Abstract

We propose a robust fuzzy design model for a sustainable closed-loop supply chain network. The model is based on a risk dynamic regulation mechanism. In this way, we can solve the problem of sudden disruptions and uncertain demand in the supply chain of Chinese herbal medicines. We also develop a hybrid algorithm solution to solve the model and design a resilient supply chain network. The specific steps are as follows: (1) The risk dynamic regulation mechanism is created with strong risk resistance by considering the information sharing platform, facility defense, drying station scheduling, safety stock, and shared inventory. (2) Based on the dynamic risk regulation mechanism, we establish a sustainable Chinese herbal medicine supply chain network design model. Then, we use the robust fuzzy method and the epsilon constraint to deal with the uncertainty and integrate the model. (3) We introduce opposition-based learning, cosine convergence factor, and levy flight to the original Whale and Grey wolf algorithms to obtain the Hybrid algorithm, which is used to solve the processed model. The results show the model and algorithm proposed in this paper have strong applicability and advantages in designing closed-loop supply chain networks for Chinese herbal medicine and provide references for relevant decision-makers.

Article highlights

• We establish a dynamic risk control mechanism with strong anti-risk ability, by considering the information sharing platform, facility defense, drying station scheduling, safety inventory, and other factors. This mechanism effectively enhances the resilience of the Chinese herbal supply chain network and reduces the risk of disruption.

• We establish a sustainable closed-loop supply chain network design model, according to the particularity of the Chinese herbal medicine supply chain network in the process of processing, storage, and transportation. The model is based on the dynamic risk control mechanism. We use the robust fuzzy method to handle the uncertainty in the model. In this way, we can enhance the reliability of the Chinese herbal supply chain while effectively controlling costs.

• We improve Grey Wolf Optimization Algorithm (GWO) and Whale Optimization Algorithm (WOA) through opposition-based learning, cosine convergence factor, and levy flight. We mixed the improved algorithm to obtain opposition-based levy Grey Whale optimization algorithm (OLGWOA). Through verification, it is concluded that OLGWOA has strong searchability. We also used OLGWOA to solve the model and found the adaptability between the algorithm and the model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The market scale of the Chinese herbal medicine industry has expanded dramatically. However, most of the industry still has the disadvantages of low-quality drying products, low efficiency, and high cost, which significantly limit the sector's development. Take the herbal medicine market in the past eight years as an example. The profit margin of herbal medicine is considerable; even some herbs are multiplied several times in price. However, its production changes have never kept up with the growth of market demand. Through market research, it is easy to find that the high preservation requirements of fresh herbs, low utilization of drying resources, high drying costs, and uncertainty of end-customer demands are all critical problems. These problems make it challenging to grow the scale of the industry. Therefore, it is of great significance for enterprises to determine a reasonable inventory level, control transportation costs, accurately plan the supply chain network, and then control costs.

The supply chain is a functional chain that connects suppliers, manufacturers, distributors, retailers, and end users [1]. As the basic structure of supply chain optimization management, supply chain network design is crucial in guiding supply chain network management. Its influence on the supply chain is consistent throughout [2]. In recent years, sustainable supply chain network design is becoming a decisive factor in measuring the competitiveness of enterprises. The design of a sustainable supply chain network is not an individual effort. Still, it requires the cooperation of upstream and downstream members of the whole supply chain to lay the foundation for the long-term development of the supply chain.

Risk is an intricate problem that no industry can escape from, and how to better avoid risk in supply chain network design is the top priority in supply chain management. It is the common goal of all supply chain managers to maintain the continuity of supply chain operations and demand satisfaction under risky conditions. Therefore, it is imperative to design a stable, efficient, and resilient supply chain.

According to the relevant data, the number of publications on agricultural supply chains in domestic and international academia has increased in the past two years. Still, it mainly focuses on reference papers and short reports, and there are few articles on Chinese herbal supply chain network design [3]. Based on the above introduction, this paper proposes a multi-objective design model for a sustainable supply chain network based on the risk dynamic control mechanism to explore the sustainable herbal supply chain network and fill the gap in the related field of the agricultural supply chain.

To address the above issues, considering previous literature as in Appendix 1, the main contributions of this paper are as follows:

-

(1)

To improve the resilience of the Chinese herbal medicine supply chain network, we propose a risk dynamic regulation mechanism (active and passive anti-risk operations). Based on the risk dynamic regulation mechanism and the characteristics of the Chinese herbal medicine industry, we establish a closed-loop sustainable supply chain network, which was based on the information sharing platform and centered on the Terahertz drying station.

-

(2)

The sustainable supply chain network design model aims at minimizing costs, minimizing carbon emissions and maximizing social benefits. For the uncertainty factors in the model, we use the fuzzy method of Me measure and robust optimization to weaken the uncertainty influence in the model. Through the sensitivity analysis, we can know the law and the advantages of the anti-risk mechanism and the robust fuzzy method.

-

(3)

Based on the original Whale Optimization Algorithm (WOA) and the original Grey Wolf Optimization Algorithm (GWO), We improve the algorithms by opposition-based learning, levy flight, and parameters of convergence. Then we obtain the hybrid OLGWOA algorithm, which improves the speed of convergence and avoids local optima. We use the OLGWOA algorithm to solve the above model, significantly improving the solution efficiency. And practical cases show that the Algorithm and model in this paper are significantly effective for solving such problems.

The remainder of this paper is organized as follows: Part II is a literature review, Part III is model building, Part IV is model processing, Part V is solution method, Part VI is case solving, and Part VII is the conclusion.

2 Literature review

2.1 Sustainable Chinese herbal medicine supply chain network design

The agricultural food supply chain network (AFSCN) study began in the early 1990s with the study of American grocery stores in crisis. After that, scholars began applying advanced industrial supply chain management theories to agricultural products, and AFSCN was born. After years of efforts by scholars, the design of AFSCN has gradually become standardized. The solutions of problems have become more complex and involve more practical issues such as pricing, supplier selection, etc. Zanoni. et al. designed a cold chain for a refrigerated products network, compared and evaluated the proposed methods [15]. Because of the perishable nature of fresh produce, Chao et al. proposed a two-stage LRITW (Location-routing-inventory problems with time-window) model with an objective of minimizing cost and solved the model using a heuristic algorithm [16]. Andisheh et al. developed a dual-objective model for a food perishable supply chain with the objectives of minimizing cost and loss, respectively, and solved it using a constant method and a heuristic algorithm and verified the effectiveness of the technique with real cases [17]. Chinese scholars such as Zhanguo et al. proposed that AFSCN faces problems such as information asymmetry, insufficient industrialization, and poor management, which leads to inefficiency [18]. Therefore, considering the particular characteristics of AFSCN, it is imperative to realize the information flow between the upstream and downstream of the supply chain.

As people pay more attention to environmental and social issues, designing a sustainable supply chain (supply chain considering economic, ecological, and social dimensions) network has become a key concern for managers. In AFSCN design, scholars have taken several conservation measures to address the release of carbon dioxide during produce spoilage. Bortolini et al. investigated fresh supply chain network design considering packaging recycling that achieves the dual objectives of low cost and low carbon [19]. Allaoui et al. proposed a sustainable agri-food supply chain network design. They identified partners first, and then considered both the carbon footprint and water footprint to make cost minimization [20]. Maiyar et al. proposed a sustainable food transportation model, and solved the model using a particle swarm algorithm [21]. Mogale et al. proposed a bi-objective decision model for grain supply chain networks. The model covers problem characteristics such as multi-echelon, multi-temporal, and multi-modal transportation and its objectives are minimizing costs and carbon emissions. [22]. Martins et al. proposed a sustainability multi-objective integer linear programming model by considering economic, environmental, and social benefits. They applied it to the Portuguese food industry [23]. Yadav et al. also considered the same objective function as Martins et al. with the same objective function [24]. Motevalli-Taher et al. proposed a multi-objective model of sustainability supply chain network design for wheat to minimize cost, water consumption, and employment opportunities. The authors also used goal programming to transform the multi-objective problem into a single-objective problem smoothly. And apply it to a real case to evaluate the effectiveness [25].

