Abstract

The need for better quality gluten-free (GF) bread is constantly growing. This can be ascribed to the rising incidence of celiac disease or other gluten-associated allergies and the widespread incorrect public belief, that GF diet is healthier. Although there is a remarkable scientific interest shown to this topic, among the numerous studies only a few deals with commercially available products. The gap between research and commercial reality is already identified and communicated from a nutritional point of view, but up to date texture studies of commercial GF breads are underrepresented. In this study, 9 commercially available GF bread were compared to their wheat-based counterparts from texture and sensory viewpoints. Results showed that among GF loaves products, some performed significantly better at hardness and springiness attributes during the 4-day-long storage test compared to the wheat-based products. Two of GF cob breads performed significantly better or on the same level as the wheat-based cob regarding to hardness and cohesiveness during 3 days. Among sensorial properties mouth-feel, softness and smell were evaluated as significantly better or similarly for some GF versus wheat-based products. Two GF bread had more salty taste which reduced the flavor experience. Both the texture and sensory data of the storage test indicate that the quality of some GF bread products has significantly improved in the recent years; they stayed comparable with their wheat-based counterparts even for a 4-day-long storage period.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

However, Celiac disease (CD) was already mentioned by Aretaeus of Cappadocia probably in the second century (AD) [1], it became an emphasized scientific and commercially important topic in the last decades. The consumption of gluten-free (GF) products is significantly increasing, just as the demand for good-quality GF products [2]. The underlying reason for the expanded interest can be attributed to better diagnostical methods of CD, wheat allergy, non-celiac gluten sensitivity and dermatitis herpetiformis [3, 4], and to the widespread incorrect public belief that GFD is healthier [5].

Gluten—as a term used to encompass prolamin proteins—can be found in wheat, barley and rye, including all their subtypes and genus [6]. It is the key structure-forming protein, which is the most common and important protein ingredient in the bakery industry. Absence of gluten in the GF formulation ends up with much weaker gas-holding properties; therefore, it causes low loaf volume [7], crumbling texture, poor color [8], choky dry mouth-feel and shorter shelf life [9,10,11].

Consumer survey studies revealed that the consumers are satisfied with the quality of GF sweets, biscuits and pasta, but still significant improvement is needed in GF bread and cakes to meet the consumers’ expectations [12,13,14]. The constantly growing number of published articles shows that several approaches were studied mostly using different modified starches, pseudocereals, enzymes, protein supplementation and/or hydrocolloids to improve the quality and nutritional properties of GF flours and breads [6, 15]. Among these numerous studies, only a few deals with commercially available products, the majority rather focuses on self-made prototypes from different raw materials. The publications that are based on commercial products concentrate on composition, nutrition values and/or prices. Based on their detailed and thorough study by examining 228 commercial products Roman et al. [12] declared a gap between commercial reality and research. Studying the ingredient list of breads they noticed that the commercial breads do not seek to use one single starch or gluten replacer, but a combination of several ingredients to optimize bread quality (hydrocolloids, acidifiers, emulsifiers, leavening agents, preservatives, and aromas or flavorings). They observed that some ingredients which have momentous attention and focus in the scientific world (e.g., pseudocereals) are hardly used in commercial products. On the UK market, GF products are 159% more expensive than their regular version, most GF bread and flour products contain higher amount of salt, fat and sugar, while some GF products are lower in fiber and protein content [16]. Similar differences were found on the Italian market [17, 18]. Spanish market sample study revealed that sodium, fat and cholesterol content were significantly higher in 20 commercial GF bread samples due to having egg, different oils like coconut, olive, sunflower, palm [19]. Although it is true that dietary fiber and sugar levels are more adequate than in the past, the GF diet might lead to CD patients’ inadequate intake of fats, proteins, sodium and vitamins [20].

In general, it can be declared that GF products are significantly more expensive compared to their wheat-based counterparts, and their on-shelf availability can be limited [21,22,23].

The studies mentioned above, give important and valuable information for the scientific community and draw attention to the gap between research and commercial reality. Despite the fact that this gap is already identified and communicated from a nutritional point of view and regarding ingredients, up to date rheological studies are hardly available dealing with commercial GF breads (Table 1).

