Abstract

Okara protein (OP) was extracted by alkali solution and acid-isolation method using bean dregs as raw materials. With OP as the main raw material, the mixed gelatin and modified starch as the gelling agent, xylitol as the sweetener, and buffered lactic acid as the sour agent, the elasticity, hardness, stickiness and chewiness of the texture analyzer were analyzed by the single-factor test and orthogonal test. Combined with sensory evaluation, the optimal formula for the preparation of OP gel gummies was comprehensively obtained as: the ratio of gelatin to modified starch was 9:1; the xylitol addition was 18 g; the addition of buffered lactic acid was 0.7mL, and the addition of OP solution was 16mL, respectively. The gel gummies prepared under this formula have the advantages of suitable sweetness and sourness, good taste, good stickiness and uniform color. It also has special physiological functions, such as immune regulation and antihypertensiveness.

Similar content being viewed by others

1 Introduction

Soybean dregs are a by-product produced when processing soybeans [1, 2], and the moisture content of okara produced by soybean is about 85%. Due to its high moisture content and perishability, it is not used properly. Soybean dregs are mostly used in livestock breeding, resulting in environmental pollution and waste of resources. Okara contains a lot of dietary fiber, protein, fat, isoflavones, niacin and rich nutrients [3,4,5,6]. Among them, okara protein is similar in amino acid composition to soybean protein isolate and is a high-quality protein. During the production of okara, heat treatment will inevitably occur, resulting in changes in the structure of okara protein with poor solubility [7]. Due to the low extraction rate of okara protein (OP) and the poor functional property, its application in food is limited. Till now, there are many methods for OP extraction, such as alkali-solution and acid-isolation, ultrasonic assistance, enzymatic treatment and membrane technology [8]. Alkali-solution and acid-isolation are widely used method for protein extraction due to their simplicity, rapidity, and low cost. Some studies have shown that the stability of plant cell walls is affected by strong alkaline pH, which favors the release and dissolution of proteins. In addition, different acid-solution processes can also affect the properties of OP to some extent. Different acid-isolation [9] or temperatur [10] will also affect the physical and chemical properties of OP. The principle of protein acid-isolation alkaline solution was used to extract OP, and the effects of different acid-isolation processes on the structure and functional properties of OP were explored.

In addition, there have been no reports on the preparation of gummies and other functional products from low fat OP. Taking the compound of gelatin and modified starch as a gelling agent, the sweetener xylitol and acidulating agent were added to buffer lactic acid. Then the gel gummies with rich high-quality protein and easy to be absorbed, hypoglycemic and lipid-lowering were developed through sol, boiling, sugar boiling and injection molding. This experiment focuses on the characterization of the sensory, hardness, elasticity, chewiness and stickiness of gel gummies. The results can provide a theoretical basis and technical support for the application of OP gel gummies, aiming to further develop and utilize Okara and broaden the market of gel gummies.

2 Materials and methods

2.1 Experimental materials

Okara powder, Dumas method was used to determine the protein content of 15.39 ± 0.02% (N × 6.25, dry basis), purchased from Shandong Xiangchi Grain and Oil Company for OP extraction. Pepsin and trypsin were purchased from Sigma Company in the United States. The gelatin was purchased in Guangzhou Xinzhiwei Food Ingredients Mall; the modified starch was purchased from Zhengzhou Yuhe Food Additive Co., Ltd; Xylitol was purchased from Haining Dayu Food Technology Co., Ltd, and the buffered lactic acid was purchased from Hubei Zhuangmei Biotechnology Co., Ltd. NaOH was purchased from Guangdong Guanghua Chemical Factory Co. LTD. HCl and H3PO4 were purchased from Lianjiang Ailian Chemical Reagent Co., LTD. All other chemicals were analytical grade.

