Abstract

This study investigated the effect of the interaction between wood vinegar and biochar feedstock on total biomass, fruit weight (yield), and sugar content of tomato plants (Solanum lycopersicum L.). An experiment was conducted in two locations with six different biochar types produced from either plant or animal feedstock. Each biochar was incorporated into soil (1:2500 g/g) along with chemical fertilizer. Wood vinegar was diluted with water (1:200 mL) and applied once weekly for the vinegar treatment. Biochar application resulted in a higher yield and biomass of the chicken manure biochar owing to its high ammonium-nitrogen content. Vinegar application increased the yields of the plant feedstock, which was particularly evident for most of the yield parameters with the bamboo biochar. Regardless of treatment, yield and biomass were not significantly different between the animal and plant feedstock. The sugar content was higher for the chicken manure and animal litter biochar, which was attributed to better pH conditions. The combination of plant feedstock biochar and vinegar application for improving the yield of tomatoes is promising. In contrast, vinegar application could potentially limit the yield and fruit sugar content of tomato plants treated with animal feedstock biochar.

Highlights

• The soil was amended with biochar, with or without vinegar application.

• The chicken manure biochar plants had the highest yield and biomass.

• Vinegar application increased the yield of the plant feedstock.

• Plant and animal feedstock plants had similar yield and biomass.

• The pH of the animal feedstock was better because of higher CO2 and MgO contents.

• Fruit sugar content for animal feedstock plants was better due to higher phosphorus.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The impact of climate change on food security, primarily in developing countries, cannot be overemphasized. Owing to soil degradation, drought and high depletion of soil mineral nutrients are common in many countries in Asia, South America, and sub-Saharan Africa (Guerra et al. 2020). Biochar is considered helpful as a soil amendment under the Climate-Smart Agriculture (CSA) approach for resilient agriculture because of its rich organic carbon sequestration (Lehmann et al. 2015). Ndede et al. (2022) demonstrated that biochar mitigates drought in sandy agricultural soils by improving their hydrological properties. Biochar use in CSA is promoted by the Food and Agricultural Organization of the United Nations (Palombi and Sessa 2013; Lipper et al. 2014). Biochar has been recognized for its carbon capture and storage in the special report of the Intergovernmental Panel on Climate Change (IPCC) (Schmidt et al. 2018). Recently, several studies have reported biochar as a soil enhancer for improving crop yield due to its ability to retain moisture and improve water-holding capacity for drought-resilient agriculture (Blanco-Canqui 2017; Kassaye et al. 2021; Martinsen et al. 2015). Similarly, biochar enhances soil fertility because of the in situ soluble, organically bound nutrients (Abbaszadeh-Dahaji et al. 2019; Karimi et al. 2020). Reports indicate that increased application of biochar in the root zone of soil deficient in phosphorus increases plant-available phosphorus concentration, increasing plant growth and phosphorus uptake by 59% and 73%, respectively (Meyer 2022). Biochar influences phosphorus mineralization and phosphatase enzyme activity, which is responsible for converting organic phosphorus into inorganic forms for uptake (Viraj et al. 2019). Nutrients are labile and supplied through mineralization over time (Kammann et al. 2015; Nele et al. 2018; Schmidt et al. 2015). This phenomenon can be dependent on feedstock material, as demonstrated by the slow release of either augmented micronutrients or NPK fertilizer with biochar for plant uptake (Das et al. 2021a, b).

The primary abiotic factor affecting tomatoes is drought, contributing to an approximate 70% reduction in yield (Ibrahim et al. 2020; Oscar 2018). Akhtar et al. (2014) and Petruccelli et al. (2015) reported that soil formulated with biochar improved tomato yield without affecting fruit sweetness, while decreasing chlorophyll, a feature for photosynthesis. Conversely, Vaccari et al. (2015) found that biochar did not increase tomato yield; instead, it increased the ammonium, phosphorus, and potassium availability. Using biochar for improving crop production without supplying the required nitrogen and other essential nutrients is not expected to increase yield (Filiberto et al. 2013; Ye et al. 2020). However, this improvement may vary depending on the feedstock (plant or animal) or biochar type.

Janu et al. (2021) and others have characterized biochar by particle size, feedstock, ash content, and specific surface area to improve its nutrient availability and pH level (Dhar et al. 2020; Pradhan et al. 2020; Prasad et al. 2020). However, the pH of soil formulated with biochar is of concern. Nutrients such as phosphorus depend on pH (Brod 2015; Lindsay 1979), and phosphorus is responsible for sugar phosphate synthesis in tomato fruits (Kanayama 2017). Moreover, vinegar, a liquid by-product of condensed vapor generated during biochar pyrolysis, has been reported to enhance yield by improving nutrient uptake (Lei et al. 2018; Pan et al. 2017). However, vinegar is acidic with a pH of 2.5–3.0, decreasing the growth medium pH and hindering phosphorus bioavailability (Travero and Mihara 2015; Yatagai et al. 2002). Applying an appropriate concentration of wood vinegar can be beneficial for crop production (Luo et al. 2019; Zhu et al. 2021) owing to the presence of various functional organic substances, including organic acids, ketones, aldehydes, alcohols, benzene and its derivatives, heterocyclic compounds, phenols and their derivatives, alkyl phenyl ethers, carbohydrate derivatives, and nitrogen compounds, in beneficial proportions (Lu et al. 2019; Ma et al. 2013). However, there is limited information on the application of both biochar and wood vinegar to improve the yield and sugar content of tomatoes, with a few studies focusing on the effect of wood vinegar on growth parameters of other crops (Lei et al. 2018; Pan et al. 2017). Therefore, this study investigated whether the interaction between vinegar application and biochar feedstock affects the yield and sugar content of tomatoes and whether different feedstocks influence the effectiveness of wood vinegar in lowering yield. The results will justify whether plant or animal feedstock is more advantageous when used with wood vinegar for the growth and development of tomato plants. The paper proposes that vinegar may be involved in increasing the yield of tomato plants owing to its chemical properties, depending on biochar type. Additionally, the growth medium pH may limit the sugar content of tomato fruit due to the unavailability of phosphorus nutrients. Overall, this study provides a scientific basis for the use of vinegar and biochar for tomato production.