Considering the rapid and constant development and changes in the GF bakery industry (ingredients, technologies, consumer needs), more and more GF bakeries are appearing on the market and selling freshly baked, preservative-free bread products. These products are based on different ingredients and recipes, but trying to be comparable with the gluten containing products in terms of lookalike, size, taste and shelf life. Therefore, it would be essential to continuously examine the textural and sensory properties of the GF freshly baked and sold bread products available on the different local markets. Following this approach, the current study aims to compare these GF commercially available, preservative-free bread products with their gluten containing wheat flour-based counterparts, focusing on their texture and sensory properties.

Materials and methods

Bread samples

The studied 9 different GF commercial bread samples were purchased from different specialized GF bakeries, while the wheat-based products from a supermarket. All the samples were selected with the aim to compare them regarding the product’s name, appearance and packaging. Special attention was taken to ensure that the products did not contain preservatives and gas or modified atmosphere in the packaging. In this study, three types of bread were selected: cob (artisan, round shaped bread), white and wholegrain loaf (baked in loaf tin). From each bread type, GF and wheat-based products were selected and compared (Table 2).

All the samples considered in this study were sliced and ready to eat, without prior heating requirement. Ingredients and nutrition values of the samples which were noted on the product’s packaging are presented in Table 3.

Texture measurement

Texture profile analysis (TPA) was performed at room temperature using Stable Micro Systems TA.XT2. Samples were taken and measured from the first, middle and last third of the sliced bread products, doing 7 different measurements on different slices of the same bread sample. The measurement was placed on the middle of the bread slices, avoiding region near to the crust. Each bread slice had 12 mm thickness. The applied settings were 35 mm diametric acryl cylindrical probe, 50% strain, 5 mm/sec crosshead speed and 5 s of waiting time between the two measurements. Firmness, cohesiveness and springiness were the main representative parameters of the sample texture. Results obtained from the GF and wheat bread samples were compared and followed up.

Sensory evaluation

During the sensory evaluation group of 15 people (13 females and 2 males, aged between 22 and 47 years) tested the bread samples. The ethical statement for the study was applied from the Hungarian University of Agriculture and Life Sciences and informed consent was obtained from each subject prior to their participation in the study. Subjects confirmed not having any known gluten, rye, milk protein, egg or lactose consumption-related disorder. All participants were recognized as regular bread consumers, consuming bread at least once per day.

The assessors received 1 full slice of the sample without any spreading, and were asked to appraise the intensity of 17 sensory attributes, which were described as relevant ones for GF bread by Pagliarini et al. [34] to cover appearance, color, taste and texture. For evaluation purpose a continuous, unstructured 10 cm long line scale with extremes at the ends (absolutely not intense and immensely intense) was used for every attribute. Samples were served with 3-digit codes on white plastic plates under white light at room temperature.

Data analysis

Received data were analyzed with IBM SPSS Statistics 25.0.2.2 software. Significant difference between the measured groups was determined by one-way analysis of variance (ANOVA) with 95% confidence level. Tukey HSD test was used after normality and standard deviation homogeneity test. Linear discriminant analysis (LDA) was performed to examine the separability of each bread type. Sensorial test data were analyzed by ANOVA. When there is significant difference, Tukey test was applied using a level of 5% of significance.

Results and discussion

Nutritional values of the bread samples

In line with the previously published data, the examined GF bread samples contained different starches, hydrocolloids, fibers and protein supplements all at the same time. The type of starches (corn, tapioca, potato, and rice) and hydrocolloids (HPMC, guar gum, xanthan gum) were the most commonly used ones among various GF breads on different markets [12, 17]. The fiber and salt content of C1, WL1 and WG1 samples were higher while the protein content was lower than in their wheat-based counterparts. Lower protein level was also detected for GF breads previously [12], but in this case of C1, WL1, WG1 samples according to the statement on the manufacturer’s website keeping the protein level low was a conscious decision, so their products can be used for people diagnosed with phenylketonuria (PKU) as well. People with PKU have to follow a low protein and phenylalanine containing diet [35]; therefore, these products are suitable not just for celiac people. Following gluten-free option as dietary practice is known and should be followed [36]. The energy and carbohydrate values were similar between the GF and wheat-based samples expect for WL2, which had the lowest level of energy and carbohydrate level among all the samples.

