Abstract

Preservation of our cultural and historical heritage as a testimony to our shared past is a responsibility that demands significant attention. One of the most critical and delicate aspects of conserving such treasures is cleaning them safely and effectively. Chemical hydrogels specifically designed for cleaning cultural heritage artifacts allow for the containment and controlled release of water. Based on a generic approach, a smart nanomagnetic hydrogel was developed using a semi-interpenetrating polymer network (semi-IPN) of polyhydroxyethyl methacrylate (p(HEMA)) and polyvinyl pyrrolidone (PVP). Gamma irradiation was employed to perform simultaneous in-situ polymerization, crosslinking, and also immobilization of iron oxide magnetic nanoparticles (MNPs). The chemical and structural characteristics of the nanomagnetic hydrogel were investigated using gel content, equilibrium water content, field-emission scanning electron microscopy, magnetic properties, compressive strength, dehydration kinetics, and adhesion tests. The optimal formula for smart hydrogel was a ratio of monomer to polymer 50:50, a water content of 60 wt.%, a gamma radiation dose of 20 kGy, and 3 wt.% of MNP. Two cotton canvas case studies demonstrate the versatility and effectiveness of the selected hydrogel in removing dirt and confining the water-based cleaning system. It was found that no color leaching occurred during the cleaning process.

Article Highlights

-

The smart nanomagnetic p(HEMA)/PVP hydrogel can remove grime from cotton canvas without manual intervention.

-

Simultaneous polymerization, crosslinking and immobilization of magnetic nanoparticles in a hydrogel structure using gamma radiation.

-

Cleaning does not affect the integrity of the hydrogel and does not leave any residues on the artwork.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cultural heritage artifacts form the foundation of every people and nation and preserve their past. It is crucial and imperative to safeguard these objects. Utilizing new technologies to optimize materials and preservation techniques promises more efficient treatment and conservation. Recently, various formulations have been introduced for cleaning cultural heritage artifacts, such as paintings, which can potentially replace traditional methods [1,2,3].

It is generally used to remove any pollutants or grime from the surface layers of a painting. This could potentially lead to the deterioration of these works of art. Pollution layers can be hydrophilic or hydrophobic. Removing hydrophilic layers is easier and possible with a water solvent, but eliminating hydrophobic layers can be done with organic solvents. Most organic solvents are toxic and do not facilitate controlled cleaning. Uncontrolled penetration of pure solvent into the porous structure of the artifact may lead to varnish and binder leaching or swelling, whose long-term consequences are unclear [4]. The solvent's confinement has been developed to prevent compounds dissolved in the cleaning solvent from diffusing deeper and wider. Gel/solvent systems are a superior alternative to pastes made from organic solvents and wax admixtures for encapsulating solvents in the cleaning process. However, the main disadvantage of using a gel/solvent combination is that it may leave residues on artwork after cleaning. This necessitates the use of a complex re-cleaning technique that often involves a blend of organic solvents [5, 6].

Since 1980, gel technology has been successfully utilized to clean artwork. Gel systems offer several benefits, including improved operator safety and a controlled, efficient cleaning procedure. This is caused by prolonging the duration of the solvent action while simultaneously decreasing the capillarity of the solvent in the paint. In addition, the gel formulation increases solvent confinement by reducing its evaporation rate. This creates a micro-environment where liquid solvent effectively cleans the surfaces. Also, these systems decrease operator exposure to toxic vapors by controlling solvent evaporation [6,7,8,9,10,11]. Polymer gels capable of loading solvents are classified into two kinds based on the crosslinking agent type; physical [12, 13] and chemical gels [1, 2]. In the latter case, gels exhibit strong cohesiveness and assume a distinct shape during synthesis. One of the pioneering studies in this field was conducted by Carretti et al. [12] who explored the use of poly(vinyl alcohol)-borate hydro/cosolvent gels, focusing on their viscoelastic properties and solubilizing power, and their application to art conservation. Their research demonstrated that PVA hydrogels effectively removed surface dirt and aged varnish layers without causing damage to the underlying paint layers. Building upon this foundational work, Bonelli et al. [14] developed a promising formulation of poly(vinyl alcohol)/poly(vinyl pyrrolidone) hydrogels that effectively removed grime from rough and irregular artistic surfaces, leaving no residue. Chemical gels derived from 2-hydroxyethyl methacrylate (HEMA), which are biocompatible, and non-toxic, constitute one of the key chemical gel systems. Although pHEMA gels have some limitations, such as poor mechanical strength and limited water absorption, researchers have been exploring methods to modify these gels to extend their water absorption capacity and applications [15, 16]. A semi-interpenetrating network (semi-IPN), which is formed by combining two polymers with at least one of the polymers synthesizing or crosslinking in the presence of the other, has proven useful in modifying p(HEMA) hydrogel physicochemical and mechanical properties by combining them with other polymers [9, 18]. For applications requiring biocompatibility, non-toxicity, and water uptake, polyvinylpyrrolidone (PVP) is a preferred choice [17]. According to Dominicgues et al. [4] and Bonelli et al. [18] semi-interpenetrating p(HEMA)/PVP networks have the potential to clean water-sensitive cultural heritage artifacts. Because these hydrogels retain a large amount of water and have a high mechanical strength, they can confine and modulate the properties of water-based cleaning systems, ensuring that grime and varnish can be safely and effectively removed. To minimize hand involvement in the cleaning process and focus on the environmental aspect, Bonini et al. [9] have explored the synthesis of magnetic nanoparticles coupled with acrylamide ethylene oxide polymers to produce a magnetic sponge. By applying them to artwork and reabsorbing them without direct contact, these sponges are safe and effective for cleaning. Despite this, due to the low mechanical strength of these sponges, their application is very limited.