2.2 Study design

2.2.1 Preparation of OP freeze-dried powder

After a slight modification, the distilled water was added according to the liquid ratio of 1:20, and the pH value of the aqueous solution of okara was adjusted to 12.0 with 1 mol/L NaOH solution. The solution was fully stirred at room temperature for 30 min, and then cooled for standby. Then it was centrifuged at 6000 rpm for 10 min (himac CR 22 G High-Speed Refrigerated Centrifuge, HITACHI, Japan) to take the supernatant. After that, the pH value of the supernatant was adjusted to 4.5 with HCl, CA and H3PO4 respectively. 7000×g (himac CR 22 G High-Speed Refrigerated Centrifuge, HITACHI, Japan) at 25 °C was centrifuged for 10 min, and repeated the wash for precipitation before standby [11]. A certain amount of wet protein precipitation was weighted and re-dispersed in a certain proportion in distilled water, then stirred slowly for dissolution. Protein solution was prepared by adjusting pH 7.5 with 1 mol/L NaOH solution, and part of the solution was lyophilized and recorded as OP (HCl), OP (CA), OP (H3PO4) for standby.

2.2.2 Preparation of OP gel gummies

OP precipitated with hydrochloric acid was selected to prepare gel gummies. The preparation points of OP gel gummies are as follows:

Sol: A certain amount of gelatin was precisely weighed into a 50mL beaker and twice its mass was added to the protein aqueous extracting solution. After fully swelling at room temperature, it was further fully dissolved in a constant temperature water bath at 60 °C to form a sol for standby [11].

Sugar dissolving: A certain amount of modified starch and xylitol was precisely weighed into a 100mL beaker to add a certain amount of water/protein water extraction. It was then heated and boiled on an electric stove and stirred constantly with a glass rod until it became a transparent paste to stop heating. Then it was cooled to 70 °C and kept warm in a thermostatic water bath for later use [11].

Acid regulation and mixing: The fully swelled gelatin was injected into the modified starch solution and stirred evenly. The gelatin solution was then injected, and a certain amount of buffered lactic acid solution was added to stir well. After that, it was placed in a 70 °C thermostatic water bath to eliminate bubbles during mixing [11].

Injection mold and demolding: The syrup mixture was poured into a dry and clean mold while it was hot, and the obtained gel gummies were naturally dried at room temperature for 24 h with a turn over once, demolded after molding [11].

2.2.3 Single-factor test design

Through previous preliminary experiments, the ratio of gelatin to modified starch, the xylitol addition, the addition of buffered lactic acid, and the addition of OP solution were determined as four main influencing factors, each of which was set at five levels. The ratio of gelatin to modified starch was set as 6:1, 7:1, 8:1, 9:1 and 10:1 respectively; the xylitol addition was 15 g, 16 g, 17 g, 18 and 19 g respectively; the addition of buffered lactic acid was 0.5mL, 0.6mL, 0.7mL, 0.8mL and 0.9mL respectively; the addition of OP solution was 0mL, 4mL, 8mL, 12mL and 16mL respectively (Prepare 4% protein solution (4.0%, w/v), and add according to the above volume ratio and 16mL in total, and then make up the deficient part of protein solution with distilled water). Combined with sensory evaluation and texture analysis, the influence of different factors and different levels on the quality of gummies was explored to select the optimal level of each factor. The optimal level of each factor and its left and right levels were selected for orthogonal test.

2.2.4 Orthogonal experimental design

According to the results of single-factor experiment, taking the ratio of gelatin to modified starch, the xylitol addition, the addition of buffered lactic acid, and the addition of OP solution as the main influencing factors, three levels of orthogonal experiments were selected for each factor. The L9 (34) orthogonal table was designed for the orthogonal optimization experiment. Then, through sensory evaluation and texture analysis, the optimal processing conditions were determined and the optimal gel gummies formula was obtained. The factors and level design of orthogonal experiment are shown in Table 1.

2.3 Determination of product quality

2.3.1 Sensory evaluation of gummies

This experiment was evaluated by sensory description. Prior to evaluation, relevant training should be conducted to provide basic techniques and methods for sensory analysis as well as basic knowledge of related products. In this way, improve their ability to detect, identify and describe sensory stimuli can be improved, and the resulting evaluators can act as special “analytical instruments” to produce reliable assessment results. The evaluators were selected by testing sensory function, sensory sensitivity and descriptive ability. A sensory assessment panel, consisting of 10 food-related professionals, scored the taste, color, organization, and appearance transparency of the gel gummies according to the scoring Tables [11, 12], as shown in Table 2.