2 Material and Methods

2.1 Plant, Soil, and Biochar Materials

The plant materials used were 24-day-old tomato (cv. Monotaro) seedlings, purchased along with the soil material from Japan Agriculture (JA) in Kanazawa. The soil had a total carbon and nitrogen content of 1.14% and 0.13%, respectively (Suppl. Table 4). Details about the soil are available online (https://www.jstage.jst.go.jp/article/dojo/53/1/53_KJ00001687356/_pdf). Soil alone was used as the control.

Biochar was produced by Meiwa Co. Ltd. (Kanazawa, Japan) by pyrolysis using a batch-type kiln carbonizer (ECO200, Kanazawa City, Ishikawa, Meiwa Co. Ltd., Japan; https://www.meiwa-ind.co.jp/en/) with an external heating mechanism for cattle manure, chicken manure, and bamboo, at a carbonization temperature of approximately 400–500 °C for 2 h. A rotary kiln carbonizer (MES50, Kanazawa City, Ishikawa, Meiwa Co. Ltd., Japan) with an internal heating mechanism was used for slaughterhouse wastewater, rice husk, and woodchip carbonization at 400–500 °C for 30 min according to procedures outlined by Ferjani et al. (2019) and Song et al. (2012) (Suppl. Table 5 Additional information). The six different biochar materials were classified into two feedstock types: plant and animal. Plant feedstocks included bamboo biochar (BB) made from dried bamboo, rice husk biochar (RHB) made from rice husks, and woodchip biochar (WB) made from Japanese cedar trees (Pinus thunbergiana). Animal feedstocks included chicken manure biochar (CMB) made from chicken manure, animal litter biochar (ALB) made from cattle manure, and sludge biochar (SB) made from slaughterhouse wastewater.

2.2 Soil and Biochar Chemical Analysis

The textural class of the soil used for potting was loamy soil, as determined at the soil chemistry laboratory of Shimane University. The acidity (pH) of the biochar, soil, and combination growth medium of the biochar and soil together were analyzed using a pH/ion meter F-72 (https://www.horiba.com/int/). Biochar and soil electrical conductivity (EC) were analyzed using the Hanna Gro Line EC Tester (https://hanna.co.jp/). The mineral nutrients analyzed included ammonium-nitrogen (NH4+-N), nitrate-nitrogen (NO3−-N), phosphorus pentoxide (P2O5), potassium oxide (K2O), calcium oxide (CaO), magnesium oxide (MgO), iron (II) ions (Fe2+), and manganese oxide (MnO) (Table 2). Soil and biochar mineral nutrients were analyzed before incorporation using the Doctor Soil test kit (Japan Bio Farm), an extraction method used for soil and ecological farming. This procedure was published by the Japan Soil Association by Daisei GOTO, Agricultural Science Equipment Division, Fujihira Industry Co., Ltd.

2.3 Soil Formulation and Experimental Site

The biochar to soil ratio was 1g/2.5 kg (1:2500 g/g) for all biochar treatments. The biochar mixed with soil was further incorporated with lime (17.07 g pot−1, 80% CaO: 20% MgO) and fertilizer (13.66 g pot−1, N: P: K: Mg: Mn: B at a ratio of 14: 10: 13: 3: 0.4: 0.2, respectively). The experiments were conducted in 2018 at the Meiwa Co. Ltd. experimental site and a farmer’s field in Minato-Kanazawa, Japan. Both experiments were conducted in a greenhouse at 36°37′26″ N and 136°37′51″ E.

2.4 Wood Vinegar, Watering, Treatment, and Transplanting

The wood vinegar was produced by Meiwa Co. Ltd. (Kanazawa, Japan). Approximately 3,000 mL of wood vinegar was harvested by condensing the syngas emitted over the 3-hour pyrolysis of 40 kg of pine wood (Pinus thunbergiana). The chemical composition of wood vinegar was previously reported by Jindo et al. (2022). Vinegar was diluted with water (1:200 mL) and applied once weekly for fertigation. Irrigation was performed manually once or twice daily to prevent dehydration of growth medium. To study the effect of vinegar application, together with the control soil treatment, each biochar type had two sets of treatments: with and without vinegar. Treatments contained five replicates each. Tomato seedlings were transplanted on April 30, 2018, from a 45 cm × 60 cm spacing (3.7 plants m −2) into an individual pot (area = 0.1138 m2).

2.5 Parameter Measurements

Yield, yield parameters, and biomass at maturity were estimated, including total fruit weight (yield), total dry weight (biomass), harvest index (yield/biomass), number of fruits per plant (# Fruit plant−1), single fruit weight (SFW), total fruit weight per plant (TFWP), 100 fresh fruit weight (100FFW), and plant height. Plant height was measured using measuring tape two weeks after transplant (2WAT) and four weeks after transplant (4WAT). Leaf chlorophyll (SPAD) in the four most expanded leaves of each plant was measured at 2WAT and 4WAT using a SPAD 502m (Konica Minolta, Inc.). Leaf area index (LAI) was calculated according to the following imaging procedures at 2WAT and 4WAT. Images were captured as described by Nakano et al. (2020). The imaging procedure used an iPhone 7plus digital camera (12 megapixels) and ImageJ software as described by Easlon et al. (2014) and Tanaka et al. (2009). ImageJ software employs threshold-based pixel count measurements (Schneider et al. 2012). Sugar content of the fruit was measured using a Refractometer IPR-2O1α (BRIX-meter) after crushing the ripe fruit using an electric blending machine.