Texture profile changes

Results of the TPA measurements during the shelf-life test are presented in Table 4. Overall, it can be seen that C2 sample had significantly (p < 0.05) higher hardness but lower cohesiveness during the whole study. C1 was significantly softer on day 1, but not different from CW on the following days. C3 showed non-significant difference in hardness from CW during the whole study. Among the GF white loaf samples compared to WLW, WL1 was significantly lower in hardness except on day 3, while WL2 was also significantly softer versus WLW except for day 2. WL3 after day 1 was not significantly different from WLW. In case of whole grain loaves, on day 1 all the GF samples were significantly softer than WGW. On the following days, there were no significant difference detected among them, except for day 3, when WG1 was significantly softer versus WGW.

High cohesiveness leads to no disintegration during mastication, in case of low cohesiveness the bread crumbles [37]. Crumbling texture of GF bread during storage test was reported in the last decades, raising awareness as a general quality issue of these products [38]. Moore et al. [25] experienced decrease in cohesiveness (p < 0.01) in GF bread samples after a two-day storage. In this study, all the GF white loaf samples had significantly higher cohesiveness during the storage test versus the wheat-based white loaf sample. In case of whole grain samples, WG1 was not significantly different in cohesiveness from WGW. WG2 and WG3 samples showed significantly higher values compared to WGW until day 4, when only WG2 was different. Among cob samples C2 and C3 were significantly different from CW, and in general C2 was different from the other cob samples during the whole study.

In bread, springiness is associated with freshness, and products with low values are linked with crumb brittleness [27]; therefore, having high springiness values during the shelf life is desired. In this study WL2 sample showed significantly (p < 0.05) lower springiness during the 4-day-long storage test compared to all other bread samples. Despite the level of springiness grew day by day, but on the 4th day, it could barely reach 80%, still being more rigid. During the storage test, WL3 had significantly higher springiness values versus WLW sample, while WL1 was significantly better or comparable with WLW. Among the whole grain samples, WG2 showed higher springiness values every day compared to WGW, while WG1 and WG3 were better or comparable with WGW. Within the cob samples only on day 1 C1 showed significantly lower springiness value, but on the other days all the GF cob samples were comparable with the wheat-based cob.

Resilience characterizes the beginning of a sample’s elasticity and calculated from the ratio of the area under curve of the second half of the first cycle to the first half of the cycle. Reduction in springiness and resilience reflects alteration of the crumb elasticity [39]. The GF white loaves and the GF whole grain samples showed higher (p < 0.05) resilience values compared to their wheat-based counterparts. This is in line with the springiness values, where the GF samples had higher or comparable values. In case of the cob samples, C3 always had higher (p < 0.05) values than CW, C1 on days 1 and 4, while C2 was all the way consentaneous with CW.

According to the results, C1, C3, WL1, WL3, WG1, WG2 and WG3 bread samples in general can be described as soft and spongy [33] as they had comparable or lower hardness, higher springiness and resilience values than their wheat-based counterparts. From cohesiveness point of view the mentioned samples performed better or comparable to their wheat-based counterparts.

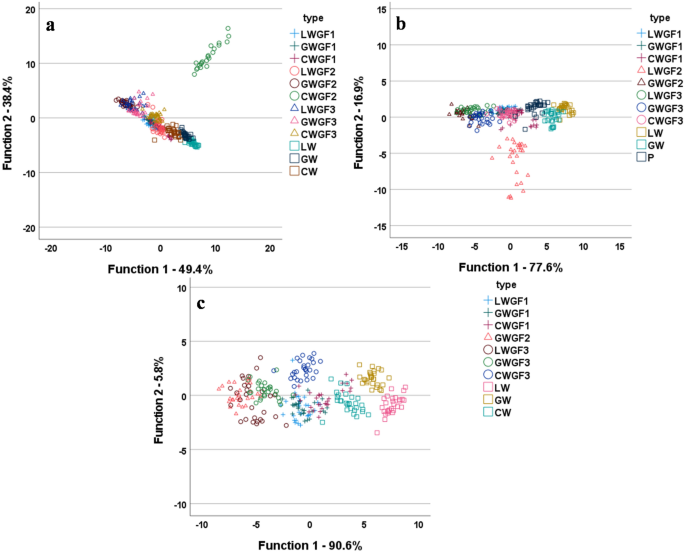

LDA results (Fig. 1) showed that WLW and WGW samples were classified as different groups from the others during the whole storage test. The significant difference in cohesiveness and resilience for both group, the springiness of WLW and the hardness of WGW attributes led together to show these samples as different product groups from the others.

