Abstract

Choosing the proper engine that fits the desired application is a crucial design factor in robotics. Accordingly, this paper compares different types of engines for other Industrial robots (IR) and proposes to put practical criteria based on the mechanical design and its application. It starts from describing the IR choice to explaining the synchronous motor with permanent magnets as a base of the motor choice. Particular attention is paid to the consideration of components and their purpose supported by the creation of the subsequent drawings. SolidWorks system was implemented to obtain expressive and high-quality graphics and three dimensions design. Moreover, the entire Electrical Magnetic Force (EMF) was simulated using the method of variational parameterization. Accordingly, a developed synchronous motor with a built-in permanent magnet is proposed, which is supported by 3D design graphics to evaluate the deformation and margin of the housing and motor shaft safety.The obtained results provide a valuable study for the robotic engines' characteristics, such as the engine's strength, torque, power, and speed. An example of the comparison results is testing the synchronous motor, which confirms that the permanent magnets built-on synchronous motor is most recommended for the lightweight robots designed to work under average load weight. More results were performed to compare the proposed design with the robotics world's leading companies, showing that the developed proposed design has significant characteristics that outperform traditional motors.

Article Highlights

The proposed work is to present a developed model of a synchronous motor with built-in permanent magnets. The proposed work presents the key characteristics of electromechanical motors and formalize them, which are: torque, power and speed. The proposed work presents a 3D design graphics that allows evaluating the deformation and margin of the housing and motor shaft's safety.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Automation is integral to modern production, where various methods and approaches are applied and used [1,2,3]. At the same time, the robotics industry is becoming more and more critical. Robotics research is one of the most popular areas, creating many different models of Industrial Robots (IR).

There are more than 100 models of Fanuc IR that cover a wide range of applications, such as painting robots, loading, unloading, Etc. [4, 5]. The reliability of the Industrial Fanuc 430iF Series Robot Arm is enhanced by direct drive in all axes, sealed bearings, and a simple modular design with a small number of components. Manual lines and motors can be quickly replaced. However, the replacement and maintenance cost may be for high price. In [5], an extremely compact FANUC LR Mate 200id/4 s, with 6-axis short-arm robot, has been designed for limited space and compact machines. In robots from Fanuc, servo drives are most common, though they have disadvantages, such as the configuration complexity and the high cost.

ASEA Broun Boveri (ABB) Robotics also lead in the industrial field, such as ABB Robotic Depalletizer and other widely utilized robots [6, 7]. Moreover, ABB's extensive range of 6-axis articulated robots is used in material handling, machine maintenance, spot welding, arc welding, cutting, assembly, testing, inspection, dosing, grinding, and polishing [8].

The Industrial Review Board (IRB) 1520 of ABB is a high-precision robotic arc welding machine with integrated machining combining 24/7 performance with 50% lower maintenance costs than other ABB types. It has a compact process upper arm designed for integrated dressing packages for arc welding. Maintenance-free Alternative Current (AC) motors are used, but with several disadvantages, mainly the inability to control the speed without losing power and the decrease of the moment when the load increases.

Keller und Knappich Augsburg. Keller Und Knappich Augsburg (KUKA) robotics manufacturing company offers various IRs for various purposes, such as material handling, protective gas welding, machine loading/unloading, and spot welding [9, 10]. The Kuka KR6-2 is versatile and flexible, which is why it is one of the most famous robots in the KUKA lineup. This KUKA model has optimized robot design with a level of precision unmatched in manual applications [9].

A Permanent Magnet Synchronous Motor (PMSM) is a synchronous AC motor. KUKA- KR 210–2, a unique robot with high accuracy of 0.2 mm, makes it better than expected from such a payload class. All axes in KUKA KR210-2 have high motor power and high torque gearboxes [10].

IRs from the American company YASKAWA are widely used to process products by applying various tools and processes, such as manipulation of blanks and products, transferring, palletizing, packaging, Etc. [11, 12]. Yaskawa GP 215 [11] is a powerful and versatile multi-purpose robot, considering that Yaskawa prefers robots with AC motor drives. However, as described above, speed control without power loss is impossible; i. e., when the load increases, the moment decreases.

Thus, in general, comparative characteristics of world leaders in the field of robot production (ABB, FANUC, KUKA, and YASKAWA) can be summarized following data in Table 1.

IR is one of the most efficient ways to automate transport, load operations, and many other technological processes. These processes are typically distinguished by their management style, functions, and application area [13]. Robotic arms usually use adaptive control, normally broken down into three categories: model standard, self-adjustment, and planned amplification [14]. In [15], software based on artificial intelligence methods where introduced.

As for IR function, such robots carry out tasks of control, movement, and movement in various production processes [16, 17].

