and were therefore replaced only partly during the timeframe of the study. For annual maintenance of the parks and yards, landscaping soil was assumed to be used at a rate of 0.001 m3 year−1 m−2 of planted area. Spent biochar products were assumed to be landfilled, maintaining the carbon sequestration function. In particular, no material cascade was assumed (e.g. spent biofilm carrier could then be used as a soil amendment for constructed soil). Stock-driven material dynamics were calculated using the ODYM python package for dynamic material flow analysis (MFA) (Pauliuk and Heeren 2020).

2.3.2 Biochar, biomass and land requirements, and climate change mitigation potential

From the dynamic MFA, aggregated biochar demand for the two lifecycle stages of the city district was calculated, both in volume and mass. Four biochar types were considered, WP-S, GW-S, LR-S, and WL-S as they differ in carbon content per unit volume (Table 1). Demand for WP and GW was compared against annual production of WP in Sweden and GW generation in Uppsala. For LR, the land requirement was estimated based on an average yield of 0.5 tonne ha−1 at final felling of forestry (Hammar et al. 2015). For WL, the land requirement was derived using an average yield of 9.2 dry tonnes ha−1 year−1 (Hammar et al. 2014). Finally, climate change mitigation and C sink potentials were calculated using the results from the product LCA.

3 Results

3.1 Sensitivity of climate change impact to biochar type and supply-chain

In Fig. 2, the cradle-to-gate LCA of biochar production (FU = 1 tonne or 1 m3) is used to illustrate the sensitivity of the climate change impact of biochar production to biochar type (carbon content and bulk density) and supply chain (biomass production, reference land or biomass use, reactor type, co-product use) and to the background energy system. In the Swedish-average energy system Σavg (Fig. 2a, b), all biochar supply chains had a net negative climate change impact, with the initial biochar C sink making the largest contribution. Per tonne of biochar, the C sink is influenced only by the carbon content of the biochar (ranging from 69.9% to 93.4%). Per cubic metre of biochar, the C sink is influenced also by the bulk density of the biochar, resulting in about 3 times greater C sink for WP biochar than for the other supply chains (Fig. 2b, d). This is important to bear in mind for applications where biochar content is set by volume. The climate impact from the supply chain excluding C sink was negative for willow biochar (−378 kg CO2-eq tonne−1 biochar) and positive for the other biochars, ranging from 351 to 688 kg CO2-eq tonne−1 biochar. The negative score for WL-S was due to an increase in soil organic carbon stocks in willow cultivation (−577 kg CO2-eq tonne−1 biochar), which outweighed the relatively large direct emissions from fertiliser and diesel use during cultivation (+400 tonne CO2-eq tonne−1 biochar). Biomass production impacts were lower for the other biomass types, as they required less inputs than cultivated bioenergy crops. Operation of the pyrolysis reactor (S, E, or M) led to smaller variations. Electricity-heated reactors (E) had a slightly higher impact than syngas-heated reactors (S and M), which was partly compensated for by the greater amount of co-produced district heat. Net transport impact varied slightly between the supply chains. Reactor manufacturing and disposal made a negligible contribution (< 10 kg CO2-eq tonne−1 biochar).

Climate change impact of biochar production for 7 biochar supply chains, expressed per tonne (a, c) and per cubic metre (b, d) of biochar, in two background energy systems (Σavg—a, b and Σfossil—c, d). WP: wood pellets, GW: garden waste, LR: logging residues, WL: willow woodchips; S: syngas-heated reactor, E: electricity-heated reactor, M: mobile syngas-heated reactor; RLBU = reference land or biomass use. A cross indicates the net impact, while a dot indicates the net impact excluding the biochar C sink. Note: differences in vertical scale

In the fossil-based energy system Σfossil (Fig. 2c, d), all energy-consuming and energy producing processes made much larger contributions. When the RLBU was an energy use (WP, GW), the net climate change impact was near zero because the reference use of biomass displaced district heat from natural gas, offsetting the benefits from the biochar C sink and energy co-production during pyrolysis. For LR and WL, the RLBU did not involve energy, and therefore the net impact remained negative. However, in this context it would still be preferable, from a climate change mitigation perspective, to use the biomass for bioenergy without biochar production.

3.2 Comparison of biochar urban applications

In this section, the biochar products are compared to their respective reference product, in the Swedish average energy system Σavg, to identify environmental hotspots and shifts in environmental burdens.

