Abstract

QbD approach empowers the pharma researchers to minimize the number of experimental trials and time. It helps identify the significant, influential factors such as critical material attributes, critical formulation variables, and critical process parameters, which may significantly impact the quality of the products. Poly lactic-co-glycolic acid (PLGA), a biocompatible and biodegradable polymer, has gained an immense potential and wide range of applications as a carrier for manufacturing of polymeric nanoparticle drug delivery systems as per US-FDA and European Medicine Agency for drug delivery. The double emulsion method for preparing PLGA nanoparticles to encapsulate hydrophilic drugs has attracted interest in manufacturing processes. The double emulsion is a two-step process consisting of two different emulsification, making the process more complicated. The stability of nanoparticles obtained by a double emulsion method remains questionable due to the many formulations and process attributes. Currently, PLGA based nanoparticles prepared by a double emulsion technique are an alternative pharmaceutical manufacturing operation for getting the quality product by employing the Quality by Design approach. This present review has discussed the QbD elements to elucidate the effect of material attributes, formulation, and process variables on the critical quality attributes of the drug product, such as particle size distribution, encapsulation efficiency, etc. The components of a double emulsion, characteristics of drugs, polymers, and stabilizers used have been discussed in detail in this review.

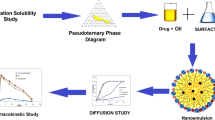

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The significant challenges in the preparation of nanoparticles are manufacturing variability due to a lack of understanding of the effect of critical material attributes (CMAs) and critical processing parameters (CPPs) to attain small size, narrow polydispersity index (PDI), and so on [1]. The nanoparticulate drug delivery system is also known for its toxicities due to the fast onset of action, increase in solubility, permeability, and bioavailability. Hence, the review aimed to describe the pharmaceuticals application of the double emulsion method for the PLGA loaded nanoparticles with the help of quality by design (QbD) approach to understanding the effect of CMAs and CPPs on critical quality attributes (CQAs) to reduce the manufacturing variability, control the manufacturing cost, and to improve the formulation safety and quality [2,3,4]. The application of the quality by design (QbD) approach has led to the development of standardized procedures which are formulation-driven for getting the optimized product. The benefit of scaling up such nanoparticles would improve the therapeutic outcome of the traditional drugs and the following generation agents [5, 6].

In this context the present review highlights the series of obstacles faced during the scaling up of PLGA nanoparticles and the feasibility of overcoming them. Other advantages associated with using QbD principles that may be listed include a better clarity and understanding of the processes/unit operations at every step [7]. It is a scientifically-driven risk-based approach that assures a more straightforward regulatory process as both the approval time and the number of audits needed are reduced. The US FDA's initiative to bring a risk-based approach utilizing both the sound science and knowledge space conveys the concept of enhanced understanding of process and product in pharmaceuticals. The best part is achieving desired target profiles due to minimum changes due to accurate time release testing complemented with monitoring by the appropriate control strategy, overall consistent commercial manufacturing [8]. A QbD approach setting up the Quality Target Product Profile-(QTPP) would be the first step in the product development cycle to get the desired quality characteristics. This phase involves assigning well-defined attributes to a given drug product. In QTPP, CQAs become a subset that defines few critical parameters that apply to a product's development [9, 10]. For any quality product, the raw materials' characteristics properties that are going to be introduced in the process technology play a vital role. For example, the input materials need to be identified as Critical Material Attributes (CMAs). In-process material properties are considered CQAs of a one-step process, which becomes CMAs for a downstream manufacturing process. The identification of Critical Process Parameters (CPPs) becomes a part of production process parameters, and finally, the risk assessment of the drug substance attributes to the development of the product [11, 12].

Biodegradable polymers are predominantly used in nanoparticle drug delivery systems over other materials, advantageous in many ways. Biodegradable polymers can be changed into different particle structures (shape, size & pore morphology), mechanical strength, and degradation rate for various applications. The autocatalytic degradation process occurs due to free radicals or acidic products or lessening of pH due to the carboxylic acid terminals enhancing the hydrolysis of biodegradable polymers [13, 14]. Different biodegradable polymers, PLA, PGA, and PLGA, are more significant biocompatible and non-toxic polymers applicable to other drug delivery systems [15,16,17]. Several encapsulation processes like single emulsion, double emulsion, mini-emulsion, nanoprecipitation, polymerization, supercritical fluids, spray drying, organic phase separation, and solvent diffusion have been explored encapsulation of drug substances in polymer nanoparticle research. Although all these techniques' primary objective is to improve bioavailability, stability, and effective delivery of the drug substances, the nature of drug substances determines the suitability of the process for drug encapsulation. It has been observed that in many types of research works, the emulsification process, along with the solvent evaporation process, has been used for producing nanoparticles of poorly soluble drug substances. Emulsion and solvent evaporation techniques are simple, easy to manufacture, less time-consuming, and easily scalable. However, emulsion techniques always suffer the problems of nanoparticles' stability, which relates to the coalescence of particles, rupture of internal globules, and phase separation. Based on the efficiency of drug encapsulation, the emulsion method is being selected. The hydrophilicity or hydrophobicity of the active molecules generally determines the effectiveness of encapsulation [18].

