Abstract

A simple, straightforward, and ultrasound-promoted method for the preparation of some highly functionalized tetrahydropyridines reported via pseudo five-component reaction of (hetero)aromatic aldehydes, different anilines, and alkyl acetoacetates in the presence of [N-CH2CO2H-3-pic]+HSO4−, as a novel ionic liquid, in green aqueous medium. The IL was synthesized utilizing simple and easily-handled substrates and characterized by FT-IR, 1H NMR, 13C NMR, GC-MASS, FESEM, EDX, and TGA/DTG techniques. The procedure contains some highlighted aspects which are: (a) performing the MCR in the presence of aqua and sonic waves, as two main important and environmentally benign indexes in green and economic chemistry, (b) high yields of products within short reaction times, (c) convenient work-up procedure, (d) preparing the new IL via simple substrates and procedure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Synthesis of various nitrogen-containing heterocyclic compounds widely attracted in organic chemistry [1, 2]. Among different types of N-heterocycles, tetrahydropyridines are particularly significant because of their organic and pharmaceutical attractions [3, 4].

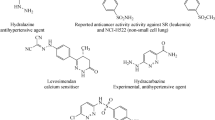

Tetrahydropyridine (THP) moiety exists in various alkaloids and natural products [5]. Tetrahydropyridine existence in heterocycles cause to different pharmacological and biological activities such as antimicrobial activity against Escherichia coli [6], antimalarial [7], anti-oxidant (which made them as potent radical scavengers) [8], anti-fungicidal and insecticidal [9], anti-tumor [10], and neuroprotective (Parkinson's disease) [11]. Some compounds hold THP scaffolds also used as corrosion inhibitors for mild steel [12],

Recently a wide range of functionalized tetrahydropyridine-3-carboxylates has been synthesized via the reaction of various aldehydes, amines, and β-keto esters utilizing various catalysts under different conditions such as: bromodimethylsulfonium bromide (BDMS) in acetonitrile at room temperature [13], FeCl3/SiO2 NPs in refluxing methanol [14], Bi(III) immobilized on triazine magnetized dendrimer (Fe3O4@TDSN-Bi(III)) in ethanol at room temperature [15], nano-Al2O3/BF3/Fe3O4 at 80 °C [16], CAN in acetonitrile at room temperature [17], nano-spherical silica sulfuric acid (NS-SSA) in acetonitrile at 65 °C [18], Ag, Ni2+, and Fe2+ immobilized on the core‐shell hydroxyapatite γ‐Fe2O3 MNPs (γ‐Fe2O3@-HAp‐Ag, γ‐Fe2O3@HAp‐Ni2+, and γ‐Fe2O3@HAp‐Fe2+) in ethanol at room temperature [19], and [(Et3N)2SO][HSO4]2 at 120 °C [20].

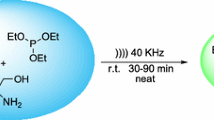

Sonochemistry, utilizing the high-power ultrasound that generate cavitation in a liquid, is a source of energy to accelerate a wide-spread chemical transformation. The hot-spot theory explains the energy release from cavitation as a physical process. The theory explains that each cavity (bubble) acts a localized microreactor that produces thousand degrees temperatures and pressures more than one thousand atmospheres [21]. Recently ultrasound, as one of the useful non-traditional condition, utilized for enhancing diverse organic reactions in heterocyclic preparations [22,23,24,25], and multi-component one-step or domino reactions [24, 26, 27], The sonochemistry is also green technique due to enhanced reactivity and acceleration leads to energy savings and cleaner products with formation of little or no by-products [23].

Performing the reactions in aqueous media achieved attention in recent organic synthesis. The phrase “on-water” that communicates to the situation in which reactants are insoluble in water, firstly expressed by Sharpless [28]. The water has some special characteristics that make it an optional green medium for organic reactions such as non-toxicity, cheapness, non-flammability, readily availability, and some physicochemical properties (polarity, hydrogen bonding, and trans-phase interactions) [29, 30]. Performing the organic transformation in aqueous media included some advantages such as: enhanced reactivity and selectivity of the procedure, work-up and purification improvement, recycling and reusability of the catalyst, milder reaction conditions, and straightforward preparation of natural and bioactive compounds [30].