3.2.1 Climate change impact

All biochar products provided a reduction in climate change impact compared with the reference technology (Fig. 3), with the reductions varying from 14 to 353%. For most products, biochar from WP and WL had the lowest climate change impacts due to the high carbon content per volume of biochar for WP, and the additional soil carbon sink in willow cultivation for WL. Even when the biochar C sink was not taken into account, most biochar products had a lower climate impact than the respective reference product (−124% to −4%). Exceptions were charcrete (+ 62% to + 130%), because of the high cement content in the product composition modelled, and trees planted using WP biochar (+14%). Not taking into account the biochar C sink is informative and can be interpreted in several ways: (i) as a worst-case scenario or precautionary principle, since biochar stability is uncertain, or (ii) because the “rights” for the biochar C sink may have been traded by the biochar producer as a separate financial product. Finally, it is worth noting that the biochar products studied did not always achieve a “net-negative” climate change impact.

Climate change impact for 6 biochar products (a–f) and 7 biochar supply chains, and for their respective reference product (Ref), in energy system Σavg. WP: wood pellets, GW: garden waste, LR: logging residues, WL: willow woodchips; S: syngas-heated reactor, E: electricity-heated reactor, M: mobile syngas-heated reactor. A cross indicates the net impact, while a dot indicates the net impact excluding the biochar C sink

Tree planting. Across biochar supply chains, the transportation of materials during manufacturing and disposal and the use of machinery made the largest positive contributions to the climate change impact. The production of biochar and other materials contributed between 11 and 39% of the emissions excluding C sink. Despite differences in product densities, transport-related emissions varied only slightly between biochar products and reference product (18% difference between the largest and smallest). Green roof. Across biochar supply chains, the production of other materials contributed to about 50% of the impact, several-fold more than the impact from biochar production. Transportation for manufacturing and disposal also accounted for a large part of the impact (43%). Between reference and biochar products, the main difference arose from the production of other materials and fertiliser use during the lifetime of the roof. Landscaping soil. Across biochar supply chains, biochar production and transportation made the highest contributions. Production of other materials, here clay and sand, contributed little to the impact of soil production. Between reference and biochar products, the main difference came from the use of peat in the reference product. Charcrete. As biochar content was set by mass, there was little difference between biochar supply-chains. The main hotspot was the production of other materials, due to the high cement content in the charcrete formulation studied. Biofilm. For the reference product, plastic production and plastic disposal contributed equally to the climate impact. For biochar filters, the main source of impact is the biochar production. Transportation and disposal played a secondary role. Pig iron. Biochar products reduced the emissions from pig iron production by half compared with hard coal and coke. Only in the case of WL, pig iron production approached climate neutrality thanks to the additional soil carbon sequestration in willow cultivation.

3.2.2 Resource use and toxicity impacts

Natural resource use for biochar-based products was either higher or lower than for the reference products, depending on the biochar supply chain and type of product (Fig. 4), contrasting with the clearer picture given by the climate change impacts (Fig. 3). No clear environmental hotspot was identified: the contributions of biochar production, other material production, and transportation (during production or disposal) were all of varying importance depending on the product and the impact category. For instance, supply of other materials for green roofs dominated the impacts except for minerals and metals where impacts were dominated by transportation (Fig. 4b).

Resource use impacts for 6 biochar products (a–f) and 7 biochar supply-chains, and for the reference products (R) in energy system Σavg. The values are expressed in percentages relative to the product with highest impact in each category. WP: wood pellets, GW: garden waste, LR: logging residues, WL: willow woodchips; S: syngas-heated reactor, E: electricity-heated reactor, M: mobile syngas-heated reactor. A dot indicates the net impact

The biochar products derived from WP-E (88% of cases), WP-S (67%), GW-E (58%), and WL-S (54%) more often than not had increased resource use impacts than the reference products. GW-S and LR-S generally had lower resource use impacts than the reference products. This can be related to the lower inputs needed to supply this biomass and the lower electricity use to produce biochar.

Land use impacts were always highest for WL-based products, followed by WP-based products. Land use impacts were low for LR and GW, because these residues were not allocated any direct land use burdens. Water impacts were always highest for products based on WP-E, due to both type of reactor and type of biomass. GW-S and LR-S biochar production made small negative contributions to water impacts, because of the interplay between biomass production impacts, reference biomass use, and pyrolysis energy substitution.

Results for human toxicity and ecotoxicity impacts are provided in SI. Similar to resource use, no simple conclusion could be drawn: biochar products led to either increased or reduced impacts compared with the reference products.

3.2.3 Climate-efficiency ranking

In the Swedish-average energy system Σavg, all biochar products except charcrete achieved as much climate change mitigation, or more, as decarbonising pig iron production, when biochar C sink was included (Fig. 5a). In addition, all biochar products led to net climate change mitigation compared with the reference (i.e. negative net score in Fig. 5a) when biochar C sink was included. When the biochar C sink was excluded, only WP-S tree planting and charcrete performed worse than the reference product. Green roofs were found to be the best performing product, due to both material substitution and fertiliser use reductions. With a mass-based FU, low-density biochar (GW-S) had twice as much benefits from other material substitutions as high-density biochar (WP-S) in all applications with a biochar content set by volume.