In the case of a single emulsion, mainly oil-in-water (O/W)) technique, poorly water-soluble drugs are getting encapsulated. For the preparation of O/W emulsion, polymer (PLGA) and drugs are solubilized in water-immiscible organic solvents (Chloroform, dichloromethane, or water-miscible solvents like ethanol, acetone, etc.) or any lipids (e.g., medium-chain triglycerides). The polymer and drug solution is then emulsified in water with suitable emulsifiers (polyvinyl alcohol, poloxamer, etc.) to induce the polymer's precipitation. The whole process is performed under stirring or homogenization (high pressure). Then the organic solvents get evaporated by continuous stirring and with suitable environment conditions. The monolithic nanocapsules/nanocrystals obtained by this process can be adsorbed on suitable carriers or lyophilized after collecting the ultracentrifugation and proper washing [19].

Hydrophilic drug shows a poor entrapment efficiency with a single emulsion technique because the water-soluble drug substances' encapsulation generally results in diffusion or rapid partitioning of a drug from internal oil or organic dispersed into external/ continuous aqueous phase, leading to microparticles or nanoparticles with poor loading efficiency [20]. The loading or entrapment efficiency of drugs within the microspheres or nanospheres is immensely reliant on drug substances' solubility in the continuous aqueous phase. Certain water-soluble drugs like theophylline, salicylic acid, and caffeine are not encapsulated within the PLGA microspheres. In contrast, specific, less aqueous soluble drugs like diazepam, hydrocortisone, and progesterone are entrapped within the PLGA microspheres using the O/W emulsion technique. Hydrophilic drugs are entrapped in a single emulsion (W/O) during oral administrations. As a result, phase separation or precipitation occurs because the external phase contains the oil phase and finally shows the major problem for the hydrophilic drug to be administered in the form of self-emulsifying drug delivery systems [21, 22].

Therefore, to overcome the limitation of poor entrapment efficiency and phase separation of water-soluble drugs by a single emulsion method, a double emulsion method (Water-in-Oil-in-Water) is employed where internal O/W emulsion would be distributed in an external aqueous phase in the presence of a stabilizer or surfactant. In some cases, double emulsions are primed in a two-step emulsification process by using two different types of surfactants in two distinct steps (hydrophobic surfactant used to stabilize the interface of the W/O emulsion and a hydrophilic surfactant used for stabilization of the external interface of the oil globules of O/W emulsion) [23, 24].

The double emulsion method is a two-step emulsification complex method where many factors and parameters are considered and optimized to obtain a stable nanosuspension. The significant challenges associated with the nanoparticles manufactured by the double emulsion technique are due to inappropriate identification of Critical Material Attributes (CMA) of the raw materials used, Critical Formulation Variables (CFV), and Critical Process Parameters (CPP), which lead to the manufacturing variability to attain the Critical Quality Attributes (CQA). Quality by design (QbD) is a risk management, systematic and science-based approach recommended by ICH and regulatory agencies (USFDA, EMEA, etc.) to ensure quality through pharmaceutical products' life cycle. In this review, an attempt has been made to describe the systematic development of PLGA nanoparticles and the QbD elements and how to correlate the impact of CMA, CFV, and CPP with the CQAs of drug products to reduce the manufacturing variability [25].

2 QBD enbaled PLGA nanoparticles by double emulsion method

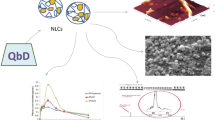

As per USFDA, Quality by Design (QbD) applications are widely valuable tools during the product or process understanding or control through sound science and quality risk management to develops the product through a systematic approach to certify the quality finished the life cycle of the product. QbD intends to trace the source of variability and accordingly construct the control strategies desirable to design a robust and reproducible product. The steps of the QbD approach for PLGA nanoparticles (Figs. 1 and 2) for the steps followed in the QbD approach [26,27,28].

Double emulsions are known as the “emulsions of emulsion” system, and it also a complex heterodisperse system. It is of two types: water in oil in water emulsion (W/O/W) and oil in water in oil emulsion (O/W/O). Generally, the emulsion is a phase dispersed in another aspect. Still, the double emulsion process includes three stages with two different emulsifiers/surfactants, and typically the internal and the external layers are of the same [29]. The concept of double emulsions was initially accessible in 1925 by William Seifriz [30] and investigated the impact of the density of the oil phase on the properties of the final emulsion. However, the little water in oil droplets formed would tend rapid destabilization and turn into a single emulsion. Therefore, these emulsions are called metastable or transitional emulsion between W/O and O/W emulsions [31]. The transitional instability of double emulsion induced water migration between the internal aqueous and continuous aqueous phases. The difference in solute concentration between dispersed water and successive aqueous phases re-equilibrate the osmotic pressure. The stability of double emulsion mainly depends on the solute concentration or osmotic pressure of the steps. The increased osmotic pressure in the outer phase convinces the enlargement of inner droplets of emulsion, whereas decreased osmotic pressure significances in the contraction of inner droplets. Other than osmotic pressure (due to difference in solute concentration in both aqueous phases), Laplace pressure (due to the size of the droplets and surface tension) also inspires identical high pressure within internal droplets and may result in early coalescence and rupture of double emulsion [32]. Double emulsions can be prepared by either a single-step process or a two-step process. The single-step process of emulsification results in the spontaneous formation of double emulsion, and hence, it has attracted attention due to its simplicity of the process [33]. However, the result of poor entrapment efficiency of drugs remains a potential limitation of this process. Matsumoto et al. first described the two-step process of emulsification for preparing double emulsions in 1976 (Fig. 3) [34]. In the first step, a W/O emulsion (primary emulsion) is being ready. In the second step, the secondary emulsion, i.e., W/O/W formed using the W/O emulsion prepared in the first step as the oil phase; afterward, the two-step emulsification process has been turned out to be the predominant technique. Many researchers have used it to produce stable double emulsions. The preparation steps of primary and secondary emulsions are described as follows [35];