Chemically synthesized hydrogels are widely used in various applications. However, toxic crosslinking agents and initiators are often required, which can harm the environment and human health. Due to these limitations, radiation synthesis has emerged as a promising alternative to hydrogel production, as it does not require cross-linking agents and initiators. Hydrogels can be enhanced in terms of mechanical properties, temperature sensitivity, and antibacterial properties, making them suitable for long-term storage. Radiation synthesis also allows hydrogel fabrication in various media, including cells, emulsions, polymer films, surfactant micelles, and glasses. Radiation synthesis offers a more sustainable and environmentally friendly method of producing hydrogels [19,20,21,22].

This study aims to present a novel irradiation-synthesized smart nanomagnetic semi-IPN hydrogel based on polyhydroxyethyl methacrylate/polyvinylpyrrolidone (p(HEMA)/PVP) with suitable mechanical strength, which can be loaded with a water-based solvent. This hydrogel can detach from artwork surfaces autonomously post-cleaning, eliminating the need for manual intervention or physical pressure and leaving no residue. Iron oxide (Fe3O4) nanoparticles were chosen for their biocompatibility, high magnetization ability, and ease of preparation and functionalization [23]. Nanomagnetic hydrogels were created through simultaneous polymerization, cross-linking, and chemical immobilization of nanoparticles using gamma irradiation. Different characteristics of this smart hydrogel will be examined and ultimately explored as a promising tool in cleaning paintings.

2 Materials and methods

2.1 Chemicals

Polyethylene glycol (PEG-4000), maleic anhydride (99%), 2-hydroxyethyl methacrylate (HEMA) (97%), and methylene bisacrylamide (MBA) as a crosslinker were all purchased from Merck. Iron (II) chloride tetrahydrate (99%) and iron (III) chloride hexahydrate (99%) were also purchased from Merck. Aldrich supplied PVP (MW 10,000). Sodium dodecyl sulfate (Sigma-Aldrich, 99%), 1-pentanol (Merck, 98.5%), and p-xylene (Sigma-Aldrich, 99%) were used as received.

2.2 Synthesis and functionalization of magnetic Fe3O4 nanoparticles

The method described in reference [24] was selected from the available methods for synthesizing magnetic Fe3O4 nanoparticles (MNPs), considering the facilities, readily available materials, conditions used, and particle quality and size reported in the articles. At first, a 0.5 M NaOH solution was prepared in a 500 ml round-bottom three-neck flask, and degassed while stirring for 30 min at 40 °C using argon gas. A 0.4 M solution of hydrochloric acid was also prepared and degassed for 30 min. 0.024 mol of FeCl3.6H2O and 0.012 mol of FeCl2.4H2O were added to the HCl solution and mixed for 15 min. Then the iron solution was added drop by drop, and the reaction temperature was increased to 80 °C. The reaction mixture was stirred for 1 h at this temperature. The obtained dark brown nanoparticles were settled using a strong magnet and the upper solution was separated. The sample was obtained by dispersing the product with ultrasonic waves and then washed with ethanol and water. It was dried at 60 °C under vacuum.

To prevent the release of nanoparticles during the cleaning process of cultural heritage surfaces and stabilize and enhance the dispersion of MNP in the structure, the chemical bonding between nanoparticles and hydrogel structure was required. Chemical bonding between nanoparticles is achieved through linkers. There are two concepts that this linker needs to satisfy: it must have reactive groups that can bind nanoparticles, as well as reactive double bonds that enable it to enter polymeric hydrogels. Polyethylene glycol-maleic anhydride (PEG-g-MA, synthesized according to [25, 26]) can solve this need. A schematic showing the corresponding reaction can be found in Fig. 1. Through the etherification reaction between PEG-MA acid groups and hydroxyl groups on nanoparticle surfaces, PEG-MA molecules are attached to MNPs to functionalize them. The linker to nanoparticle weight ratio was selected as 1:10 for this purpose [27]. In deionized and degassed water, a certain weight of nanoparticles was dispersed for 30 min. After adding the PEG-g-MA solution, sonication was continued for an additional hour. A mechanical stirrer was also used to bind the linker to the MNPs. The finished product underwent washing, magnetic separation from unreacted materials, and freeze-drying.

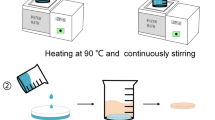

2.3 Irradiation synthesis of semi-interpenetrating networks magnetic hydrogel

By combining different amounts of components (HEMA monomer, PVP, water, and MBA) and utilizing gamma irradiation as the initial step, semi-IPNs were created without functionalized nanoparticles (F-MNPs). The various hydrogel formulas were combined to create solutions with three different monomer-to-polymer ratios (50:50, 40:60, and 30:70 (wt. ratio)) and varying amounts of water. In all formulas, the MBA content was 0.5 mol% (relative to the monomer). As can be seen in Table 1, a variety of formulations have been prepared. The solutions were exposed to nitrogen gas for 10 min before receiving a dose of 20 kGy radiation. By promoting the formation of free macro-radicals, which ultimately result in a crosslinked structure, irradiation synthesis can introduce simultaneous in-situ polymerization, crosslinking, and immobilization of F-MNPs (Fig. 1). Each sample was immersed for 24 h to separate the unreacted monomer from the hydrogel and then dried using a freeze-dryer. Next, 1%, 3%, and 5% by weight of F-MNPs were added to the components of the optimal formulation after being dispersed in deionized (DI) water using an ultrasonic bath. After degassing, polymerization, cross-linking, and F-MNP immobilization were performed simultaneously in the hydrogel structure using gamma radiation at 20 kGy.