In the fossil energy system Σfossil (Fig. 5b), only the biochar products that had large amounts of other materials substituted had net climate change mitigation potential, but the potential was largely reduced or even approached zero. Even fossil fuel substitution in pig iron production was not preferable over production of district heat, substituting natural gas, for both WP-S and GW-S. For biochar to deliver climate change mitigation, it is therefore important that biochar has high stability (above 80%), that the biochar product replaces products with a high climate impact (such as peat or plastics), and that the heat and power supply are decarbonised.

3.3 Uppsala case study

The LCA inventory and climate change impact results were scaled to the district level using the case of Uppsala’s new city district.

3.3.1 Biochar demand and waste flow

At the district level, biochar demand was estimated to be around 43 200 m3 (± 0.8% between biochar types) during the 25-year construction period. This corresponds to an annual average demand of 1728 m3 year−1. During construction, biochar was mainly consumed as landscaping soil, for parks and yards, and as constructed soils for tree planting. Green roofs, concrete elements, and water filtration together represented less than 6% of the demand for biochar.

For maintenance and renovation works between 2050 and 2100, the demand was 18,300 m3 and was concentrated in the last decades of the century (Fig. 6a) with the renovation of constructed soils in hard-paved areas. An equivalent volume of spent biochar material was also sent to disposal during that time (Fig. 6b). Thus, at the end of the study period (2100), biochar was distributed between parks and yards (57%), other urban uses (20%) and landfill (23%).

3.3.2 Carbon sink & climate change mitigation potential

In mass units, biochar demand ranged from to 8 500 (LR) to 21 300 (WP) tonnes, leading to a wide range of biochar C sink and climate change mitigation potential values (Table 3). It can be noted that while green roofs had the largest climate change mitigation benefits at the product level (Fig. 5), the effect was limited at the district level due to limited roof area compared with the size of other biochar markets (Table 3). Overall, substitution of reference products with biochar products led to the mitigation of 4.4 (WP-S) to 30 (WL-S) 103 tonnes CO2-eq, besides the biochar C sink (Table 3).

3.3.3 Biomass and land requirement

The biochar demand was also converted to biomass requirement (Table 3), and where possible, to land requirement. For WP, the annual demand during construction (3400 tonnes year−1) represented 0.3% of Swedish annual WP production in 2020. For GW, the annual demand during construction (1700 tonnes year−1) was within the same range as the amount of GW collected at recycling stations in Uppsala (Uppsala Vatten 2020). The total demand for LR corresponded to harvesting of residues at final felling of forestry operation over an area of more than 2 700 ha year−1 for 25 years. For comparison, about 200,000 ha are felled annually in Sweden (Swedish Forest Agency 2020). For WL, 203 hectares needed to be cultivated with willow for 25 years to meet the demand during city district construction.

4 Discussion

4.1 Modelling limitations

4.1.1 Biochar properties

We illustrated how different biochar bulk densities and carbon content could influence the carbon footprint of biochar products (Figs. 2, 3). However, the biochars may also differ with respect to other properties, such as surface area, water-holding capacity or ash content. Despite these potential differences, it was assumed that the resulting biochar products had similar performance. For soil applications (tree, roof, landscaping) in particular, it was unclear to what extent such material differences (at constant biochar volume content) would lead to different products because several mechanisms are at play simultaneously. For water biofilm, Perez-Mercado (2018) found that a wide variety of biochar types all performed well for carbon oxidation. For charcrete, on-going experiments have also been performed with various biochars leading to useable products (Vinnova 2021). Our results demonstrate the importance of biochar product manufacturers disclosing not only the volume content of biochar, but also disclosing (or keeping track of) other biochar supply chain information, e.g. biomass origin, pyrolysis conditions, and biochar properties. Voluntary certificates like the EBC are a step in that direction, but are not complete (EBC 2012).

4.1.2 Product design variability

For each product, a specific design was modelled even though multiple product designs may exist. For instance, trees planted in urban areas may have access to root volumes in the range of 10 to 20 m3, owing to different street dimensions and terrace depth. Further, constructed soil designs previously included a 5-cm base layer of pure powdered biochar (Stockholm Stad 2020). Likewise, the green roof modelled had a thickness of 3 cm, but other types of green roofs exist (e.g. designed for different roof slopes or carrying capacity) (Cao et al. 2014). These design variations will lead to different material requirements and different contributions to environmental impacts in LCA, which are of importance for city planners. In this study, however, both the reference and biochar products had the same design, leading to meaningful comparisons. The parameterised model and tools developed in the study can be re-used and adapted for different product designs.