2.6 Definition of the Effectiveness of Vinegar

The effectiveness was defined as the ratios of measurements from those treated with vinegar to those without the vinegar treatment, as follows:

When effectiveness = 1, > 1, or < 1, the effectiveness of vinegar was deemed neutral, positive, or negative, respectively.

2.7 Experimental Design and Statistical Analysis

The experimental design of this study was a randomized complete block. Six different biochar types were designed as three-factorial experiments, comprising two feedstocks (animal feedstock and plant feedstock), two treatments (vinegar and no-vinegar), and two locations. ANOVA and T-tests were conducted using R software (R Core Team 2015), and graphs were created using Microsoft Excel 2017.

3 Results

3.1 pH and EC of the Soil and Biochar

The soil pH (5.42) indicated the soil was acidic and EC value (0.03) indicated low soil salinity (Table 1). The pH and EC values were 8.1 and 0.84 for BB, 7.28 and 0.39 for WB, 5.64 and 0.2 for RHB, 7.39 and 0.48 for SB, 9.56 and >4 for ALB, and 9.41 and >4 for CMB, respectively. In accordance with Brady and Weil (2008), plant feedstock pH values indicate that BB is alkaline, WB is neutral, and RHB is acidic. Overall, EC values of all plant feedstocks indicate low salinity. For the animal feedstocks, pH values indicated ALB and CMB are alkaline, while SB was neutral. The EC values indicated CMB and ALB have high salinity, while that of SB is low. EC values of animal feedstocks, except SB, were high because their mineral nutrients were high.

3.2 Soil and Biochar Chemical Composition

Soil mineral nutrient analysis indicated poor nutrients content, except for the NO3-N readily available for plant uptake (2.82 mg·kg−1 DW), which was considerably higher (p=0.000) than those of the biochar types (Table 2). However, mineral nutrients varied among the different plant feedstock biochar types. According to the soil fertility classification, BB had a medium P2O5 level of 1.39 g·kg−1 DW (Sanchez et al. 1982). WB had the highest CaO (1.78 g·kg−1 DW) of all biochar types. CaO in biochar increases its stability and enhances its interaction with mineral surfaces (Gui et al. 2021). Additionally, BB had the highest Fe2+ level (8.09 mg·kg−1 DW) among the plant feedstocks. Fe2+ is also responsible for increasing biochar stability and aiding the interaction of biochar surfaces with polyvalent metals (Jiang et al. 2022).

Animal feedstocks had considerably higher levels of mineral nutrients than the plant feedstocks. CMB had the highest levels of essential mineral nutrients for plant growth, with significantly (p=0.000) high NH4-H (224.8 mg·kg−1) and moderate P2O5 (>1.58 g·kg−1 DW) levels, according to the soil fertility classification (Sanchez et al. 1982). Additionally, high CaO (9.35 g·kg−1 DW) and Fe2+ (43.07 mg·kg−1 DW) levels (p=0.000) made it more stable and enhanced its interaction with mineral surfaces (Jiang et al. 2022) compared with other animal feedstocks. Moreover, ALB was similar to the CMB in terms of some of the essential nutrient levels (P2O5, K2O, and MgO). However, ALB had the highest NO3-N levels among the animal feedstocks, indicating high organic matter in the animal feed. In comparison, SB mineral nutrient content was the lowest among the animal feedstocks.

3.3 Yield and Yield Parameters

Table 3 shows the yield, biomass, and yield parameters for the various biochar, feedstock, and vinegar treatments. The effects of location were insignificant. The yields for the control soil groups were 109.2 ton·ha−1 and 111.1 ton·ha−1 for the tomatoes without and with vinegar treatment, respectively. The yields for the SB groups were similar to those of the control groups and had the lowest results. However, the mean yields and biomass of the CMB groups, either without (193.7 and 212.1 ton·ha−1, respectively) or with vinegar (177.5 and 195.1 ton·ha−1, respectively), were significantly higher than those of the other groups (p=0.000). The higher yields of the CMB groups were correlated with their significantly higher TFWP (p=0.000) (Suppl. Table 1). Additionally, the number of fruits per plant was significantly higher in the animal compared to plant feedstock groups (p=0.049). However, the mean yield of the animal feedstock groups was not different from those of plant feedstock groups. SFW and 100FFW were significantly higher in BB (p=0.000, respectively), which became evident in the plant feedstock in comparing to the animal feedstock biochar (p=0.007 and 0.044, respectively). Interestingly, the yield and yield parameters were not significantly different in tomatoes with and without vinegar application.

3.4 Plant Height, LAI, and SPAD

Table 4 shows plant height, LAI, and SPAD results for the various biochar, feedstock, and vinegar treatment groups. The effect of location was insignificant at the 2WAT and 4WAT. However, at 2WAT, plant and animal feed stocks have significantly different effects on plant height (p=0.001), while the mean plant height for each biochar type was only significant (p=0.000) for some of the plant and animal feedstocks. Plant height was higher for the BB, WB, CMB, and SB groups.

The effects of treatment, feedstock, and biochar type were all significantly higher (p=0.000) for LAI at 2WAT. The treatment effect was more significant (p=0.000) without vinegar application by 6.5% when compared to that with vinegar application. Additionally, the LAI of tomatoes in the animal feedstock groups were significantly (p=0.000) higher than those of the plant feedstock groups by 28.3%, as evident for the CMB group with a mean LAI of 0.62 (p=0.000) (Suppl. Table 2 for statistical analyses).

