Abstract

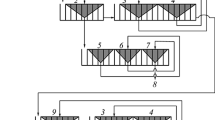

A common problem recently encountered with the increase in the rate of input feed at Enrichment Plant 2 of the Sarcheshmeh Copper Complex is the loss of value to the tails, translating to lower recoveries. The feasibility of the direct transfer of part of the high-grade concentrate from rougher stages to an appropriate position along the circuit was studied, and two positions were proposed for direct transfer of the concentrate. One position was the feed flow into cleaner cells, and the other was the feed flow into the recleaner cell. The results indicated that transferring the concentrate from the first unit of the rougher stage to the feed flow into the cleaner cells was feasible, with no limitations, while the second position required the installation of a set of hydrocyclones. It was found that the transfer of concentrate to the proposed positions not only addressed the problem of limited cell capacity, resulting in debottlenecking of the circuit, but also improved metallurgical separation efficiency up to 1.4%.

Similar content being viewed by others

References

Connolly AF (2000) Prince RGH. Performance improvement in minerals beneficiation circuits by retrofitting. Sep Purif Technol 19(1–2):77–83. https://doi.org/10.1016/S1383-5866(99)00071-4

Hu W (2014) Flotation circuit optimisation and design. Department of Earth Science and Engineering, Imperial College London, London

Shean B, Hadler K, Cilliers JJ (2017) A flotation control system to optimise performance using peak air recovery. Chem Eng Res Des 117:57–65. https://doi.org/10.1016/j.cherd.2016.10.021

Wunder GW. (1979). Sarcheshmeh Concentrator Operating Manual (Section5: Flotation and Regrinding) Parson-Jurden International Corporation. National Iranian Copper Industries. http://hdl.handle.net/10044/1/24805

Shean BJ, Cilliers JJ (2011) A review of froth flotation control. Int J Miner Process 100(3–4):57–71. https://doi.org/10.1016/j.minpro.2011.05.002

Laurila H, Karesvuori J, Tiili O (2002) Strategies for instrumentation and control of flotation circuits. Mineral Processing Plant Design, Practice and Control 2:2174–2195

Wright BA. (1999). The development of a vision-based flotation froth analysis system (Doctoral dissertation, University of Cape Town). http://hdl.handle.net/11427/9923

Jamett NE, Vielma JP, Cisternas LA (2012) Design of flotation circuits including uncertainty and water efficiency. In Computer Aided Chemical Engineering 30:1277–1281. https://doi.org/10.1016/B978-0-444-59520-1.50114-7

Rojas D, Cipriano A (2011) Model based predictive control of a rougher flotation circuit considering grade estimation in intermediate cells. Dyna. 78(166):29–37

Van Schalkwyk T. (2002). Multivariable control of a rougher flotation cell (Doctoral dissertation, University of Cape Town). http://hdl.handle.net/11427/11550

Calisaya DA, López-Valdivieso A, Marcos H, Gálvez EE, Cisternas LA (2016) A strategy for the identification of optimal flotation circuits. Miner Eng 96:157–167. https://doi.org/10.1016/j.mineng.2016.06.010

Parsapour GA, DarvishTafvisi S, Arghavani E, Rajabi MJ, Akbari A, Banisi S (2017) Modification of the Sarcheshmeh copper complex flotation circuit in response to a reduction in feed grade. Journal of Mining and Environment 8(4):539–544. https://doi.org/10.22044/jme.2017.879

Sepúlveda FD, Cisternas LA, Gálvez ED (2014) The use of global sensitivity analysis for improving processes: applications to mineral processing. Comput Chem Eng 66:221–232

Noble A, Luttrell GH, Amini SH (2019) Linear circuit analysis: a tool for addressing challenges and identifying opportunities in process circuit design. Mining, Metallurgy & Exploration 36(1):159–171

Cisternas LA, Lucay FA, Acosta-Flores R, Gálvez ED (2018) A quasi-review of conceptual flotation design methods based on computational optimization. Miner Eng 117:24–33

Shafaei Z, Noaparast M, Abdollahia H (2019) Recent developments in configuration design and optimization of mineral separation circuits; a review. International Journal of Mining and Geo-Engineering 53(1):51–61

Yarahmadi MR, Banisi S (1998) Movazen: a mass balancing software. Chemical Engineering Congress of Iran, Sharif University 4:107–115

King RP (1986) Modsim: A Modular Method Or the Design, Balancing and Simulation of Ore Dressing Plant Flowsheets. University of the Witwatersrand, Department of Metallurgy and Materials Engineering

King RP (2001) Modeling and simulation of mineral processing systems. Department of Metallurgical Engineering University of Utah

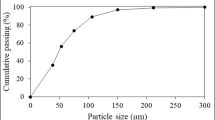

Azizi A, Hassanzadeh A, Fadaei B (2015) Investigating the first-order flotation kinetics models for Sarcheshmeh copper sulfide ore. Int J Min Sci Technol 25(5):849–854. https://doi.org/10.1016/j.ijmst.2015.07.022

Seyyedi J (2014) Modeling and optimization of regrinding circuit in the Sarcheshmeh cu complex. Iran Unpublished master’s Thesis. Yazd University. Yazd

Zanin M, Ametov I, Grano S, Zhou L, Skinner W (2009) A study of mechanisms affecting molybdenite recovery in a bulk copper/molybdenum flotation circuit. Int J Miner Process 93(3–4):256–266. https://doi.org/10.1016/j.minpro.2009.10.001

Zanin M, Grano SR, Ametov I (2010) Technical challenges in the flotation of molybdenite form porphyry copper ores. Circuit International Journal of Mineral Processing 93(3–4):256–266. https://doi.org/10.1016/j.minpro.2009.10.001

Triffett B, Veloo C, Adair BJI, Bradshaw D (2008) An investigation of the factors affecting the recovery of molybdenite in the Kennecott Utah copper bulk flotation circuit. Miner Eng 21(12–14):832–840. https://doi.org/10.1016/j.mineng.2008.03.003

Ametov I, Grano SR, Zanin M, Gredelj S, Magnuson R., Bolles T, Triffet B (2008) Copper and molybdenite recovery in plant and batch laboratory cells in porphyry copper rougher flotation. 1129–1137

Acknowledgments

The authors would like to thank the research and development center of Sarcheshmeh Copper Complex for funding this project, and the University of Kashan for their contribution to this project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

ESM 1

(DOCX 72 kb)

Rights and permissions

About this article

Cite this article

Kohan, R., Taheri, B., Heshami, M. et al. Feasibility Study on the Modification and Improvement of Flotation Circuits at Enrichment Plant 2 of the Sarcheshmeh Copper Complex. Mining, Metallurgy & Exploration 37, 555–566 (2020). https://doi.org/10.1007/s42461-020-00177-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-020-00177-x