Step-I: Preparation of primary W/O emulsion: Initially, the measured amount of water-soluble drug substance is first solubilized in the aqueous phase environment, and the polymer (PLGA) or lipid-soluble drugs are suspended in a suitable organic solvent. Then the aqueous drug phase is added to the organic polymeric phase under vigorous stirring to yield a W/O emulsion. Primary emulsion is generally prepared under high shear conditions and a hydrophobic surfactant to produce stable fine droplets of W/O emulsion [36,37,38].

Step-II: Preparation of secondary emulsification (W/O/W): The primary W/O emulsion is added into a second aqueous phase with a suitable emulsifier (PVA) poloxamer) with continuous stirring or homogenization followed by the removal of organic solvent by evaporation. A hydrophilic surfactant is unusually used in the second step to stabilize the external interface of the oil globules of O/W emulsion. The double emulsion can be adsorbed on the suitable adsorbent, or nanoparticles can be isolated by centrifugation at high speed/ultracentrifugation and proper washing. The subsequent emulsification step is usually performed without extreme shear to avoid rupture of the droplets of primary emulsion or internal droplets. The components in a double emulsion (W/O/W) are presented in Fig. 4 [36,37,38,39,40,41,42,43].

3 Selection criteria for major components required for PLGA nanoparticles by double emulsion method

3.1 Drug substances

Presently, the nanoparticulate drug delivery system is an alternative drug delivery system to increase the drug properties such as saturation solubility, drug release, and stability to enhance the biological activities, e.g., the pharmacokinetic parameters and pharmacodynamics of drug substance. Polymeric nanoparticles constitute a significant share of nanoparticle drug delivery systems. Targeted drug molecules (e.g., anticancer drugs) to specific organs or cells have been achieved through polymeric nanoparticles. A wide variety of hydrophilic or hydrophobic small drugs, vaccines, and biological macromolecules can be delivered mainly through nanoparticle formulations [44, 45]. To develop a polymeric nanoparticle drug delivery system, the physical, chemical, and biological drug properties must be evaluated. Solid-state form (crystalline or amorphous), solubility, and degradation kinetics of drug substances need to be studied before entering into the design of polymeric nanoparticles. The degradation potential of drug substance in PLGA polymer, stabilizer, and solvent system needs to be established by conducting a compatibility study. It is always better to elucidate the mechanism of drug release based on the category or chemistry of polymer and kind of drug [46, 47]. Acidic or basic drugs can alter the mechanism of drug release from the PLGA polymeric matrix. If the impregnated drug in the PLGA matrix is a weak acid, the degradation rate would be faster due to autocatalysis. However, for essential drugs, conflicting views have been published by various researchers. In some cases, it has been published that the degradation rate would be accelerated with essential drugs like tertiary amines or nucleophilic drugs and accelerate the drug release owing to the bulk erosion of polymer matrix [46, 48, 49]. A contrasting view is that the acid generated from PLGA hydrolysis can be neutralized by the essential drugs and results in slower drug release attributed to the slower rate of polymer degradation. Studies reported the impact of drug-polymer interaction on Ibuprofen in vitro drug release (pKa 4.4, weakly acidic drug) and Lidocaine (pKa 7.9, poorly basic drug) from the PLGA matrix. The complete drug release was observed in 7 days in Ibuprofen, whereas with Lidocaine, the entire drug release was achieved 45 days at pH 7.4 [50,51,52,53].

-

Hydrophilicity or hydrophobicity of drug substance also impacts the drug release mechanism from the PLGA matrix. Earlier studies testified that the diffusion rate of hydrophilic drugs (Aspirin, solubility-4.99 mg/mL) was substantially higher than that of the hydrophobic drug (Haloperidol, solubility-0.13 mg/mL). In hydrophobic drugs, the degree of initial burst release is lower due to its low aqueous solubility [47, 54].

-

The drug release mechanism and degradation of polymer-drug matrix changes based upon the type of drug selected.

-

Hydrophilicity (aqueous solubility) and pKa of the drug also impact the drug release from the polymer matrix.