In 2022, Yadav et al. obtained a review paper through a concise analysis of the literature on the design of agricultural supply chain networks in the last 20 years [26]. The authors concluded that the most prominent challenges are food waste, safety and security, information asymmetry, and sustainability issues. As an agricultural product unique to Asia, Chinese herbal medicine has less literature on its supply chain management due to its unique nature, but the above challenges still apply. The herbal supply chain also needs to overcome the risks and enhance the resilience of the supply chain network from the above aspects. Therefore, scholars have adopted the Internet of Things or blockchain technology to solve the problems of the extended life cycle, complex types, and diverse risk factors in the network design of the Chinese herbal medicine supply chain [27, 28]. Few AFSCNs have been designed to reduce waste and achieve sustainability through a "closed-loop supply chain (CLSC)" [29,30,31]. Even fewer have used CLSC to design herbal supply chain networks [32].In summary, this paper studies the design of a terahertz wave drying station-led herbal CLSC supply chain network, which enables information sharing and ready deployment through an information-sharing platform, significantly saving drying costs and time. At the same time, multiple farmers can share one drying station, which can be mixed and dried, which can better integrate the existing drying resources.

2.2 Robust fuzzy optimal design of resilient supply chain networks

How to avoid risks or reduce risk indices in supply chain network design is an essential issue of concern for managers. Due to the globalization of the economy and trade, while the benefits are doubled, the risks are also increased, and the losses after risk disruption are huge. Therefore, in supply chain network design, we cannot ignore resilience (the ability of the system to return to the original or more desirable state after being disrupted) [33]. There are two types of resilience strategies: active and passive methods. Active systems refer to taking measures before a risk event occurs, e.g., buffer design, alternative suppliers [34], safety stock, facility defense [35], etc. Passive strategies refer to taking approaches by managers to minimize the risk at or after the occurrence of risk approaches to reduce losses, e.g., shared inventory [36], disruption redesign, etc. In reactive strategies, we can usually adjust parameters and structures depending on the degree of compromise [37, 38].

Shrivastava H. et al. investigated the problem of facility siting and allocation planning for perishable supply chain networks under uncertainty. They considered multiple transportation routes for various manufacturers and developed a cost-minimizing mixed-integer optimization model to cope with random disruptions [39]. Sneock et al. proposed a two-stage planning approach for supply chain network design by considering the penalty cost of unexpected situation plant closure or maintenance cleaning [40]. Zhao et al. proposed a decision support system using topology analysis for robustness in supply chain network disruptions but they didn’t consider upstream and downstream disturbances in the model [41]. After that, the author further investigated topological analysis and proposed an adaptation strategy for high raw material network disruptions [42]. Nezhadroshan et al. proposed a multi-objective optimal design model considering resilience levels. The model mainly applied to post-earthquake transportation network routes and designed the network using scenario-based likelihood stochastic programming [43] Arani et al. developed a multi-objective optimal design model considering shared inventory for blood supply chains [44].

In supply chain network design, uncertainty also leads to risk multiplication. Scholars have devised many methods to deal with these uncertainties, such as stochastic programming [45], robust optimization, and fuzzy optimization [46]. Considering the case of demand uncertainty, Lu et al. designed a multi-objective stochastic closed-loop supply chain network [47]. Stochastic planning methods are more demanding and limited by historical data and experience, robust and fuzzy optimization methods are more widely used. Fattahi et al. used a robust optimization approach to deal with the lack of data in the design phase of the distribution function [48]. Because of the advantages of robust and fuzzy planning in dealing with uncertainty, some scholars have started combining them to obtain new methods with more robustness. Both Ghaderi et al. and Ouhimmou et al. proposed a multi-objective robust possibility planning model for bioethanol supply chain network design considering uncertainty [49, 50]. Habib et al. proposed an uncertainty optimization model for minimizing the cost and carbon emission of animal fat-based biodiesel supply chain network design with a robust-based likelihood planning approach [51]. After comparison and discussion, the author found that the robust fuzzy method can achieve an effective solution with high robustness. Tsao et al. proposed a robust fuzzy optimization model based on a combination of robust optimization and vague planning for a steel company in Taiwan, solving the uncertainty problem of demand and cost [52]. Through the case study, it is proved that the result of the robust fuzzy model is better than that of scenario-based robust stochastic programming. After verification and comparison by scholars, the robust fuzzy combination is indeed more advantageous in dealing with uncertainty. Therefore, we design a risk-dynamic regulation mechanism to enhance resilience and use a robust fuzzy approach to deal with uncertainty, in designing the Chinese herbal medicine supply chain network.

2.3 Intelligent algorithms

Large-scale supply chain network design is considered an NP-hard problem. Scholars believe it is challenging to solve NP-hard problems using traditional mathematical methods. At this point, the heuristic algorithm highlights its mighty computing power and can solve significant problems [53, 54]. Guo et al. proposed a distributed approximation algorithm (DAA) to solve the supply chain network design [55]. After that, Guo et al. further studied and proposed a multi-objective mixed integer linear programming model (MILP) that considers carbon emissions and social responsibility. To solve the sustainable supply chain network design, they use a multi-neighborhood descent traversal algorithm (MNDTA) s to solve the problem and verify the effectiveness of the algorithm [56].

As the research on intelligent algorithms deepens, scholars start to hybridize different algorithms to enhance the solving ability of intelligent algorithms and complement each other's shortcomings to get hybrid algorithms. Hasani A. et al. proposed a hybrid heuristic algorithm that incorporated the improved Pareto Evolutionary Algorithm 2 (SPEA2) and used it to solve the green global supply chain design problem in a disrupted state [57]. Tawhid et al. addressed complex nonlinear systems and unconstrained optimization problems. They proposed a hybrid population-based algorithm WOFPA, which is a mix of the whale optimization algorithm (WOA) and the flower pollination algorithm (FPA) [58]. Chakraborty et al. proposed a new and improved algorithm that combines the difference algorithm with the whale algorithm to obtain the m-SDWOA Algorithm and verify the effectiveness of the Algorithm [59].In this paper, we mix the improved Whale algorithm and the improved Grey wolf algorithm to solve the robust fuzzy optimization design model of the Chinese herbal medicine supply chain network.

Based on the above literature review, this paper will approach the solution to the problem from the following aspects.

-

(1)

We establish a tri-objective optimization model with minimum cost, minimum carbon emission, and maximum social benefit for the closed-loop supply chain network of Chinese herbal medicine, and consider a risk dynamic regulation mechanism to enhance resilience.

-

(2)

We combine Me measure and robust optimization with the triangular fuzzy number and opportunity planning to deal with uncertain parameters in the model. Meanwhile, the epsilon constraint is used to integrate it into a single-objective model.

-

(3)

We improve and mix the improved Whale Algorithm and the improved Grey Wolf Algorithm to obtain the OLGWOA algorithm, OLGWOA can enhance the search capability of the algorithm and avoid the algorithm limitations. If five iterations of the same solution appear, it will be reinitialized to get a better solution. We use the OLGWOA algorithm to solve the processed model in this paper.

3 Problem definition and modeling

In this section, we will study a multi-level, multi-cycle, multi-product closed-loop supply chain integration network and use a risk dynamic regulation mechanism to increase the supply chain network resilience. The closed-loop supply chain network studied is shown in Fig. 1. The network diagram contains the following nodes: information sharing platform, farmer (supplier)\(F\), sorting center \(I\), drying station \(M\), packaging center \(O\), distribution center \(K\), recycling and reprocessing center \(R\), and customer \(C\). In the forward logistics, the process of each node for raw material \(A\), product \(P\), and water \(H\) generated by drying is shown in Fig. 1. In reverse logistics, customers return expired \(P\) to reprocessing center \(R\) and process them into complementary herbal products (for example, herbal bath bags, herbal pillows, etc.).