Modern IR can be used in various industries such as:

-

The automotive industry, such as Fanuc M-710 articulated robot to solve problems of sealing internal space of car body, and subsequently accelerate production, reduce costs, improve quality, and protect its workers from harm [18, 19];

-

Production of electronic devices or parts, such as Apollo Seiko J-CAT COMET robot [20] or KUKA KR 6 R900 for soldering printed circuit boards [21]; Yaskawa Motoman MH12 for building computer hard drives [22];

-

The food industry, such as manipulator UR 10 from Atria Scandinavia for packaging, marking, and stacking [23]; and

-

The agriculture industry uses robot R150 from XAG for pest control [24] for spraying, weeding, harvesting, Etc.

Thus, IRs can be implemented in many production processes, so their development and implementation significantly expand the possibilities and prospects of usual robotics; IR can be promising in developing and manipulating all robotic systems.

An essential element in the design of IR is the electric motor, which is the primary source of movement and helps robots to perform tasks. However, while selecting motors (drives), it is essential to remember that the electric industry must have high dynamic characteristics to produce sophisticated control algorithms. The executive engine must respond rapidly to control signals and have tiny, lightweight dimensions. Importing into MATLAB-SimMechanics enables the study of all IR or robotic arm functions, element sizes, coordinate systems, vector interactions between elements, mass, the center of mass and volume, gravity, and inertia modules, making the construction of a 3D model of the engine an essential first step.

The rest of the paper is organized as follows: Section II provides solid knowledge for the related work to the robotic systems electric motors, Section III illustrates the modeling critical requests of the EMRS modeling, and Section IV explains the proposed developed modeling system for the EMRS, Section V. shows the main components of the synchronous motor with the Built-in permanent magnets utilizing SolidWorks System software, Section VI illustrates the 3D modeling design processes for the developed EMRS, Section VII describes the obtained characteristics for the developed EMRS with its simulation results, and finally, Section VIII concludes the paper.

2 Related work to the robotic systems electric motors

Electric Motors of Robotic Systems (EMRS) convert electrical energy into mechanical energy based on electromagnetic phenomena. Based on this, the types of EMRS are distinguished:

-

Direct Current (DC) motors;

-

AC motors.

The DC motor is widely used drive-in industry and robotics, as evidenced by the research presented [25]. So Branch M. Pillai and Jackrit Suthakorn consider DC motors in their work [25]; A sensorless method for determining DC motor parameters, including the moment of inertia, torque coefficient, and friction components using Disturbance Observer (DOB) as torque sensor, where the authors cited mathematical models for only two parameters, namely engine inertia and torque constant. Moreover, the simulation in [25] was carried out in Matlab and also did not particularly justify the reasons for performing the test over different consistent speeds in the range of 5000 rpm to 5000 plus rpm.

AC motors offer a relatively efficient method of producing mechanical energy by consisting of two main parts: the outer stator, which contains coils powered by the alternating current to create a rotating magnetic field, and the inner rotor attached to the output shaft, which makes a second rotating magnetic field. Moreover, AC servo motors are widely used in industrial robotic arms to control high dynamic loads.

E. A. Padilla-Garcia, A. Rodriguez-Angeles et al. considered selecting and controlling AC servo motors of the power unit for IRs [26], where the authors present a dynamic model of manipulator and transmission; Electrodynamic model of drives, Etc. Parameters, limits, and ranges of possible motors are given, and necessary information was taken exclusively from manufacturers' catalogs. However, there was no emphasis on parameters that should be considered vital.

M. Usama, J. Kim presents a mathematical model of AC motor drives [27], where a vector control method for effective control of AC motor drive speed was proposed. The operation method adopted in [27] can be applied to both synchronous and asynchronous motors; however, it requires some additional hardware and software improvements though the mathematical basis of this method has been developed for a long time.

Synchronous and asynchronous motors are also widely used in robotics, where asynchronous motors are most commonly operating electric motors in industrial applications [28]. In the asynchronous electric motors, the rotation frequency of the stator magnetic field is always more significant than the rotational speed of the rotor, such as speed control of asynchronous motor based on fuzzy logic using a 6-switched 3-level inverter which was introduced [28]. An experiment was conducted to investigate high-speed responses in which the asynchronous motor started with and without load. However, it should be borne in mind that asynchronous motors cannot stably keep rotational speed.

The most common DC motors for IRs are brushless [29], one of the drive types that are gaining popularity in robotics because such an engine does not use brushes for switching. Nevertheless, instead, it is switched electronically. Staszak J. et al. considered sensorless brushless DC motor with low gain [29]. However, the brushless motor requires an additional controller to change or control its speed.

The stepper motor is a drive that has become increasingly popular in robotics. Roshanna L. N., Konduru N. R. [30] described the design and implementation of the stepper motor control system that can be successfully applied, including for IRs and manipulators, Etc. Furthermore, it is proposed to control the position of the stepper motor based on IoT [30], understanding that IoT can reveal a significant amount of personal data in minor details.

In [31], Liu C. H. et al. introduced an innovative, motor-driven, and three-finger-compatible gripper for adaptive capturing thin objects of various sizes. The optimized compatible finger design is determined numerically using the topology optimization method. A stepper motor is used to activate three similar, compatible fingers that can function through elastic bending deformation; nevertheless, the usage of such motors has a peculiarity—a limitation of steps; as a result, the actual position of the shaft may be out of sync [32]. In production systems, precise servo control is essential, and to improve precision, servo control on IRs is actively employed in motion control systems.