3.2 Selection of PLGA polymer

The polymers (synthetic and natural) are used as inert material in drug delivery systems and targeted site-specific drug delivery systems. However, recently, biodegradable polymers have been increased due to upgraded cognizance in consumers about environmental safety and global warming. Upon administration, biodegradable polymers don’t produce any immunological, systemic, teratogenic, and carcinogenic reactions owing to their biocompatibility. Biodegradable polymers are retained in part of the body permanently or for a temporary period to reinstate, supplement, or substitute the natural functions of the living tissue or organs [15, 55]. These polymers are also toxicologically safe and eliminated by normal metabolic pathways after enzymatic degradation or non-enzymatic degradation.

Among all the biodegradable polymers, PLGA has gained significant attention in polymeric nanoparticle research and has been approved by the US-FDA and European Medicine Agency for drug delivery due to its wide range of applications. PLGA is widely used among the other biodegradable polymers because of the following features [56,57,58,59,60].

-

Biocompatibility and biodegradability

-

Favourable degradation characteristics

-

Possible to tune the physical properties of the polymer (e.g., the ratio of monomers, crystallinity, and molecular weight) to achieve desired dosage and drug release.

-

Sustained-release action of PLGA owing to the degradation rate of the polymer.

-

Capable of surface modifications for hydrophilic or hydrophobic small molecules and macromolecules (Proteins) for better encapsulation and effective biological interactions.

-

Protection of drug from degradation (better stability) and affinity to target specific organs or cells.

Typically, a PLGA is a linear copolymer comprised of two monomers, glycolic acid (GA) and lactic acid (LA), which the body can quickly degrade. The two different monomers have a minor difference in a structure where the glycolic acid lacks a methyl side group when compared to lactic acid. The absence of the methyl group in the polymer of glycolic acid makes it more hydrophilic with higher crystallinity to fasten the degradation rate compared to the lactic acid polymer [61]. The glycolic acid part contributes significantly to the crystallinity of PLGA. However, it has been reported that the copolymerization of glycolic acid with lactic acid reduces the crystallinity of PLGA polymer and encourages the hydration rate. Several properties of PLGA, such as mechanical strength, hydration kinetics, swelling behavior, and the biodegradation rate, are influenced by the degree of crystallinity of PLGA polymer. The type and molar ratio of the individual monomer components in the copolymer chain, i.e., the proportion of glycolic acid and lactic acid (LA/GA ratio), determines the crystallinity of the polymer [62]. The composition of PLGA polymer is a vital material attribute that influences the degradation kinetics of polymer. The degradation rate of the PLGA matrix depends on the ratio of Lactic acid (LA) and Glycolic acid (GA). Higher glycolic acid content makes the polymer more hydrophilic and exhibits faster degradation [63, 64]. For example, a more rapid rate of degradation for PLGA 50:50 (LA/GA = 50/50) is faster when compared with PLGA 85:15 (LA/GA = 85/15). The higher lactide content of PLGA 85:15 makes it more hydrophobic [65]. The drug release could achieve by changing the LA/GA ratio during the synthesis of PLGA. PLGA polymer generally exists either with ester or acid as an end group and suffers hydrolytic degradation in an aqueous environment, and the ester linkages of the polymer chain break [66]. Different grades of PLGA can obtain based on the ratio of lactic acid (LA) to glycolic acid (GA) used for the polymerization. Various grades of PLGA available commercially depending on molecular weight, viscosity, the ratio of LA and GA are described below (Table 1) with their degradation rank. Generally, PLGA polymers are amorphous and have glass transition temperature (Tg) between 45–55 °C (above 37 °C). The decrease in LA content has further been reported in a decrease in Tg of PLGAs and a reduction in molecular weight. It has also been reported that the Tg of PLGA decreases under the wet condition, which leads to the plasticization of the polymer matrix and lessening in mechanical properties of PLGA [63, 67, 68]. The physical properties of PLGA depend upon molecular weight, LA or GA ratio, and storage temperature. An increase in GA content enhances the hydrophilicity and decreases the tensile strength [64, 69].

The polymer, PLGA sometimes undergoes autocatalytic degradation in a biological system and releases Lactic-acid glycolic acid, which makes the microenvironment acid and impacts the entrapped drug's stability and soluble in a wide range of organic solvents such as Dichloromethane, Tetrahydrofuran, Ethyl acetate, Chloroform, Hexafluoro isopropanol, Acetone, and Benzyl alcohol. Regarding the selection of PLGA polymer, it can be summarized as follows [15, 70];

-

The Glycolic Acid (GA) part of the PLGA polymer contributes to the polymer's hydrophilicity and crystallinity.

-

Variation in LA/GA ratio in PLGA polymer affects the physicochemical properties like crystallinity, glass transition temperature, viscosity.

-

LA/GA ratio in PLGA polymer regulates the degradation rate and drug release. Hence, the LA/GA ratio becomes a critical CMA, which affects the polymer matrix's drug release.

-

PLGA containing high lactide (LA) content is less hydrophilic and may be used for delivery systems intending for sustained drug release delivery. PLGA possessing lower lactide (LA) content is appropriate for nanoparticle drug delivery or short-term use, or targeted use.

-

Autocatalytic degradation of PLGA polymer creates an acidic environment and may lead to instability of encapsulated drugs.