4.1.3 Biochar effects

Biochar is expected to deliver beneficial side-effects during the use phase of some biochar-products (Azzi et al. 2021). The only side-effect included here was reduced fertiliser use for green roof maintenance, since clear recommendations were provided by the manufacturer. For tree planting and green roofs, it is commonly mentioned that biochar can affect stormwater quality and quantity (Cao et al. 2014). However, divergent observations have been made in Stockholm so far, and little research has been published on the subject. Trees planted in biochar-based constructed soils are also generally expected to display improved growth. Ariluoma (2021) for instance assumed that trees planted with biochar would have improved condition (from “good” to “excellent”) and reduced mortality (from 2 to 1%), which in turn could lead to increased biogenic carbon stock in the trees. However, the long-term permanence of this carbon stock can be questioned as 1% mortality implies that 34% of the originally planted trees will die in a 50-year timeframe (Ariluoma et al. 2021). Finally, differences in lifetime between biochar and reference products were not accounted for here, as they are mostly unknown today.

4.1.4 Material flows

In the Uppsala case study, we estimated biochar demand for several applications with various degrees of confidence and constraints. Biochar demand in the district could have been higher if other product designs had been chosen or if larger markets had been assumed (e.g. green roofs covering a larger area, concrete elements used more extensively).

The Uppsala case study also allowed estimation of flows of waste biochar generated up to the end of the century, a rarely discussed topic in the literature. It is worth noting that the total waste flow is in fact larger than that shown in Fig. 6b since biochar is mixed with other products (soil, macadam, concrete). In the present analysis, this annual waste flow and its peak were mainly set by the lifetime (50 years) of the constructed soils for trees. The actual lifetime of these constructed soils is currently unknown, leading to key uncertainty (Fridell 2020).

The composition of biochar-material blends will also affect how they can be recycled or re-used. Here, the worst case, landfilling, was modelled. Biochar-material blends could also be re-used in secondary applications, e.g. mineral soil from green roofs can be re-used for new roofs (Pettersson 2020). It is worth noting that recycling of biochar would lead to lower demand for primary biochar in the future, and thus lower the total C sink generated. In addition, since the biochar C sink is meant to be long-term, it is important to consider how biochar is dispersed in the technosphere over time. The modelling did not include biochar losses to the environment during the use phase, e.g. via water drainage and erosion from constructed soils, parks, and roofs, although such losses have been observed in agriculture (Major et al. 2010; Kätterer et al. 2019) and conceptualised elsewhere (Azzi et al. 2021).

4.1.5 Climate change impact metric

In both the LCA and the MFA, climate change potential impacts were characterised using GWP100, a static impact category. A recent LCA study has shown that biochar climate impacts are robust to the time horizon selected for GWP, but also to global temperature potential (Tisserant et al. 2021). However, in the MFA, the deployment of biochar spanned several decades and maintenance activities were studied up to the year 2100. While it is common to neglect these temporal aspects (Pauliuk et al. 2013; Lausselet et al. 2020), other approaches combining time-dependent MFA, life cycle inventories, and impact assessment metrics could also have been used (Ericsson et al. 2013, 2017; Beloin-Saint-Pierre et al. 2020).

4.1.6 Parameter variability not investigated

In all biochar supply chains, biochar yield was set to an average value of 25%. However, different pyrolysis setups can lead to different product distributions and compositions (Woolf et al. 2014), which usually control the trade-off between bioenergy generation and carbon sequestration (Azzi et al. 2019). Another set of parameters kept unchanged was transport distances. In this study, distances were selected to represent generic conditions for South-Central Sweden, and for several materials used, the main source of climate impact was transportation rather than actual production (e.g. sand, clay, gravel).

4.2 Interpretation of results

4.2.1 Biochar emission factor

Figure 2 present cradle-to-gate emission factors for biochars. Excluding soil carbon stock changes, climate impacts from biochar production were in the range 0.20 (willow) to 0.69 (pellets) tonne CO2-eq tonne biochar−1 in the Swedish average energy system. Despite differences in scope, biomass type, and pyrolysis yield, previous studies reported similar values: 0.36 for willow (Leppäkoski et al. 2021), 0.85 for miscanthus pellets (Bartocci et al. 2016), 0.29–0.35 for straw residues (Roberts et al. 2010), or 0.065 for yard waste (Roberts et al. 2010). As stressed earlier, the range is further skewed by varying bulk densities when expressing impact per cubic metre of biochar, which is the unit used in most urban applications.

4.2.2 At the product-level

Tisserant and colleagues (2019) reviewed the climate change impact of biochar systems in 34 LCA studies (including C sink, supply-chain emissions, substitutions and soil effects) and found an average value of −0.9 tonne CO2-eq tonne−1 biomass (range −1.5 to 0 tonne CO2-eq tonne−1 biomass). The results in Fig. 5 and SI (with all biochar supply chains) converted to biomass unit were within this range, with an average of −0.73 tonne CO2-eq tonne−1 biomass (−1.4 to −0.11 tonne CO2-eq tonne−1 biomass). The values at the lower end were obtained for low-density biochars used in green roofs, which provided large benefits from substitution of peat.