2.3.2 Texture analysis of the gummies

In this test, the hardness, elasticity, chewiness and stickiness of the gummies were determined using the TMS-PRO food texture analyzer. The determination conditions are as follows: a universal cylindrical probe with a probe diameter of 25.4 mm and a length of 35.0 mm; Mode: TPA; Determination speed: 60 mm/min; Probe residence time: 1s; Compression degree: 60%; The height of probe rise to sample surface: 10 mm; Starting force: 0.05 N. Then the gummy was cut into small square shapes, and each group of glue was determined in parallel 3 times [11, 12].

2.4 Data processing

At least three independent experiments were conducted in this experiment. SPSS19.0 was used for analysis of variance (ANOVA), and Duncan multiple comparison was used for significance analysis (p < 0.05). The single-factor mean value, standard deviation and orthogonal experimental data are processed by Excel2016, and Origin2018 plots the data.

3 Results and discussions

3.1 Recovery and purity of OP

OP was extracted from an aqueous solution at pH 12.0, and the OP in the alkali extraction solution was recovered by HCl, CA and H3PO4, respectively. It can be seen from Table 3 that there is no significant difference in the recovery of OP by different acid-isolation, which is about 70%. The purity of OP varied with the acid-isolation. Among them, OP (CA) has the highest purity, which is probably because citric acid is a strong ternary organic acid that continuously ionizes H + during acid-isolation process for better protein precipitation. The purity of OP (HCl) is higher than that of OP (H3PO4), which probably because HCl is more acidic than H3PO4 and precipitates more protein.

3.2 Single-factor analysis of gummy preparation

3.2.1 Effect of the ratio of gelatin to modified starch on the quality of gel gummies

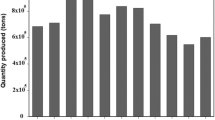

Single gelatin does not have a good taste, so that a certain amount of modified starch is added to the colloid with a compound gel agent. The compound colloid of gelatin and modified starch is a new type of gel gummies, and the gummies made by it have good chewiness and taste. As shown in Fig. 1, different proportions of gelatin and modified starch have little effect on the elasticity of gummies, while the hardness, stickiness and chewiness increase with the increase of gelatin. When the ratio of gelatin to modified starch was 6:1, the hardness of gummies was low. Demolding was slightly difficult, with the worst texture characteristics and sensory scores. When the ratio of gelatin to modified starch was 10:1, the high chewiness of gummies, too high hardness and heavy gelatin taste made the score decline. When the ratio of gelatin to modified starch was 8:1, the gummies had moderate hardness, best taste and high transparency, and the sensory score was the best. Based on texture analysis and sensory score, the ratio of gelatin to modified starch at 7:1, 8:1 and 9:1 was selected for orthogonal experiment [13, 14].

3.2.2 Effect of buffered lactic acid dosage on the quality of gel gummies

As shown in Fig. 2, as the buffered lactic acid increases, the hardness and stickiness of the gummies decrease, and the chewiness and sensory scores first increase and then decrease. Choosing buffered lactic acid as an acidulant can improve the taste. Compared with other acidulants, the buffered lactic acid has minimal damage to the colloid compared, and its flavor is soft. When the dosage of buffered lactic acid was 0.5ml, the chewiness of gel gummies was high, but the sour taste was light and the taste was general. When the dosage of buffered lactic acid was 0.6 mL, the gummies had moderate acidity and sweetness optimal shapes, and the highest chewiness and sensory scores. When the dosage of buffered lactic acid was higher than 0.6 mL, the gummies was slightly acidic with poor shapes. Demolding is slightly more difficult, and chewiness and sensory scores are declining. Based on texture characteristics and sensory score analysis, the optimal amount of buffered lactic acid was 0.6 mL, and 0.5 mL, 0.6 mL and 0.7 mL were selected for orthogonal testing.