Ionic liquids (ILs, salts melted without decomposing or vaporizing) are very famous and versatile catalysts and/or solvents in organic transformations. These liquid salts which could own dual catalytic/solvent role are classified as task-specific ionic liquids (TSILs) [31], room temperature ionic liquids (RTILs) [32, 33], chiral ionic liquids [34], basic ionic liquids (BILs) [35], acidic ionic liquids [36], Brønsted acidic ionic liquids (BAILs) [37], and Lewis acidic ionic liquids [38]. They also utilized as part of multi-layered structures which causes to enhance the total efficacy through synergic effects [39,40,41]. Recently pyridinium-based ILs attached special attention in various kind of organic transformations such as cyclocondensation-Knoevenagel-Michael domino reactions [42], synthesis of bis‐naphthodipyrans [43], synthesis of spiropyrans [44], and prepation of pyranopyrazoles [45].

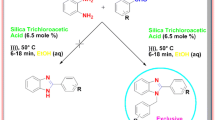

In extending our research group preferences for the synthesis of novel nano promoters to catalyze various MCRs [46,47,48,49,50,51] here in we report preparation of a new organic IL on the basis of 3-picoline, named N-carboxymethyl-3-methylpyridinium hydrogensulfate ([N-CH2CO2H-3-pic]+HSO4-). Its catalytic activity was examined to obtain multi-substituted tetrahydropyridine-3-carboxylates via a pseudo five-component ultrasound-assisted reaction of (hetero)aromatic aldehydes, different anilines, and alkyl acetoacetates in water (Scheme 1).

2 Experimental

2.1 Materials and measurements

The chemicals and reagents purchased from Merck Chemical Company and utilized without any purification. FT-IR spectra were run on a Bruker, Tensor 27 spectrometer. The 1H NMR and 13C NMR were recorder by A Bruker (DRX-300 Avanes) apparatus. Melting points were determined by Electro thermal 9200. Field emission scanning electron microscopy (FESEM) gained by a VEGA//TESCAN-LUM. The mass spectra were recorded on a GC-Mass 5973 Network Mass Selective Detector, GC 6690 and Mass l 5973 Network Mass Selective Detector, Agilent Technology (HP) Agilent. Thermal gravimetric analysis (TGA) done through a “TGA1 METTLER TOLEDO” apparatus. A centrifuge machine UNIVERSAL 320 (capacity of 1000 W) used in the preparation procedure of IL. Homogenization performed in a Wise clean bath with power of 90 W. The ultrasonic device was an HD 3100 ultrasonic homogenizer form Bandelin Company (Germany). The SH 70 G horn, which emits 20 kHz ± 500 Hz ultrasound at intensity levels tunable up to maximum sonic power density of 100 Wcm-2, was used. Sonication carried out at 100% (maximum amplitude 245 μ m). An MS73 probe with the 3 mm diameter was immersed directly to the reaction mixture.

2.2 General procedure for the preparation of [N-CH2CO2H-3-Pic]+HSO4 −

A solution of 3-methylpyridine (10 mmol) and chloroacetic acid (10 mmol) in dry acetone (40 ml), in a two necked round bottomed flask, was refluxed within 7 h. The reaction completing-time monitored by TLC (eluent: n-hexane:EtOAc, 5:3). After that the flask put into ice-bath and a solution of concentrated sulfuric acid in dried acetone (20 ml) poured into the balloon through a dropping funnel drop by drop and stirred for 90 min at room temperature. The resulting mixture centrifuged (10,000 rpm) and the solid residue washed with further dried acetone (3 × 10 ml). The obtained solid was dissolved in 20 ml acetone and sonicated in a bath for 30 min to be homogenized. After air-drying and oven-drying at 50 °C for 2 h, the obtained white solid is [N-CH2CO2H-3-pic]+HSO4− IL (M.P. = 80–82 °C). FT-IR (KBr): 3386, 3171, 3063, 2930, 2809, 1631, 1475, 1313, 1231, 119, 1054 cm–1. 1H NMR (300 MHz, DMSO-d6): 2.45 (s, 3H, CH3), 3.85 (s, 2H, CH2), 7.99 (dd, 1H, J = 7.8, 5.7 Hz, Ar), 8.46 (d, 1H, J = 7.8 Hz, Ar), 8.73–8.78 (br s, 2H, Ar), 12.67 (br s, 2H, OH). 13C NMR (75 MHz, DMSO-d6): 17.9, 127.0, 138.2, 139.3, 141.5, 147.1. MS (EI) (m/z): 248 [M+-1], 234 [M+]–Me, 186 [M+]–CO2H, –H2O, 175 [M+]–CH2CO2H, –Me, 152 [M+]–HSO4, 138 [M+]–HSO4−, –Me, 93 [3-methylpyridine]+, 80 [pyridine]+, 60 [MeCO2H]+.