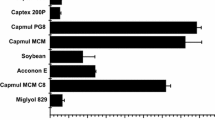

3.3 Selection of stabilizer and surfactant

Drug nanocrystal technology, a multipurpose formulation approach to enhance the pharmacokinetics and pharmacodynamics of insoluble drugs, has the drawbacks of instability caused by nucleation and particle growth [71]. The large surface area and high surface energy associated with nanoparticles encourage particle size aggregation and crystal growth (Ostwald ripening) making the nanoparticulate system thermodynamically unstable. Stabilizers play a crucial role in reducing the agglomeration potential of nanoparticles [72, 73]. The use of both polymers and surfactants or mixtures has been explored as stabilizing agents for nanoparticles by many researchers. Surfactants may be ionic or non-ionic. The ionic surfactants provide electrostatic repulsion to stabilize the nanosuspension, whereas the polymers and non-ionic surfactants facilitate the stabilization of nanosuspension by steric repulsion [74]. To facilitate the stabilization of nanoparticles by steric or electrostatic stabilization, the surfactants or polymers should be adsorbed on the surfaces of drug nanoparticles and act by decreasing Van Der Waals forces and thereby decreasing interfacial tension and rate of crystallization [75]. Commonly, the polymers act by forming a steric barrier (physical polymeric layer) around the particles, which ceases the particle motion and decreases the contact between the particles, thereby reducing the attraction forces to inhibit agglomeration [76, 77]. Polymeric stabilizers effectively inhibit the aggregation of nanoparticles by increasing the viscosity of the medium and decelerating the Brownian motion of nanoparticles [78]. A range of steric stabilizers has been evaluated for the development of drug nanoparticles, including cellulose derivative (methylcellulose, hydroxypropyl methylcellulose, and hydroxypropyl cellulose) [79, 80], polyvinyl pyrrolidone (PVP), polyvinyl alcohol (PVA) [81], poloxamer (188 and 407) and Vitamin-E TPGS [79, 82]. Suitable stabilizers at appropriate concentrations confer stability by avoiding agglomeration of the nanoparticles via steric or electrolytic stabilization [83, 84]. Surfactants offer better wetting of the hydrophobic drug nanoparticles than the polymeric stabilizers and provide better dispersibility [85]. The use of several electrostatic stabilizers like polysorbates (Tween 80), sodium lauryl sulfate (SLS), amphoteric surfactant (e.g., lecithin) have been explored by many researchers for the stabilization of nanosuspensions [86, 87]. The nanosuspensions stabilized solely by electrostatic stabilizers generally show zeta potentials of ± 30 mV [88]. If the polymer to drug ratio is less compared to the ratio of ionic surfactant to the drug, there is a probability of the rise of zeta potential value. The rise in zeta potential may be attributed to the insufficient covering drug particle by polymeric stabilizer, in which the ionic surfactant gets more access to drugs. Adsorption of anionic surfactant like Sodium Lauryl Sulfate on the surface of the drug particle leads to a high zeta potential value [89]. The stability of the nanosuspensions is generally reflected by a rise in zeta potential (to 60 mv) and zeta potentials to lower than ± 5 mV indicates agglomeration [90]. The absolute zeta potential value of ± 20 mV for a stable nanosuspension depends on selecting the types of polymeric stabilizers such as PVP and HPMC based on the drug characteristics to provide adequate stabilization. Many types of research infer that a strong affinity of nanoparticles for the polymeric stabilizer should exist for effective stabilization [91,92,93]. The hydrophobic part of the polymer chain determines the degree of adsorption of polymers to the hydrophobic drug particles. The hydrophilic moiety of the polymer chain interacts with the medium of nanosuspension for better stabilization. Hydrophilic Lipophilic Balance (HLB) of polymer or surfactant determines the degree of attraction between water and lipid and greatly impacts their application [93]. Lower the HLB signifies more lipophilicity of the polymer and vice versa. Hydrophobic drug molecules have more affinity towards lipophilic surfactants (with low HLB value). The HLB values of commonly used stabilizers are summarized in Table 1. In the case of a two-step double emulsion method (W/O/W), the surfactant having an HLB value less than 7 (preferentially around 3–4) should be preferred to prepare the primary W/O emulsions. W/O globules are generally cohesive and may tend to aggregate and coalesces. Therefore, the surfactants having a low HLB value (lipophilic) used in primary emulsion will prevent the destabilization of internal droplets. For the outer and external phases, a surfactant of high HLB value (preferably greater than 10) is essential to stabilize the globules generated after the second step emulsification [94]. The concentration of both lipophilic surfactants in the inner and hydrophilic surfactants in the external phase of W/O/W plays a crucial role in stabilizing the emulsion. The migration of lipophilic surfactants from the primary emulsion to the external phase should be balanced by the hydrophilic surfactant used in the external phase to stabilize the double structure. However, a higher concentration of hydrophilic surfactants may impact adversely, i.e., low entrapment efficiency, induces destabilization and uncontrolled droplet size [34]. Many researchers proposed that polymeric surfactants result in W/O emulsion with a stable interface and less potential for desorption or migration of stabilized internal droplets to the external phase [38]. The stability of double emulsion depends upon the balance between the surfactants used in two different phases. Therefore, the other and most significant way to improve the stability of a double emulsion is that transforming the aqueous phases (both internal and external) to a polymeric gel phase, e.g., using a polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (Poloxamer) [95]. Long-chain and high molecular weight polymers like poloxamers also provide a higher degree of steric stabilization [96]; however, with high molecular weight polymers, the rate of surface adsorption is slower [79]. The thickness of the steric or physical polymeric barrier on the drug nanoparticles should be not less than 5-10 nm to avoid weak flocculation and to provide effective steric stabilization [86, 97]. A low concentration of polymeric stabilizers would not be enough to form the desired physical barrier to afford steric hindrance, which induces aggregation. Also, too much polymeric surface stabilizer tends to increase the medium's viscosity and affects the rheological property of suspension. On the other hand, applying a high concentration of surfactant influences the formation and stabilization of the nanosuspension. A high concentration of surfactant induces the solubility of drug nanoparticles and causes Ostwald ripening. Thus, the concentration of surfactant and polymeric stabilizer is a critical attribute that needs to be optimized to achieve a stable nanosuspension [98].