3.2.3 Effect of xylitol addition on the quality of gel gummies

As shown in Fig. 3, as the xylitol addition increases, the hardness and chewiness of the gummies increase. The sensory score first increases and then decreases, and there was no significant change in elasticity. As a sweetener, xylitol has the effect of lowering blood sugar and preventing dental caries, and has been widely used in food industry. When the xylitol addition was 18 g, the gummies has the highest sensory score, high chewiness, moderate acidity and sweetness, appropriate softness and hardness, and the best taste. When the xylitol addition was less than 18 g, the acid sweetness of gummies was l mild or acidic; when it was more than 18 g, the gummies were sweet with high hardness. In this way, 18 g of xylitol was the optimal amount, and 17 g, 18 and 19 g were selected for orthogonal experiment [15].

3.2.4 Effect of OP solution addition on the quality of gel gummies

It can be seen from Fig. 4 that the sensory score, firmness, elasticity, viscosity and chewiness of gummies have a significant effect under the fixed conditions of other factors. The essential amino acid composition and content of OP and soy protein isolate are basically the same, which is mainly composed of albumin and globulin. Similar to the eight amino acids content of meat, it is easy to absorb and is a high-quality protein. To this end, the more protein in gummies, the better, regardless of the cost. 0mL and 4 mL are not considered. When the dosage of OP solution was 12mL and 16mL, the taste was better than others, with the highest chewiness and sensory scores. Considering the cost, the optimal dosage of OP solution was 12mL. 8mL, 12mL and 16mL were selected for orthogonal experiment.

3.3 Results and analysis of orthogonal experiment

The ratio of gelatin to modified starch, the dosage of buffered lactic acid, the addition of xylitol and the dosage of OP solution were the four influencing factors. According to the sensory score and texture analysis of single-factor, three better levels were selected to optimize the formula of gel fudge by L9(34) orthogonal test [16, 17]. As shown in Tables 4 and 5, the elasticity of the gummies obtained by orthogonal experiment has little change. Based on the conditions that gel gummies needs low hardness, high stickiness and high chewiness, the results show that Group 9 scored the highest because of its high transparency, moderate acidity and sweetness and best taste. Group 1 has the lowest score for difficult demolding, softness, low transparency, and poor body compaction. It can be seen from Table 5 that different schemes with better indicators are different. When the hardness is used as an index, the ratio of gelatin to modified starch, the dosage of OP solution, the dosage of buffered lactic acid, and the xylitol addition are the main and secondary factors. The optimal scheme is A3D3B1C2. When the elasticity is used as an index, the ratio of gelatin to modified starch, the addition of xylitol, the dosage of OP solution, and the dosage of buffered lactic acid are the primary and secondary factors. The better scheme is A1C2D2B2. When the stickiness is used as an index, t the ratio of gelatin to modified starch, the dosage of OP solution, the dosage of buffered lactic acid, and the addition of xylitol are the primary and secondary factors. The optimal scheme is A3D2B1C2. When the chewiness is used as an index, the ratio of gelatin to modified starch, the dosage of OP solution, the addition of xylitol, and the dosage of buffered lactic acid are the primary and secondary factors. The optimal scheme is A3D2C2B1. When the sensory score is used as an index, the ratio of gelatin to modified starch, the dosage of buffered lactic acid, the dosage of OP solution, and the xylitol addition are the primary and secondary factors. The optimal scheme is A3B3D3C2.

Through the orthogonal experiment, a better scheme was obtained from the hardness, elasticity, gumminess, chewiness and sensory score of the gummies, and the elasticity was not considered due to little change. Based on the conditions of low hardness, high stickiness and high chewiness, the optimal solution was finally selected as A3B3D3C2. That is, the ratio of gelatin to modified starch was 9:1; the dosage of buffered lactic acid was 0.7mL, the dosage of OP solution was 16mL, and the addition of xylitol was 18 g [18,19,20].