Finally, for SPAD, the effects of treatment and biochar type were significant (p=0.029 and 0.000, respectively). SPAD of plants treated with vinegar was 0.8% higher than that of plants not treated with vinegar. The significant effect of biochar type was evident for WB with a mean SPAD value of 58.9 (p=0.000) (Suppl. Table 2).

At 4WAT, biochar type had a significant effect on plant height, LAI, and SPAD (p=0.000). Plant height was significantly higher only for the CMB group (53.4 cm) (p=0.000). LAI was significantly higher for the WB and CMB groups with a mean LAI of 0.66 m2·m−2, respectively (p=0.000). SPAD was significantly higher for the WB group with a mean SPAD value of 60.7 (p=0.000) (Suppl. Table 2).

3.5 Growth Media pH and Sugar Content

Table 5 shows the growth media pH and sugar content for the various biochar, feedstock, and vinegar treatment groups. The effects of location and treatment were insignificant. Biochar type had a significant effect on the growth media pH (p=0.000). Specifically, this was evident for the BB group with a mean pH of 6.9 (p=0.000) (Suppl. Table 3). Biochar type also had a significant (p=0.000) effect on the sugar content. The CMB and ALB had mean °Brix values of 7.4 and 7.2, respectively (p=0.000) (Suppl. Table 3).

3.6 Effectiveness of Vinegar Application for Yield and Yield Parameters

Table 6 shows the effectiveness of vinegar application on the yield, biomass, and yield parameters for the various biochar types and feedstocks. The effectiveness was positive only for the plant feedstocks, not the animal feedstocks or control soil. Specifically, it was significantly higher in terms of yield, biomass, SFW, TFWP, and 100FFW (p=0.000–0.024). Particularly, these values were significantly higher for the BB (p=0.000–0.05).

3.7 Interaction Between Wood Vinegar and Other Factors in Growth

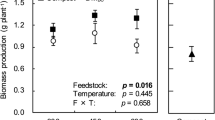

Interactions between treatments and feedstocks (T × F) were significant for the yield, biomass, SFW, TFWP, 100FFW, and sugar content (p=0.000–0.030) (Tables 3 and 5, respectively). Most parameters were higher in the plant feedstock treated with vinegar (Suppl. Fig. 1a–e), whereas sugar content was higher in the animal feedstock without vinegar treatment (Suppl. Fig. 1f)

Moreover, interactions between treatments and biochar types (T × B) were significant for SFW, 100FFW, and LAI at 2WAT (p=0.000) (Tables 3 and 4). At 2WAT, SFW and 100FFW were greater in the BB treated with vinegar, while LAI was greater in the CMB without vinegar treatment.

4 Discussion

This study examined the effect of the interaction between vinegar and biochar feedstocks on yield and sugar content in tomato plants and whether the effectiveness of vinegar causes a lower yield and yield parameters in the presence of various feedstocks. There was a significant effect of the interaction between treatments and feedstock (T × F) on yield, biomass, SFW, TFWP, 100FFW, and sugar content (Tables 3 and 5). This implies that the plant feedstock-vinegar interaction was better than the animal feedstock-vinegar interaction for most of these parameters, with the exception of the greater sugar content seen in plants treated with animal feedstock and no vinegar. The effect of the plant feedstock-vinegar interaction on yield and biomass was related to the similar interaction effect seen on TFWP. For the animal feedstock, the positive impact of the interaction on sugar content without the vinegar application was affected by the poor sugar content of the SB under vinegar application, which tends to have a lower pH value. The feedstock variation might be related to other studies that indicate vinegar may serve as a substrate or be toxic for microbial growth and metabolism, depending on the feedstock material (Fan et al. 2022; McClellan et al. 2007).

Notably, the interaction between treatment and biochar type (T × B) had a significant effect on SFW, 100FFW, and LAI at 2WAT (Tables 3 and 4). Various biochar types showed different interactions with the vinegar treatment. Notably, the SFW, 100FFW were significantly greater for the BB with vinegar application than those of other groups (Suppl. Fig. 2a and b). This may also be associated with better physiological traits of the BB, such as photosynthesis and water use efficiency, due to the higher surface area and readily available water among the biochar types (Suppl. Table 4) (Ndede et al. 2022; Zhang et al. 2017). The superiority of the BB-vinegar interaction for traits related to yield might also be supported by the higher P2O5 and FeO2 levels among the plant feedstock biochars. The LAI at 2WAT was significantly greater for the CMB without vinegar application (Suppl. Fig. 2c). However, this seemed to be counterbalanced by a higher SPAD in the CMB treated with vinegar at 2WAT. The higher LAI for the CMB at early growth stages might be attributed to its high NH4-N levels may be altered by vinegar application. Understanding these interactions is important for nitrogen use efficiency; however, the mechanism of these interactions will be discussed later.

Vinegar effectiveness in different feedstocks was clarified using yield parameters. In the plant feedstocks, vinegar application had significantly positive effects on yield, biomass, SFW, TFWP, and 100FFW (p=0.024, 0.025, 0.000, 0.024, and 0.000, respectively) in comparison to the control and animal feedstocks (Table 6). Vinegar effectiveness on yield, biomass, SFW, TFWP, and 100FFW was evident for the BB (p= 0.05, 0.05, 0.000, 0.05, and 0.000, respectively), which is related to the existing interactions. Vinegar has been utilized for several purposes, such as crop yield improvement and foliar fertilizer (Sun et al. 2021; Zhu et al. 2021; Mungkunkamchao et al. 2013). However, concentrated vinegar has biocidal properties. Concurrently, dilute doses stimulate microbial activity due to the utilization of organic compounds (acids, aldehydes, and alcohols) as carbon sources (Fan et al. 2022; Mattos et al. 2019; Ray et al. 2022), potentially relating to the effect of vinegar on the plant feedstock biochar groups. The reduction of microbial growth in CMB by vinegar has been reported by Mohammadi-Aragh et al. (2021) and may be responsible for the negative effect of vinegar on the yield and yield parameters of the animal feedstock biochar groups, likely due to the slow conversion of NH4-N to nitrate. Therefore, the biocidal effect of vinegar on microbes based on biochar feedstock needed to be elucidated.