2.4 Characterization

Spectroscopy in the Ultraviolet–visible (UV–Vis) range was conducted using a Beckman Coulter DU® 800 instrument. Using a Bruker Tensor 27 model, the fourier transform infrared (FTIR) spectrum was recorded between 400 and 4000 cm−1. The field emission scanning electron microscope (FESEM) TESCAN MIRA3 equipped with X-ray energy diffraction (EDX) acquired images from magnetic nanoparticles, control hydrogel, and magnetic hydrogel (freeze-dried hydrogels) using a working potential of 30 kV. A vibrating sample magnetometer (Kavir Kashan Magnetic Company, Model LBKFB) was used to investigate the magnetic properties of the synthesized MNP and nanomagnetic hydrogel at room temperature. The samples were irradiated by a Co-60 source with an activity of 8775 Ci. The gel content of each sample was calculated as the weight of the dry gel divided by the total weight of the monomer and polymer. For each hydrogel sample, the amount of water absorbed in the structure reaches a constant and saturated value after being immersed in water. Equation 1 is calculates the equilibrium water content (EWC), which represents the hydrophilicity of the hydrogel.

where Wd is the weight of dried gel and Ww is the weight of saturated gel.

As soon as they were saturated with water, the hydrogels were weighed for dehydration kinetics (Ww). Subsequently, they were placed in a chamber with a relative humidity of 45% and a temperature of 22 °C (representing operating environment conditions). The change in water release over time (WD) was then calculated using the formula in Eq. 2 below, where Wi represents the weight of the sample at time i and Wd is the dry weight of the sample.

Uniaxial compression experiments were conducted using disc-shaped samples prepared from control and magnetic hydrogel samples (2.3 cm diameter). A cylinder-shaped 400 g weight is applied over the samples' surface for 5 min to create a 50 g/cm2 weight-to-surface ratio, which completely covers the hydrogel surface. In this step, the force is removed, and four points on each sample are measured with calipers to determine the height of the discs. Based on the equation [28, 29], the shear modulus was calculated as follows:

In this equation, τ is the compression load, F is the pressure load, A is the cross-sectional area of swollen gels, and λ is the compression strain (L/L0), with L = sample height under strain, and L0 = Initial height of the sample.

The presence of gel residues on the cleaned surface was evaluated using attenuated total reflectance fourier transform infrared spectroscopy (ATR-FTIR). For this purpose, water-saturated control and nanomagnetic gels were placed on the surface of the cotton canvas model without mechanical force for 10 min and then removed. FTIR-ATR analysis was conducted on an area of 100–200 mm2 of these canvases within the range of 4000–600 cm−1, and the data were processed using OPUS software.

3 Result and discussion

The UV–Vis absorption spectrum of synthesized nanoparticles at ambient temperature is shown in Fig. S1 of the supplementary material. The transparent colloid of Fe3O4 nanoparticles dispersed in DI does not show any quantifiable characteristics in the region [30, 31]. Also, Fig. S2 in the supplementary material illustrates the FTIR spectrum of MNP and F-MNP. The peak at 3389 cm−1 is due to O–H stretching vibration caused by hydroxyl groups on nanoparticle surfaces. The absorption peak at 1605 cm−1 may be related to the vibrational deformation of water molecules trapped in magnetic colloidal particles, whereas the peak at 1338 cm−1 can be attributed to the iron phase vibrations. The absorption peaks at 586 and 449 cm−1 correspond to the Fe–O vibrational band of nanoparticles. These peaks show iron nanoparticle structure and are consistent with previous researchers' observations [27, 32,33,34,35]. The functionalized nanoparticle's FTIR spectrum shows a peak at 1727 cm−1, which denotes the vibration of the (C = O)-O group and verifies the chemical attachment of the linker agent to the nanoparticle's surface [36, 37]. The characteristic peaks confirm the chemical attachment of the linker agent to the nanoparticle's surface.

The nanoparticles, shown in the FESEM photograph Fig. 2a have an irregular shape and a relatively narrow particle size distribution (Fig. 2c) with an average diameter of 34.02 nm, and some particles appear to be agglomerated smaller particles. Based on the elemental composition of the MNPs determined using EDX, inset: Fig. 2c, it is clear that MNPs are composed of oxygen and iron. According to Fig. 2b and checking the statistical data in Fig. 2d, it seems that the functionalization of nanoparticles has led to a slight increase in the size of the particles (the average diameter of F-MNPs is 39.1 nm) and a broader distribution of the size of the particles.

Figure 3a shows the gel content of hydrogels prepared with 87.5 wt.% and 75 wt.% water contents in various HEMA/PVP ratios. It was observed that increasing the amount of water has a significant impact on decreasing the gel content. A significant increase in gel content was observed when water content was decreased. A decrease in water content is accompanied by an increase in monomer content in a hydrogel formulation. The number of monomer molecules participating in polymerization reactions and cross-link formation increases, increasing cross-link density and network formation. In turn, this results in a denser, more crosslinked polymer network, resulting in higher gel content [38, 39]. Thus, lower water contents in the original formula were also explored in a subsequent stage—60%, 50%, and 40% by weight. Higher monomer-to-polymer ratios can also produce the same effect. For further study, we chose the formula with a monomer/polymer ratio of 50:50 that produced a high gel content and better structural continuity.

Gel content and equilibrium water content for 50:50 HEMA/PVP ratio hydrogels and various water contents are shown in Fig. 3b. The hydrogel samples synthesized with water content of 40%, 50%, and 60% by weight were transparent and maintained their shape during separation from the container and washing. The samples containing 50% and 60% water by weight were very soft and flexible, while the sample with 40 wt.% initial water was inflexible and rigid. According to Fig. 3b, the sample containing 40 wt.% water has the highest gel content, which leads to reduced water absorption.

A gel intended to clean cultural artifacts should have the appropriate flexibility, cohesiveness, strength, and a high EWC. Additionally, a hydrogel with 60 wt.% water has the highest EWC, as shown in Fig. 3b. This sample was soft and flexible, with adequate structural cohesion and continuity. Therefore, the optimal hydrogel (control gel) conditions were determined to be a 50:50 monomer-to-polymer ratio, a 60 wt.% initial water content, and a 20 kGy radiation dose.

Figure 4 shows the gel content and equilibrium water content of the nanomagnetic hydrogels obtained. When the nanoparticle concentration is raised from 1 to 5 wt.%, the gel content increases. Loading F-MNPs into hydrogel structures as a crosslinking agent (via chemical immobilization into hydrogel structure (Fig. 1)) controls the gel content through cross-linking density [40].