4 Conclusion

In this experiment, using okara as raw material, OP was extracted by alkali-solution and acid-isolation. The effects of different acid-isolation on the structure and functional properties of OP and the application of gel gummies were explored. It was concluded that the use of different acid-isolation had little effect on the recovery rate of OP, and the recovery rate could be roughly stable at about 70%. Since citric acid is a ternary organic acid, it continuously ionizes H + during acid-isolation, and OP (CA) has the highest purity. OP was more hydrophobic than SPI, and its solubility was much lower than SPI. The solubility of the three OPs was OP (H3PO4) > OP (CA) > OP (HCl) (pH 7.0).

The best solution to prepare gel gum with okara protein (OP (HCl)) as the main raw material is: the mass ratio of gelatin to modified starch is 9:1, the amount of buffered lactic acid is 0.7ml; the amount of xylitol is 18 g, and the dosage of OP solution is 16ml. Under this formula, a kind of gel gummies was prepared, which has uniform denseness, suitable acidity and sweetness, moderate softness and hardness, high transparency, good elasticity, non-stickiness, lipid-lowering function and a certain amount of high-quality protein. This experiment aims to develop the gel gummies prepared from the extracted protein as raw materials to maximize their residual nutritional value and enrich the market of gel gummies as a food product.

References

Li B, Qiao M, Lu F (2012) Composition, nutrition, and utilization of okara (soybean residue). Food Rev Int 28(3):231–252. https://doi.org/10.1080/87559129.2011.595023

Vong WC, Liu SQ (2016) Biovalorisation of okara (soybean residue) for food and nutrition. Trends Food Sci Technol 52:139–147. https://doi.org/10.1016/j.tifs.2016.04.011

Tang XM, Lu JW, Zeng YH (2021) Effect of protein removal methods and superfine grinding on the chemical composition and functional properties of dietary fiber prepared from okara. J Chin Cereals Oils Assoc 36(1):74–79

Shen XM, Luo ZJ, Hou JJ, Xie CY, Wang JM, Chen WH (2022) Effects of enzyme-assisted cavitation on structural and physicochemical properties of okara fibers. Mod Food Sci Technol 38(9):285–291. https://doi.org/10.13982/j.mfst.1673-9078.2022.9.1260

Voss GB, Rodríguez-Alcalá LM, Valente LMP, Pintado MM (2018) Impact of different thermal treatments and storage conditions on the stability of soybean byproduct (okara). J Food Meas Charact 12:1981–1996. https://doi.org/10.1007/s11694-018-9813-5

Luo ZJ, Shen XM, Jiang YQ, Yang J, Wang JM (2021) Preparation and characterization of Okara protein-phytosterol nanoparticles. Mod Food Sci Technol 37(10):112–117. https://doi.org/10.13982/j.mfst.1673-9078.2021.10.0228

Hadidi M, Khaksar FB, Pagan J, Ibarz A (2020) Application of Ultrasound-Ultrafiltration-Assisted alkaline isoelectric precipitation (UUAAIP) technique for producing alfalfa protein isolate for human consumption: optimization, comparison, physicochemical, and functional properties. Food Res Int 130:108907. https://doi.org/10.1016/j.foodres.2019.108907

Eze OF, Chatzifragkou A, Charalampopoulos D (2022) Properties of protein isolates extracted by ultrasonication from soybean residue (okara). Food Chem 368:130837. https://doi.org/10.1016/j.foodchem.2021.130837

Tao X, Cai Y, Liu T, Long Z, Huang L, Deng X, Zhao Q, Zhao M (2019) Effects of pretreatments on the structure and functional properties of okara protein. Food Hydrocolloids 90:394–402. https://doi.org/10.1016/j.foodhyd.2018.12.028

Wu CL, Tian T, Wang DM, Li B, Chen L, Wang ZJ, Li Y, Jiang LZ, Fan ZJ (2018) Effects of superfine comminution of low temperature on the structural and functional properties of soy dregs protein. Sci Technol Food Ind 39(23):50–55. https://doi.org/10.13386/j.issn1002-0306.2018.23.009