To improve the flexibility of the supply chain network, we propose a risk dynamic regulation mechanism, which comprehensively considers active and passive strategies. Active strategy 1: facility defense when establishing each node in the network. The defense level of facilities (e.g., 5%, 20%, 50%, etc.) is included in the construction cost. Different protection levels represent different expected armor classes, and different protection levels have additional construction costs. Strategy 2: safety stock. It can deal with risks when we set up a distribution center.

In addition, we consider the passive strategy, using the information sharing platform in the supply chain network to share information with each node at any time and schedule immediately. As shown in Fig. 2a, if the customer demands surge, the distribution center can consider sharing inventory internally to relieve the inventory pressure. At the same time, to cope with the equipment aging or the interruption of the electricity restriction policy implemented in China in 2021, farmers choose alternative drying stations according to the location distance, capacity, delivery time, and existing workload, as shown in Fig. 2b.

3.1 Assumptions

The assumptions in this paper are as follows: (1) each transportation process uses one transportation method and all transportation vehicles consume the same amount of energy; (2) both customer demand and the number of farmer product types are not fixed; (3) the locations of farmer \(f\), customer \(c\) and recycling and reprocessing center \(r\) are fixed, and the location, number and workload of sorting center \(i\), drying station \(m\), packaging center \(o\) and distribution center \(k\) are the parts to be decided; (4) Failure is uncertain, such as power limitation of drying station \(m1\), the control center will immediately analyze the situation and quickly transfer to the nearby screened drying station \(m2\); (5) distribution center has zero inventory from the first phase and allows transferring shared inventory between distribution centers; (6) drying stations have a variety of product types and can be collocating dried if the drying box is not full; (7) The distribution center is the only node with safety stock in the whole text; (8) the amount of carbon dioxide generated by mixed drying and separate drying is the same; (9) recycling reprocessing center \(r\) can recycle the shape broken product \(p\), drying wastewater \(h\) and expired product \(p\); (10) the standard of subsidy is different according to the type, value and quantity of cultivated herbs. When the corresponding standards are met, the government will give corresponding subsidies to herb growers.

3.2 Notation, parameters, and variables definition

(1) Based on the modeling needs, the following notation is defined in this paper.\(f \in F\) denotes a collection of farmers; \(m \in M\) denotes a collection of drying stations; \(i \in I\) denotes a collection of sorting centers; \(k \in K\) denotes a collection of distribution centers; \(c \in C\) denotes a collection of customer collection; \(o \in O\) denotes a collection of packaging centers; \(r \in R\) denotes a collection of recycling reprocessing centers; \(t \in T\) denotes a collection of time slots; \(p \in P\) denotes a collection of finished product; \(a \in A\) denotes a collection of Raw material; \(e \in E\) denotes a collection of defensive level; \(h \in H\) denotes a collection of drying station recycling wastewater; \(n \in N\) denotes a collection of drying priority.

(2) The parameters are defined as follows:

\(Fix_{m}^{e}\),\(Fix_{i}^{e}\),\(Fix_{k}^{e}\),\(Fix_{r}^{e}\),\(Fix_{o}^{e}\) denote the costs required to build a single drying station \(m\), sorting center \(i\), distribution center \(k\), recycling and reprocessing center \(r\), and packaging center \(o\) with defense level \(e\), respectively. \(Fix_{f}^{e}\) denotes the unit cost for farmers \(f\) to grow herbs with defense class \(e\). \(\psi\) denotes the dehydration rate of drying.

\(\mu_{iat}\),\(\mu_{kpt}\),\(\mu_{opt}\),\(\mu_{rpt}\),\(\mu_{rht}\),\(\mu_{rat}\) denotes the cost of cleaning and sorting, drying, distribution, recycling, and packaging per unit of raw material \(a\), dried wastewater \(h\), and finished product \(p\), respectively, at each node, with priority \(n\) in period \(t\).\(\mu_{dist}\) indicates the cost of fuzzy penalties for not meeting customer needs. \(\mu_{ksit}\) denotes the fuzzy freight rate per unit of inventory, per unit of distance, shared among distribution centers \(k\) in period \(t\).\(\mu_{matn1}\),\(\mu_{matn2}\) represent the fuzzy cost of the drying station \(m\) alone or mixed with drying feedstock \(a\), respectively.\(\mu_{fat}\) denotes the government subsidy received by herbal growers per unit of herbal medicine. \(\mu_{sakt}\) represents the product's cost of holding safety stock at the distribution center \(k\).

\(Tr_{a}\),\(Tr_{p}\),\(Tr_{h}\) denote the fuzzy costs of delivering unit quantities \(a\) and \(h\), respectively.\(dem_{pt}\) indicates the fuzzy demand for the product by the customer \(c\) at time \(t\).\(SA_{pkt}\) represents the safety stock level for the product at the distribution center \(k\) in period \(t\).\(r_{if}\),\(r_{mi}\),\(r_{om}\),\(r_{ko}\),\(r_{kc}\),\(r_{ri}\),\(r_{rm}\),\(r_{ro}\),\(r_{cr}\) denote the coverage radius between the nodes sorting center \(i\), the farmer \(f\), the drying station \(m\), the packaging center \(o\), the distribution center \(k\), the customer \(o\), and the recycling reprocessing center \(r\) respectively. \(T_{an}\) denotes the processing time for each priority level for raw material a.

\(Dis_{fi}\),\(Dis_{im}\),\(Dis_{mo}\),\(Dis_{ok}\),\(Dis_{kc}\),\(Dis_{mr}\),\(Dis_{ir}\),\(Dis_{cr}\) \(Dis_{ro}\) denotes the distance between the nodes. \(T_{job}\) Indicates the total drying time. \(Dis_{ksi}\) represents the distance of shared inventory between distribution centers \(k\). \(Cap_{f}\),\(Cap_{i}\),\(Cap_{m}\),\(Cap_{o}\),\(Cap_{r}\) indicates the maximum growing capacity, processing capacity, or stock of each node.

\(\varphi_{i}\),\(\varphi_{m}\),\(\varphi_{o}\),\(\varphi_{k}\),\(\varphi_{r}\) indicates the amount of CO2 consumed by each node that establishes a defense level of \(e\). \(\varphi_{fa}\),\(\varphi_{ia}\),\(\varphi_{ma}\),\(\varphi_{op}\),\(\varphi_{kp}\),\(\varphi_{rp}\),\(\varphi_{rh}\),\(\varphi_{ra}\) suggests the amount of CO2 consumed per unit of product for each node of operation. \(\varphi_{car}\) indicates the amount of CO2 consumed per unit distance transported by car.\(work_{f}\),\(work_{i}\),\(work_{m}\),\(work_{r}\),\(work_{o}\),\(work_{k}\) denotes the number of jobs in farmer \(f\), drying station \(m\), sorting center \(i\), recycling reprocessing center \(r\), packaging center \(o\), and distribution center \(k\).

(3)The decision variables are as follows: \(Z_{i}\),\(Z_{m}\),\(Z_{o}\),\(Z_{k}\),\(Z_{r}\) for respectively indicates 1 if the sorting center \(i\), drying station \(m\), packaging center \(o\), distribution center \(k\), reprocessing center \(r\) is constructed, and 0 otherwise. \(Z_{f}\) represents 1 if the farmer grows herbs, 0 otherwise. \(Z_{f}^{^{\prime}}\) is the decision variable of whether to grant subsidies. If the farmers' planting amount reaches the subsidy standard, it is 1 and 0 otherwise.