Chemical composition, crosslinking density, and nanoparticle additives influence hydrogel equilibrium water content [41]. The observed changes in equilibrium water content for the samples with 1%, 3%, and 5 wt.% of F-MNPs, fall within a relatively narrow range. Two conflicting effects compete in determining the equilibrium water content as the nanoparticle content changes [40]. On the one hand, increased nanoparticle content reduces the average distance between nodes, increases gel content, and decreases the swelling ability of hydrogels [42]. On the other, the presence of hydrophilic groups on the surface of magnetic nanoparticles causes more water uptake. The result of these two effects determines the final amount of the equilibrium water content [40].

In a cleaning application, the gel content must be suitable to provide the necessary structural integrity and retentiveness of the cleaning solvent. In contrast, a hydrogel containing more water can load and deliver more water-based cleaning solvents. Hence, the magnetic hydrogel with 3 wt.% F-MNPs was selected as the optimal sample to clean works of art and to load water-based cleaning solvent.

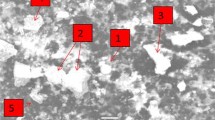

Figure 5 shows FESEM images of the freeze-dried samples of the control hydrogel and the nanomagnetic hydrogel, respectively. The interconnected cavities in gel and nanomagnetic hydrogel samples exhibit sponge-like structure. The structure is extremely porous, and the holes range from a few hundred nanometers to several microns. It's crucial to remember that the porous structure of these materials enables them to retain liquids such as water, solvents, or microemulsions [4].

A structure with more heterogeneity is observed for nanomagnetic hydrogels than regular gels. The cavity walls are thicker than the gel, measuring several microns. Compared to the control gel, the nanomagnetic gel structure exhibits smaller holes. Electron-rich magnetic nanoparticles are responsible for the bright spots in the image. Nanoparticles with irregular shapes are dispersed throughout the hydrogel while stabilizing into the hydrogel structure. This is due to the presence of a covalent bond between the acid group of maleic anhydrides and the hydroxyl groups on the surface of the nanoparticles. As the nanomagnetic hydrogel is extracted and purified, any nanoparticles trapped within the gel structure should be released. As a result of using a linker, nanoparticles have been stabilized in nanomagnetic gel networks.

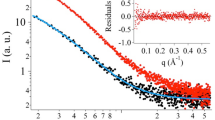

Nanomagnetic materials have crucial magnetic properties because the degree of magnetization determines the types of applications in which these materials can be used. To investigate the magnetic behavior of MNPs, F-MNPs, and nanomagnetic hydrogel, the alterations in their magnetic moments were analyzed as a function of the applied magnetic field (Oe) ranging from -10,000 to 10,000 at room temperature (Fig. 6).

Figure 6a shows that as the external magnetic field (Oe) increases, MNP magnetization gradually increases until it reaches saturation at higher magnetic fields. Superparamagnetic particles have permanent magnetizations (Mr) and extremely low coercive fields, almost negligible. Higher magnetic fields lead to magnetic saturation when all particles' magnetic moments align with the applied field direction. The saturation magnetization (Ms) for MNPs and F-MNPs is 34.20 and 37.28 emu/g, respectively. The Ms and Hc decrease as the particle size decreases because superparamagnetic behavior occurs in nanoscale magnetic particles [43]. The results of this test validate and agree with the measurements of F-MNP and MNP size made during the FESEM test.

Figure 6b shows that the saturation magnetization of nanomagnetic gels containing 0.5, 1, 3, and 5 wt.% is 0.24, 0.70, 1.93, and 2.60 emu/g, respectively. Because there are only 0.5–5 wt.% of nanoparticles in the hydrogel, the Ms value of nanomagnetic gels is significantly lower than that of nanoparticles. Based on this curve, the second region of MNPs, which forms in hydrogel networks and exhibits the singular phenomenon of superparamagnetism, is indicated by the low values of Hc and Mr of magnetic hydrogels [44].

Examining the saturation magnetization level reveals the existence of a transition limit at a content of 3% by weight of functionalized nanoparticles, after which the increasing trend of saturation magnetization (Ms) slows down. Therefore, the nanomagnetic gel sample with 3 wt.% F-MNPs is confirmed as the most appropriate choice. This sample offers suitable magnetic properties for cleaning cultural heritage works. It allows the easy and quick removal of nanomagnetic gel after cleaning using an external magnet.

Dehydration kinetics provide an improved understanding of the solvent retention capability of the investigated gels. PVP and p(HEMA) are both hydrophilic compounds with good water retention and as demonstrated by hydrogels developed [4, 45] can be loaded with water-based solvent-cleaning systems such as micellar solutions and microemulsions. The test confirmed that the dehydration kinetics of the nanomagnetic hydrogel in the first few hours are completely similar to the control gel, and magnetic nanoparticles do not affect dehydration behavior (Fig. 7). Due to the low concentration of magnetic nanoparticles in the hydrogel structure, these nanoparticles do not contribute significantly to final properties. p(HEMA) by nature is a diamagnetic polymer with a weak and negative response to magnetic fields [46]. Fe3O4 is a superparamagnetic material with a positive susceptibility (i.e., its ability to respond to magnetic fields), and the response is several hundred times greater than that of diamagnetic materials [46]. However, as Fig. 6 shows the hydrogel's magnetic properties are minimal, even when 5 wt.% of magnetic nanoparticles are present. Also, the published results confirm that the decrease in the magnetic saturation value in nanomagnetic p(HEMA) hydrogel is due to the presence of the diamagnetic p(HEMA) polymer [47, 48]. This indicates that the hydrophilic p(HEMA) polymer network is the dominant factor determining the hydrogel's properties rather than the embedded magnetic nanoparticles [47, 48], as illustrated in Fig. 4, Fig. 6, and Fig. 7.