2.3 General procedure for synthesis of alkyl 1,2,6-triaryl-4-(arylamino)-1,2,5,6-tetrahydropyridine-3-carboxylates (4a-s)

A mixture of aromatic aldehydes 1a-h (2 mmol), aromatic amines 2a-f (2 mmol), alkyl acetoacetate 3a-b (1 mmol), and [N-CH2CO2H-3-Pic]+HSO4− IL (0.032 g, 12.8 mol%) in water (5 ml), sonicated by a probe (60 Wcm-2) for the appropriate time monitored by TLC (eluent: n-hexane:EtOAc, 5:3). After completion of the reaction, the mixture was dissolved in hot methanol to obtain the desired products 4a-s.

2.4 Ethyl 2,6-bis(2-hydroxy-4-nitrophenyl)-1-(4-nitrophenyl)-4-((4-nitrophenyl)amino)-1,2,5,6-tetrahydropyridine-3-carboxylate (4 l)

Yellow solid; M.P. 194–195 °C; FT-IR (KBr): 3348 (NH), 3368 (OH), 2923 (CH), 1623 (CO), 1588 (C=C), 1515 (N–O), 1345 (N–O), 1291(C–O, ester), 1223 (CO, phenol) cm−1; 1H NMR (300 MHz, DMSO-d6) δ/ppm: 1.86 (m, 3H, CH3), 3.15–3.27(m, 2H, CH2), 3.27–3.28 (m, 2H, CH2), 6.56–6.59 (m, 1H, CH), 6.71 (d, 1H, J = 8.9 Hz, Ar), 7.11–7.14 (m, 2H, Ar), 7.40 (d, 2H, J = 8.8 Hz, Ar), 7.49 (d, 1H, J = 9.0 Hz, Ar), 7.55 (d, 2H, J = 8.8 Hz, Ar), 8.13–8.37 (m, 5H, Ar), 8.57–8.58 (m, 1H, Ar), 10.25 (s, 1H, NH), 11.78 (br s, 1H, OH), 12.93 (br s, 1H, OH).

Ethyl 1-(4-chlorophenyl)-4-((4-chlorophenyl)amino)-2,6-di(1H-pyrrol-2-yl)-1,2,5,6-tetrahydropyridine-3-carboxylate (4m).

Black solid; M.P. 288–289 °C; FT-IR (KBr): 3444 (NH), 2922 (C–H), 1648 (CO), 1558 (C=C), 1462 (C=C), 1263 (C–O), 777 (C–Cl) cm−1; 1H NMR (300 MHz, DMSO-d6) δ/ppm: 1.99–2.48 (m, 3H, CH3), 3.16–3.46 (m, 1H, CH), 3.57–3.62 (m, 4H, 2CH2), 6.27–6.57 (m, 5H, Ar), 6.77–7.02 (m, 6H, Ar), 7.20 (m, 1H, Ar), 7.40 (br s, 1H, NH), 7.55 (br s, 1H, NH), 8.19–8.57 (M, 2H, Ar), 11.46–12.18 (br s, 1H, NH).

3 Results and discussion

The FESEM images of the [N-CH2CO2H-3-Pic]+HSO4− IL has been obtained in order to recognize the structure and size of the particles. As it is illustrated in Fig. 1, there is moderate uniformity in the structure of the IL in μm scale. There are some IL nanoparticles with the average diameter of 35–55 nm on the surface of the [N-CH2CO2H-3-Pic]+HSO4−.

TGA/DTG analysis of [N-CH2CO2H-3-Pic]+HSO4− IL in Fig. 2 showed that the nanostructure decomposes through an endothermic one-step process. It is thermally stable up to about 300 °C and total decomposition occurred at 360 °C.

The EDX analysis of the IL illustrated in Fig. 3. The results show the existence of the elements such as C (40.12%), N (6.98%), O (42.02%), and S (10.87%). The impurities related to the solvents and materials used in the catalyst manufacturing process didn't observe.