The most commonly assessed impact category for biochar systems is climate change, but other impact categories are also important to study (Tisserant and Cherubini 2019; Azzi et al. 2021; Terlouw et al. 2021). Using the ILCD impact categories, we showed that other impact categories could be either better or worse, and that the type of biomass used to produce the biochar plays an important role. The results confirmed previous findings that cultivated biomass tends to have higher impacts than residue biomass. However, the amounts of residue biomass available are limited and often already used (e.g. energy recovery from garden waste), and may not be enough to meet demand.

We argued that the LCA of biochar-based products should display results both with and without C sink, in line with previous recommendations (Tisserant and Cherubini 2019; Terlouw et al. 2021). Despite research efforts (Wang et al. 2016; IPCC 2019; Woolf et al. 2021), biochar stability is inherently uncertain, and it is currently not possible to distinguish between the stability of different biochars with high confidence. To comply with the precautionary principle, the products containing biochar should perform better than the reference product they are intended to replace, even without the C sink. In addition, due to the high policy and marketing attraction of CDR, many actors are interested in claiming ownership of the biochar C sink, including biochar producers, biochar product manufacturers, biochar product owners, and negative emissions credit buyers.

Comparing the climate change impact of products and services is more complex for a renewable and bio-based economy than for a fossil-fuel economy because of: (i) the dynamic nature of the biosphere (as opposed to the relatively static character of geological processes), and the (ii) diversity of land management options, cultivated species, and transformation pathways. In LCA terminology, this includes reference land use or alternative fate of biomass, both for the system under study, and for the reference system used for comparisons (Koponen et al. 2018). Here, our main result (that biochar is better than a reference product, or the amount of substitution benefits) depends on assumptions on peat emissions and reference land use, biomass cultivation systems for biochar production, and green waste compost being burden free. All these terms can vary widely with the geographical and technological context.

4.2.3 At the district-level

We estimated an average C sink for the construction of Uppsala’s new city-district of 0.87 to 2.4 103 tonnes CO2 year−1. This amount can be compared to (i) the territorial emissions of the whole Uppsala municipality as reported for 2020, approaching 1 106 tonnes CO2-eq (Jedland 2021), (ii) the national consumption-based GHG emissions for the expected population of the new district, around 0.5 106 tonnes CO2-eq (Naturvårdsverket 2019), or (iii) the expected emissions for the construction of the residential buildings of the new district, estimated by the municipality to be around 20 103 tonnes CO2 year−1 (Jedland 2021). In all cases, the biochar C sink was one to several orders of magnitude lower. Here, an area of further work is to include biochar technologies in existing models that cover the entire urban metabolism, rather than only the activities affected by biochar. This could be applied in municipal planning practice (Byfors and Sundberg 2015) or in research to identify suitable climate mitigation pathways in urban areas (Pauliuk et al. 2013; Lausselet et al. 2020).

It can be difficult to interpret the practical implications of the climate change mitigation potentials presented in Fig. 5 and Table 3, and we want to stress two concepts relevant for the biochar industry: market mixes and market segmentation. First, market mixes refer to the fact that a product or service can be supplied by various technologies, e.g. steel can be produced in blast furnaces with hard coal, but also with bio-coal, or with hydrogen. It is unlikely that only one technology will replace hard-coal furnaces. Rather, a mix of alternatives technologies will be deployed, and the total climate change impact of the future steel sector will be a weighted average of the market mix. Therefore, the reader must bear in mind that biochar-products are not the only option to improve the environmental performance of existing products, and that the market might be shared between these options. Second, market segmentation refers to the fact that biomass and biochar may not be suitable for all applications, e.g. biochar suited for steel application may require a very specific (low) ash content, while soil applications may be less sensitive to this parameter. In other words, within the range of biochar types produced, they may not be perfectly substitutable. Thus, the results do not mean that all biochar types should be used for the highest-ranked applications, as some biochars may not be suitable for these.

5 Conclusion

We performed LCA of 5 biochar products for urban environments, compared them with reference products, benchmarked them against an energy use of biochar, and investigated the effect of their potential deployment in a city district. In an energy system with low-carbon heat and electricity, all biochar products had lower climate change impacts than the reference products when biochar C sequestration was included. Even when biochar C sequestration was excluded, most products had lower climate change impacts than the reference products due to lower use of other greenhouse gas intensive materials. However, in terms of resource use, human toxicity and ecotoxicity, the biochar products assessed gave either increased or decreased potential impacts depending on the biochar supply chain. Biochar produced from waste biomass tended to perform better, but waste biomass is a limited resource. From a biomass use efficiency perspective, biochar products could provide as much or more climate change mitigation as the use of biochar in steel production, but only if biochar stability is high and if other greenhouse-gas intensive materials are substituted. At the district level, we showed that biochar deployment in a future urban residential district would reduce the climate footprint of the district, but that the total biochar C sink was at least one order of magnitude smaller than other greenhouse gas emissions from the district.