Peelability is a crucial feature that solvent gels traditionally used in conservation lacked. The residues could have caused damage to the substrate surface and required a second cleaning intervention. It is important to determine the shear modulus of hydrogels because it affects the peelability [49]. Network polymers undergo elastic deformation when subjected to external forces. An assessment of the gel's elasticity was made through a compression test [50]. The control gel and nanomagnetic gel samples have L/L0 ratios of 0.960 ± 0.03 and 0.940 ± 0.03 and shear modulus of 398.24 and 259.80 g/cm2, respectively. It was shown that hydrogels are capable of loading water, micellar solvent, or microemulsion solvents. During gamma radiation, the double bonds in HEMA can form polymer chains and crosslink as well. Additionally, the functionalized nanoparticles and double bonds in the PEG-g-MA structure allow nanoparticles to enter the hydrogel polymer. Figure 1 shows the chemical structure of the polymer network and how the nanoparticle acts as a cross-linking agent for the p(HEMA) chains. Therefore, magnetic semi-IPN p(HEMA)/PVP exhibits a sufficient shear elastic modulus, which allows a restorer to easily peel them from cleaned surfaces, minimizing residues and the need for additional rinsing.

A hydrogel's structural integrity must be maintained during cleaning for it to be effective in cleaning works of art [51]. Hydrogels that have weak structural integrity may break apart during cleaning, leaving residues on artwork that are damaging. ATR-FTIR analysis was used to verify the hydrogel structure's integrity. ATR-FTIR spectra, as depicted in Fig. 8, were collected from cotton canvas before and after direct exposure to gel and nanomagnetic hydrogel. This was done to validate this claim and assess the influence of Fe3O4 nanoparticles on the performance of the nanomagnetic hydrogel during cleaning. The characteristic peaks (1724 cm−1 and 1654 cm−1) associated with the stretching vibration of the carbonyl groups in polyvinyl pyrrolidone and hydroxymethyl methacrylate are not visible in the canvas spectrum after contact with the gel (Fig. 8b). Additionally, the spectrum of the canvas before and after contact with the gel is remarkably similar. The irradiation method produced a highly cohesive and continuous hydrogel of p(HEMA)/PVP. As a result of the cohesion of the polymer network, the gel does not remain on the surface after cleaning. Thus, it is possible to clean the artwork without leaving any gel residues [4]. As a result of contact with the canvas, the ATR spectrum (Fig. 8c) of the nanomagnetic hydrogel has not changed, and the adhesion of the hydrogel in the presence of iron nanoparticles is also great.

Additionally, the spectral region (800–400 cm−1) enlarged to locate the peaks responsible for the identification of Fe–O bond. The characteristic Fe–O vibration peaks at 586 and 449 cm−1 [27, 32,33,34,35] are not observed (Fig. 8, inset) due to the chemical bonding and immobilization of magnetic nanoparticles. As a result, nanoparticles have not been released onto the canvas surface from the nanomagnetic hydrogel. In practical applications, this function is particularly useful since it eliminates the need for additional washing processes. It can cause problems for surfaces that are sensitive to solvents after they are cleaned.

Two experimental painting models on cotton canvas were employed to determine nanomagnetic hydrogel's efficacy and control cleaning action. In the first stage, artificial grime was used following the technique described [52, 53]. Table 2 lists the type and quantity of grime component elements To create the artificial grime, all of the solid ingredients were thoroughly mixed with mineral oil after being pounded into a fine powder in a mortar. The grime mixture was then applied as a surface layer to a section of Model No. 1 (a just-completed oil painting that measured 30 × 40 cm2 (Fig. 9b)) using a soft sponge. Model No. 1 (top left corner polluted) is seen in Fig. 9c.

The oil-in-water microemulsion was prepared by mixing the appropriate components following reference [54]. The contaminated area of model No. 1 was covered with microemulsion-saturated nanomagnetic hydrogel (Fig. 9d). After a certain time, the magnetic hydrogel was removed using an external magnet (Fig. 9e). Cleaning was done effectively, as shown in Fig. 9f. Color leaching resulting from over-wetting the treated surface and colorant diffusion upon contact with nanomagnetic hydrogel were not observed.

Theoretically, a microemulsion-loaded hydrogel can remove pollution from the surface in two stages. In the first stage, wetting the surface removes any electrical force between the pollutant particles and the surface, allowing them to be separated. In the second stage, it overcomes any molecular forces that hold pollutant particles to the surface [55]. The gel releases tiny water droplets from its pores onto the surface in contact with the pollutant. The droplets dissolve pollutants and absorb the particles, transferring them into the gel structure.

The application of microemulsion-loaded nanomagnetic hydrogel over short periods, each lasting a few minutes, was found to be the most effective method for progressive and controlled cleaning activity. Nanomagnetic hydrogel does not require manual cleaning, in contrast to conventional hydrogel and traditional cleaning techniques.

Magnetic nanoparticles within the hydrogel provide magnetic responsiveness. An external magnet simplifies the handling of this nanomagnetic hydrogel. Nanomagnetic hydrogel exhibited repeatable on–off switching behavior when the magnetic field was applied and removed alternately. Using this feature, the hydrogel can be precisely positioned and moved for targeted cleaning applications on delicate or hard-to-reach surfaces. Due to its flexible structure, a magnetic hydrogel can also be cut into a variety of shapes (Fig. 9a). To prevent damage from excessive liquid treatments in other areas of the artwork and to safeguard cultural heritage pieces with a tailored and safe approach, these hydrogels can be directed to specific sections of the artwork based on their shape and accessibility.

The efficacy of nanomagnetic hydrogel was further evaluated using Model No. 2, an oil painting on canvas that was 10 years old and measured 30 × 40 cm2. The painting had been exposed to environmental pollution from dust and grime (Fig. 10).