In the next step, in order to examine the catalytic activity of newly-prepared IL, the reaction of benzaldehyde 1a (2 mmol), 4-chloroaniline 2d (2 mmol), and ethyl acetoacetate 3a (1 mmol) was chosen as the model. To achieve the optimized conditions different exams performed that are presented in Table 1. As it observed, in the solvent-free conditions the best amount of the catalyst is 0.032 g (12.8 mol%) (Entries 1 & 2). The temperature investigations showed that 60 °C is the best choice (entries 3 & 4). Implementation of the reaction in ethanol (entry 5) and water (entry 6) defined that the reaction progressed better in the absence of solvent (compare the results of entries 1, 5, and 6). In the best try, the reaction investigated under the sonic waves with various power density (entries 7–10). The results affirmed that utilizing sonic waves with the power of 60 Wcm−2 in aqueous medium is the best choice (entry 7). Eventually due to results, performing the reaction in the presence of 0.032 g (12.8 mol%) of the [N-CH2CO2H-3-Pic]+HSO4− IL in aqueous medium under sonic waves (60 Wcm−2) is the best choice. In order to check the IL efficacy and necessity to accelerate the reaction, the model reaction also examined in the absence of [N-CH2CO2H-3-Pic]+HSO4− through addition of 5 drops of concentrated sulfuric acid as protic inorganic acid catalyst (entry 11). According to the result the reaction progress is not satisfactory in comparison to the entry 7, which confirmed the crucial role of IL to perform the reaction. This phenomena could be due to the amphipathic (hydrophilic and lipophilic) characteristics of the CH2CO2H-3-Pic]+HSO4− that could be dissolved better than mineral acid (H2SO4) in the micelles of the organic reactants suspended in water [52]. The model reaction also repeated in the presence of chloroacetic acid, as an organic acid which is one of the staring materials to prepare the IL (entry 12). The model reaction accomplishment in the absence of IL (entry 13) didn't generate the corresponding product. The results summarized in entries 11–13, affirmed the importance catalytic role of IL for the reaction progress. It seems that the optimized reaction conditions which consist of ultrasound/ionic liquid/water media could enhanced the reaction progress through generation of hot-spots and cavitation in addition with the catalytic aid of the IL.

Afterwards, the synthesis of various multi-substituted THP-3-carboxylates surveyed under the optimized conditions. Based on the data summarized in Table 2 and Scheme 1, benzaldehydes, various anilines, and ethyl acetoacetate gained their corresponding THPs in good yields (entries 1–13). In order to extend the efficacy of the method methyl acetoacetate also performed the pseudo-five component condensation well (entries 14–19). No significant substituent effect on the time and/or yield of the reactions didn't observe.

Although no mechanistic verification examined, the proposed mechanism illustrated in Scheme 2. According to suggested plan, the synthesis of THPs 4 could be proceeded through two pathways (I & II). In the pathway I, the ionic liquid ([N-CH2CO2H-3-Pic]+HSO4−) activates the C = O group of aldehyde 1 which condensed to aniline 2 to obtain imine A. Activation the carbonyl group of alkyl acetoacetate 3 by IL followed by condensation with aniline 2 generates β-enaminone B. The intermolecular Mannich addition of A and B affords the intermediate C. Subsequently, the condensation of activated aldehyde with the intermediate C generates intermediate D that follows by tautomerization to intermediate E. The intramolecular ring closure follows by tautomerization obtains the final product 4. The pathway II, the Knoevenagel condensation of β-enaminone B with aldehyde 1, yields intermediate G that tautomerizes respectively to H. the [4 + 2] Aza Diels–Alder reaction of H with imine A obtained the desired product 4.

Finally, to clarify the efficacy of the protocol, a comparison performed for the synthesis of with the previously reported methods illustrated in Table 3. According to data, presence of [N-CH2CO2H-3-Pic]+HSO4− IL, in addition with sonic waves in aqueous medium, elevated the reaction progress.

4 Conclusions

In summary, an efficient MCR protocol to obtain multi-substituted tetrahydropyridine-3-carboxylates catalyzed by novel ionic liquid [N-CH2CO2H-3-Pic]+HSO4− was developed. These compounds were prepared from the ultrasound-assisted pseudo five-component condensation of anilines, (hetero)aromatic aldehydes and alkyl acetoacetates in a one-pot one-step aqueous-mediated process. Utilizing aqua as green solvent in the presence of sonic waves, as powerful microreactors which prepare hot-spots and cavitation, and the catalytic efficacy of the newly prepared organo-based ionic liquid, clean synthesis, and high yields of products, are some advantages of this methodology.