Availability of data and materials

Data behind the Figs and tables from the manuscript is to a large extent made available in Excel format as part of the supporting information. In addition, data can be supplied on request.

Code availability

Code for analysis of the modelling results is available online at https://github.com/ntropy-esa/P5_uppsala.

Abbreviations

- BOD:

-

Biological oxygen demand

- CDR:

-

Carbon dioxide removal

- C:

-

Carbon

- EBC:

-

European Biochar Certificate

- FU:

-

Functional unit

- GW:

-

Garden waste

- GWP100 :

-

Global warming potential, with a 100-year time horizon

- ILCD:

-

International Life Cycle Data system

- LCA:

-

Life cycle assessment

- LR:

-

Logging residue

- MFA:

-

Material flow analysis

- PFAS:

-

Per- and polyfluoroalkyl substances

- RLBU:

-

Reference land or biomass use

- WL:

-

Willow woodchips

- WP:

-

Wood pellet

- E:

-

Electricity-heated pyrolysis reactor

- S:

-

Syngas-heated pyrolysis reactor

- M:

-

Mobile syngas-heated pyrolysis reactor

References

Ahlgren S, Björklund A, Ekman A et al (2015) Review of methodological choices in LCA of biorefinery systems—key issues and recommendations. Biofuel Bioprod Biorefin 9:606–619. https://doi.org/10.1002/bbb.1563

Ariluoma M, Ottelin J, Hautamäki R et al (2021) Carbon sequestration and storage potential of urban green in residential yards: a case study from Helsinki. Urban Urban Green 57:126939. https://doi.org/10.1016/j.ufug.2020.126939

Azzi ES, Karltun E, Sundberg C (2019) Prospective life cycle assessment of large-scale biochar production and use for negative emissions in Stockholm. Environ Sci Technol 53:8466–8476. https://doi.org/10.1021/acs.est.9b01615

Azzi ES, Karltun E, Sundberg C (2021) Assessing the diverse environmental effects of biochar systems: an evaluation framework. J Environ Manage 286:112154. https://doi.org/10.1016/j.jenvman.2021.112154

Bartocci P, Bidini G, Saputo P, Fantozzi F (2016) Biochar pellet carbon footprint. Chem Eng Trans 50:217–222. https://doi.org/10.3303/CET1650037

Beloin-Saint-Pierre D, Albers A, Hélias A et al (2020) Addressing temporal considerations in life cycle assessment. Sci Total Environ 743:140700. https://doi.org/10.1016/j.scitotenv.2020.140700

Bolan N, Hoang SA, Beiyuan J et al (2021) Multifunctional applications of biochar beyond carbon storage. Int Mater Rev. https://doi.org/10.1080/09506608.2021.1922047

Brandão M, Azzi E, Novaes RML, Cowie A (2021) The modelling approach determines the carbon footprint of biofuels: the role of LCA in informing decision makers in government and industry. Clean Environ Syst. https://doi.org/10.1016/j.cesys.2021.100027

Byfors S, Sundberg C (2015) Modellering av Uppsala kommuns energisystem och växthusgasutsläpp i LEAP. Uppsala

Cao CTN, Farrell C, Kristiansen PE, Rayner JP (2014) Biochar makes green roof substrates lighter and improves water supply to plants. Ecol Eng 71:368–374. https://doi.org/10.1016/j.ecoleng.2014.06.017

Classen M, Althaus H-J, Blaser S, et al (2009) Life cycle inventories of metals. Final report ecoinvent data v2.1, No 10. Dübendorf

Curran MA (2017) Overview of goal and scope definition in life cycle assessment. In: Curran MA (ed) Goal and scope definition in life cycle assessment. Springer, Netherlands, Dordrecht, pp 1–62

EBC (2012) European Biochar Certificate - Guidelines for a Sustainable Production of Biochar. Version 9.5E of 1st August 2021. Arbaz, Switzerland

Envigas AB (2020) envigas. https://www.envigas.com/. Accessed 7 May 2021

Ericsson N, Porsö C, Ahlgren S et al (2013) Time-dependent climate impact of a bioenergy system—methodology development and application to Swedish conditions. GCB Bioenergy 5:580–590. https://doi.org/10.1111/gcbb.12031

Ericsson N, Sundberg C, Nordberg Å et al (2017) Time-dependent climate impact and energy efficiency of combined heat and power production from short-rotation coppice willow using pyrolysis or direct combustion. GCB Bioenergy 9:876–890. https://doi.org/10.1111/gcbb.12415