A servo is an electromechanical motor that, unlike steppers, does not rotate continuously but moves in response to a signal and stores its position until the next signal. Servo drive systems in IRs mainly consist of servo motors [32]. The widespread use of servo systems of IRs is explained by the control algorithm, the accuracy of machining in system design, and maintenance during system operation.

T. Yuan, D. Wang et al. described high-precision servo control of IR, which led to an experimental relationship between torque and flow of synchronous motor with permanent magnets when using conventional direct torque control, single active vector modulation system of efficiency, spatial-vector modulation strategy with a simple proportional-integral regulator or sliding observer mode, and direct torque control [32]. However, the servo systems used in [32] have a complex system of connection and control.

Glebov N., Kruglova T., et al. in [33] described an electro-pneumatic module (Pneumatic actuator is a type of drive used in robotics for its low smoothness and accuracy of operation) which consists of a pneumatic cylinder, electromagnetic pneumatic distributor, fuzzy controller, and sensors (pressure, position, and environmental control). However, the pneumatic actuator has relatively low efficiency.

The Hydraulic drive, the actuator mainly used in industrial robotics, where the engine converts fluid pressure into mechanical pressure, was applied in [34].

Suzumori K., Faudzi A. A. in [34], hydraulic actuators and components in legged and rigid robots were investigated, where the study provided an overview of hydraulic trends in challenging robotic applications that focus on robots with legs, such as humanoid, search and rescue robot, and large machinery.

The peculiarity of hydraulics has a high power-to-weight ratio compared to other power transmission systems, which makes it suitable for work in harsh and reliable conditions. However, it is not easy to track the accuracy of work.

A generalized comparative characteristic of considered EMRS for robotic systems is presented in Table 2.

As a result of the literature analysis, based on the advantages and disadvantages of the main types of motors, the synchronous motor with built-in permanent magnets was chosen for the proposed study in this paper. This is due to the small size, low weight, and high power density of these motors and their good dynamic response properties, which make them suited for the proposed robot design, particularly for high-speed applications in robotic manipulation systems. Specifying these EMRS's primary parameters is provided in the following sections.

3 Electric motor’s modeling key requests

This study aims to create a suitable robotic systems EMRS model with its key characteristics, including the designing model of housing, rotor, core, and bearing EMRS with specified parameters.

The proposed modeling is carried out in three stages:

-

Stage one: The EMRS model is being developed. Initially, element drawings are made, each item recorded in a separate file, and the primary dimensional attributes are verified. Based on drawings, the parameters' dimensions are determined.

-

Phase two involves the EMRS assembly.

-

Stage three: A simulation is carried out for the entire body consisting of two parts: EMRS and the shaft. As a result, the strength of EMRS is determined at constant applied force.

This paper emphasizes the strength of EMRS (without deformation) since the reliable operation of electric motors determines the reliability of IR as a whole or for each component separately. Specify that the operational reliability of electric motors is determined by the design and quality of manufacture, operating conditions, frequency, rate of repair, Etc.

During the operation of EMRS, forces affect the appearance of defects, which can appear in the form of local insulation defects in the state of cracks. Large electrodynamic forces can occur when starting electric motors with drives rotating in opposite directions (for example, due to skipping gates, valves, Etc.).

In addition to the primary purpose of this study, the study of critical characteristics and their relationship is considered.

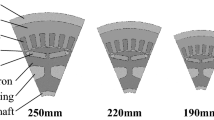

To develop the EMRS model, Fanuc's unique M-710 series of IR was used as a reference because these lightweight robots are meant to operate with loads weighing between 20 and 70 kg on average. It is conceivable to offer synchronous electric motors with permanent magnets for these IRs, as these motors are utilized in IRs with average load capacity and mobility degrees between 3 and 6. The positioning precision of an electric drive can approach 0.05 mm. The synchronous motor with permanent magnets is compact, powerful, and may be integrated into an automation system.

In most housing, synchronous motors operate in stationary modes when some parameters do not change over time.

The paper considers mode for constant load moment, where desired static method is in continuous rotation speed mode.

The critical characteristics of electromechanical motors include:

-

Shaft speed: That describes the rate at which the rotor rotates. In a synchronous motor, it is assumed that the rotor speed is constant and does not depend on the load. The rotor speed is determined by the rotation speed of the stator field;

-

Moment;

-

Mechanical power;

-

Shaft speed: That describes the rate at which the rotor rotates. In a synchronous motor, it is assumed that the rotor speed is constant and does not depend on the load, so the rotation speed of the stator field determines the rotor speed.

Rotation speed of stator field as introduced in [35]:

where θ is the angle of rotor rotation, counted from phase axis to axis of rotor pole.

