Abstract

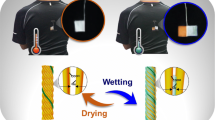

Smart textiles are able to self-adapt to an irregular surface. So, they found new applications in intelligent clothes and equipments, where the properties and functionality of traditional polymeric fibers are insufficient, and hard to be realized. Inspired by the supercontraction behavior of the spider silk, we prepared a spinnable hydrogel to form a sheath-core-like composite yarn, after being coated on cotton yarn. The strong hydrogen bonding between the cotton yarn and the polar groups of the hydrogel provides an outstanding mechanical stability, and the twists insertion forms a spiral-like architecture, which exhibited moisture-responsive super contraction behavior. By structural tailoring the chirality of the fiber twists and coiling extends into homo-chiral and heterochiral architectures, as displays contraction and expansion when is exposed to the moisture. Once the relative humidity is increased from 60 to 90%, a homochiral yarn exhibits 90% contraction, while a heterochiral yarn shows 450% expansion, and the maximum work capacity reached up to 6.1 J/Kg. The super contracted yarn can be re-stretched to its original length manifesting cyclability, which can be exploited to build a smart textile, self-adaptive to irregular surfaces. Such a strategy may be further extended to a wide variety of materials to achieve intelligent textiles from common fiber or yarns.

Similar content being viewed by others

References

Cheng H, Liu J, Zhao Y, Hu C, Zhang Z, Chen N, Jiang L, Qu L. Graphene fibers with predetermined deformation as moisture-triggered actuators and robots. Angew Chem Int Ed Engl 2013;52:10482–6.

Chen P, Xu Y, He S, Sun X, Pan S, Deng J, Chen D, Peng H. Hierarchically arranged helical fibre actuators driven by solvents and vapours. Nat Nanotechnol 2015;10:1077–83.

Foroughi J, Spinks GM, Aziz S, Mirabedini A, Jeiranikhameneh A, Wallace GG, Kozlov ME, Baughman RH. Knitted carbon-nanotube-sheath/spandex-core elastomeric yarns for artificial muscles and strain sensing. ACS Nano 2016;10:9129–35.

Haines CS, Lima MD, Li N, Spinks GM, Foroughi J, Madden JD, Kim SH, Fang S, Jung de Andrade M, Goktepe F, Goktepe O, Mirvakili SM, Naficy S, Lepro X, Oh J, Kozlov ME, Kim SJ, Xu X, Swedlove BJ, Wallace GG, Baughman RH. Artificial muscles from fishing line and sewing thread. Science 2014;343:868–72.

Shi J, Liu S, Zhang L, Yang B, Shu L, Yang Y, Ren M, Wang Y, Chen J, Chen W, Chai Y, Tao X. Smart textile-integrated microelectronic systems for wearable applications. Adv Mater 2020;32:e1901958.

Jost K, Dion G, Gogotsi Y. Textile energy storage in perspective. J Mater Chem A 2014;2:10776–87.

Chen D, Jiang K, Huang T, Shen G. Recent advances in fiber supercapacitors: materials, device configurations, and applications. Adv Mater 2020;32:e1901806.

Zhang Y, Wang H, Lu H, Li S, Zhang Y. Electronic fibers and textiles: recent progress and perspective. iScience 2021;24:102716.

Wang H, Zhang Y, Liang X, Zhang Y. Smart fibers and textiles for personal health management. ACS Nano 2021;15:12497–508.

Lee J, Ko S, Kwon CH, Lima MD, Baughman RH, Kim SJ. Carbon nanotube yarn-based glucose sensing artificial muscle. Small 2016;12:2085–91.

Leng X, Hu X, Zhao W, An B, Zhou X, Liu Z. Recent advances in twisted-fiber artificial muscles. Adv Intell Syst 2020;3:2000185.

Lee SH, Kim TH, Lima MD, Baughman RH, Kim SJ. Biothermal sensing of a torsional artificial muscle. Nanoscale 2016;8:3248–53.

Khattab TA, Fouda MMG, Abdelrahman MS, Othman SI, Bin-Jumah M, Alqaraawi MA, Al FH, Allam AA. Development of illuminant glow-in-the-dark cotton fabric coated by luminescent composite with antimicrobial activity and ultraviolet protection. J Fluoresc 2019;29:703–10.

Zhang X, Ma P. Application of knitting structure textiles in medical areas. Autex Res J 2018;18:181–91.

Li T, Li Y, Zhang T. Materials, structures, and functions for flexible and stretchable biomimetic sensors. Acc Chem Res 2019;52:288–96.

He X, Fang X, Luo B, Liu H, Bian C, Zhu Z. Fundamentals and applications of ion migration induced polymer sensor detecting bending, pressure and shear force. IEEE Instrum Meas Mag 2019;22:13–23.

Cao J, Lu C, Zhuang J, Liu M, Zhang X, Yu Y, Tao Q. Multiple hydrogen bonding enables the self-healing of sensors for human–machine interactions. Angew Chem Int Ed 2017;56:8795–800.

Huang W, Li J, Liu D, Tan S, Zhang P, Zhu L, Yang S. Polyelectrolyte complex fiber of alginate and poly(diallyldimethylammonium chloride): humidity-induced shape memory and mechanical transition. ACS Appl Polym 2020;2:2119–25.