References

Lygin AV, de Meijere A (2010) Isocyanides in the synthesis of nitrogen heterocycles. Angew Chem 49:9094–9124. https://doi.org/10.1002/anie.201000723

Zhang B, Studer A (2015) Recent advances in the synthesis of nitrogen heterocycles via radical cascade reactions using isonitriles as radical acceptors. Chem Soc Rev 44:3505–3521. https://doi.org/10.1039/C5CS00083A

Mateeva NN, Winfield LL, Redda KK (2005) The chemistry and pharmacology of tetrahydropyridines. Curr Med Chem 12:551–571. https://doi.org/10.2174/0929867053362776

Khan MM, Khan S, Iqbal S, Iqbal S (2016) Recent developments in multicomponent synthesis of structurally diversified tetrahydropyridines. RSC Adv 6:42045–42061. https://doi.org/10.1039/C6RA06767K

O’Hagan D (2000) Pyrrole, pyrrolidine, pyridine, piperidine and tropane alkaloids. Nat Prod Rep 17:435–446. https://doi.org/10.1039/A707613D

SilvaJr L, Carrion LL, Groll A, Costa SS, Junqueira E, Ramos DF, Cantos J, Seus VR, Couto I, Fernandes L, Bonacorso HG, Martins MAP, Zanatta N, Viveiros M, Machado KS, da Silva PEA (2017) In vitro and in silico analysis of the efficiency of tetrahydropyridines as drug efflux inhibitors in Escherichia coli. Int J Antimicrob Agents 49:308–314. https://doi.org/10.1016/j.ijantimicag.2016.11.024

Naranjo-Montoya OA, Martins LM, da Silva-Filho LC, Batagin-Neto A, Lavardae FC (2015) The correlation between electronic structure and antimalarial activity of tetrahydropyridines. J Braz Chem Soc 26:255–265. https://doi.org/10.5935/0103-5053.20140263

Petrovic ZD, Simijonovic D, Orovic JD, Milovanovic V, Markovic Z, Petrovic VP (2017) One-pot synthesis of tetrahydropyridine derivatives: liquid salt catalyst vs glycolic acid promoter. structure and antiradical activity of the new products. ChemistrySelect 2:11187–11194. https://doi.org/10.1002/slct.201701873

Zhu YJ, Guo XF, Fan ZJ, Chen L, Ma LY, Wang HXW et al (2016) Approach to thiazole-containing tetrahydropyridines via Aza–Rauhut–Currier reaction and their potent fungicidal and insecticidal activity. RSC Adv 6:112704–211711. https://doi.org/10.1039/C6RA24342H

León G, LG, Carballo RM, Vega-Hernández MC, Martín VS, Padrón JI, JM Padrón, (2007) antiproliferative activity of 2-alkyl-4-halopiperidines and 2-alkyl-4-halo-1,2,5,6-tetrahydropyridines in solid tumor cell lines. Biorog Med Chem Lett 17:2681–2684. https://doi.org/10.1016/j.bmcl.2007.03.010

Li Ch, Biswas S, Li X, Dutta AK, Le W (2010) Novel D3 dopamine receptor-preferring agonist D-264: evidence of neuroprotective property in Parkinson’s disease animal models induced by 1-methyl-4-phenyl-1,2,3,6-tetrahydropyridine and lactacystin. J Neurosci Res 88:2513–2523. https://doi.org/10.1002/jnr.22405

Haque J, Verma Ch, Srivastava V, Quraishi MA, Ebenso EE (2018) Experimental and quantum chemical studies of functionalized tetrahydropyridines as corrosion inhibitors for mild steel in 1 M hydrochloric acid. Results Phys 9:1481–1493. https://doi.org/10.1016/j.rinp.2018.04.069

Khan AT, Parvin T, Choudhury LH (2008) Effects of substituents in the β-position of 1,3-dicarbonyl compounds in bromodimethylsulfonium bromide-catalyzed multicomponent reactions: a facile access to functionalized piperidines. J Org Chem 73:8398–8402. https://doi.org/10.1021/jo8014962