Let us formalize the second characteristic, which is the moment (torque) [35]:

where the electromagnetic moment EMRS Ce = const, and ik at k = a, b, c is the phase currents.

It should be borne in mind that at the constant moment of load [35]:

where \(\theta_{0}\) is the unknown initial value of the rotor rotation angle and \(\omega\) the stator field's rotation speed.

Another characteristic considered most important is the power of the electric motor, which depends on the model, considering that the mode can vary widely. Power defines the type of power system and the engine to which it is attached, as well as the design and performance of the equipment and the engine to which it is coupled.

Summing up the power of three phases, the electrical energy consumed by EMRS is described as [35]:

where Im is the amplitude of the phase currents, Mmax is the maximum electromagnetic moment, and \(U_{m}\) is the voltage.

Taking into account the equality of field and rotor speeds, the electromagnetic moment has a maximum value [35]:

where Em is the electro Driving Force of Rotation \(E_{m} = C_{e} (d\theta /dt)\), and \(L_{m}\) is the inductance.

Mechanical power (output) is determined by the expression [35]:

where \(\phi_{0}\) is the angle of rotor lag from the stator's rotating field.

By the extent of the stator winding's active resistance loss, EMRS's electrical power consumption exceeds its mechanical power output. According to commonly held assumptions, this conforms to the energy conservation law.

Consequently, the characteristics mentioned above and the structural reliability of EMRS are crucial to the type of EMRS under consideration. These characteristics (speed, torque, and power of EMRS) will be prioritized in developing and evaluating corresponding model types of engines.

4 The developed electric motor’s modeling system

Choosing the right system to develop a three-dimensional model is essential and strictly related to the proposed project.

Vladimir Kuts et al. conducted a 3D simulation of an autonomous vehicle engine [36]. Visualization of power drive test bench is implemented in Unity3D game engine, connected to physical simulator via Robot Operation System (ROS).

Unity3D is a tool capable of working on several hardware platforms and allows working with 2D and 3D graphics processed in real-time. However, such a system is not suitable for the proposed research work in this paper since it is not convenient for this area of solvable tasks, which are creating a drawing, executing solid-state processes in 3D format, and surface design of parametric type.

Ionuţ Gabriel Ghionea et al. represented a 3D model of a micro-pump in an actual design solution, where its parametric assembly is modeled in CATIA v5 based on laboratory and operational requirements [37], where the author is determined to shape, size, and position of contact surfaces, which are subject to wear during operation. In this paper, the authors made some design changes; some components of the micro-pump have been created and proposed for analysis.

CATIA–CAD of the upper level, that is, the creation of 2D and 3D objects and describing products. At the same time, attention is paid to all stages of creating a product, starting from the development of the concept to the actual production. CATIA has rich functionality for volumetric modeling, while a complete description of processes accompanies the development of the model. However, such a system is not particularly convenient, as the interface may have difficulties working with CATIA. It is impractical for the proposed study as it has a weak module for creating drawings.

Krol O., Sokolov V. improved gears of gear drive of metal-cutting machines according to the criterion of carrying capacity [38]. A technique for accelerated creation of 3D models of gear drive and its components using specialized software application "Shafts and mechanical transmissions-3D" in an environment of integrated CAD system KOMPAS-3D is proposed in [38] as well, where in KOMPAS-3D–CAD for a 3D modeling system, it is possible to create both individual elements and whole. Prefabricated objects, however, are unsuitable for this paper's proposed study since KOMPAS-3D does not provide a connection between dimensional lines in drawing and the model's geometry. There is also no automatic display of the relationship of primitives.

Lee J. et al. simulated a PMSM vehicle drive system based on Ansys [39]. Ansys is a CAD system for modeling, analyzing, and calculating objects and physical processes. Ansys allows for improved integration with CAD (parametric two-way relationships with all major CAD systems) and good speed when creating databases using existing standard templates. However, this system is not suitable for the proposed study as well since the system is not very easy to learn, and challenging to build a structural grid for complex volumetric products.

The results of a comparison of the most commonly used EMRS modeling environments are presented in Table 3.

Thus, in the proposed study, the SolidWorks system was chosen to create a 3D model, where SolidWorks is a system with many functions for creating high-quality three-dimensional models [34]. Although the system sometimes contains incorrect automatic sizing, it can be easily corrected manually. SolidWorks allows the development of projects at any level of complexity.

5 Main components of synchronous electric motor with built-in permanent magnets as modeling objects in solidworks system

The 3D model of EMRS created consists of a rotor, housing, two bearings, and stator. The rotor has a shaft and magnets on its surface as shown Fig. 1a, where 1 is the permanent magnets, and 2 is the shaft).

The shaft is usually made of 45 carbon steel or alloy steel grades containing chromium, nickel, and other materials to increase the strength and resistance of loads.

Electric motors' magnet is usually made of ferrite, as ferrite magnets are composed of oxide materials with barium carbonate or strontium carbonate made of powder metallurgy. The feature of low permeability and high forced force makes ferrite magnets very resistant to the demagnetization of fields.