Concerning the selection of stabilizers or surfactants, it can be described as follows;

-

The drug should have little solubility in the stabilizer solution.

-

Polymers and non-ionic surfactants provide steric stabilization by adsorption onto surfaces of drug particles.

-

Long-chain polymers offer a higher degree of steric stabilization.

-

Ionic surfactants stabilize nanosuspension by electrostatic stabilization.

-

The degree of adsorption of polymer on the covers of drugs or steric stabilization is powered by the force of hydrophobic moieties in the stabilizers.

-

Hydrophobic drugs have more affinity towards lipophilic surfactants (Have low HLB value).

-

For the internal phase of a W/O/W emulsion, a lipophilic surfactant has an HLB value of around 3–4. For the external aqueous phase, a hydrophilic surfactant having an HLB value greater than 10 should have better stability.

-

The drug should be protected entirely by a polymeric stabilizer for effective steric stabilization, and the adsorbed layer should be not less than 5 nm to 10 nm to avoid any weak flocculation.

-

Transformation of aqueous phase to gel phase using polymeric surfactants results in better double emulsion stability and better control of particle/ droplet size.

-

An adequate amount of stabilizer used for effective stabilization of nanoparticles

-

An increase in zeta potential reflects stability, and a fall in zeta potential confers aggregation of nanoparticles. Outright zeta potential of ± 20 mV seems to be enough to get a stable nanosuspension [99].

4 Quality by design (QbD) elements for PLGA nanoparticles

4.1 Quality target product profile (QTPP)

According to ICH Q8 (R2), the quality target product profile (QTPP) is “a prospective summary of the quality attributes of a drug product that ideally should ensure the desired quality, taking into account safety and efficacy of the drug product” (ICH, 2009). This review article focuses on defining QTPP for a prototype PLGA nanoparticle produced by a double emulsion method. To establish a QTPP for a drug product, the regulatory requirements, scientific and practical aspects, the risk involved, and safety and efficacy factors also were considered. From the QTPP, the potential CQAs, CMAs, and CPPs were selected to accomplish the predetermined qualitative product profile target (QTPP). A structured QTPP for PLGA nanosuspension is described in Table 2 [25,26,27, 100,101,102].

4.2 Critical quality attributes (CQAs)

According to the ICH Q8 definition, a Critical Quality Attributes (CQA) is a physical, chemical, biological, or microbiological property or characteristic that should be within an appropriate limit, range, or distribution to ensure the desired product quality [26]. Based on the QTPP, the quality attributes that can impact products' safety directly and efficacy is considered CQAs and monitor during product development. All the material and process-related factors influencing the CQAs are listed, and an Ishikawa fishbone diagram is made. Among the listed factors based on prior knowledge, preliminary experiment trials, detailed literature review, the most significant factors are selected, and the selected CQAs for nanosuspension are listed in Table 2 [102]. During the risk assessment, all the critical elements (CMAs, CFVs, and CPPs) should consider identifying the potential risks and corresponding causes that have the most significant contribution to product failure [25, 103,104,105,106]. The parameters such as particle size, PDI, zeta potential, entrapment efficiency, and drug release are the primary quality attributes of the nanoparticles for risk assessment and analysis of CQAs [27, 106].

4.3 Particle size, polydispersity index (PDI) and zeta potential

Particle size and distribution are essential characteristics of nanosuspensions and critically determine the drug saturation solubility, dissolution rate, physical stability, and pharmacokinetics. The particle size of nanoparticles must be in a specific range to exhibit intended pharmacokinetic characteristics. PDI is a dimensionless measurement that determines the broadness of the particle size distribution. A smaller PDI signifies the dispersion is homogenous or highly monodisperse. A broad range of particle size or high PDI value (> 1) is probably not accepted for nanosuspension. The dynamic light scattering technique (e.g., Malvern master sizer or zeta sizer) is applicable to determine the nanoparticles' average particle size and size distribution. To obtain the size distribution, it must plot the relative intensity of light scattered by particles in various size classes [18, 107, 108]. PDI value indicates the uniformity of nanoparticle dispersion. A nanocrystal dispersion with uniform particle size is termed a monodispersed system and characterized by PDI value 0. PDI value lies between 0.10 to 0.20, indicates a narrow size distribution, whereas the PDI value of 0.5 or above indicates a broad size distribution of a nanocrystal dispersion. Therefore, PDI is a tool that can show the instability of nanoparticles due to agglomeration or crystal growth of particles over time or age [109].