Erlandsson M (2010) Miljödata för krossprodukter och naturgrus—generell byggproduktinformation (BPI) för bygg- och fastighetssektorn. IVL Swedish Environmental Institute, Stockholm, Sweden

Fridell K (2020) Personal communication with representative for Edges AB

Fryda L, Visser R, Schmidt J (2019) Biochar replaces peat in horticulture: environmental impact assessment of combined biochar and bioenergy production. Detritus 05:132–149. https://doi.org/10.31025/2611-4135/2019.13778

Hammar T, Ericsson N, Sundberg C, Hansson P-A (2014) Climate impact of willow grown for bioenergy in Sweden. BioEnergy Res 7:1529–1540. https://doi.org/10.1007/s12155-014-9490-0

Hammar T, Ortiz C, Stendahl J et al (2015) Time-dynamic effects on the global temperature when harvesting logging residues for bioenergy. BioEnergy Res 8:1912–1924. https://doi.org/10.1007/s12155-015-9649-3

Hasselfors AB (2020) Växtjord typ A (Planting soil of type A). https://www.hasselforsgarden.se/produkter/vaxtjord-typ-a/. Accessed 10 Apr 2021

Hasselfors AB (2021) Hasselfors landscaping product catalogue. https://www.hasselforsgarden.se/produktkatalog-landscaping-2021/. Accessed 7 May 2021

IPCC (2019) 2019 refinement to the 2006 IPCC guidelines for national greenhouse gas inventories. https://www.ipcc-nggip.iges.or.jp/public/2019rf/index.html

Jayakumar A, Wurzer C, Soldatou S et al (2021) New directions and challenges in engineering biologically-enhanced biochar for biological water treatment. Sci Total Environ 796:148977. https://doi.org/10.1016/j.scitotenv.2021.148977

Jedland D (2021) Personal communication with representative for Uppsala municipality

JRC (2012) Characterisation factors of the ILCD Recommended Life Cycle Impact Assessment methods. Database and Supporting Information, 1st edn. Luxemburg

Kätterer T, Roobroeck D, Andrén O et al (2019) Biochar addition persistently increased soil fertility and yields in maize-soybean rotations over 10 years in sub-humid regions of Kenya. F Crop Res 235:18–26. https://doi.org/10.1016/j.fcr.2019.02.015

Koponen K, Soimakallio S, Kline KL et al (2018) Quantifying the climate effects of bioenergy—choice of reference system. Renew Sustain Energy Rev 81:2271–2280. https://doi.org/10.1016/j.rser.2017.05.292

Lausselet C, Urrego JPF, Resch E, Brattebø H (2020) Temporal analysis of the material flows and embodied greenhouse gas emissions of a neighborhood building stock. J Ind Ecol 25:1088–1980. https://doi.org/10.1111/jiec.13049

Lehmann J, Joseph S (2009) Biochar for environmental management : science and technology. Sterling, Earthscan, London

Leppäkoski L, Marttila MP, Uusitalo V et al (2021) Assessing the carbon footprint of biochar from willow grown on marginal lands in finland. Sustain 13:1–18. https://doi.org/10.3390/su131810097

Major J, Rondon M, Molina D et al (2010) Maize yield and nutrition during 4 years after biochar application to a Colombian savanna oxisol. Plant Soil 333:117–128. https://doi.org/10.1007/s11104-010-0327-0

McCleaf P (2020) Personal communication with representative for Uppsala Vatten och Avfall AB

McQuarrie JP, Boltz JP (2011) Moving bed biofilm reactor technology: process applications, design, and performance. Water Environ Res 83:560–575. https://doi.org/10.2175/106143010X12851009156286

Naturvårdsverket (2019) Fördjupad analys av den svenska klimatomställningen 2019. Industrin i fokus.

Nemet G, Callaghan M, Creutzig F et al (2018) Negative emissions—part 3: innovation and upscaling. Environ Res Lett 13:63003. https://doi.org/10.1088/1748-9326/aabff4

Pauliuk S, Heeren N (2020) ODYM—an open software framework for studying dynamic material systems: principles, implementation, and data structures. J Ind Ecol 24:446–458. https://doi.org/10.1111/jiec.12952

Pauliuk S, Sjöstrand K, Müller DB (2013) Transforming the norwegian dwelling stock to reach the 2 degrees celsius climate target. J Ind Ecol 17:542–554. https://doi.org/10.1111/j.1530-9290.2012.00571.x

Perez-Mercado LF, Lalander C, Berger C, Dalahmeh SS (2018) Potential of biochar filters for onsite wastewater treatment: effects of biochar type. Phys Prop Operating Conditions Water. https://doi.org/10.3390/w10121835

Peters JF, Iribarren D, Dufour J (2015) Biomass pyrolysis for biochar or energy applications? A life cycle assessment. Environ Sci Technol 49:5195–5202. https://doi.org/10.1021/es5060786