To achieve controlled and effective cleaning action on Model No. 2, the most efficient method is to utilize a nanomagnetic hydrogel loaded with water for a specified duration. The experimental investigation of nanomagnetic hydrogel performance on Model No.1 showed that effective cleaning takes between 20 and 30 min. During this period, and based on the data from the dehydration kinetic test, the hydrogel retains a significant amount of water and does not damage the painting. In addition, the method used does not require mechanical action, whereas traditional cleaning methods require it.

The nanomagnetic hydrogel remained in contact with Model No. 2 for 25 min. Figure 10 illustrates the uniform and contained cleaning achieved with nanomagnetic hydrogel, effectively removing the dirt layer without color leaching. After washing and rehydrating, it should be noted that the nanomagnetic hydrogel can be reused multiple times.

4 Conclusion

The study presents a groundbreaking approach to art restoration and conservation by developing an irradiation-assisted synthesized nanomagnetic hydrogel. This innovative gel, incorporating magnetic iron nanoparticles functionalized with polyethylene glycol/maleic anhydride and their immobilization in the hydrogel structure, demonstrates exceptional potential for delicate artificial artwork cleaning.

By varying the components' contents, a 50:50 HEMA/PVP ratio, 60 wt.% water, and 3 wt.% F-MNPs according to their characterizations were chosen. As a result of the gel's porous structure, the nanomagnetic hydrogel has an equilibrium water content of over 63%. Nanomagnetic hydrogel was utilized as an active container for water and other detergents to clean artificial artworks. According to the dehydration test, the gel can retain water within its structure and release it gradually. The nanomagnetic hydrogel is more effective at cleaning than traditional methods, as it can retain water and cleaning liquids, reducing the possibility of damage caused by excessive solvent penetration. It offers a non-invasive solution that minimizes damage to priceless artifacts, significantly impacting art restoration and conservation.

To propel this research forward, future investigations could optimize the gel's composition for diverse art restoration applications. In addition, they could assess its long-term effects on different artistic materials. Despite its promising attributes, the study acknowledges limitations. These limitations include the need for further toxicity assessments and scalability considerations to ensure widespread applicability.

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Code availability

Not applicable.

References

Passaretti A, Cuvillier L, Sciutto G, Guilminot E, Joseph E. Biologically derived gels for the cleaning of historical and artistic metal heritage. Appl Sci. 2021;11:3405–21. https://doi.org/10.3390/app11083405.

Guilminot E. The use of hydrogels in the treatment of metal cultural heritage objects. Gels. 2023;9:191–206. https://doi.org/10.3390/gels9030191.

Filippidis G, Massaouti M, Selimis A, Gualda EJ, Manceau JM, Tzortzakis S. Nonlinear imaging and THz diagnostic tools in the service of cultural heritage. Appl Phys A. 2012;106:257–63. https://doi.org/10.1007/s00339-011-6691-7.

Domingues JAL, Bonelli N, Giorgi R, Fratini E, Gorel F, Baglioni P. Innovative hydrogels based on semi-interpenetrating P(Hema)/Pvp networks for the cleaning of water-sensitive cultural heritage artifacts. Langmuir. 2013;29:2746–55. https://doi.org/10.1021/la3048664.

Baij L, Hermans J, Ormsby B, Noble P, Iedema P, Keune K. A review of solvent action on oil paint. Heritage Science. 2020;8:43–65. https://doi.org/10.1186/s40494-020-00388-x.

Baglioni M, Giorgi R, Berti D, Baglioni P. Smart cleaning of cultural heritage: a new challenge for soft nanoscience. Nanoscale. 2012;4:42–53. https://doi.org/10.1039/C1NR10911A.

Balliana E, Ricci G, Pesce C, Zendri E. Assessing the value of green conservation for cultural heritage: positive and critical aspects of already available methodologies. Int J Conserv Sci. 2016;7:185–202.

Bonini M, Lenz S, Falletta E, Ridi F, Carretti E, Fratini E, et al. Acrylamide-based magnetic nanosponges: a new smart nanocomposite material. Langmuir. 2008;24:12644–50. https://doi.org/10.1021/la802425k.

Bonini M, Lenz S, Giorgi R, Baglioni P. nanomagnetic sponges for the cleaning of works of art. Langmuir. 2007;23:8681–5. https://doi.org/10.1021/la701292d.

Baglioni P, Dei L, Carretti E, Giorgi R. Gels for the conservation of cultural heritage. Langmuir. 2009;25:8373–4. https://doi.org/10.1021/la900961k.

Pirsa S, Asadzadeh F, Karimi SI. Synthesis of magnetic gluten/pectin/Fe3O4 nano-hydrogel and its use to reduce environmental pollutants from lake urmia sediments. J Inorg Organomet Polym Mater. 2020;30:3188–98. https://doi.org/10.1007/s10904-020-01484-y.

Carretti E, Grassi S, Cossalter M, Natali I, Caminati G, Weiss RG, et al. Poly(vinyl alcohol)-borate hydro/cosolvent gels: viscoelastic properties, solubilizing power, and application to art conservation. Langmuir. 2009;25:8656–62. https://doi.org/10.1021/la804306w.

Carretti E, Bonini M, Dei L, Berrie BH, Angelova LV, Baglioni P, et al. New frontiers in materials science for art conservation: responsive gels and beyond. Acc Chem Res. 2010;43:751–60. https://doi.org/10.1021/ar900282h.

Bonelli N, Poggi G, Chelazzi D, Giorgi R, Baglioni P. Poly(vinyl alcohol)/poly(vinyl pyrrolidone) hydrogels for the cleaning of art. J Colloid Interface Sci. 2019;536:339–48. https://doi.org/10.1016/j.jcis.2018.10.025.

Sánchez-Cid P, Jiménez-Rosado M, Romero A, Pérez-Puyana V. Novel trends in hydrogel development for biomedical applications: a review. Polymers. 2022;14:3023–52. https://doi.org/10.3390/polym14153023.

