Abstract

Recovering valuable metals from tailings not only provides a source of income but also helps conserve natural resources, thus reducing the environmental impact of mining activities. This study aimed to recover cobalt using tailings of the Küre flotation plant, which were determined to contain 0.17% Co. Flotation tests were conducted on samples taken from the tailings to investigate the effects of pH and pH conditioning time, as well as types and amounts of depressant, collector, and frother on the grade and recovery of Co in rougher flotation tests. Optimal flotation conditions were determined to be pH 6, a pH conditioning time of 7 min, and dosages of 50 g/t, 100 g/t, and 20 g/t of sodium hexametaphosphate, X-231, and DF250, respectively. According to the rougher flotation test results, a concentrate with a Co grade of 0.46% and a Co recovery of 84.15% was obtained. In the concentrate obtained using cleaner flotation tests, the Co grade increased to 0.49% and Co recovery increased to 90.56%. These results show that froth flotation, carried out with the appropriate reagents, is a successful method for recovering Co by enriching the flotation plant tailings.

Similar content being viewed by others

References

Beşe AV (2017) The recovery of metals from copper slags. Sinop Uni J Nat Sci 2(1):140–149

Brest KK, Henock MM, Guellord N, Kimpiab M, Kapiamba KF (2021) Statistical investigation of flotation parameters for copper recovery from sulfide flotation tailings. Results Eng 9:100207

COM (2020) Critical raw materials resilience: charting a path towards greater security and sustainability. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0474. Accessed 12 November 2022

Mandys F (2021) Electric vehicles and consumer choices. Renew Sustain Energy Rev 142:110874

Cobalt Institute (2022) Cobalt use. https://www.cobaltinstitute.org/about-cobalt/cobalt-life-cycle/cobalt-use/. Accessed 19 December 2022

USGS (2017) Mineral Commodity Summaries. https://d9-wret.s3.us-west-2.amazonaws.com/assets/palladium/production/mineral-pubs/mcs/mcs2017.pdf. Accessed 7 August 2022

Okudan MD (2009) Acidic and alkaline leaching application to spent hydrodesulfurization (hds) catalysts including cobalt and molybdenum. Dissertation, Süleyman Demirel University

Crundwell FK, Du Preez NB, Knights BDH (2020) Production of cobalt from copper-cobalt ores on the African Copperbelt–an overview. Miner Eng 156:106450

Yaylalı B (2017) Recovery of cobalt from pyritic tailings. Dissertation, Karadeniz Technical University

Tsurukawa N, Prakash S, Manhart A (2011) Social impacts of artisanal cobalt mining in Katanga, Democratic Republic of Congo. Öko-Institut eV, Freiburg

USGS (2020) Mineral commodity summaries. https://pubs.usgs.gov/periodicals/mcs2020/mcs 2020.pdf. Accessed 16 September 2022

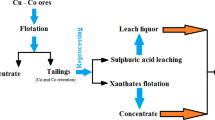

Lutandula MS, Maloba B (2013) Recovery of cobalt and copper through reprocessing of tailings from flotation of oxidised ores. J Environ Chem Eng 1(4):1085–1090

Shengo ML, Kime MB, Mambwe MP, Nyembo TK (2019) A review of the beneficiation of copper-cobalt-bearing minerals in the Democratic Republic of Congo. J Sustain Min 18(4):226–246

Yaylali B, Yazici E, Celep O, Deveci H (2016) Extraction of cobalt from a flotation tailings in different mineral acids under oxidative conditions. In: Çelik MS (ed) 15. International Mineral Processing Symposium (IMPS), İstanbul, pp 726–736

Arslan C, Arslan F (2002) Recovery of copper, cobalt, and zinc from copper smelter and converter slags. Hydrometallurgy 67(1–3):1–7. https://doi.org/10.1016/S0304-386X(02)00139-1

Rudnik E, Burzyńska L, Gumowska W (2009) Hydrometallurgical recovery of copper and cobalt from reduction-roasted copper converter slag. Miner Eng 22(1):88–95. https://doi.org/10.1016/j.mineng.2008.04.016

Zhai XJ, Li NJ, Zhang X, Fu Y, Jiang L (2011) Recovery of cobalt from converter slag of Chambishi Copper Smelter using reduction smelting process. Trans Nonferrous Met Soc China 21(9):2117–2121. https://doi.org/10.1016/S1003-6326(11)60982-5

Pryor B, Lunt D (2003) Development of the Kolwezi tailings copper/cobalt flowsheet. In: ALTA Conference, Perth, pp 1–9

Dehaine Q, Tijsseling LT, Glass HJ, Törmänen T, Butcher AR (2021) Geometallurgy of cobalt ores: A review. Miner Eng 160:106656

Hayat MB, Alagha L, Sannan SM (2017) Flotation behavior of complex sulfide ores in the presence of biodegradable polymeric depressants. Int J Polym Sci 2017:1–9

Çağatay A, Pehlivanoğlu H, Altun Y (1980) Cobalt-gold minerals in Kure pyritic copper deposits and their economic values. Bull Min Res Exp 93–94:110–117

Uçurum M, Yıldırım M, Köse M (1982) Küre piritli bakır yataklarındaki kobaltın flotasyon yöntemiyle zenginleştirme çalışmaları. MTA Report, Ankara.