Due to its hardness results C2 was also classified as a separate group (Fig. 1a), and WL2 because of its springiness and resilience attribute (Fig. 1b). LDA result without these two groups (Fig. 1c) showed an overlap between C1 and CW samples (79.3% of cross-validated grouped cases were correctly classified). This result clearly showed that the quality and texture profile attribute changes of C1 during a 4-day-long storage test were as good as the highest quality wheat-based product’s considered to be artisan.

Sensory evaluation

Mean ratings (given in cm) for the 17 sensory descriptors of the 12 bread samples are presented in Table 5. Less homogeneous crumb porosity for GF bread samples were previously reported [40, 41], which was linked to high starch and low protein content, impacting the dough interfacial properties and rheological attributes. Pagliarini et al. [34] found commercial GF bread product with uniform crumb porosity but with higher protein value. The commercial GF samples included in the study had significantly lower protein content versus the wheat-based ones, but received as high or even significantly higher values for crumb homogeneity perception. The reason for that could be linked to more effective protein supplements and/or better understanding of starch–protein–hydrocolloid interactions.

From crumb color behavior point of view, participants found this attribute at same or more intense level than their wheat-based counterparts, except for WL3 and WG3. This result showed that it was achievable with the combination of GF ingredients like starches (corn, tapioca, rice), pseudocereals (amaranth, buckwheat) and fibers (apple, potato, psyllium) to create crumb color for GF breads, which was typical for the wheat-based counterparts, and preferable even for non-celiac consumers. However, the exact ratio just based on the ingredient list information could not be determined. The improvement of crumb and crust color intensity indicating that appearance, as one of the most important factors at bread purchasing had significantly improved in the last decade in the case of fresh baked GF breads.

One of the biggest struggle with GF bread formulations had been their flavor. GF products were often described as having dry, tasteless or unpleasantly strong corny taste [15, 17, 27, 34]. In this study the GF samples did not have type-unusual corny and cheesy flavor and/or odor. From taste point of view, the two most dominant difference were detected by the saltiness of C1 and the sweetness of WGW. Latter can be explained with the highest level of added sugar (3.8 g/100 g).

WLW was characterized by the most intense fermented taste and smell, which was probably due to the presence of sourdough.

Concerning texture properties, sensory results were in line with the instrumental measurements. The link between hardness and springiness measurement and softness scores was confirmed, they strengthened each other. C2 sample was the hardest during all days, which was reflected in the sensory test as well with the least intense softness value. WL2 sample is not just hard, but also rubbery. However, the exact level of ingredients was not mentioned on the labels, which can be linked to a higher level of hydrocolloids.

In general, checking all the texture properties together, C1, WL1 and WG1 samples were performing at the same level or better (p < 0.0.5) compared to their wheat-based counterparts.

Conclusion

This study aims to provide up to date data regarding the so far neglected topic of texture and sensory aspects of commercially available, freshly baked, preservative-free GF bread products designed for celiac consumers. Results show that the market has the ability to produce preservative-free, ready-to-eat bread products with comparable texture properties and attributes to their wheat-based counterparts during storage at room temperature. The higher fiber and the comparable or even lower energy and carbohydrates values decrease the gap in the nutrition area between GF and wheat-based bread products. In the future, it would be important that shelf-life studies aiming to evaluate the texture and sensory qualities of GF bread samples would concentrate on the commercially available GF products and in that case, these results and parameters could be used as reference. If the focus would shift more to the commercially available GF products, it would become more apparent that these products are not as low quality anymore. The hardness, springiness and cohesiveness data of the storage test prove the very opposite, the quality of these products has significantly improved during the last few years.

Availability of data and material

Data which support the outcome of the study are available from the corresponding author upon request.