Liu D, Zhu L, Huang W, Yang S. Humidity induced relaxation transition of hydrogen-bonded complex fibers. Polymer 2021;225:123794.

Lima MD, Li N, Jung de Andrade M, Fang S, Oh J, Spinks GM, Kozlov ME, Haines CS, Suh D, Foroughi J, Kim SJ, Chen Y, Ware T, Shin MK, Machado LD, Fonseca AF, Madden JD, Voit WE, Galvao DS, Baughman RH. Electrically, chemically, and photonically powered torsional and tensile actuation of hybrid carbon nanotube yarn muscles. Science 2012;338:928–32.

Foroughi J, Spinks GM, Wallace GG, Oh J, Kozlov ME, Fang S, Mirfakhrai T, Madden JDW, Shin MK, Kim SJ, Baughman RH. Torsional carbon nanotube artificial muscles. Science 2011;334:494–7.

Mu J, Jung de Andrade M, Fang S, Wang X, Gao E, Li N, Kim SH, Wang H, Hou C, Zhang Q, Zhu M, Qian D, Lu H, Kongahage D, Talebian S, Foroughi J, Spinks G, Kim H, Ware TH, Sim HJ, Lee DY, Jang Y, Kim SJ, Baughman RH. Sheath-run artificial muscles. Science 2019;365:150–5.

Cheng Y, Wang R, Chan KH, Lu X, Sun J, Ho GW. A biomimetic conductive tendril for ultrastretchable and integratable electronics, muscles, and sensors. ACS Nano 2018;12:3898–907.

Zhou X, Fang S, Leng X, Liu Z, Baughman RH. The power of fiber twist. Acc Chem Res 2021;54:2624–36.

Jia T, Wang Y, Dou Y, Li Y, Jung de Andrade M, Wang R, Fang S, Li J, Yu Z, Qiao R, Liu Z, Cheng Y, Su Y, Minary-Jolandan M, Baughman RH, Qian D, Liu Z. Moisture sensitive smart yarns and textiles from self-balanced silk fiber muscles. Adv Funct Mater 2019;29:1808241.

Agnarsson I, Dhinojwala A, Sahni V, Blackledge T. Spider silk as a novel high performance biomimetic muscle driven by humidity. J Exp Biol 2009;212:1990–4.

Dou Y, Wang ZP, He W, Jia T, Liu Z, Sun P, Wen K, Gao E, Zhou X, Hu X, Li J, Fang S, Qian D, Liu Z. Artificial spider silk from ion-doped and twisted core-sheath hydrogel fibres. Nat Commun 2019;10:5293.

He W, Qian D, Wang Y, Zhang G, Cheng Y, Hu X, Wen K, Wang M, Liu Z, Zhou X, Zhu M. Protein-like nanogel for spinning hierarchically structured artificial spider silk. Adv Mater 2201843.

Kulshreshtha AK, Patel AR, Baddi NT, Srivastava HC. Studies on never-dried cotton. J Polym Sci A Polym Chem 1977;15:165–83.

Li Y, Leng X, Sun J, Zhou X, Wu W, Chen H, Liu Z. Moisture-sensitive torsional cotton artificial muscle and textile. Chin Phys B 2020;29:048103.

You C, Qin W, Yan Z, Ren Z, Huang J, Ii J, Chang W, He W, Wen K, Yin S, Zhou X, Liu Z. Highly improved water tolerance of hydrogel fibers with a carbon nanotube sheath for rotational, contractile and elongational actuation. J Mater Chem A 2021;9:10240–50.

Gu X, Fan Q, Yang F, Cai L, Zhang N, Zhou W, Zhou W, Xie S. Hydro-actuation of hybrid carbon nanotube yarn muscles. Nanoscale 2016;8:17881–6.

Lee JA, Li N, Haines CS, Kim KJ, Lepro X, Ovalle-Robles R, Kim SJ, Baughman RH. Electrochemically powered, energy-conserving carbon nanotube artificial muscles. Adv Mater 2017;29:1700870.

Acknowledgements

This work was supported by the National Key Research and Development Program of China (Grant # 2019YFE0119600), the National Natural Science Foundation of China (Grants 51973093, U1533122, and 51773094), “Frontiers Science Center for New Organic Matter”, Nankai University, Tianjin, China (Grant # 63181206), the Science Foundation for Distinguished Young Scholars of Tianjin (Grant # 18JCJQJC46600), the Xingliao Talent Plan (XLYC1802042), Key Laboratory of Display Materials and Photoelectric Devices, Ministry of Education (LX20200420001), the Fundamental Research Funds for the Central Universities (Grant # 63171219), and National Special Support Plan for High-level Talents people (C041800902).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file2 (MP4 1040 KB)

Rights and permissions

About this article

Cite this article

Khan, A.Q., Yu, K., Li, J. et al. Spider Silk Supercontraction-Inspired Cotton-Hydrogel Self-Adapting Textiles. Adv. Fiber Mater. 4, 1572–1583 (2022). https://doi.org/10.1007/s42765-022-00185-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-022-00185-0