Canbazoğlu M, Uzun M, Çelik Ö, Köse M (1985) Extraction of cobalt, copper, gold and silver from cinders of Küre pyritic coppers ores: a hydrometallurgical approach. In: 9. Scientific and Technical Mining Congress of Turkey, Ankara, pp 59–73

Mordoğan H (1989) Kastamonu-Küre-Bakibaba piritli bakır cevherindeki kobalt dağılımı ve kazanılma olanağı. Turkish J Chem 13(1)

Çokgör O, Topkaya YA (1988) Extraction of cobalt and copper from Küre pyrite concentrate. Miner Eng 1(3):213–223

Topkaya YA, Çokgör O (1991) Solvent ekstraksiyon yöntemiyle bakır ve kobalt kazanımının denge ve kinetiği. TUBİTAK Project no:785, Ankara

Yalçın S (1995) Distribution of base, rare and precious metals and their recovery in Kure massive ore. Dissertation, Istanbul Technical University

Perek KT, Arslan F (2003) Extraction of metallic values from Küre massive rich copper ore by pressure leaching. itu dergisi/d 2(3):65–72.

Arslan F, Kangal MO, Bulut G, Gül A (2004) Leaching of massive rich copper ore with acidified ferric chloride. Miner Process Extr Metall Rev 25(2):143–158

Bulut G (2006) Recovery of copper and cobalt from ancient slag. Waste Manag Res 24(2):118–124

Bulut G, Perek KT, Gül A, Arslan F, Önal G (2007) Recovery of metal values from copper slags by flotation and roasting with pyrite. Min Metall Explor 24(1):13–18

Yuksel U, Tegin I, Ziyadanogullari R (2017) Recovery of copper and cobalt from copper slags as selective. J Environ Sci Eng A 6(8):388–394

Xiao J, Zhang Y (2019) Recovering cobalt and sulfur in low grade cobalt-bearing V-Ti magnetite tailings using flotation process. Processes 7(8):536

Zanin M, Lambert H, Du Plessis CA (2019) Lime use and functionality in sulphide mineral flotation: a review. Miner Eng 143:105922

Bulatovic S (2007) Handbook of flotation reagents: chemistry, theory and practice: Vol 1: Flotation of sulfide ores. Elsevier, Boston

Taner HA (2019) The effect of structural properties of clay minerals on flotation performance of metal sulphides. Dissertation, Konya Technical University

Wang XH, Forssberg KSE (1991) Mechanisms of pyrite flotation with xanthates. Int J Miner Process 33(1–4):275–290. https://doi.org/10.1016/0301-7516(91)90058-q

Castellón CI, Toro N, Gálvez E, Robles P, Leiva WH, Jeldres RI (2022) Froth flotation of chalcopyrite/pyrite ore: a critical review. Materials 15(19):6536

Dimou A (1986) The flotation of pyrite using xanthate collectors. Dissertation, University of Cape Town

Chander S, Briceno A (1987) Kinetics of pyrite oxidation. Min Metall Explor 4(3):171–176

Ekmekçi Z, Demirel, H (1997) Effects of pulp potential and galvanic interaction on flotation of chalcopyrite and pyrite. In: Güyagüler T (ed) The 15. Mining Congress of Turkey, Ankara, pp 353–360

Deng W, Xu L, Tian J, Hu Y, Han Y (2017) Flotation and adsorption of a new polysaccharide depressant on pyrite and talc in the presence of a pre-adsorbed xanthate collector. Minerals 7(3):40

Davenport WG, King MJ, Schlesinger ME, Biswas AK (2002) Extractive metallurgy of copper, Elsevier

Molaei N, Hoseinian FS, Rezai B (2018) A study on the effect of active pyrite on flotation of porphyry copper ores. Physicochem Probl Miner 54(3):922–933

Banza AN, Kongolo K (2001) Flotation of a silicated oxide copper-cobalt ore from Fungurume deposit. In: Proceeding of The VI Southern Hemisphere Meeting on Mineral Technology (SHMMT) vol 1, Rio de Janeiro, pp 230–234

Yılmazer BZ (2002) The effects of hydrodynamic parameters on mechanical entrainment in the flotation of Küre rougher concentrate. Dissertation, Süleyman Demirel University

Song S, Lopez-Valdivieso A, Espinoza-Ortega O (2009) Role of sodium hexametaphosphate in the flotation of acanthite fines from finely disseminated ores. Sep Sci Technol 44(12):2971–2982

Wills B (1997) Mineral Processing Technology, 6th edn. Butterworth Heinemann, London

Bell DT (2012) Flotation of cobalt bearing minerals from a mixed copper-cobalt oxidized ore. Dissertation, University of Johannesburg

Shahcheraghi SH, Abdollahy M, Khalesi MR, Hossein SM (2012) A study on the effect of some operating parameters on the flotation kinetics of copper sulfide minerals. In: Proceedings of the XXVI International Mineral Processing Congress (IMPC), New Delhi, pp 24–28

Khoshdast H, Sam A (2011) Flotation frothers: review of their classifications, properties and preparation. The Open Miner Process J 4(1):25–44

Mordogan H (1985) Karadeniz bölgesi kompleks bakırlı cevherlerden bazı metallerin kazanılmasında optimal koşulların saptanması. Dissertation, Ege University

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aras, A., Rasa, M.H. Investigation of Flotation Conditions for Cobalt Recovery from Mine Tailings. Mining, Metallurgy & Exploration 40, 939–948 (2023). https://doi.org/10.1007/s42461-023-00769-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-023-00769-3