Safaei-Ghomi J, Ziarati A (2013) An efficient FeCl3/SiO2 NPs as a reusable heterogeneous catalyzed five-component reactions of tetrahydropyridines under mild conditions. Iran Chem Soc 10:135–139. https://doi.org/10.1007/s13738-012-0134-z

Asadi B, Landarani-Isfahani A, Mohammadpoor-Baltork I, Tangestaninejad Sh, Moghadam M, Mirkhani V, Amiri Rudbari H (2017) Diastereoselective synthesis of symmetrical and unsymmetrical tetrahydropyridines catalyzed by Bi(III) immobilized on triazine dendrimer stabilized magnetic nanoparticles. ACS Comb Sci 19:356–364. https://doi.org/10.1021/acscombsci.6b00180

Babaei E, Mirjalili BBF (2018) One-pot synthesis of five substituted tetrahydropyridines using nano-Al2O3/BF3/Fe3O4 as a highly efficient nano-catalyst. Res Chem Intermed 44:3493–3505. https://doi.org/10.1007/s11164-018-3320-5

Wang HJ, Mo LP, Zhang Z (2011) Cerium ammonium nitrate-catalyzed multicomponent reaction for efficient synthesis of functionalized tetrahydropyridines. ACS Comb Sci 13:181–185. https://doi.org/10.1021/co100055x

Daraei M, Zolfigol MA, Derakhshan-Panah F, Shiri M, Kruger HG, Mokhlesi M (2015) Synthesis of tetrahydropyridines by one-pot multicomponent reaction using nano-sphere silica sulfuric acid. J Iran Chem Soc 12:855–861. https://doi.org/10.1007/s13738-014-0548-x

Sajjadifar S, Rezayati S, Shahriari A, Abbaspour S (2018) Silver, iron, and nickel immobilized on hydroxyapatite-core-shell γ-Fe2O3 MNPs catalyzed one-pot five-component reactions for the synthesis of tetrahydropyridines by tandem condensation of amines, aldehydes, and methyl acetoacetate. Appl Organometal Chem 32:e4172. https://doi.org/10.1002/aoc.4172

Ghassempour Nikfarjam F, Mahmoodi Hashemi M, Ezabadi A (2019) Design, preparation, and characterization of a novel il-based catalyst, [(Et3N)2SO][HSO4]2, as an efficient and recyclable catalyst in biginelli reaction under solvent-free conditions. Polycycl Aromat Comp. https://doi.org/10.1080/10406638.2019.1653943

Mason TJ (1997) Ultrasound in synthetic organic chemistry. Chem Soc Rev 26:443–451. https://doi.org/10.1039/CS9972600443

Cella R, Stefani HA (2009) Ultrasound in heterocycles chemistry. Tetrahedron 65:2619–2641. https://doi.org/10.1016/j.tet.2008.12.027

Cintas P (2016) Ultrasound and green chemistry-further comments. Ultrason Sonochem 28:257–258. https://doi.org/10.1016/j.ultsonch.2015.07.024

Penteado F, Monti B, Sancineto L, Perin G, Jacob RG, Santi C, Lenardão E (2018) Ultrasound-assisted multicomponent reactions, organometallic and organochalcogen chemistry. J Asian J Org Chem 7:2368–2385. https://doi.org/10.1002/ajoc.201800477

Kaur N (2018) Ultrasound-assisted green synthesis of five-membered O- and S-heterocycles. Synth Commun 48:1715–1738. https://doi.org/10.1080/00397911.2018.1460671

Lu L, Zhou S, Sun M, Chen J, Xia W, Yu X, Xu X, He W (2019) Metal- and solvent-free ultrasonic multicomponent synthesis of (Z)-β-iodo vinylthiocyanates. ACS Sustain Chem Eng 7:1574–1579. https://doi.org/10.1021/acssuschemeng.8b05344

Alizadeh A, Ghasemzadeh H, Roosta A, Halvagar MR (2019) An efficient ultrasound promoted three-component and regioselective synthesis of indenoquinoxaline compounds containing pyrrolopyrimidine skeleton. ChemistrySelect 4:4483–4486. https://doi.org/10.1002/slct.201900639

Harry NA, Radhika S, Neetha M, Anilkumar G (2019) Recent advances and prospects of organic reactions “on water.” ChemistrySelect 4:12337–12355. https://doi.org/10.1002/slct.201903360