The stator consists of a core made of electrical steel sheets and three-phase winding as shown Fig. 1b, where 3 is the winding and 4 is the core.

The wire winding material is uniform along its entire length, where the shape and cross-sectional area of the wire have certain precision.

On wire intended for winding without fail in industrial conditions, the insulation layer in the form of varnish is applied.

An algorithm is proposed according to which modeling of EMRS will be implemented as shown Fig. 2.

This algorithm allows considering the development process in more detail, as all drawings of motor elements were created in the SolidWorks system during this process. Such aspects of EMRS will include the first and second parts of housing, rotor, core, and bearings.

The drawings of the first chassis part are shown in Fig. 3. The drawings of these elements will be used in the future to simulate variational parameterization.

Variational or dimensional parameterization is based on the construction of miniatures (with the imposition of various parametric relations on skEtch objects) and imposition of restrictions by the user in the form of an equations system to determine the relationship between parameters.

The drawing of the chassis second part building is presented in Fig. 4.

The body is one of the main components of any object, where inside it should be enough space for air circulation. Also, it protects the internal elements of the structure from deformation.

The drawing of the rotor is shown in Fig. 5., where the rotor of the synchronous electric motor creates a constant magnetic field.

The drawing of the electric motor core is shown in Fig. 6.

The core consists of windings arranged in a circle at an angle of 120 º and enclosed in the housing, where the windings made of particular cross-section wire are installed on it, which are necessary to reduce the magnetic resistance and improve the passage of magnetic flux.

The bearing drawing is shown in Fig. 7, where the electric motor bearings are the assembly unit responsible for the uniform air gap between the rotor and the engine stator.

Next, the material for each component was selected, and drawings were created for another modeling of the electric motor.

Notably, the process of generating a parametric model using variational parameterization consists of the following steps:

-

First stage: the thumbnail (profile) is created for three-dimensional operation;

-

Second stage: the necessary parametric connections are superimposed on the skEtch;

-

Third stage: the thumbnail is created by size;

-

Fourth stage: the individual profile sizes are specified. At this point, particular dimensions can be marked as variables (e.g., given the name "Length") and set to other measures on those variables as formulas (e.g., “Length/2”);

-

Fifth stage: the three-dimensional operation is performed (for example, squeezing), and the value of the process attributes also serves as a parameter (for example, the buy by which Fig. is squeezed out);

-

Sixth stage: if it is necessary to create an assembly, the mutual position of assembly components is specified by specifying the combinations between them (coincidence, parallelism or perpendicularity of faces and edges, location of objects at a distance or angle to each other, Etc.).

Thus, variational parameterization makes it easy to change the shape of the skEtch or the operation size parameters, making it convenient to change the three-dimensional model [15].

6 Robotic system electric motor’s 3d model design processes

Based on the created drawing in the SolidWorks system, the rotor model was created using the method of variational parameterization as shown Fig. 8a, whereby the «Pull/Base» method, each element is extracted according to the drawing as shown Fig. 8b.

Then, using SolidWorks «Round» tool, round to smoothly transition between the shaft diameters as shown Fig. 5.

Next is the development of the stator model and the core skEtch, where the core modeling is performed as shown Fig. 9 a by first using the SolidWorks skEtch «Circular Array» tool to repeat binding and then by employing the SolidWorks «Extract/ Base» method to pull the core from the drawing as shown Fig. 6. Next, the SolidWorks «Linear Array» tool repeats the core, generating the winding skEtch. The illustration is made using the method of «Elongated bobbin/base» by pulling the wires along the core and detaching them by the procedure «Base/base by sections» as shown Fig. 9b.

Next, “simulate connection” as shown Fig. 9c of the windings using the “Base/base by sections” approach to link them according to the scheme, where green, orange, and black represent the phases and blue represents neutral. Based on the initial portion of the house drawing, the necessary modeling is carried out using the “Elongated Base / Base” method, in which each diameter is pulled out. The «Shell» instrument provides body thickness as shown Fig. 3.

The next step is to round the body using the «Rounding» tool.

On the simulated body, ribs are developed to improve the cooling of the electric motor's body and to boost the body's resistance to deformation. The holes are then designed for housing attachment.

Created first and second parts of housing as shown in Fig. 10.

Based on the housing second part drawing as shown Fig. 4, the model of the housing is built using the «Elongated base/base» method, the skEtch elements are pulled out, and the «Rounding» tool is used to make the rounding.

Based on the drawing created, the 3D model is built using the «Rotate» method to rotate each skEtch element around its axis, and then the «Circular Scale» tool is used to duplicate the ball.

After modeling each element of the electric motor, Fig. 10, d assembles them.

7 The characteristics of the proposed electric motor's and simulation results

The strength of the IR structural element is regarded as one of the most important key aspects of EMRS since the structural part is the body that protects the entire system from deformations, resulting in the construction of a motor that is more robust and reliable.

Using the SolidWorks Simulation software environment, motors’ body and rotor shaft may be examined for their strength (possible deformation at certainly used force).