Nevertheless, the yield and biomass of the CMB group were significantly higher, irrespective of the biochar material (p=0.000), which is attributed to the significantly high TFWP, in the CMB (p=0.000) (Suppl. Table 1). The superior effect of CMB over other biochar types on yield can be attributed to its abundant in situ mineral nutrients, particularly NH4-N (p=0.000), which was seen through a consistently higher plant height and LAI. Chicken manure has been reported to increase the yield of maize grains more readily compared to farmyard manure (Das et al. 2022a). Similarly, the mineralization of in situ biochar nutrients is dependent on feedstock material (Sarfaraz et al. 2020). High-nitrogen feedstock materials, such as swine manure biochar, incorporated into soil have increased nitrogen mineralization. Soil incorporated with either wood or sewage sludge biochar, categorized as a low-nitrogen feedstock, had low and similar nitrogen mineralization. Therefore, the in situ mineral nutrients of biochar may serve as a complementary nutrient source. The bioavailability of biochar mineral nutrients for plant uptake might be related to the growth media pH. Das et al. (2021a, b) reported that phosphorus movement was increased in the soil column for biochar with a high pH value (6.6) used as a slow-release fertilizer. In another study, biochar increased the nodule-solubilizing sugars in maize grains (Das et al. 2022b). An excellent growth media pH for most plants, including tomatoes, should be between pH=6-7 because strong acid or weak alkaline conditions makes phosphorus form complexes with other elements such as aluminium, iron, and calcium, resulting in nutrient unavailability (Brod 2015; Bray et al. 1945). Thus, enabling mineral nutrients in biochar to be labile and available for plant uptake might require maintaining an adequate soil pH range. The pH of the CMB and ALB remained constant (pH=6.4), regardless of the vinegar application (Table 5), likely due to their higher CaO and MgO serving as buffer agent/liming material. Limited phosphorus availability is associated with poor sugar synthesis, photosynthates, and energy (Kanayama 2017; Wu et al. 2021). This phenomenon might be related to the higher sugar content of the CMB and ALB groups (oBrix=7.2 and 7.4, respectively) (Suppl. Table 3), with higher P2O5 and MgO contents (Kim et al. 2020). This study suggests that the use of vinegar with biochar needs careful consideration as the advantage of vinegar application in enhancing plant growth is dependent on the biochar feedstock. These findings will be helpful in selecting appropriate biochar to use in conjuncture with vinegar for tomato production to improve yield and quality.

5 Conclusion

In conclusion, our findings indicate that chicken manure biochar resulted in the highest yield, attributed to its higher ammonium-nitrogen content. Moreover, the application of vinegar positively affected the yield and yield parameters of plant feedstock groups, particularly bamboo biochar. However, animal feedstock groups, especially chicken manure biochar and animal litter biochar, demonstrated significantly higher fruit sugar content without vinegar treatment, likely due to favorable pH conditions. These results suggest that the selection of biochar and vinegar should be based on the feedstock type, as the biocidal properties of vinegar may adversely affect tomato fruit yield and quality. Overall, our study highlights the importance of considering feedstock and treatment options for optimizing biochar application in agricultural practices.

Data Availability

Data will be made available on request.

References

Abbaszadeh-Dahaji P, Masalehi F, Akhgar A (2019) Improved growth and nutrition of Sorghum (Sorghum bicolor) plants in a low-fertility calcareous soil treated with plant growth–promoting rhizobacteria and Fe-EDTA. J Soil Sci Plant Nutr 20:31–42. https://doi.org/10.1007/s42729-019-00098-9

Akhtar SS, Guitong L, Neumann AM, Fulai L (2014) Biochar enhances yield and quality of tomato under reduced irrigation. Agric Water Manag 138:37–44. https://doi.org/10.1016/j.agwat.2014.02.016

Blanco-Canqui H (2017) Biochar and soil physical properties. Soil Sci Soc Am J 84:687–711. https://doi.org/10.2136/sssaj2017.01.0017

Brady NC, Weil RR (2008) The nature and properties of soils, 14th edn. Pearson Education, Inc., Upper Saddle River, NJ: Prentice Hall, pp 662–710

Bray RH, Kurtz LT (1945) Determination of total, organic, and available form of phosphorus in soil. Soil Sci 59:39–45 https://journals.lww.com/soilsci/Citation/1945/01000/Determination_of_Total,_Organic,_and_Available.6.aspx

Brod E, Ogaard AF, Hansen E, Wragg D, Haraldsen TK, Krogstad T (2015) Waste products as alternative phosphorus fertilisers part I: inorganic P species affect fertilisation effects depending on soil pH. Nutr. Cycling Agroecosyst 103:167–185. https://doi.org/10.1007/s10705-015-9734-1

Das SK, Ghosh GK (2021a) Development and evaluation of biochar based secondary and micronutrient enriched slow release nano-fertilizer for reduced nutrient losses. Biomass Conv Bioref 1:12. https://doi.org/10.1007/s13399-021-01880-5

Das SK, Ghosh GK (2021b) Developing biochar-based slow-release N-P-K fertilizer for controlled nutrient release and its impact on soil health and yield. Biomass Conv Bioref 1:13. https://doi.org/10.1007/s13399-021-02069-6