Lipshutz BH, Ghorai S, Cortes-Clerget M (2018) The hydrophobic effect applied to organic synthesis: recent synthetic chemistry “in water.” Chem Eur J 24:6672–6695. https://doi.org/10.1002/chem.201705499

Simon MO, Li Ch (2012) Green chemistry oriented organic synthesis in water. Chem Soc Rev 41:1415–1427. https://doi.org/10.1039/C1CS15222J

Xu H, Zhang C, Chen G, Shen R, Ying A (2016) Application of task-specific ionic liquids to organic synthesis. Chinese J Org Chem 36:2353–2367. https://doi.org/10.6023/cjoc201604053

Jindal R, Sablok A (2015) Preparation and applications of room temperature ionic liquids in organic synthesis: a review on recent efforts. Curr Green Chem 2:135–155. https://doi.org/10.2174/2213346101666140915212515

Javed F, Ullah F, Zakari MR, Md Akil H (2018) An approach to classification and hi-tech applications of room-temperature ionic liquids (RTILs): A review. J Mol Liq 271:403–420. https://doi.org/10.1016/j.molliq.2018.09.005

Ding J, Armstrong DW (2005) Chiral ionic liquids: synthesis and applications. Chirality 17:281–292. https://doi.org/10.1002/chir.20153

Hajipour AR, Rafiee F (2009) Basic ionic liquids. A short review. J Iran Chem Soc 6:647–678. https://doi.org/10.1007/BF03246155

Amarasekara AS (2016) Acidic ionic liquids. Chem Rev 116:6133–6183. https://doi.org/10.1021/acs.chemrev.5b00763

Vafaeezadeh M, Alinezhad H (2016) Brønsted acidic ionic liquids: Green catalysts for essential organic reactions. J Mol Liq 218:95–105. https://doi.org/10.1016/j.molliq.2016.02.017

Chiappe C, Rajamani S (2011) Structural effects on the physico-chemical and catalytic properties of acidic ionic liquids: an overview. Eur J Org Chem 2011:5517–5539. https://doi.org/10.1002/ejoc.201100432

Yao N, Chen Ch, Li DJ, Hu YL (2020) Cobalt nanoparticles embedded over periodic mesoporous organosilica functionalized with benzotriazolium ionic liquid for efficient and heterogeneous catalytic transformation of carbon dioxide to cyclic carbonates. J Environ Chem Eng 8:103953. https://doi.org/10.1016/j.jece.2020.103953

Correia DM, Fernandes LC, Martins PM, García-Astrain C, Costa CM, Reguera J, Lanceros-Méndez S (2020) Ionic liquid–polymer composites: a new platform for multifunctional applications. Adv Funct Mater 30:1909736. https://doi.org/10.1002/adfm.201909736

Rajabzadeh M, Eshghi H, Khalifeh R, Bakavoli M (2018) 2-Hydroxyethylammonium formate ionic liquid grafted magnetic nanoparticle as a novel heterogeneous catalyst for the synthesis of substituted imidazoles. Appl Organomet Chem 32:e4052. https://doi.org/10.1002/aoc.4052

Moosavi-Zare AR, Zolfigol MA, Noroozizadeh E, Khaledian O, Shirmardi Shaghasemi B (2016) Cyclocondensation–Knoevenagel–Michael domino reaction of phenyl hydrazine, acetoacetate derivatives and aryl aldehydes over acetic acid functionalized ionic liquid. Res Chem Intermed 42:759–4772. https://doi.org/10.1007/s11164-015-2317-6

Rajabi-salek M, Zolfigol MA, Zarei M, Noroozizadeh E, Mohammadpoor-Baltork I, Amiri Rudbari H (2018) Synthesis and characterization of 1-(carboxymethyl)pyridinium bromide [CMPy]Br molten salt: application as a novel nanocatalyst for the synthesis of bis-naphthodipyrans. ChemistrySelect 3:12791–12796. https://doi.org/10.1002/slct.201802971

Moosavi-Zare AR, Zolfigol MA, Salehi-Moratab R, Noroozizadeh E (2017) Synthesis of spiropyran derivatives over 1-(carboxymethyl) pyridinium iodide as nanostructured pyridinium salt under aqueous media. Can J Chem 95:194–198. https://doi.org/10.1139/cjc-2016-0374