In this investigation, the force parameter will be 200 N. As a material, 6061 aluminum alloys will be used for the body, while alloy steel will be recommended for the rotor shaft. Because it is a heat-treated and hardenable alloy formed by heat treatment with pre-extraction, these materials are chosen for high-quality housings [40].

Figure 11a depicts the deformation effect, while Fig. 11 b depicts the power reserve plot.

The results of the second housing part are shown in Fig. 12.

When 200 N of force was applied is shown by purple arrows on drawings where the margin of safety is assessed. Where the material does not change its shape at all, the color blue is displayed.

Figure 13 illustrates the findings of the shaft analysis.

The following EMRS properties that must be tested are speed, torque, and mechanical power, whose formalization is described in the preceding section. These attributes are illustrated in Fig. 14.

The proposed developed EMRS design has been compared to various sorts of motors. The results of such comparisons are displayed in Tables 4 (generic comparison features) and 5 (comparative characteristics) (a reference to specific types of motors).

The asynchronous motor was chosen as an illustration from Table 4 because it is the most often used electric motor in industrial applications [28] and one of the synchronous motor types with the surface installation of permanent magnets.

A synchronous electric motor with built-in permanent magnets is optimal for lightweight robots designed to deal with loads of average weight and multiple degrees of mobility between 3 and 6 since it can deliver high power at the needed speed and efficiency over an extended operating range.

A synchronous motor with permanent magnets is a potential electric machine for low- and medium-power applications, including washing machines, infrared (IR), and electric trains.

Table 5 compares the properties of EMRS to those of various categories of EMRS previously described.

It turns out that the proposed motor is the best option in all respects when used for robotic fields.

8 Conclusions

The article examined Industrial Robots (Rs) and their motors. A comparison of the primary parameters of ABB, FANUC, KUKA, and YASKAWA robots is conducted. The literature on motor modeling is reviewed, and its significance is demonstrated; as a result, a comparative table of settings/tools for generating 3D models of motors is provided, along with a discussion of their benefits and drawbacks (starting from Unity3D game engine and ending with CAD system of highest level CATIA), where broad simulation methodology was examined. Torque, power, and speed are stressed and defined as the essential features of electromechanical motors. The selection of IR to represent its Electric Motors of Robotic Systems (EMRS) is briefly explained. As a motor, a synchronous motor with permanent magnets was chosen. Particular thought is given to the components and their purpose, for which future drawings are developed.

The full EMRS was simulated using the variational parameterization method based on SolidWorks designs. In the research, the strength of EMRS was emphasized as one of its most essential qualities, directly affecting the motor's dependability. As a result of the modeling, the work provides diagrams showing the force reserve of the housing and rotor, as well as color representations of the housing and rotor that depict the places most sensitive to deformation and those least susceptible to deformation. Considering three codified properties of EMRS (torque, power, and speed), dependence graphs for these parameters are also presented. During a comparison of the produced EMRS and other standard motors, it was decided that the synchronous motor with built-in permanent magnets is most appropriate for our study. The conducted research may be necessary and valuable for the continued development of the IR model.

Future work will be directed to improve the relation between the torque and speed through designing different types or robots that fit various practical applications, moreover, improving the designed robotic and implementing it is regarded as another direction.

Data availability

The authors confirm that the data used in this work is available at and ready upon request. Please contact the Corresponding author (Hattar@zu.edu.jo).

References

Attar H, Abu-Jassar AT, Yevsieiev V, Lyashenko V, Nevliudov I, Luhach AK (2022) Zoomorphic mobile robot development for vertical movement based on the geometrical family caterpillar. Comput Intell Neurosci. https://doi.org/10.1155/2022/3046116

Mustafa SKh, Yevsieiev V, Nevliudov I, Lyashenko V, Alharbi AR, Rajeh W (2022) HMI development automation with gui elements for object-oriented programming languages implementation. Int J Eng Trends Technol. https://doi.org/10.14445/22315381/IJETT-V70I1P215

Akhmetov V., et al.. (2019). New approach for pixelization of big astronomical data for machine vision purpose. IEEE 28th International Symposium on Industrial Electronics (ISIE), DOI: https://doi.org/10.1109/ISIE.2019.8781270.