Das SK, Ghosh GK, Avasthe R (2022a) Biochar and organic manures on produce quality, energy budgeting, and soil health in maize-black gram system. Arab J Geosci 15:18. https://doi.org/10.1007/s12517-022-10790-3

Das SK, Ghosh GK, Choudhury BU, Hazarika S, Mishra VK (2022b) Developing biochar and organic nutrient packages/technology as soil policy for enhancing yield and nutrient uptake in maize-black gram cropping system to maintain soil health. Biomass Conv Bioref 1:13. https://doi.org/10.1007/s13399-022-02300-y

Dhar SA, Sakib TU, Hilary LN (2020) Effects of pyrolysis temperature on production and physicochemical characterization of biochar derived from coconut fiber biomass through slow pyrolysis process. Biomass Conv Bioref 12(7):2631–2647. https://doi.org/10.1007/s13399-020-01116-y

Fan Q, Fan X, Fu P, Li Y, Zhao Y, Hua D (2022) Anaerobic digestion of wood vinegar wastewater using domesticated sludge: focusing on the relationship between organic degradation and microbial communities (archaea, bacteria, and fungi). Bioresour Technol 347:126384. https://doi.org/10.1016/j.biortech.2021.126384

Easlon HM, Bloom AJ (2014) Easy leaf area: automated digital image analysis for rapid and accurate measurement of leaf area. Appl Plant Sci 2:1400033. https://doi.org/10.3732/apps.1400033

Ferjani AI, Jeguirim M, Jellali S, Limousy L, Courson C, Akrout H, Thevenin N, Ruidavets L, Muller A, Bennici S (2019) The use of exhausted grape marc to produce biofuels and biofertilizers: effect of pyrolysis temperatures on biochars properties. Renewable Sustainable Energy Rev 107:425–433. https://doi.org/10.1016/j.rser.2019.03.034

Filiberto DM, Gaunt JL (2013) Practicality of biochar additions to enhance soil and crop productivity. Agriculture 3:715–725. https://doi.org/10.3390/agriculture3040715

Guerra CA, Rosa IMD, Valentini E, Wolf F, Filipponi F, Karger DN, Nguyen Xuan A, Jerome Mathieu J, Lavelle P, Eisenhauer N (2020) Global vulnerability of soil ecosystems to erosion. Landscape Ecol 35:823–842. https://doi.org/10.1007/s10980-020-00984-z

Gui X, Song B, Chen M, Xu X, Ren Z, Li X, Cao X (2021) Soil colloids affect the aggregation and stability of biochar colloids. Sci Total Environ 771:145414. https://doi.org/10.1016/j.scitotenv.2021.145414

Ibrahim MFM, Elbar OHA, Farag R, Hikal M, El-Kelish A, El-Yazied AA, Alkahtani J, El-Gawad HGA (2020) Melatonin counteracts drought induced oxidative damage and stimulates growth, productivity and fruit quality properties of tomato plants. Plants 9:1276. https://doi.org/10.3390/plants9101276

Janu R, Mrlik V, Ribitsch D, Hofman J, Sedláček P, Bielská L, Soja G (2021) Biochar surface functional groups as affected by biomass feedstock, biochar composition and pyrolysis temperature. Carbon Resour Convers 4:36–46. https://doi.org/10.1016/j.crcon.2021.01.003

Jiang M, Wang K, Xue R, Zhao Q, Wang L, Wang W, Ding J (2022) Remediation of antimony-contaminated soil with composite materials of Fe/Fe2+-fly ash-concrete additive in seasonal freezing regions. Process Saf Environ Prot 167:247–256. https://doi.org/10.1016/j.psep.2022.09.018

Jindo K, Goron TL, Kurebito S, Matsumoto K, Masunaga T, Mori K, Miyakawa K, Nagao S, Tokunari T (2022) Sustainable plant growth promotion and chemical composition of pyroligneous acid when applied with biochar as a soil amendment. Molecules 27:3397. https://doi.org/10.3390/molecules27113397

Kammann CI, Schmidt HP, Messerschmidt N, Linsel S, Steffens D, Müller C, Koyro HW, Conte P, Joseph S (2015) Plant growth improvement mediated by nitrate capture in co-composted biochar. Sci Rep 5:11080. https://doi.org/10.1038/srep11080

Kanayama Y (2017) Sugar metabolism and fruit development in the tomato. J Hortic 86:417–425. https://doi.org/10.2503/hortj.OKD-IR01

Karimi A, Moezzi A, Chorom M (2020) Application of biochar changed the status of nutrients and biological activity in a calcareous soil. J Soil Sci Plant Nutr 20:450–459. https://doi.org/10.1007/s42729-019-00129-5

Kassaye KT, Boulange J, Kurebito S, Tokunari T, Saito H, Watanabe H (2021) The role of biochar in improving soil properties, water retention and potato yield in a Fluvisol under temperate monsoon climate. Soil Use Manage 38(1):1069–1083. https://doi.org/10.1111/sum.12769

Kim YX, Kwon MC, Lee S, Jung ES, Lee CH, Sung J (2020) Effects of nutrient and water supply during fruit development on metabolite composition in tomato fruits (Solanum lycopersicum L.) grown in magnesium excess soils. Front Plant Sci 11:1–8. https://doi.org/10.3389/fpls.2020.562399

Lehmann J, Joseph S (2015) Biochar for environmental management: science, technology and implementation, 2nd edn. Earthscan, London, UK, pp 3–71

Lei M, Liu B, Wang X (2018) Effect of adding wood vinegar on cucumber (Cucumis sativus L) seed germination. IOP Conf Ser: Earth Environ Sci 128:012186. https://doi.org/10.1088/1755-1315/128/1/012186