Zeta potential is another essential quality attribute which estimates the surface charge and significantly affects the physical stability of nanosuspension. Zeta potential with a significant positive or negative value (± 30 mV) of nanoparticles indicates excellent physical stability of nanosuspensions owing to the presence of enough electrostatic repulsion force between individual particles. Conversely, the physical instability induced by particle aggregation or flocculation phenomenon and lower the zeta potential value. The magnitude of zeta potential displays colloidal dispersion stability and a universal interpretation of zeta potential concerning stability behaviour (Table 1). The dispersion must be homogenous for enhanced zeta potential determination and should have an optimum concentration of particles to scatter the light effectively [109, 110].

4.4 Drug encapsulation efficiency

It is better to prepare a nanoparticulate system with high drug encapsulation efficiency to reduce the frequency of drug administration and better drug target. The double emulsion is a complex and time-consuming method and suffers from low drug encapsulation efficiency (DDE). Many researchers have established several efforts and controls to enhance drug encapsulation efficiency for W/O/W emulsion [111]. Generally, the formulation variables like stabilizer concentration, polymer concentration, and process parameters like stirring/sonication/homogenization speed, time, and temperature positively impact DEE. The polymers having hydrophilic groups tend to migrate into an aqueous phase, leading to the drug leaking from the nanocapsules and, thus, provide the lowest DEE [112]. The geometry of the stabilizer or and concentration also affects the DEE. A balanced geometry, long and tightly closed chain polymer/ surfactant at high concentration gives a better DEE since they provide a tightly sealed barrier around the drug substance, which improves the residence of the drug in the internal phase [113, 114]. The homogenization speed is the influential variable during the manufacturing operation of the nanoparticles formulation. This speed may significantly affect the drug entrapment efficiency of the formulations and improved the dispersion of liquids and formation of the globules during the manufacturing operations. As per the literature, the most significant effect of drug encapsulation efficiency for PLGA based nanoparticles due to the concentrations of PLGA and stabilizer, but homogenization speed shows a more negligible effect on DDE, and the % DEE is determine using equation-2 [111].

4.5 In vitro drug release

Since nanotechnology is effective drug delivery, it is essential to understand how the drug is getting released. To understand the drug release behaviour, in vitro drug release testing should be performed according to the physicochemical properties (e.g., solubility, stability, etc.) of drug substances. In vitro drug release data analysis is the significant quality control parameter to determine the in vivo drug product performance (bioavailability) and investigate the behaviour of drug products during the development stage and life cycle management. Classical analytical technologies like UV spectroscopy or high-performance liquid chromatography HPLC are used to estimate the in vitro drug release [115, 116].

4.6 Impurity or degradation products

The impurities obtained from the degradation of the drug substance or drug products mainly affect the drug product's safety. The degradation products of drug/impurities generated from the drug substances must clearly understand based on selecting the excipients, solvent system, or container closure system. The significance of the degradation products observed during manufacturing or stability studies of the drug product must be evaluated. The impurities should comply with ICH guidelines to ensure the safety of the product [116].

4.7 Pharmacokinetic study

A pharmacokinetic study or bioavailability study determines the therapeutic effectiveness of the drug product administered. A suitable animal model and a defined protocol are required to conduct pharmacokinetic or bioavailability research. Animal experiments to be performing as per the ethical committee requirement and compliance. Pharmacokinetic parameters like Cmax, Tmax, and AUC of the drug substance to be monitored to be established and compared with any referenced product (if any) to ensure therapeutic effectiveness [117].

5 Determination of CMAs, CFVs, and CPPs

5.1 Critical material attributes (CMAs)

The physical, chemical, biological/microbiological characteristics of the input material used to prepare double emulsion (W/O/W) directly impact the CQAs of the product. They should be maintained within an appropriate limit to ensure the desired quality of the product. A CMA can be a CQA of excipient or drug substance. Sometimes the variability in the manufacturing process or starting material can lead to changes in CQAs of excipients and drug substances. It is essential to identify those CQAs of excipients and drug substances that are liable to change. For those, an appropriate limit or range has to be established to get the material's inconsistent quality to meet the desired quality of the product. For PLGA nanoparticle prepared by double emulsion, the properties of PLGA (LA/GA ratio, molecular weight, Tg, etc.), properties of drug substance (solubility, crystallinity, etc.), features of stabilizer (HLB value, molecular weight, crosslinking, etc.) and properties of solvents are the probable CMAs to be considered. All the critical attributes about drug substance, PLGA polymer, and stabilizer, which can impact drug products' CQA, need to be evaluated to achieve a stable double emulsion [117,118,119].