\(Q_{fat}\),\(Q_{iat}\),\(Q_{matn1}\),\(Q_{matn2}\),\(Q_{opt}\),\(Q_{rpt}\),\(Q_{kpt}\),\(Q_{rht}\),\(Q_{rat}\) represents the number of raw materials \(a\), products \(p\), and wastewater \(h\) grown, sorted, dried, packaged, and recycled at the farmer \(f\), sorting center \(i\), drying station \(m\), packaging center \(o\), distribution center \(k\), and recycling reprocessing center \(r\), in unit time of period \(t\). \(Q_{matn}^{in}\) denotes herbal raw material a with priority n that has been affected by the interruption of the drying station involving the processing schedule. \(Q_{afit}\),\(Q_{airt}\),\(Q_{aimt}\),\(Q_{pmot}\),\(Q_{pokt}\),\(Q_{pkct}\),\(Q_{pmrt}\),\(Q_{prot}\),\(Q_{pcrt}\),\(Q_{hmrt}\) denote the volume of goods transported between the nodes of the farmer \(f\), sorting center \(i\), drying station \(m\), packaging center \(o\), distribution center \(k\), recycling and reprocessing center \(r\), and customer \(c\), respectively, per unit time.\(Q_{dist}\) indicates the number of products for which the customer has not been satisfied. \(Q_{ksit}\) denotes the number of products shared in stock between distribution centers \(k\).

\(Z_{ksi}\) denotes a 0/1 variable, 1 if distribution centers can share the inventory, 0 otherwise. \(Z_{mex}\) represents a 0/1 variable, 1 if the drying station is replaced, 0 otherwise.\(Z_{mat}\) indicates 1 if m is selected as the primary drying site, 0 otherwise. \(Z_{m^{\prime}at}\) indicates 1 if m is designated as an alternate site and 0 otherwise.\(Z_{fit}\),\(Z_{imt}\),\(Z_{mot}\),\(Z_{okt}\),\(Z_{kct}\),\(Z_{crt}\),\(Z_{mrt}\),\(Z_{irt}\),\(Z_{rot}\) indicates that if the drying station drying box is collocated, then it is 1; otherwise, it is 0.

3.3 Modeling

Based on the above, this paper establishes the models as follows, which are minimizing cost (F1), minimizing carbon emission (F2), and maximizing social benefit (F3), and the related functions are as follows (1)-(3).

F1 = minimization cost = flexible construction cost + safety stock cost + operation cost + demand unsatisfied cost + transportation cost (including transportation cost of interrupted exchange of drying stations) + shared stock cost—government subsidy.

F2 = Minimization carbon emission = construction carbon emission + operation carbon emission of production and holding + transportation carbon emission (including transportation carbon emission of shared stock and exchange of drying stations) + carbon emission of mixed loading and drying.

F3 = Maximization Social benefits = the number of jobs provided by each node.

The following are capacity constraints, flow constraints, inventory constraints, coverage constraints, customer demand constraints, and shared inventory constraints.

Equation (4)–(8) denote the capacity constraints at each point of the farmer \(f\), drying station \(m\), sorting center \(i\), reprocessing center \(r\), and packaging center \(o\), respectively, and Eq. (9) denotes that the confidence level of the distribution center \(k\) is not less than \(\omega_{k} \in \left[ {0, 1} \right]\).

Equation (10)-(15) represents the flow balance among the nodes of farmer f, drying station m, sorting center i, distribution center k, recycling and reprocessing center r, and packaging center o, respectively.

Equation (16) indicates the coverage range of farmer f and sorting center i. Equation (16) also applies to the following parameters:\(Z_{imt} ,Z_{mot} ,Z_{okt} ,Z_{mrt} ,Z_{irt} ,Z_{rot} ,Z_{kct} ,Z_{crt} ,Dis_{im} ,Dis_{mo} ,Dis_{ok} ,Dis_{mr} ,Dis_{ir} ,Dis_{ro} ,Dis_{kc} ,Dis_{cr} ,r_{mi} ,r_{om} ,\) \(r_{ko} ,r_{rm} ,r_{ri} ,r_{ro} ,r_{kc} ,r_{cr}\).

Equation (17) in large is to take the maximum function. (17) Shows that the total processing time takes the longest of all products when mixing and drying. Equation (18) indicates that each drying station can be the main and backup drying place. The formula (19)-(20) shows the range of values of decision variables and parameters.

4 Model processing

4.1 Multi-objective processing

This section uses \(\varepsilon\)-constraints to integrate the multi-objective optimization function into a single-objective model to reduce the difficulty of solving. The principle of the epsilon constraint method is to use the highest priority objective as the preferred primary objective and the other objectives as additional constraints. This method is a common means of solving multi-objective mathematical models, which this paper represents as an Eq. (21).

4.2 Uncertainty treatment

For the uncertain parameters in the model, this section uses a combination of robust and fuzzy methods to convert the model into an RFP model [60].

4.2.1 Fuzzy optimization

This section uses a combination of fuzzy triangular numbers and Me measure to deal with uncertainties in the model. Me measure is a fuzzy measure between the necessity measure (pessimistic) Nec and possibility measure (optimistic) Pos, by controlling the optimistic-pessimistic parameter \(\lambda\) to make the Me measure flexible between optimistic and pessimistic values, where \(\lambda \in \left\{ {0,1} \right\}\).

In summary, we will modify the model according to Eqs. (23)-(25), considering nominal values and left–right perturbation ratios.

Modify model F1 in this paper to a transparent equivalence model with both LAM and UAM, as shown in Eqs. (26)-(28).

s.t.

4.2.2 Robust fuzzy optimization

This section uses robust fuzzy optimization to enhance the model robustness with freely set weight parameters \(\gamma \in [0,1]\) and confidence levels \(\omega_{k} \in [0,1][0,1]\). Equation (29) summarizes the robust optimization method, where \(F1_{max}\)、\(F1_{min}\) as in Eqs. (30) and (31). \(\rho\) and \(\theta\) are the unit penalty for a possible violation of each constraint.

5 Solving methods

5.1 The original whale algorithm

The Whale Optimization Algorithm (WOA) [61] is a biomimetic algorithm proposed by Australian scholars Mirjalili et al.. Through observation, they found that whales create a spiral bubble net to surround and target the fish at a distance of 12 m from the school when hunting and finally catch the prey. The WOA algorithm contains three main steps: searching for prey, surrounding the prey, and a bubble-net attack.

5.1.1 Surrounding prey

In WOA, the current solution is assumed to be optimal and unknown, so the real-time position of the whale needs to be updated continuously to get the optimal solution gradually. The specific expressions are as follows in Eqs. (32) and (33).

where \(step\) is the enclosing step \(\varpi\),\(\theta\) is the coefficient vector, \(Y_{iter}^{*}\) denotes the optimal whale position, \(Y_{iter}\) denotes the current whale position, and \(Y_{iter}^{^{\prime}}\) denotes the new optimal position updated at each iteration. Equation (34)-(35) describe the coefficient vectors ϖ and \(\theta\) in Eq. (32)-(33), where \(rand\) is the random number between \([0,1]\) and \(\vartheta\) is the linear iteration coefficient decreasing from 2 to 0. As described in Eq. (36), \(iter\) is the current iteration number and \(max_{iter}\) is the maximum iteration number.

5.1.2 Bubble net attack

The local development phase of the WOA algorithm is the bubble net attack phase. Its steps are as follows: the search shrinkage envelope mechanism and the spiral update mechanism.

The shrinkage envelope mechanism is similar to the global search. It reduces the linear iteration coefficient \(\vartheta\), with the number of iterations from 2 to 0 to achieve the position update and take the value \(\varpi = [ - 1,1]\).

The renewal mechanism means that whales have a 50% probability of approaching prey in a spiral shape in a gradually decreasing circle. The logarithmic spiral curve is mainly constructed based on the current position and the optimal agent so that the search agent slowly approaches the optimal position. As described in the following Eq. (37)-(38).

5.1.3 Searching for prey

The search of prey phase takes the form of a stochastic location update of the fish population, as described in Eq. (39)-(40) below.