Moosavi-Zare AR, Zolfigol MA, Salehi-Moratab R, Noroozizadeh E (2016) Catalytic application of 1-(carboxymethyl)pyridinium iodide on the synthesis of pyranopyrazole derivatives. J Mol Catal A 415:144–150. https://doi.org/10.1016/j.molcata.2016.02.003

Nikoofar K, Mehrikaram F, Lashanizadegan M, Aghaei A (2021) Copper(II)-schiff base complex Embedded on multi-walled carbon nanotubes (APTMS@MWCNTs/Schiff Base/Cu): a novel versatile nanostructure to promote four-component preparation of dihydro-spiro[cycloalkane-1,4′-quinoline]-2′,5′-diones. Polycycl Aromat Compd 41:663–675. https://doi.org/10.1080/10406638.2019.1614636

Nikoofar K, Mehrikaram F (2019) Graphite decorated nano alumina (nano Al2O3@Cg): a versatile inorganic nano-promoter for the synthesis of 4-alkyl-5-methyl-1H-pyrazol-3-ols in aqueous media. Polyhedron 159:330–336. https://doi.org/10.1016/j.poly.2018.12.008

Nikoofar K, Peyrovebaghi SSh (2019) 1-Butyl-2-methylpipyridinium iodide ([BMPPY]I): novel ionic liquid for the synthesis of 6-hydroxy-6-(1H-indol-3-yl)indolo[2,1-b]quinazolin-12(6H)-ones under green solvent-free conditions. Res Chem Interemd 45:4287–4298. https://doi.org/10.1007/s11164-019-03831-2

Nikoofar K, Shahriyari F (2020) Novel bio-based core-shell organic-inorganic nanohybrid from embedding aspartic acid-guanine ionic liquid on the hydroxylated nano silica surface (nano [(Asp-Gua) IL@PEG-SiO2]): a versatile nanostructure for the synthesis of bis(2,3-dihydroquinazolin-4(1H)-one) derivatives and tricarboxamides under green media. Polyhedron 179:114361. https://doi.org/10.1016/j.poly.2020.114361

Nikoofar K, Khani Sh (2018) New crown ether-based nano ionic liquid ([DB-18-C-6K+][OH−] nIL): a versatile nanocatalyst for the synthesis of spiro[indoline-3,2′-quinoline] derivatives via the cascade four-component reaction of arylamines, dialkylacetylenedicarboxylates, isatins and dimedone. Catal Lett 148:1651–1658. https://doi.org/10.1007/s10562-018-2391-7

Nikoofar K, Khademi Z, Haghighi M (2016) Nano MgBi2O4: a novel green catalyst for the one-step cascade condensation of arylamines, acetone and isatins in water. J Chem Sci 128:1805–1811. https://doi.org/10.1007/s12039-016-1183-0

Saeedi Mirak-Mahaleh M, Rad-Moghadam K (2020) A novel amphipathic low-melting complex salt: an efficient homogeneous catalyst for synthesis of pyran-annulated heterocyclic scaffolds and pyrido[2,3-d]pyrimidines. J Mol Liq 307:112989. https://doi.org/10.1016/j.molliq.2020.112989

Zhou Q, Wan Y, Zhang X, Zhang L, Zou H, Cui H, Zhou Sh, Wang H, Wu H (2015) The first example of glucose-containing carbene Brønsted acid synthesis and catalysis: efficient synthesis of five substituted tetrahydropyridines. Tetrahedron 71:7070–7072. https://doi.org/10.1016/j.tet.2015.06.062

Kangani M, Hazeri N, Yazdani-Elah-Abadi A, Maghsoodlou MT (2018) Lactic acid: an efficient and green catalyst for the one-pot five-components synthesis of highly substituted piperidines. Polycycl Aromat Comp 38:322–328. https://doi.org/10.1080/10406638.2016.1207686

Acknowledgements

The authors thank Alzahra University for financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nikoofar, K., Shahriyari, F. Ultrasound-assisted aqua-mediated synthesis of multi-substituted tetrahydropyridine-3-carboxylates using N-carboxymethyl-3-pyridinium hydrogensulfate ([N-CH2CO2H-3-pic]+HSO4−) as a new efficient ionic liquid catalyst. SN Appl. Sci. 3, 672 (2021). https://doi.org/10.1007/s42452-021-04671-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-021-04671-9