Mazni M, Ayub MA, Muhammad N (2021) Calibration of Industrial Fanuc 430iF Series Robot Arm. Intelligent manufacturing and energy sustainability. Springer, Singapore, pp 11–19. https://doi.org/10.1007/978-981-16-6482-3_2

Li M (2022) Developing a Portrait Drawing Robot with FANUC LR Mate 200id/4s. ICT Systems and Sustainability. Springer, Singapore, pp 491–497. https://doi.org/10.1007/978-981-16-5987-4_50

Silva, M. Z., Brito, T., Lima, J. L., & Silva, M. F. (2021, March). Industrial Robotic Arm in Machining Process Aimed to 3D Objects Reconstruction. In 2021 22nd IEEE International Conference on Industrial Technology (ICIT) (Vol. 1, pp. 1100–1105). IEEE. DOI: https://doi.org/10.1109/ICIT46573.2021.9453596. ISBN:978–1–7281–5731–3

Chauhan A, Brouwer B, Westra E (2022) Robotics for a quality-driven post-harvest supply chain. Curr Robot Rep. https://doi.org/10.1007/s43154-022-00075-8

Chauhan SS, Khare AK (2020) Kinematic analysis of the ABB IRB 1520 industrial robot using roboanalyzer software. Evergreen 7(4):510–518. https://doi.org/10.5109/4150470

Crenganiș, M., Bârsan, A., Racz, S. G., & Iordache, M. D. (2018). Single point incremental forming using Kuka KR6–2 industrial Robot-a dynamic approach. Proceedings in Manufacturing Systems, 13(3), 133–140. ISSN 2067–9238.

Bârsan, A., Racz, S. G., & Breaz, R. (2021). Incremental forming using KUKA KR210–2 industrial robot research regarding design rules and process modeling. In MATEC Web of Conferences (Vol. 343). EDP Sciences. DOI: https://doi.org/10.1051/matecconf/202134308005

Sotnik S, Lyashenko V (2022) Modern industrial robotics industry. Int J Acad Eng Res 6(1):37–46

Song, X. B., & Tian, X. C. (2019, July). Research on 6R Industrial Robot Intersection Curve Welding Control and 3D Simulation Technology. In 2019 IEEE 4th International Conference on Advanced Robotics and Mechatronics (ICARM) (pp. 666–671). IEEE. DOI: https://doi.org/10.1109/ICARM.2019.8833820. ISBN:978–1–7281–0065–4

Vladareanu V, Munteanu RI, Mumtaz A, Smarandache F, Vladareanu L (2015) The optimization of intelligent control interfaces using Versatile Intelligent portable robot platform. Procedia Computer Science 65:225–232. https://doi.org/10.1016/j.procs.2015.09.115

Zhang D, Wei B (2017) A review on model reference adaptive control of robotic manipulators. Annu Rev Control 43:188–198. https://doi.org/10.1016/j.arcontrol.2017.02.002

Vassilyev SN, Kelina AY, Kudinov YI, Pashchenko FF (2017) Intelligent control systems. Procedia Comput Sci 103:623–628. https://doi.org/10.1016/j.procs.2017.01.088

Merckaert K, De Beir A, Adriaens N, El Makrini I, Van Ham R, Vanderborght B (2018) Independent load carrying and measurement manipulator robot arm for improved payload to mass ratio. Robotics Comput-Integr Manufact 53:135–140. https://doi.org/10.1016/j.rcim.2018.04.001

Li, G., & Luo, Y. (2019, March). Industrial Robots' Application in Processing Production Line of Mechanical Parts. In Journal of Physics: Conference Series (Vol. 1176, No. 5, p. 052051). IOP Publishing. DOI:https://doi.org/10.1088/1742-6596/1176/5/052051

Chen X, &, et al (2022) I-fiber implantation robot for composite parts. Text Res J 92(3–4):383–399. https://doi.org/10.1177/00405175211036209

Gao M, Wang H, Hao K, Mu H, Zeng X (2019) Evolutions in microstructure and mechanical properties of laser lap welded AZ31 magnesium alloy via beam oscillation. J Manuf Process 45:92–99. https://doi.org/10.1016/j.jmapro.2019.07.001

Apollo Seiko J-CAT COMET. apollo-seiko-europe.com. [Electron resource]. URL: J-CAT COMET - Apollo Seiko (apollo-seiko-europe.com). date of last contact: 20.12.2022

Mehrez, R., Affes, E., Kadri, I., Bouslimani, Y., Ghribi, M., & Kaddouri, A. (2020, May). Location and vision techniques to control a KUKA KR6 R900 sixx robot arm. In 2020 1st International Conference on Communications, Control Systems and Signal Processing (CCSSP) (pp. 311–316). IEEE. DOI: https://doi.org/10.1109/CCSSP49278.2020.9151573. ISBN:978–1–7281–5836–5

Wang N, Zhong K, Shi X, Zhang X (2020) A robust weld seam recognition method under heavy noise based on structured-light vision. Robot Comput-Integr Manufact. https://doi.org/10.1016/j.rcim.2019.101821

Pilat Z, Klimasara W, Pachuta M, Słowikowski M, Smater M, Zieliński J (2018) Możliwości praktycznego wprowadzania robotów współpracujących w różnych technologiach wytwórczych realizowanych w środowisku przemysłowym. Pomiary Automatyka Robotyka. https://doi.org/10.14313/PAR_227/59

Sotnik S, Lyashenko V (2022) Agricultural robotic platforms. Int J Eng Inform Syst 6(4):14–21

Pillai BM, Suthakorn J (2019) Motion control applications: observer based DC motor parameters estimation for novices. Int J Power Electron Drive Syst 10(1):195–210. https://doi.org/10.11591/ijpeds.v10n1