5.2 The original grey wolf algorithm

The Grey Wolf Algorithm (GWO) [62] is a biomimetic algorithm proposed by Australian scholars Mirjalili et al. It has been widely used for solving NP-hard problems in various fields because of its simple operation, few adjustable parameters, and high solution efficiency. The main principle of GWO is to simulate the wolf pack hunting mechanism and the status hierarchy within the wolf pack and to divide the wolf pack into \(\alpha\) wolf, \(\beta\) wolf, and \(\delta\) wolf. Its principle contains searching for prey, surrounding prey, and attacking prey as the following Eq. (41)-(42).

where \(step^{G}\) denotes the envelope step, \(\varpi^{G} ,\theta^{G}\) is the coefficient vector, \(Y_{iter}^{G*}\) denotes the optimal wolf position, \(Y_{iter}^{G}\) denotes the current wolf position,\(Y_{iter}^{G^{\prime}}\) denotes the new optimal position updated at each iteration. And the calculation method of the coefficient vectors \(\varpi^{G} ,\theta^{G}\) are similar to (34) and (35).

(43) denotes the distance between each wolf and the optimal solution wolf \(\alpha ,\beta ,\delta\); (44) represents the position of the next wolf; Eq. (45) denotes the next position of each wolf.

5.3 Opposition-based learning

Opposition-based learning (OBL) is one of the effective means to enhance the searchability of the Algorithm. The stochastic backward learning [63] method used in this section is embedded in the original WOA or GWO to enhance the population diversity and improve the searchability of the algorithm. The method is to use the solution opposite to the existing solution as the candidate solution of the second group to expand the population range to get more solutions. The results show that the method effectively enhances global search ability.

The primary method of OBL is as follows: in each iteration, an agent is first searched from the population immediately according to Eq. (46). And Eq. (47) is used to change the solution to the opposite. Where \(Ind\) denotes the individual index, \(Ceil,Y_{iter} ,rand_{2}\) represent the upward rounding function, the random individual, and the random number between \([0,1]\). \(Y_{Ind} ,Y_{g}\) indicate the new and original positions. \(lb,ub\) show the upper and lower bounds of the decision variables, respectively.

5.4 Improvement steps

5.4.1 Linear iteration coefficients

WOA and GWO are both heuristic algorithms proposed in recent two years, which have the characteristics of fast solution speed, few parameters, and simple operation. But in contrast, their search ability is limited. To maximize the searchability, this section adopts the cosine convergence factor to improve the linear iteration coefficients, such as in Eq. (48).

5.4.2 Levy flight modified step size

The search space becomes more diversified. It makes the search process more complex and it often falls into local optimization. To solve the problem that WOA quickly falls into the local optimum, we introduce the Levy flight mechanism with dynamic step size to WOA. The Levy flight mechanism is a special kind of stochastic motion, a combination of short-range and long-range step operation modes. It can reduce the possibility of falling into a local minimum in WOA, as in Eq. (49)-(53). In these Eqs., \(\phi\) is the dynamic step factor, \(Levy(\chi ,v)\) is the flight step. \(\chi\),\(v\) obey the normal distribution, respectively. \(o\) has the initial setting of 1.5, and declines slowly. To jump out of the local optimum, it will decline exponentially at the end of the iteration.

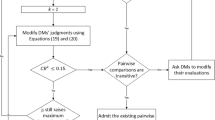

5.5 Hybrid algorithm

Through the above improvements, we obtain the improved hybrid algorithm OLGWOA. Figure 3 shows the detailed hybrid algorithm process, The specific operations are as follows:

Firstly, we divide the population into POP1 and POP2 by opposition-based learning to increase the population diversity. Second, we introduce the linear iteration parameter into GWO to obtain the improved GWO algorithm and enhance its search capability. We introduce linear iteration coefficients and Levy flights into WOA to obtain the improved WOA algorithm, which improves the search step and avoids falling into the local optimum. Finally, we use these two algorithms to solve this POP1 and POP2, respectively. during the iteration, if the same solution appears five times (falls into the local optimum), it will re-enter the initialization and solve again.

6 Solution approach

Jilin province, China, as a large Chinese medicine output province, has a wide variety of Chinese medicine products with abundant production. In this section, we will take Baishan city and Yanbian Korean Autonomous Prefecture in Jilin province as an example to verify the effectiveness of the model part, robust fuzzy processing part, and algorithm part. The specific location is shown in Fig. 4. September–October is the harvesting season of Chinese herbal medicines. The data in Appendix 1, 2, 3 were generated based on the actual situation of the current 30 herbal cultivation cooperative bases.

6.1 Model validity verification

To verify the validity of the model, this section uses lingo software. It tests the range of values in the Appendix to discuss the impact of shared inventory and drying station swap on cost in the deterministic model. The results are shown in Fig. 5. As seen in Fig. 5a, the total cost gradually increases as the number of out-of-stocks increases due to the penalty cost. However, the trend shows that shared inventory can ensure lower prices while meeting customer demand within a certain number of out-of-stocks. As seen from Fig. 5b, as the number of interruptions increases, consumption cost increase, too. However, there is no need for drying station scheduling within a certain interruption length.

6.2 Algorithm validation

This section uses Taguchi experiments to select the optimal combination of the algorithm parameters of the OLGWOA. We take the SearchAgents_no value of {100,200,300,500}, take the Maxiteration value of {100,150,200,250}, take the \(\varsigma\) value of {0.1,0.2,0.4,0.6}. The optimal combination of the number of search agents, 200, the maximum number of iterations, 260, and the selection parameter, 0.6, was obtained from Taguchi's experiment. Based on the above optimal parameters, this section uses IGWO, IPSO (improved linear iterative parameters), ILWOA(improved linear iterative parameters, Levy flight), and HWOA[77] to compare with the OLGWOA of this paper. These algorithms use cosine convergence factors to improve parameters. We use the above four algorithms to test the test functions in the Appendix 2 respectively and obtain Table 1. From Table 1, we can see that the algorithm OLGWOA proposed in this paper has a small variance and relatively higher reliability, accuracy, and optimization capability.

6.3 Sensitivity analysis

This section uses the OLGWOA to solve the robust fuzzy model. And we set \(\rho ,\lambda\) to the optimal value between [100,1100]. And Table 2 is obtained by adjusting the importance of \(\omega ,\gamma\). By analyzing the data in Table 2, it can be concluded that the cost decreases as the confidence level increases when confident. As the uncertainty increases, the proposed optimization model shifts toward the conservative value of the uncertain parameters. And the cost of considering uncertainty is higher than the value of deterministic cost. As uncertainty increases, more cost is needed to maintain stability.

Figure 6 shows the iteration diagram of this algorithm for solving the cost model in this paper and compares it with IGWO and ILWOA. It can be seen from the chart that the improved Algorithm proposed in this paper is superior in solving the problem of the closed-loop supply chain network of Chinese herbal medicine in this paper. The Figure shows that the solution cost of IGWO is lower than that of OLGWOA, but it is more likely to fall into the local optimum and take longer to solve. At the same time, compared with ILWOA, OLGWOA has a relatively low cost and more substantial search capability.

6.4 Practical case study

In this section, we take Yanbian Korean Autonomous Prefecture and Baishan City in Jilin Province, China as an example. When the number of participating herbal farmers is 10, the specific situation of the supply chain network is shown in Fig. 7. From Fig. 7, it can be obtained that when the cultivated farmers are fewer and scattered, the packaging center is set near the center to achieve the relative optimum cost, carbon emission, and social benefits. At the same time, when farmers are more dispersed, it is not suitable for drying station dispatching. And the layout of sorting center i, recycling and remanufacturing center r, drying station m, and packaging center o roughly shows a clustering type and then output to each distribution center. When the farmers involved in growing herbs are 30, the specific situation of the supply chain network is shown in Fig. 8. As seen from the Figure, when the number of farmers is large, the overall supply chain network layout shows a radial shape and is exported level by level.