Pettersson L (2020) Personal communication with representative for VegTech AB

Riva L, Nielsen HK, Skreiberg Ø et al (2019) Analysis of optimal temperature, pressure and binder quantity for the production of biocarbon pellet to be used as a substitute for coke. Appl Energy 256:113933. https://doi.org/10.1016/j.apenergy.2019.113933

Roberts KG, Gloy BA, Joseph S et al (2010) Life cycle assessment of biochar systems: estimating the energetic, economic, and climate change potential. Environ Sci Technol 44:827–833. https://doi.org/10.1021/es902266r

Schmidt H-P, Kammann C, Hagemann N (2020) EBC-Guidelines for the Certification of Biochar Based Carbon Sinks. 1–35

Shaheen SM, Niazi NK, Hassan NEE et al (2019) Wood-based biochar for the removal of potentially toxic elements in water and wastewater: a critical review. Int Mater Rev 64:216–247. https://doi.org/10.1080/09506608.2018.1473096

Sørmo E, Silvani L, Thune G et al (2020) Waste timber pyrolysis in a medium-scale unit: emission budgets and biochar quality. Sci Total Environ 718:137335. https://doi.org/10.1016/j.scitotenv.2020.137335

Stockholm Stad (2020) Växtbäddar i Stockholms stad—en handbok 2017 (Planting beds in Stockholm city - Handbook 2017). https://leverantor.stockholm/entreprenad-i-stockholms-offentliga-miljoer/vaxtbaddshandboken/. Accessed 30 Nov 2020

Swedish Forest Agency (2020) Swedish Forest Agency: the gross felling increased in 2019 but is expected to decrease in 2020. https://www.skogsstyrelsen.se/en/news/the-gross-felling-increased-in-2019-but-is-expected-to-decrease-in-2020/. Accessed 31 Aug 2021

Terlouw T, Bauer C, Rosa L, Mazzotti M (2021) Life cycle assessment of carbon dioxide removal technologies: a critical review. Energy Environ Sci 14:1701–1721. https://doi.org/10.1039/D0EE03757E

Tisserant A, Cherubini F (2019) Potentials, limitations, co-benefits, and trade-offs of biochar applications to soils for climate change mitigation. Land. https://doi.org/10.3390/LAND8120179

Tisserant A, Morales M, Cavalett O et al (2021) Life-cycle assessment to unravel co-benefits and trade-offs of large-scale biochar deployment in Norwegian agriculture. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2021.106030

Uppsala Vatten (2020) Uppsala Vatten: Collection record at recycling stations (Insamlingsrekord på återvinningscentralerna). https://www.uppsalavatten.se/nyheter/insamlingsrekord-pa-atervinningscentralerna/. Accessed 31 Aug 2021

Vinnova (2021) Charcrete—the new black in the field of urban green constructions. https://www.vinnova.se/en/p/charcrete---the-new-black-in-the-field-of-urban-green-constructions/. Accessed 7 May 2021

Wang J, Xiong Z, Kuzyakov Y (2016) Biochar stability in soil: meta-analysis of decomposition and priming effects. GCB Bioenergy 8:512–523. https://doi.org/10.1111/gcbb.12266

Wernet G, Bauer C, Steubing B et al (2016) The ecoinvent database version 3 (part I): overview and methodology. Int J Life Cycle Assess 21:1218–1230. https://doi.org/10.1007/s11367-016-1087-8

Woolf D, Lehmann J, Fisher EM, Angenent LT (2014) Biofuels from pyrolysis in perspective: trade-offs between energy yields and soil-carbon additions. Environ Sci Technol 48:6492–6499. https://doi.org/10.1021/es500474q

Woolf D, Lehmann J, Ogle S et al (2021) Greenhouse gas inventory model for biochar additions to soil. Environ Sci Technol. https://doi.org/10.1021/acs.est.1c02425

Acknowledgements

EcoTopic AB, Biokol Produkter AB, Uppsala Vatten AB, Stockholm Exergi AB, VegTech AB, Hasselfors AB, edges AB, Skanska AB.

Funding

The research was funded by Sweden's innovation agency (VINNOVA) under grant number 2016-03392.

Author information

Authors and Affiliations

Contributions

ESA designed the study, collected the data, performed the modelling, analysed the results, and wrote the manuscript. EK contributed to the design of the study, revised the modelling and revised the manuscript. CS contributed to the design of the study, revised the modelling, revised the manuscript, and acquired funding for the research project. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest nor competing interests to declare.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Azzi, E.S., Karltun, E. & Sundberg, C. Life cycle assessment of urban uses of biochar and case study in Uppsala, Sweden. Biochar 4, 18 (2022). https://doi.org/10.1007/s42773-022-00144-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42773-022-00144-3