Lipper L, Thornton P, Campbell BM, Baedeker T, Braimoh A, Bwalya M, Caron P, Cattaneo A, Garrity D, Henry K, Hottle R, Jackson L, Jarvis A, Kossam F, Mann W, McCarthy N, Meybeck A, Neufeldt H, Remington T et al (2014) Climate-smart agriculture for food security. Nat Clim Change 4:1068–1072. https://doi.org/10.1038/nclimate2437

Lindsay WL (1979) Chemical equilibria in soils. John Wiley and Sons Ltd., Hoboken, NJ, USA, p 449

Lu X, Jiang J, He J, Sun K, Sun Y (2019) Effect of pyrolysis temperature on the characteristics of wood vinegar derived from Chinese fir waste: a comprehensive study on its growth regulation performance and mechanism. ACS Omega 4:19054–19062. https://doi.org/10.1021/acsomega.9b02240

Luo X, Wang Z, Meki K, Wang X, Liu B, Zheng H, Li F (2019) Effect of co-application of wood vinegar and biochar on seed germination and seedling growth. J. Soils Sediments 19:3934–3944. https://doi.org/10.1007/s11368-019-02365-9

Ma C, Song K, Yu J, Yang L, Zhao C, Wang W, Zu G, Zu Y (2013) Pyrolysis process and antioxidant activity of pyroligneous acid from Rosmarinus officinalis leaves. J Anal Appl Pyrolysis 104:38–47. https://doi.org/10.1016/j.jaap.2013.09.011

Martinsen V, Alling V, Nurida NL, Mulder J, Hale SE, Ritz C (2015) pH effects of the addition of three biochars to acidic Indonesian mineral soils. J Soil Sci Plant Nutr 61:821–834. https://doi.org/10.1080/00380768.2015.1052985

Mattos C, Veloso MCC, Romeiro GA, Folly E (2019) Biocidal applications trends of bio-oils from pyrolysis: characterization of several conditions and Biomass, a review. J Anal Appl Pyrolysis 139:1–12. https://doi.org/10.1016/j.jaap.2018.12.029

McClellan AT, Deenik J, Uehara G, Antal M (2007) Effects of flashed carbonized© macadamia nutshell charcoal on plant growth and soil chemical properties. Agron J. Abstracts. 3-7 Nov., New Orleans, LA. Available via https://www.ctahr.hawaii.edu/deenikj/Downloads/Tai_Charcoal_CTAHR_Sym_2007.pdf

Meyer Zu Drewer J, Köster M, Abdulai I, Rötter RP, Hagemann N, Schmidt HP (2022) Impact of different methods of root-zone application of biochar-based fertilizers on young cocoa plants: insights from a pot-trial. Sci Hortic 8:328. https://doi.org/10.3390/horticulturae8040328

Mohammadi-Aragh MK, Stokes CE, Street JT, Linhoss JE (2021) Effects of loblolly pine biochar and wood vinegar on poultry litter nutrients and microbial abundance. Animals 11:2209. https://doi.org/10.3390/ani11082209

Mungkunkamchao T, Kesmala T, Pimratch S, Toomsan B, Jothityangkoon D (2013) Wood vinegar and fermented bioextracts: natural products to enhance growth and Yield of tomato (Solanum lycopersicum L.). Sci Hortic 154:66–72. https://doi.org/10.1016/j.scienta.2013.02.020

Nakano S, Purcell LC, Homma K, Shiraiwa T (2020) Modeling leaf area development in soybean (Glycine max L.) based on the branch growth and leaf elongation. Plant Prod Sci 23:247–259. https://doi.org/10.1080/1343943X.2019.1702468

Ndede EO, Kurebito S, Idowu O, Tokunari T, Jindo K (2022) The potential of biochar to enhance the water retention properties of sandy agricultural soils. Agronomy 12:1–12. https://doi.org/10.3390/agronomy12020311

Nele M, Gerhard W, Andrei R, Nils B, Christopher M, Wulf A (2018) Nitrogen and phosphorus supply controls soil organic carbon mineralization in tropical topsoil and subsoil. Soil Biol Biochem 119:152–161. https://doi.org/10.1016/j.soilbio.2018.01.024

Palombi L, Sessa R (2013) Climate-smart agriculture: sourcebook. Food and Agriculture Organization of the United Nation, Rome, Italy http://www.fao.org/3/a-i3325e.pdf

Pan X, Zhang Y, Wang X, Liu G (2017) Effect of adding biochar with wood vinegar on the growth of cucumber. IOP Conf Ser Earth Environ Sci 61:012149. https://doi.org/10.1088/1755-1315/61/1/012149

Oscar G, Patrick Q (2018) Shane C (2018) Ascophyllum nodosum extract biostimulants and their role in enhancing tolerance to drought stress in tomato plants. Plant Physiol Biochem 126. https://doi.org/10.1016/j.plaphy.2018.02.024

Pradhan S, Abdelaal AH, Mroue K, Al-Ansari T, Mackey HR, McKay G (2020) Biochar from vegetable wastes: agro-environmental characterization. Biochar 2:439–453. https://doi.org/10.1007/s42773-020-00069-9

Prasad M, Chrysargyris A, McDaniel N, Kavanagh A, Gruda NS, Tzortzakis N (2020) Plant nutrient availability and pH of biochars and their fractions, with the possible use as a component in a growing media. Agronomy 10:1–17. https://doi.org/10.3390/agronomy10010010

Petruccelli R, Bonetti A, Traversi ML, Faraloni C, Valagussa M, Pozzi A (2015) Influence of biochar application on nutritional quality of tomato (Lycopersicon esculentum). Crop Pasture Sci 66:747–755. https://doi.org/10.1071/CP14247

R Core Team (2015) R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria https://www.r-project.org/