7 Conclusion

This paper studies a multi-level, multi-cycle, multi-product, closed-loop supply chain integration network of Chinese herbal medicine. It solves the problems of high cost, low resource utilization rate, and uncertain risk of traditional Chinese herbal medicine supply chain network and draws the following conclusions:

-

(1)

Considering risk dynamic regulation mechanisms, we establish a multi-objective optimization model with the objectives of minimum cost, carbon emission, and maximum social benefit. Meanwhile, to deal with the uncertainty in supply chain network design, the model is transformed into a robust fuzzy optimization model of resilient supply chain networks. Practical cases and sensitivity analysis show that the model and robust fuzzy analysis method proposed in this paper can effectively improve the resilience of supply chain networks and quickly deal with disruption risks.

-

(2)

To solve the NP-hard problem of supply chain network design, we combined the original Whale algorithm and the Grey wolf algorithm. We use the opposite learning mechanism to expand the population. The levy flight mechanism is used to jump out of the local optimum, and the cosine convergence factor is used to enhance the searchability, thus obtaining the OLGWOA algorithm. Compared with the ILWOA, IGWO, IPSO, and HWOA, the OLGWOA has a faster convergence rate, stronger stability, and can jump out of local optimum better.

-

(3)

The improved OLGWOA algorithm is used to solve the robust fuzzy optimization model of the closed-loop supply chain network. The actual case proves that the model and algorithm proposed can well solve the problems of the Chinese herbal medicine supply chain network and provide suggestions for related management departments.

In the actual supply chain of the herbal medicine industry, there are special circumstances such as seasonal supply, geographical supply, climatic influence, and many types of transportation. It is not discussed in detail in this paper. Meanwhile, the supply chain network attempted to be constructed in this paper can evolve into a herbal medicine supply chain network alliance. But the design of the alliance must consider the internal revenue distribution and cost-sharing of each member. Therefore, the research on the Chinese herbal medicine supply chains needs to be further developed. Our next research work focuses on refining different kinds of herbal supply chain networks, and supply chain network alliances to ensure closer to realistic operation and further innovation.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Change history

16 May 2024

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1007/s42452-024-05955-6

References

Xuelong Z., Doudou W. (2020) An Optimal Design Model of Multi-stage Supply Chain Network with Interval Grey Features. Statistics and Decision Making, 1 :167–171. https://doi.org/10.13546/j.cnki.tjyjc.2020.01.037

Qiuyang G, Chunhua J, Gongxing W (2021) Research on the design and optimization of closed-loop supply chain network with consideration of carbon emission and quantity discount. Control Theory and Application 38(3):349–363. https://doi.org/10.7641/CTA.2020.00276

Salehi-Amiri A., Zahedi A., Akbapour N., et al. (2021) Designing a sustainable closed-loop supply chain network for walnut industry. Renewable and Sustainable Energy Reviews, 141 :110821. https://doi.org/10.1016/j.rser.2021.110821

Ghahremani-Nahr J, Kian R, Sabet E (2019) A robust fuzzy mathematical programming model for the closed-loop supply chain network design and a whale optimization solution algorithm. Expert Syst Appl 116:454–471. https://doi.org/10.1016/j.eswa.2018.09.027

Yavari M, Geraeli M (2019) Heuristic method for robust optimization model for green closed-loop supply chain network design of perishable goods. J Clean Prod 226:282–305. https://doi.org/10.1016/j.jclepro.2019.03.279

Boronoos M, Mousazadeh M, Torabi SA (2021) A robust mixed flexible-possibilistic programming approach for multi-objective closed-loop green supply chain network design. Environ Dev Sustain 23(3):3368–3395. https://doi.org/10.1007/s10668-020-00723-z

Fragoso R, FigueiraI JR (2021) Sustainable supply chain network design: An application to the wine industry in Southern Portugal. J Oper Res Soc 72(6):1236–1251. https://doi.org/10.1080/01605682.2020.1718015

Jouzdani J., Govindan K. (2021) On the sustainable perishable food supply chain network design: A dairy products case to achieve sustainable development goals. Journal of Cleaner Production, 278 (1) :123060. https://doi.org/10.1016/j.jclepro.2020.123060

Pahlevan SM, Hosseini SMS, Goli A (2021) Sustainable supply chain network design using products’ life cycle in the aluminum industry. Environ Sci Pollut Res 2021:1–25. https://doi.org/10.1007/s11356-020-12150-8

Habib M. S., Asghar O., Hussain A., et al. (2022) A robust possibilistic flexible programming approach toward a resilient and cost-efficient biodiesel supply chain network. Journal of Cleaner Production, 366 (15) :132752. https://doi.org/10.1016/j.jclepro.2020.122403

Mohammed A, Harris I, Soroka A et al (2019) A hybrid MCDM-fuzzy multi-objective programming approach for a G-Resilient supply chain network design. Comput Ind Eng 127:297–312. https://doi.org/10.1016/j.cie.2018.09.052

Yolmen A, Saif U (2021) Closed-loop supply chain network design integrated with assembly and disassembly line balancing under uncertainty: an enhanced decomposition approach. Int J Prod Res 59(9):2690–2707. https://doi.org/10.1080/00207543.2020.1736723

Namdar J, Ali TS, Sahebjamnia N et al (2020) Business continuity-inspired resilient supply chain network design. Int J Prod Res 59(5):1331–1367. https://doi.org/10.1080/00207543.2020.1798033

Hasani A., Mokhtari H., Fattahi M. (2021) A multi-objective optimization approach for green and resilient supply chain network design: A real-life case study. Journal of Cleaner Production, 278 (1) :123199. https://doi.org/10.1016/j.jclepro.2020.123199

Zanoni S, Mazzoldi L, Ferretti I (2019) Eco-efficient cold chain networks design. Int J Sustain Eng 12(5):349–364. https://doi.org/10.1080/19397038.2018.1538268

Chao C, Zhihui T, Baozhen Y (2019) Optimization of two-stage location–routing–inventory problem with time-windows in food distribution network. Ann Oper Res 273(1–2):111–134. https://doi.org/10.1007/s10479-017-2514-3

Andisheh A., Anita A., Navid A., et al. (2020) Innovative approaches to design and address green supply chain network with simultaneous pick-up and split delivery. Journal of Cleaner Production, 250 (20) :119437. https://doi.org/10.1016/j.jclepro.2019.119437

Zhanguo Z, Feng C, Dolgui A et al (2018) Recent advances and opportunities in sustainable food supply chain: a model-oriented review. Int J Prod Res 56(17):5700–5722. https://doi.org/10.1080/00207543.2018.1425014

Bortolini M, Gabriele FG, Mora C et al (2018) Bi-objective design of fresh food supply chain networks with reusable and disposable packaging containers. J Clean Prod 184(20):375–388. https://doi.org/10.1016/j.jclepro.2018.02.231

Allaoui H, Guo Y, Choudhary A, Bloemhof J (2018) Sustainable agro-food supply chain design using two-stage hybrid multi-objective decision-making approach. Comput Oper Res 89:369–384. https://doi.org/10.1016/j.cor.2016.10.012

Maiyar LM, Thakkar JJ (2019) Modelling and analysis of intermodal food grain transportation under hub disruption towards sustainability. Int J Prod Econ 217:281–297. https://doi.org/10.1016/j.ijpe.2018.07.021

Mogale DG, Cheikhrouhou N, Tiwari MK (2020) Modelling of sustainable food grain supply chain distribution system: a bi-objective approach. International Journal Production Research 58(18):5521–5544. https://doi.org/10.1080/00207543.2019.1669840

Martins CL, Melo MT, Pato MV (2019) Redesigning a food bank supply chain network in a triple bottom line context. International Journal Production Economics 214:234–247. https://doi.org/10.1016/j.ijpe.2018.11.011