Padilla-Garcia EA, Rodriguez-Angeles A, Resendiz JR, Cruz-Villar CA (2018) Concurrent optimization for selection and control of AC servomotors on the powertrain of industrial robots. IEEE Access 6:27923–27938. https://doi.org/10.1109/ACCESS.2018.2840537

Usama M, Kim J (2020) Vector control algorithm based on different current control switching techniques for Ac motor drives. arXiv preprint. https://doi.org/10.1051/e3sconf/202015203009

Saygin, A., & Kerem, A. (2017, September). Fuzzy logic based control of a loaded asynchronous motor using a 6-switched 3-level inverter. In 2017 18th International Conference on Computational Problems of Electrical Engineering (CPEE) (pp. 1–4). IEEE. DOI: https://doi.org/10.1109/CPEE.2017.8093055. ISBN:978–1–5386–1041–1

Yen SH, Tang PC, Lin YC, Lin CY (2019) A sensorless and low-gain brushless DC motor controller using a simplified dynamic force compensator for robot arm application. Sensors 19(14):3171. https://doi.org/10.3390/s19143171

Roshanna LN, Konduru NR (2017) IoT based stepper motor position control for industrial automation. Am J Sci Eng Technol 2(4):106–111. https://doi.org/10.11648/j.ajset.20170204.12

Liu CH, Chung FM, Chen Y, Chiu CH, Chen TL (2020) Optimal design of a motor-driven three-finger soft robotic gripper. IEEE/ASME Trans Mechatron 25(4):1830–1840. https://doi.org/10.1109/TMECH.2020.2997743

Yuan T, Wang D, Wang X, Wang X, Sun Z (2019) High-precision servo control of industrial robot driven by PMSM-DTC utilizing composite active vectors. IEEE Access 7:7577–7587. https://doi.org/10.1109/ACCESS.2018.2890539

Glebov, N., Kruglova, T., & Shoshiashvili, M. (2019, October). Intelligent Electro-pneumatic Module for Industrial Robots. In 2019 International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon) (pp. 01–04). IEEE. DOI:https://doi.org/10.1109/FarEastCon.2019.8934864. ISBN:978–1–7281–0062–3

Suzumori K, Faudzi AA (2018) Trends in hydraulic actuators and components in legged and tough robots: a review. Adv Robot 32(9):458–476. https://doi.org/10.1080/01691864.2018.1455606

Korshunov A (2008) Stacionarnye rezhimy sinhronnogo dvigatelya s postoyannymi magnitami. Silovaya elektronika 3:48–53

Kuts, V., Rassõlkin, A., Partyshev, A., Jegorov, S., & Rjabtšikov, V. (2021, May). ROS middle-layer integration to Unity 3D as an interface option for propulsion drive simulations of autonomous vehicles. In IOP Conference Series: Materials Science and Engineering (Vol. 1140, No. 1, p. 012008). IOP Publishing. DOI https://doi.org/10.1088/1757-899X/1140/1/012008

Ghionea IG, Opran CG, Ghionea AL, TARBĂ, C. I., & ĆUKOVIĆ, S. (2018) Adaptive design of a 3D model magnetic drive micropump for an extended life cycle and low maintenance. Acta Technica Napocensis-Series 61(2):201–212

Krol O, Sokolov V (2020) Research of modified gear drive for multioperational machine with increased load capacity. Diagnostyka 21(3):87–93. https://doi.org/10.29354/diag/126026

Lee J, Ha J, Kim M, Yun S, Kim Y, Nah W (2019) Prediction of conducted emission in a PMSM-drive braking system using a circuit model combined with EM simulation. Int J Automot Technol 20(3):487–498. https://doi.org/10.1007/s12239−019−0046−3

Alirshedat, S., Attar, H., Saad, A., Al-Shami, F., & Amer, A. (2021). Reactive lift-type Spherical Turbine Design for the Disi-Station Pipes in Jordan -Study Case, 12th International Renewable Engineering Conference (IREC), 2021, 1–6, DOI: https://doi.org/10.1109/IREC51415.2021.9427795. ISBN:978–1–6654–4701–0

Acknowledgements

The author of this paper would like to thank the Zarqa University and Kharkiv National University of Radio Electronics Ukraine for opening the labs to the authors in order to complete the practical work presented in this research.

Funding

Authors confirm that the paper is not funded.

Author information

Authors and Affiliations

Contributions

All authors contribute in the paper as follows: HA participated by the research ideas with sharing the theory with TA-J and VL. AA helped in the building the hardware with both of SS, NA and AS. Finally, it is important to mention that all authors shared the writing up task, software work, hardware work, and the fund support.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Attar, H., Abu-Jassar, A.T., Lyashenko, V. et al. Proposed synchronous electric motor simulation with built-in permanent magnets for robotic systems. SN Appl. Sci. 5, 160 (2023). https://doi.org/10.1007/s42452-023-05375-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-023-05375-y