Pereira AT, Henriques PC, Costa PC, Martins MCL, Magalhães FD, Gonçalves IC. Graphene oxide-reinforced poly(2-hydroxyethyl methacrylate) hydrogels with extreme stiffness and high-strength. Compos Sci Technol. 2019;184:107819–28. https://doi.org/10.1016/j.compscitech.2019.107819.

Franco P, De Marco I. The use of poly(N-vinyl pyrrolidone) in the delivery of drugs: a review. Polymers. 2020;12:1114–42. https://doi.org/10.3390/polym12051114.

Bonelli N, Chelazzi D, Baglioni M, Giorgi R, Baglioni P. Confined aqueous media for the cleaning of cultural heritage: innovative gels and amphiphile-based nanofluids. In: Dillmann P, Bellot-Gurlet L, Nenner I, editors. Nanoscience and Cultural Heritage. Paris: Atlantis Press; 2016. p. 283–311.

Yang J, Rao L, Wang Y, Zhao Y, Liu D, Wang Z, et al. Recent Advances in smart hydrogels prepared by ionizing radiation technology for biomedical applications. Polymers. 2022;14:4377–94. https://doi.org/10.3390/polym14204377.

Elbarbary AM, Ghobashy MM, El Khalafawy GK, Salem MA, Kodous AS. Radiation cross-linking of pH-sensitive acrylic acid hydrogel based polyvinylpyrrolidone/ 2-dimethylamino ethyl methacrylate loaded with betamethasone dipropionate drug and in vitro anti-inflammatory assessment. J Drug Delivery Sci Technol. 2023;89:105024. https://doi.org/10.1016/j.jddst.2023.105024.

Manaila E, Craciun G, Ighigeanu D, Cimpeanu C, Barna C, Fugaru V. Hydrogels synthesized by electron beam irradiation for heavy metal adsorption. Materials. 2017;10:540–61. https://doi.org/10.3390/ma10050540.

Rosiak JM, Ulański P. Synthesis of hydrogels by irradiation of polymers in aqueous solution. Radiation Phys Chem. 1999;55:139–51. https://doi.org/10.1016/S0969-806X(98)00319-3.

Liu H, Wang C, Gao Q, Liu X, Tong Z. Magnetic hydrogels with supracolloidal structures prepared by suspension polymerization stabilized by Fe2O3 nanoparticles. Acta Biomater. 2010;6:275–81. https://doi.org/10.1016/j.actbio.2009.06.018.

McCarthy SA, Davies G-L, Gun’ko YK. Preparation of multifunctional nanoparticles and their assemblies. Nat Protoc. 2012;7:1677–93. https://doi.org/10.1038/nprot.2012.082.

Sarier N, Arat R, Menceloglu Y, Onder E, Boz EC, Oguz O. Production of PEG grafted PAN copolymers and their electrospun nanowebs as novel thermal energy storage materials. Thermochim Acta. 2016;643:83–93. https://doi.org/10.1016/j.tca.2016.10.002.

NOYAN ECB. The development of heat storing nanocomposite nanofibers. Turkey: ISTANBUL TECHNICAL UNIVERSITY; 2015.

Thapa B, Diaz-Diestra D, Beltran-Huarac J, Weiner BR, Morell G. Enhanced MRI T2 relaxivity in contrast-probed anchor-free PEGylated iron oxide nanoparticles. Nanoscale Res Lett. 2017;12:312–24. https://doi.org/10.1186/s11671-017-2084-y.

Lin Y-S, Lee H-H, Lee W-F, Lin C-H. Synthesis and qualitative analysis of BACy and its self-polymer. J Chin Chem Soc. 2013;60:223–8. https://doi.org/10.1002/jccs.201200271.

Harsh DC, Gehrke SH. Characterization of ionic water absorbent polymers: determination of ionic content and effective crosslink density. In: Brannon-Peppas L, Harland RS, editors. Studies in Polymer Science. Elsevier; 1990. p. 103–24.

Basavegowda N, Somai Magar KB, Mishra K, Lee YR. Green fabrication of ferromagnetic Fe3O4 nanoparticles and their novel catalytic applications for the synthesis of biologically interesting benzoxazinone and benzthioxazinone derivatives. New J Chem. 2014;38:5415–20. https://doi.org/10.1039/C4NJ01155D.

Sari IP, Yulizar Y. Green synthesis of magnetite (Fe3O4) nanoparticles using Graptophyllum pictum leaf aqueous extract. IOP Conf Series Mater Sci Eng. 2017;191: 012014. https://doi.org/10.1088/1757-899x/191/1/012014.

Safari J, Zarnegar Z. A highly efficient magnetic solid acid catalyst for synthesis of 2,4,5-trisubstituted imidazoles under ultrasound irradiation. Ultrason Sonochem. 2013;20:740–6. https://doi.org/10.1016/j.ultsonch.2012.10.004.

Chaki SH, Malek TJ, Chaudhary MD, Tailor JP, Deshpande MP. Magnetite Fe3O4 nanoparticles synthesis by wet chemical reduction and their characterization. Adv Natural Sci Nanosci Nanotechnol. 2015;6:035009–14. https://doi.org/10.1088/2043-6262/6/3/035009.

Gupta AK, Wells S. Surface-modified superparamagnetic nanoparticles for drug delivery: preparation, characterization, and cytotoxicity studies. IEEE Trans Nanobiosci. 2004;3:66–73. https://doi.org/10.1109/TNB.2003.820277.

Kim KD, Kim SS, Choa Y-H, Kim HT. Formation and surface modification of Fe3O4 nanoparticles by co-precipitation and sol-gel method. J Industr Eng Chem. 2007;13:1137–41.

Qin Y, Huang Z, Liu H. Synthesis of PEG-MAH crystalline polymer and its thickening traits to LPMC. J Wuhan Univ Technol-Mater Sci Ed. 2008;23:403–6. https://doi.org/10.1007/s11595-007-3403-4.