Yadav V. S., Singh A. R., Raut R. D., et al. (2020) Blockchain technology adoption barriers in the Indian agricultural supply chain: an integrated approach, Resources. Conservation and Recycling, 161 :104877. https://doi.org/10.1016/j.resconrec.2020.104877

Motevalli-Taher F., Paydar M. M., Emami S. (2020) Wheat sustainable supply chain network design with forecasted demand by simulation. Computers and Electronics in Agriculture, 178 :105763. https://doi.org/10.1016/j.compag.2020.105763

Yadav VS, Singh AR, Gunasekaran A et al (2022) A systematic literature review of the agro-food supply chain: challenges, network design, and performance measurement perspectives. Sustainable Production and Consumption 29:685–704. https://doi.org/10.1016/j.spc.2021.11.019

Li D, Gong Y, Zhang X et al (2022) An Exploratory Study on the Design and Management Model of Traditional Chinese Medicine Quality Safety Traceability System Based on Blockchain Technology. Security and Communication Networks 2022:1–24. https://doi.org/10.1155/2022/7011145

He M., Jianhua S., (2021) Circulation traceability system of Chinese herbal medicine supply chain based on internet of things agricultural sensor. Sustainable Computing: Informatics and Systems, 30 :100518. https://doi.org/10.1016/j.suscom.2021.100518

Sgarbossa F, Russo I (2017) A proactive model in sustainable food supply chain: insight from a case study. International Journal Production Economics 183:596–606. https://doi.org/10.1016/j.ijpe.2016.07.022

Banasik A, Kanellopoulos A, Claassen GDH et al (2017) Closing loops in agricultural supply chains using multi-objective optimization: A case study of an industrial mushroom supply chain. Int J Prod Econ 183:409–420. https://doi.org/10.1016/j.ijpe.2016.08.012

Harrison B, Foley C, Edwards D et al (2019) Outcomes and challenges of an international convention center’s local procurement strategy. Tour Manage 75:328–339. https://doi.org/10.1016/j.tourman.2019.05.004

Garai A., Biswajit S., (2022) Economically independent reverse logistics of customer-centric closed-loop supply chain for herbal medicines and biofuel. Journal of Cleaner Production, 334 :129977. https://doi.org/10.1016/j.jclepro.2021.129977

Shekarian M, Parast MM (2021) An Integrative approach to supply chain disruption risk and resilience management: a literature review. Int J Logist 24(5):427–455. https://doi.org/10.1080/13675567.2020.1763935

Lahri V., Shaw K., Ishizaka A. (2021) Sustainable Supply chain network design problem: using the integrated BWM, TOPSIS, possibilistic programming, and e-constrained methods. Expert Systems with Applications, 168 (15) :114373. https://doi.org/10.1016/j.eswa.2020.114373

Ivanov D, Dolgui A (2019) Low-Certainty-Need (LCN) supply chains: a new perspective in managing disruption risks and resilience. Int J Prod Res 57(15–16):5119–5136. https://doi.org/10.1080/00207543.2018.1521025

Ding Y., Jiang Y., Wu, L., et al. (2021) Two-echelon supply chain network design with trade credit. Computers & Operations Research, 131 :105270. https://doi.org/10.1016/j.cor.2021.105270

Dolgui A, Ivanov D, Sokolov B (2020) Reconfigurable supply chain: the X-network. Int J Prod Res 58(13):4138–4163. https://doi.org/10.1080/00207543.2020.1774679

Yuhong L, Kedong C, Collignon S et al (2021) Ripple effect in the supply chain network: forward and backward disruption propagation, network health and firm vulnerability. Eur J Oper Res 291(3):1117–1131. https://doi.org/10.1016/j.ejor.2020.09.053

Shrivastva H, Dutta P, Krishnamoorthy M et al (2018) Facility Location and Distribution Planning in a Disrupted Supply Chain. Operations Research and Optimization 225:269–284. https://doi.org/10.1007/978-981-10-7814-9_19

Sneock A, Udenio M, Fransoo JC (2019) A stochastic program to evaluate disruption mitigation investments in the supply chain. European Journal Operation Research 274(2):516–530. https://doi.org/10.1016/j.ejor.2018.10.005

Zhao K, Scheibe K, Blackhurst J et al (2019) Supply Chain Network Robustness Against Disruptions: Topological Analysis, Measurement, and Optimization. IEEE Trans Eng Manage 66(1):127–139. https://doi.org/10.1109/TEM.2018.2808331

Zhao K, Scheibe K, Blackhurst J et al (2019) Modelling supply chain adaptation for disruptions: An empirically grounded complex adaptive systems approach. J Oper Manag 65(2):190–212. https://doi.org/10.1002/joom.1009

Nezhadroshan A. M., Fathollahi-Fard A. M., Hajiaghaei-keshteli M. (2021) A scenario-based possibilistic-stochastic programming approach to address resilient humanitarian logistics considering travel time and resilience levels of facilities.International Journal of Systems Science: Operations & Logistics, 8 (4) :321–347. https://doi.org/10.1080/23302674.2020.1769766)

Arani M, Chan Y, Liu X et al (2021) A lateral resupply blood supply chain network design under uncertainties. Appl Math Model 93:165–187. https://doi.org/10.1016/j.apm.2020.12.010

Trochu J., Chaabane A., Ouhimmou M. (2020) Carbon-constrained stochastic model for eco-efficient reverse logistics network design under environmental regulations in the CRD industry. Journal of Cleaner Production, 245(1) :118818. https://doi.org/10.1016/j.jclepro.2019.118818

Sephr A., Saboury A., Jabalameli M. S. (2020) Reliable supply chain network design for 3PL providers using consolidation hubs under disruption risks considering product perishability: An application to a pharmaceutical distribution network. Computers & Industrial Engineering, 152 :107019. https://doi.org/10.1016/j.cie.2020.107019

Lu Z, Lufei H, Wencheng W (2019) Green and sustainable closed-loop supply chain network design under uncertainty. J Clean Prod 227:1195–1209. https://doi.org/10.1016/j.jclepro.2019.04.098

Fattahi M (2020) A data-driven approach for supply chain network design under uncertainty with consideration of social concerns. Ann Oper Res 288(1):265–284. https://doi.org/10.1007/s10479-020-03532-9

Ghaderi H, Moini A, Pishvaee MS (2018) A multi-objective robust possibilistic programming approach to sustainable switchgrass-based bioethanol supply chain network design. J Clean Prod 179(1):368–406. https://doi.org/10.1016/j.jclepro.2017.12.218

Ouhimmou M, Nourelfath M, Bouchard M, Bricha N (2019) Design of robust distribution network under demand uncertainty: A case study in the pulp and paper. Int J Prod Econ 218:96–105. https://doi.org/10.1016/j.ijpe.2019.04.026

Habib M. S., Asghar O., Hussain A., Imran M., et al. (2021). A robust possibilistic programming approach toward animal fat-based biodiesel supply chain network design under uncertain environment. Journal of Cleaner Production, 278 (1) :122403. https://doi.org/10.1016/j.jclepro.2020.122403

Tsao Y., Amir E. N. R., Thanh V., et al. (2021) Designing an eco-efficient supply chain network considering carbon trade and trade-credit: A robust fuzzy optimization approach. Computers & Industrial Engineering, 160 :107595. https://doi.org/10.1016/j.cie.2021.107595

Zahedi A, Salehi-Amiri A, Hajiaghaei-Keshteli M et al (2021) Designing a closed-loop supply chain network considering multi-task sales agencies and multi-mode transportation. Soft Comput 25(8):6203–6235. https://doi.org/10.1007/s00500-021-05607-6

Zahedi A., Salehi-Amiri A., Smith N. R., et al. (2021b) Utilizing IoT to design a relief supply chain network for the SARS-COV-2 pandemic. Applied Soft Computing, 104 :107210. https://doi.org/10.1016/j.asoc.2021.107210