References

Tekiner H (2015) Aretaeus of Cappadocia and his treatises on diseases. Turk Neurosurg 25:508–512

Gobbetti M, Pontonio E, Filannino P, Rizzello CG, De Angelis M, Di Cagno R (2018) How to improve the gluten-free diet: the state of the art from a food science perspective. Food Res Int 110:22–32

Ludvigsson JF, Leffler DA, Bai JC, Biagi F, Fasano A, Green PH, Hadjivassiliou M, Kaukinen K, Kelly CP, Leonard JN, Lundin KE, Murray JA, Sanders DS, Walker MM, Zingone F, Ciacci C (2013) The Oslo definitions for coeliac disease and related terms. Gut 62:43–52

Ortiz C, Valenzuela R, Lucero AY (2017) Celiac disease, non celiac gluten sensitivity and wheat allergy: comparison of 3 different diseases triggered by the same food. Rev Chil Pediatr 88:417–423

Hartmann C, Hieke S, Taper C, Siegrist M (2018) European consumer healthiness evaluation of ‘free-from’ labelled food products. Food Qual Pref 68:377–388

Capriles DV, Areas GJA (2014) Novel approaches in gluten-free breadmaking: Interface between Food Science, Nutrition, and Health. Compr Rev in Food Sci Food Saf 13:871–890

Elgeti D, Jeckle M, Becker T (2015) Strategies for the aeration of gluten-free bread—a review. Trends in Food Sci Technol 46:75–84

Conte P, Del Caro A, Balestra F, Piga A, Fadda C (2018) Bee pollen as a functional ingredient in gluten-free bread: A physical-chemical, technological and sensory approach. LWT Food Sci Technol 90:1–7

Ronda F, Perez-Quirce S, Villanueva M (2017). Rheological properties of gluten-free bread doughs: relationship with bread quality. Adv Food Rheol Appl 297–334

Martínez MM, Gómez M (2017) Rheological and microstructural evolution of the most common gluten-free flours and starches during bread fermentation and baking. J Food Eng 197:78–86

Rybicka I, Doba K, Binczak O (2019) Improving the sensory and nutritional value of gluten-free bread. Int J Food Sci Technol 54:2661–2667

Roman L, Belorio M, Gomez M (2019) Gluten-free breads: the gap between research and commercial reality. Compr Rev Food Sci Food Saf 18:690–702

Ozola L, Straumite E (2014) Characteristic of gluten-free products: Latvian consumer survey. Int J Nutr Food Eng 8:1848–1852

Potter R, Stojceska V, Plunkett A (2014) An investigation of the consumer perception on the quality of the gluten and wheat free breads available on the UK market. J Food Meas 8:362–372

Capelli A, Oliva N, Cini E (2020) A systematic review of gluten-free dough and bread: dough rheology, bread characteristics, and improvement strategies. Appl Sci 10:6559

Fry L, Madden AM, Fallaize R (2018) An investigation into the nutritional composition and cost of gluten-free versus regular food products in the UK. J Human Nutr Diet 31:108–120

Foschia M, Horstmann S, Arendt EK, Zannini E (2016) Nutritional therapy - Facing the gap between coeliac disease and gluten-free food. Int J Food Microbiol 239:113–124

Cornicelli M, Saba M, Machello N, Silano M, Neuhold S (2018) Nutritional composition of gluten-free food versus regular food sold in the Italian market. Dig Liver Dis 50:1305–1308

Tres A, Tarnovska N, Varona E (2020) Determination and comparison of the lipid profile and sodium content of gluten-free and gluten-containing breads from the Spanish market. Plant Foods Hum Nutr 75:344–354

Melini V, Melini F (2019) Gluten-free diet: gaps and needs for a healthier diet. Nutrients 11:170

Missbach B, Schwingshackl L, Billmann A, Mystek A, Hickelsberger M, Bauer G, König J (2015) Gluten-free food database: the nutritional quality and cost of packaged gluten-free foods. PeerJ 3:e1337

Jamieson JA, Gougeon L (2017) Gluten-free foods in rural maritime provinces: limited availability, high price, and low iron content. Can J Diet Prac Res 78:192–196

MohdFauad SNA, Kaur S, Shafie SR (2020) Nutritional composition and cost differences between gluten-free and gluten-containing food products in Kuala Lumpur, Malaysia. Mal J Med Health Sci 16:178–183