Yang J, Dai JN, Liang CT, Li YL (2021) Optimization of preparation technology of Eucommia ulmoides gel soft sweets. Sci Technol Food Ind 42(3):147–152. https://doi.org/10.13386/j.issn1002-0306.2020030002

Fu XM (2019) Texture analyzer analysis and sensory evaluation on gelatin gummy. Food Nutri China 25(5):33–36

Du MC, Liu SY, Zhang YX, Zhang W, Su EZ (2019) Development of fructus ginkgo and mulberry jelly. Farm Prod Process 20:17–18. https://doi.org/10.16693/j.cnki.1671-9646(X).2019.10.040

Za XYZ, Ma MH, Xiao H, Liu SJ (2018) Study on processing technology of celery jelly candy. Cereal Oils 31(12):76–80. https://doi.org/10.3969/j.issn.1008-9578.2018.12.021

Gao HY, Wang Q, Lai CN, Jiang F (2021) Optimized formulation of a chewable candy containing loquat flower tea. Fujian J Agric Sci 36(8):964–971. https://doi.org/10.19303/j.issn.1008-0384.2021.08.014

Yang J, Li CL, Luo YQ, Li YL (2020) Preparation of paederia scandens gel soft candy and its process optimization. Food Eng 3:26–31. https://doi.org/10.3969/j.issn.1673-6044.2020.03.008

Tian QY (2018) Study on process optimization of soft candy with hericium and agar. Sci Technol Food Ind 39(10):228–230. https://doi.org/10.13386/j.issn1002-0306.2018.10.041

Zhang WX, Wu SL, Song CL (2021) Development of sweet potato lotus seed compound health care soft sweets. Farm Prod Process 16:42–46. https://doi.org/10.16693/j.cnki.1671-9646(X).2021.08.045

Liu F, Chen J, Liu CM, Luo SJ, Ling HS, Liu JY, Wan J (2020) Formulation optimization and its texture properties of the choerospondias axillaris soft candy with high dietary fibre. Sci Technol Food Ind 41(8):117–123. https://doi.org/10.13386/j.issn1002-0306.2020.08.019

Guo JL, Dou KN, Wang F, Wang DY (2022) Application progress of soybean dregs in food. Cereal Oils 35(2):15–17

Acknowledgements

The authors gratefully acknowledge Dr. Jinmei Wang for experimental assistance. The research work was funded by Guangdong Basic and Applied Basic Research Foundation (No. 2020A1515010852 and No. 2023A1515012184), Scientific Research Capacity Improvement Project of the Key Construction Discipline of Guangdong Province (No. 2022ZDJS079) and Lingnan Normal University scientific research project (No. LY2211), Innovation and Entrepreneurship Training Program for College Students (202210579010X and S202210579006) and 2022 Special Fund for Science and Technology Innovation of Guangdong Province (Special Fund for Climbing Plan, No. pdjh2022b0318).

Funding

Guangdong Basic and Applied Basic Research FoundationNo. 2020A1515010852 and No. 2023A1515012184Scientific Research Capacity Improvement Project of the Key Construction Discipline of Guangdong Province2022ZDJS079Lingnan Normal University scientific research projectLY2211, Innovation and Entrepreneurship Training Program for College Students (202210579010X and S202210579006) and 2022 Special Fund for Science and Technology Innovation of Guangdong Province (Special Fund for Climbing Plan, No. pdjh2022b0318).

Author information

Authors and Affiliations

Contributions

ZL and WF: Designed and performed the experiments, work. JY and ZL: participated to collect the materials related to the experiment. JY and BJ: Designed the experiments and revised the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests. The corresponding author affirms that all of the authors have read and approved the manuscript.

Ethical approval

The authors declare their responsibility for any ethical issues that may arise after the publication of this manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, Z., Yang, J., Fan, W. et al. Preparation and quality of okara protein gel gummies. SN Appl. Sci. 5, 139 (2023). https://doi.org/10.1007/s42452-023-05355-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-023-05355-2