Guo Y, Hu F, Allaoui H et al (2019) A distributed approximation approach for solving the sustainable supply chain network design problem. Int J Prod Res 57(11):3695–3718. https://doi.org/10.1080/00207543.2018.1556412

Guo Y., Yu J., Boulaksil Y., Allaoui H., et al. (2021) Solving the sustainable supply chain network design problem by the multi-neighborhoods descent traversal algorithm. Computers & Industrial Engineering, 154 :107098. https://doi.org/10.1016/j.cie.2021.107098

Hasani A, Mokhtari H (2019) An integrated relief network design model under uncertainty: A case of Iran. Saf Sci 111:22–36. https://doi.org/10.1016/j.ssci.2018.09.004

Tawhid MA, Ibrahim AM (2021) Solving nonlinear systems and unconstrained optimization problems by hybridizing whale optimization algorithm and flower pollination algorithm. Math Comput Simul 190:1342–1369. https://doi.org/10.1016/j.matcom.2021.07.010

Chakraborty S, Saha AK, Sharma S et al (2021) A hybrid whale optimization algorithm for global optimization. Mathematics 9(13):1477. https://doi.org/10.3390/math9131477

Zahiri B, Jula P, Tavakkoli-Moghaddam R (2018) Design of a pharmaceutical supply chain network under uncertainty considering perishability and substitutability of products. Inf Sci 423:257–283. https://doi.org/10.1016/j.ins.2017.09.046

Mirjalili S, Lewis A (2016) The Whale Optimization Algorithm. Adv Eng Softw 95:51–67. https://doi.org/10.1016/j.advengsoft.2016.01.008

Mirjalili S, Lewis A (2014) Grey Wolf Optimizer. Adv Eng Softw 69:46–61. https://doi.org/10.1016/j.advengsoft.2013.12.007

Xinming Z., Shaochen W. (2021) Hybrid whale optimization algorithm with gathering strategies for high-dimensional problems. Expert Systems with Applications, 179(1) :115032. https://doi.org/10.1016/j.eswa.2021.115032

Funding

The authors received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Contributions

Yao Wu designed the research protocol, wrote the first draft of the manuscript, and worked on the code. Weiwei Liu proposed the research selection, revised the paper several times, and worked on the experimental design. The two of them approved the final manuscript together.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been retracted. Please see the retraction notice for more detail: https://doi.org/10.1007/s42452-024-05955-6

Appendices

Appendix Range of values

Qfat, Qmatn1, Qmatn2, Qafit ~ U (2.5 × 104,3.4 × 105); Qiat, Qaimt ~ U (1.5 × 105,2 × 105); Qopt, Qpmot ~ U (1.2 × 105,1.6 × 105); Qpokt ~ U (1.8 × 105, 2.5 × 105); Qkpt, Qpkct ~ U (7 × 104,1 × 105); Qprot ~ U (1 × 105,3 × 105); Qrpt ~ U (1.5 × 105,2 × 105); Qairt, Qpmrt ~ U(1 × 104,2 × 104); Qhmrt ~ U (1.2 × 105,1.7 × 105); Qpcrt, Qrat ~ U(1 × 104,2 × 104); Qrht ~ U (3.6 × 105,5 × 105); Qmatnin ~ U (5 × 104,1.5 × 105); Qdist ~ U (0,3 × 105); Qksit ~ U (0,1 × 105).

\(Tr_{a}\): ~ U (3.2, 12.8), ~ U (12.8, 22.4), ~ U (22.4, 32); \(Tr_{h}\): ~ U (16, 24), ~ U (24, 32), ~ U (32, 40);

\(Tr_{p}\): ~ U (3.2, 15.2), ~ U (15.2, 27.2), ~ U (27.2,40);

\(\mu_{dist}\): ~ U (5 × 105, 6.5 × 105), ~ U (6.5 × 105, 8 × 105), ~ U (8 × 105, 1 × 106);

\(\mu_{matn1}\): ~ U (1 × 103, 2.5 × 103), ~ U (2.5 × 103, 4 × 103), ~ U (4 × 103, 6 × 103);

\(\mu_{matn2}\): ~ U (2 × 103, 3.5 × 103), ~ U (3.5 × 103, 5 × 103), ~ U (5 × 103, 324);

\(\mu_{ksit}\): ~ U (1 × 104, 2.5 × 104), ~ U (2.5 × 104, 4 × 104), ~ U (4 × 104, 5 × 104);\(dem_{pt}\): ~ U (7, 1 × 105), ~ U (1 × 105, 2 × 105), ~ U (2 × 105, 3 × 105).

\(Fix_{m}^{e}\): ~ U (9*105,1.5*106); \(Fix_{i}^{e}\),\(Fix_{k}^{e}\),\(Fix_{r}^{e}\),\(Fix_{o}^{e}\): ~ U (1*105,1.5*105); \(Fix_{f}^{e}\): ~ U (5*105,5*106)/t;

\(\mu_{iat}\): ~ U (100,200)/t; \(\mu_{kpt}\),\(\mu_{opt}\),\(\mu_{sakt}\): ~ U (200,500)/t; \(\mu_{rpt}\),\(\mu_{rht}\),\(\mu_{rat}\): ~ U (100,300)/t; \(T_{job}\): ~ U (0,10);

\(\varphi_{f}\),\(\varphi_{i}\),\(\varphi_{o}\),\(\varphi_{k}\),\(\varphi_{r}\): ~ U (1*105,2*105) t; \(\varphi_{fa}\),\(\varphi_{ia}\),\(\varphi_{ma}\),\(\varphi_{rh}\),\(\varphi_{kp}\),\(\varphi_{rp}\),\(\varphi_{op}\),\(\varphi_{car}\): ~ U (1.5,2) t; \(T_{an}\): ~ U (0,6);

\(Cap_{f}\),\(Cap_{m}\): ~ U (2.5*105,3.4*105) t; \(Cap_{i}\): ~ U (1.5*105,2*105) t; \(Cap_{k}\): ~ U (7*104,1*105) t;

\(Cap_{o}\): ~ U (1.8*105,2.4*105) t; \(Cap_{r}\): ~ U (1*105,3*105) t; \(SA_{pkt}\): ~ U (3*104,5*104) t;

\(\gamma\):0.5:0.1:1; \(\omega\),\(\rho\),\(\lambda\): 0.6:0.1:1; \(\varepsilon_{1}\),\(\varepsilon_{2}\): [0,1]; \(\varphi_{m}\): ~ U (1*105,2*105) t; \(\mu_{fat}\): ~ U(500,1000) /t;\(r_{if}\): ~ U(20,60) km; \(r_{mi}\),\(r_{om}\): ~ U(60,200) km; \(r_{ko}\),\(r_{rm}\),\(r_{ko}\),\(r_{rc}\),\(r_{kc}\),\(r_{ri}\),\(r_{kr}\): ~ U(100,300) km.

Table content explanation

-

(1)

For expresses the Forward Logistics

-

(2)

Re expresses the Reverse Logistics

-

(3)

CLSC expresses the closed-loop supply chain

-

(4)

S expresses the Single-objective model

-

(5)

Multiple expresses the Multi-objective model

-

(6)

C expresses the Cost

-

(7)

CO2 expresses the Carbon dioxide emissions

-

(8)

Em expresses the employment

-

(9)

Ro expresses the Robust

-

(10)

Fu expresses the Fuzzy

-

(11)

Math expresses the Mathematical method

-

(12)

Algo expresses the Algorithm

-

(13)

Agr expresses the agricultural

-

(14)

Ot expresses the Other product

-

(15)

ac expresses the active anti-risk operations

-

(16)

pa expresses the passive anti-risk operations

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, Y., Liu, W. RETRACTED ARTICLE: Sustainable and optimal design of Chinese herbal medicine supply chain network based on risk dynamic regulation mechanism. SN Appl. Sci. 5, 159 (2023). https://doi.org/10.1007/s42452-023-05367-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-023-05367-y