Gallagher E, Gormley TR, Arendt EK (2003) Crust and crumb characteristics of gluten free breads. J Food Eng 56:153–161

Moore MM, Schober TJ, Dockery P, Arendt EK (2004) Textural comparisons of gluten-free and wheat-based doughs, batters, and breads. Cereal Chem 81:567–575

Hager AS, Wolter A, Czerny M, Bez J, Zannini E, Arendt EK (2012) Investigation of product quality, sensory profile and ultrastructure of breads made from a range of commercial gluten-free flours compared to their wheat counterparts. Eur Food Res Technol 235:333–344

Matos ME, Rosell CM (2012) Relationship between instrumental parameters and sensory characteristics in gluten-free breads. Eur Food Res Technol 235:107–117

Mariotti M, Pagani MA, Lucisano M (2013) The role of buckwheat and HPMC on the breadmaking properties of some commercial gluten-free bread mixtures. Food Hydrocoll 30:393–400

Wolter A, Hager AS, Zannini E, Arendt EK (2014) Influence of sourdough on in vitro starch digestibility and predicted glycemic indices of gluten-free breads. Food Funct 5:564–572

Mazzeo T, Brambillasca F, Pellegrini N, Valmarana R, Corti F, Colombo C, Agostoni C (2014) Evaluation of visual and taste preferences of some gluten-free commercial products in a group of celiac children. Int J Food Sci Nutr 65:112–116

Paciulli M, Rinaldi M, Cirlini M, Scazzina F, Chiavaro E (2016) Chestnut flour addition in commercial gluten-free bread: a shelf-life study. LWT Food Sci Technol 70:88–95

Feizollahi E, Mirmoghtadaie L, Mohammadifar MA, Jazaeri S, Hadaegh H, Nazari B, Lalegani S (2018) Sensory, digestion, and texture quality of commercial gluten-free bread: impact of broken rice flour type. J Texture Stud 49:395–403

Puerta P, Laguna L, Villegas B, Rizo A, Fiszman S, Tarrega A (2020) Oral processing and dynamics of texture perception in commercial gluten-free breads. Food Res Int 134:109233

Pagliarini E, Laureati M, Lavelli V (2010) Sensory evaluation of gluten-free breads assessed by a trained panel of celiac assessors. Eur Food Res Technol 231:37–46

Parlak O, Dundar AN (2021) Production of low protein and gluten-free cookies for phenylketonuria (PKU) and/or celiac patients. Czech J Food Sci 39:29–34

MacDonald A, van Wegberg AMJ, Ahring K, Beblo S, Bélanger-Quintana A, Burlina A, Campistol J et al (2020) PKU dietary handbook to accompany PKU guidelines. J Rare Dis 15:171

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2011) Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT Food Sci Technol 44:681–686

Naqash F, Gani A, Gani A, Masoodi FA (2017) Gluten-free baking: combating the chellenges—a review. Trends Food Sci Technol 66:98–107

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2010) Rheological and baking characteristics of batter and bread prepared from pregelatinized cassava starch and sorghum and modified suing microbial transglutaminase. J Food Eng 97:465–470

Pruska-Kedzior A, Kedzior Z, Goracy M, Pietrowska K, Przybylska A, Spychalska K (2008) Comparison of rheological, fermentative and baking properties of gluten-free dough formulations. Eur Food Res Technol 227:1523–1536

Witczak T, Juszczak L, Ziobro R, Korus J (2017) Rheology of gluten-free dough and physical characteristics of bread with potato protein. J Food Process Eng 40:1–21

Acknowledgements

The authors appreciated Barbara Pém and Nikolett Lázár for their high-level assistance in proofreading and editing. The authors acknowledge the Hungarian University of Agriculture and Life Sciences’ Doctoral School of Food Science for the support in this study.

Funding

Open access funding provided by Hungarian University of Agriculture and Life Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors have no conflict of interest to declare.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Ethical approval

Ethics approval was not required for this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tóth, M., Kaszab, T. & Meretei, A. Texture profile analysis and sensory evaluation of commercially available gluten-free bread samples. Eur Food Res Technol 248, 1447–1455 (2022). https://doi.org/10.1007/s00217-021-03944-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-021-03944-2