Thong-On B, Rutnakornpituk B, Wichai U, Rutnakornpituk M. Magnetite nanoparticle coated with amphiphilic bilayer surfactant of polysiloxane and poly(poly(ethylene glycol) methacrylate). J Nanopart Res. 2012;14:953–64. https://doi.org/10.1007/s11051-012-0953-y.

Ninciuleanu CM, Ianchiş R, Alexandrescu E, Mihăescu CI, Scomoroşcenco C, Nistor CL, et al. The effects of monomer, crosslinking agent, and filler concentrations on the viscoelastic and swelling properties of poly(methacrylic acid) hydrogels: a comparison. Materials. 2021;14:2305–12. https://doi.org/10.3390/ma14092305.

Martens P, Blundo J, Nilasaroya A, Odell RA, Cooper-White J, Poole-Warren LA. Effect of Poly(vinyl alcohol) macromer chemistry and chain interactions on hydrogel mechanical properties. Chem Mater. 2007;19:2641–8. https://doi.org/10.1021/cm0626381.

Cong H-P, Wang P, Yu S-H. Stretchable and self-healing graphene oxide-polymer composite hydrogels: a dual-network design. Chem Mater. 2013;25:3357–62. https://doi.org/10.1021/cm401919c.

Pawłowska S, Cysewska K, Ziai Y, Karczewski J, Jasiński P, Molin S. Influence of conductive carbon and MnCo2O4 on morphological and electrical properties of hydrogels for electrochemical energy conversion. Beilstein J Nanotechnol. 2024;15:57–70. https://doi.org/10.3762/bjnano.15.6.

Messing R, Frickel N, Belkoura L, Strey R, Rahn H, Odenbach S, et al. Cobalt ferrite nanoparticles as multifunctional cross-linkers in paam ferrohydrogels. Macromolecules. 2011;44:2990–9. https://doi.org/10.1021/ma102708b.

Chia CH, Zakaria S, Ahamd S, Abdullah MH, Jani SM. Preparation of magnetic paper from kenaf: lumen loading and in situ synthesis method. Am J Appl Sci. 2006;3:1750–4. https://doi.org/10.3844/ajassp.2006.1750.1754.

Nagireddy NR, Yallapu MM, Kokkarachedu V, Sakey R, Kanikireddy V, Pattayil Alias J, et al. Preparation and characterization of magnetic nanoparticles embedded in hydrogels for protein purification and metal extraction. J Polym Res. 2011;18:2285–94. https://doi.org/10.1007/s10965-011-9642-2.

Tamburini G, Canevali C, Ferrario S, Bianchi A, Sansonetti A, Simonutti R. Optimized semi-interpenetrated p(HEMA)/PVP hydrogels for artistic surface cleaning. Materials. 2022;15:6739–53. https://doi.org/10.3390/ma15196739.

Zasońska BA, Brož A, Šlouf M, Hodan J, Petrovský E, Hlídková H, et al. Magnetic superporous Poly(2-hydroxyethyl methacrylate) hydrogel scaffolds for bone tissue engineering. Polymers. 2021;13:1871–83. https://doi.org/10.3390/polym13111871.

Ludeña MA, Meza FdL, Huamán RI, Lechuga AM, Valderrama AC. Preparation and characterization of Fe3O4/Poly(HEMA-co-IA) magnetic hydrogels for removal of methylene blue from aqueous solution. Gels. 2024;10:15–34. https://doi.org/10.3390/gels10010015.

Goiti E, Salinas MM, Arias G, Puglia D, Kenny JM, Mijangos C. Effect of magnetic nanoparticles on the thermal properties of some hydrogels. Polymer Degradation Stabil. 2007;92:2198–205. https://doi.org/10.1016/j.polymdegradstab.2007.02.025.

Natali I, Carretti E, Angelova L, Baglioni P, Weiss RG, Dei L. Structural and mechanical properties of “peelable” organoaqueous dispersions with partially hydrolyzed poly(vinyl acetate)-borate networks: applications to cleaning painted surfaces. Langmuir. 2011;27:13226–35. https://doi.org/10.1021/la2015786.

Lee D, Zhang H, Ryu S. Elastic modulus measurement of hydrogels. In: Mondal MIH, editor. Cellulose-Based Superabsorbent Hydrogels. Cham: Springer International Publishing; 2018. p. 1–21.

José Alves Oliveira M, Otubo L, Pires A, Fernando Brambilla R, Cristina Carvalho A, Santos PS, et al. Silver nanoparticles-based hydrogels synthetized by ionizing radiation for cleaning of tangible cultural heritage surfaces. Radiation Phys Chem. 2022;199:110345. https://doi.org/10.1016/j.radphyschem.2022.110345.

Wolbers R. Cleaning painted surfaces: aqueous methods. London: Archetype Publications; 2000.

Park HJ, Hwang M, Chung YJ. Cleaning fabricated metal thread: a post-treatment stability assessment after artificial deterioration and the application of synthetic soil. J Conserv Sci. 2019;35:19–31. https://doi.org/10.1654/JCS.2019.35.1.03.

Carretti E, Dei L, Baglioni P. Solubilization of acrylic and vinyl polymers in nanocontainer solutions application of microemulsions and micelles to cultural heritage conservation. Langmuir. 2003;19:7867–72. https://doi.org/10.1021/la034757q.

Galatis P, Boyatzis S, Theodorakopoulos C. Removal of a synthetic soiling mixture on mastic, shellac & Laropal® K80 coatings using two hydrogels. E-Preserv Sci. 2012;9:72–83.

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

ZR-S and NS prepared the samples, the results were interpreted. ZR-S and NS participated in the laboratory measurements. ZR-S did all writing and revising of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in the submitted manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rafiei-Sarmazdeh, Z., Sheikh, N. Irradiation-assisted synthesis of smart hydrogels based on nanomagnetic semi-interpenetrating p(HEMA)/PVP networks for the cleaning of cultural heritage artifacts. Discov Appl Sci 6, 285 (2024). https://doi.org/10.1007/s42452-024-05971-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-024-05971-6