Ray A, Ganguly S, Sankar A (2022) Biocides through pyrolytic degradation of biomass: potential, recent advancements and future prospects. Biopesticides:337–352. https://doi.org/10.1016/B978-0-12-823355-9.00025-0

Sanchez PA, Couto W, Buol SW (1982) The fertility capability soil classification system: interpretation, applicability and modification. Geoderma 27:283–309. https://doi.org/10.1016/0016-7061(82)90019-2

Sarfaraz Q, Silva LSD, Drescher GL, Zafar M, Severo FF, Kokkonen A, Solaiman ZM (2020) Characterization and carbon mineralization of biochars produced from different animal manures and plant residues. Sci Rep 10:1–9. https://doi.org/10.1038/s41598-020-57987-8

Schmidt HP, Pandit BH, Martinsen V, Cornelissen G, Conte P, Kammann CI (2015) Fourfold increase in pumpkin yield in response to low-dosage root zone application of urine-enhanced biochar to a fertile tropical soil. Agronomy 5:723–741. https://doi.org/10.3390/agriculture5030723

Schmidt H-P, Anca-Couce A, Hagemann N, Werner C, Gerten D, Lucht W, Kammann C (2018) Pyrogenic Carbon Capture & Storage (PyCCS). GCB Bioenergy 11:573–591. https://doi.org/10.1111/gcbb.12553

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH Image to ImageJ: 25 years of image analysis. Nat Methods 9:671–675. https://doi.org/10.1038/nmeth.2089

Song W, Guo M (2012) Quality variations of poultry litter biochar generated at different pyrolysis temperatures. J Anal Appl Pyrolysis 94:138–145. https://doi.org/10.1016/j.jaap.2011.11.018

Sun X, Guo Y, Zeng L, Li X, Liu X, Li J, Cui D (2021) Combined urea humate and wood vinegar treatment enhances wheat–maize rotation system yields and nitrogen utilization efficiency through improving the quality of saline–alkali soils. J Plant Nutr Soil Sci 21:1759–1770. https://doi.org/10.1007/s42729-021-00477-1

Tanaka Y, Shiraiwa T (2009) Stem growth habit affects leaf morphology and gas exchange traits in soybean. Ann Bot 104:1293–1299. https://doi.org/10.1093/aob/mcp240

Travero JT, Mihara M (2015) Impacts of pyroligneous acid to biological and chemical properties of depleted soil in bohol, philippines. Int J Environ Rural Dev 132:132–137. https://doi.org/10.32115/ijerd.6.1_132

Vaccari FP, Maienza A, Miglietta F, Baronti S, Di Lonardo S, Giagnoni L, Lagomarsino A, Pozzi A, Pusceddu E, Ranieri R, Valboa G (2015) Biochar stimulates plant growth but not fruit yield of processing tomato in a fertile soil. Agr Ecosyst Environ 207:163–170. https://doi.org/10.1016/j.agee.2015.04.015

Viraj G, Nishanta R, Udaya G, Jayanta KB, Zach AR, Meththika V (2019) Influence of soil water content and soil amendments on trace metal release and seedling growth in serpentine soil. J Soils Sediments 19:3908–3921. https://doi.org/10.1007/s11368-019-02349-9

Wu S, Li M, Zhang C, Tan Q, Yang X, Sun X, Hu C (2021) Effects of phosphorus on fruit soluble sugar and citric acid accumulations in citrus. Plant Physiol Biochem 160:73–81. https://doi.org/10.1016/j.plaphy.2021.01.015

Yatagai M, Nishimoto M, Hori K, Ohira T, Shibata A (2002) Termiticidal activity of wood vinegar, its components and their homologues. J Wood Sci 48:338–342. https://doi.org/10.1007/BF00831357

Ye L, Camps-Arbestain M, Shen Q, Lehmann J, Singh B, Sabir M (2020) Biochar effects on crop yields with and without fertilizer: a meta-analysis of field studies using separate controls. Soil Use Manage 36:2–18. https://doi.org/10.1111/sum.12546

Zhang Y, Ma Z, Zhang Q, Wang J, Ma Q, Yang Y, Luo X, Zhang W (2017) Bio-char characteristics. BioResources 12:4652–4669. https://doi.org/10.15376/biores.12.3.4652-4669

Zhu K, Gu S, Liu J, Luo T, Khan Z, Zhang K, Hu L (2021) Wood vinegar as a complex growth regulator promotes the growth, Yield, and quality of rapeseed. Agronomy 11:510. https://doi.org/10.3390/agronomy11030510

Acknowledgements

The authors acknowledged Samuel Munyaka Kimani, Takamasa Ueno, and the staff of Meiwa Co. Ltd. for their kind support during this study. We appreciated Professor Tsugiyuki Masunaga (Shimane University, Japan) for the soil analysis and Prof. Shiraiwa Tatsuhiko for assisting us with the SPAD-502 meter for chlorophyll measurement. Keiji Jindo wishes to acknowledge financial support (3710473400).

Funding

This study was conducted during an internship program at Meiwa Co. Ltd. under the government of Japan through the African business initiative program by Japan International Cooperation Agency (JICA). There was no dedicated financial support received for this study; thus, there is no funding number.

Author information

Authors and Affiliations

Contributions

OI, SK, and TT conceived the idea; OI and SK designed the study; OI performed experiment; OI and EON analyzed the data; OI wrote the manuscript; OI, EON, and SK edited the manuscript; TT and KJ review the manuscript. All authors have read and approved the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Idowu, O., Ndede, E.O., Kurebito, S. et al. Effect of the Interaction between Wood Vinegar and Biochar Feedstock on Tomato Plants. J Soil Sci Plant Nutr 23, 1599–1610 (2023). https://doi.org/10.1007/s42729-023-01227-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42729-023-01227-1