5.2 Critical formulation variables (CFVs)

A certain level of concentration of ingredients is required to develop a product with the desired quality and stability. The quality of the product can be changed due to the change in the level of concentration of these ingredients. Therefore, it is recommended to establish a fixed or a range of levels at which the desired quality of product will be ensured. It is always advantageous to optimize the formulation at different levels of excipients or ingredients and evaluate the interaction between the excipients at a different level to design a stable and robust product. The formulation factors by which the quality of the product can be altered due to change in their standards and due to the interaction with other factors are called Critical Formulation Variables. For PLGA nanoparticles prepared by double emulsion, the concentration of the drug/PLGA/stabilizer and the ratio of organic phase to aqueous phase are the critical formulation variables for a nanosuspension prepared by double emulsion [118, 119]. The concentration of polymer may be a crucial factor influencing the properties of the particles, and it may affect the entrapment efficiency as well. It has been observed that there is no significant effect until a specific percentage of polymer, and beyond that, by increasing its concentration, the particle size also increases [120]. Drug or polymer ratio to be chosen based on the intent of use, i.e., long-term (control drug) delivery or short-term or targeted delivery. With a 1:1 drug/polymer ratio, biphasic and faster drug release could be achieved, whereas increasing polymer concentration, a monophasic, and control drug release may be achieved [121]. The biphasic drug release observed with the formulation having a 1:1 drug/polymer ratio may be attributed to the presence of drug particles close to or at the PLGA surface, which contributes to initial burst release [122]. Subsequently, the drug release gets delayed due to the gradual release through the thicker drug depleted layer [123]. Many research works suggest that the concentration of hydrophobic emulsifiers in primary emulsion (W/O), level of stabilizer (hydrophilic) in the external phase, and the ratio of organic phase to aqueous phase are the other important factor influencing particle size and their long-term stability. The hydrophobic emulsifier used in primary emulsion (W/O) at higher concentrations increases the more stable double emulsion and higher encapsulation efficiency. In contrast, the concentration of hydrophilic surfactant (high HLB value) is the primary factor responsible for the stability of W/O/W emulsion. However, increasing the concentration of hydrophilic surfactants in the external phase may decrease the encapsulation efficiency and impact the particle size [124]. The stable W/O emulsion (primary emulsion) will be prepare by using hydrophobic emulsifiers at a higher concentration, i.e., around 10–30% w/w (classical surfactants or non-polymeric surfactant) or at a lower concentration of polymeric surfactants at about 3–5%w/w of W/O emulsion [23, 38, 125]. The amount of stabilizer in the external aqueous phase contributes significantly to the stabilization of double emulsion droplets against coalescence. It has been reported that with the higher concentration of hydrophilic surfactant, smaller droplets are getting obtained but with a decreased encapsulation efficiency [126]. It has been reported that the hydrophilic emulsifier at low concentrations, i.e., 0.5–5% w/w of total emulsion, will yield a stable emulsion. The ratios of the aqueous phase and organic phase, and polymer concentrations mainly impact the nanosuspension's stability prepared by the emulsion method. With a low volume ratio and a higher concentration of polymer, the fragmentation of bigger droplets to smaller ones is very difficult during the subsequent emulsification step, which resulted in increased droplet size. On the other hand, the higher volume ratio (water/organic solvent) leads to higher drug loading efficiency. Still, it may yield higher porosity of the globules and internal network [119, 127, 128].

5.3 Critical process parameters (CPPs)

The process parameter whose variability has a direct impact on drug product CQAs is known as CPPs. Therefore, these CPPs should be monitored or controlled to ensure the manufacturing process produces the product's desired quality. These CPPs should be optimized to establish the operating range or limits where the manufacturing process will provide the products with the desired quality. PLGA nanoparticle prepared by double emulsion process is a two-step emulsification process. Rate of the addition of aqueous phase to the organic phase, stirring time, stirring speed, rate of acquisition of internal emulsion to external stage containing stabilizer, sonication or homogenization time, sonication amplitude/ homogenization speed, and temperature are the probable CPPs that can impact the CQAs of the drug product [117,118,119]. An energy contribution is an utmost requirement to enhance the dispersibility of the aqueous phase in an organic phase or lipid phase. Stirring or homogenization, or sonication methods used in the preparation of polymeric nanoparticles, provides the required energy to make the different phases miscible. The stirring or sonication speed for an emulsion process is an essential factor that contributes significantly to the resultant particle size distribution because the speed generates adequate energy to mix dispersion. Stirring/ sonication time for secondary emulsion significantly impacts the particle size distribution. If the secondary emulsion is not adequately dispersed, it may cause aggregation particles and larger particles. The high rate of stirring speed during the emulsification process reduces the particle size of the primary emulsion [129, 130]. Therefore, an optimum stirring speed and time can produce encouraging results rather than a very high/low speed. The temperature during the solvent evaporation process also influences the property of PLGA nanoparticles prepared by the double emulsion method. The particle size or distribution of the emulsion globules increase with temperature. Rapid evaporation occurs at high temperatures, and nanoparticles from a low viscosity solution are transformed into a high viscosity solution. The stirring rate significantly influences the particle size distribution during evaporation. It has been reported that evaporation at low temperatures yields porous and thick nanoparticles, whereas evaporation at high temperatures presents a more homogeneous polymeric layer [127, 128]. The complete list of the CMAs, CFVs and CPPs QbD based parameters for the manufacturing of PLGA nanoparticles by the double emulsion method (Fig. 5). After identification of all the critical factors associated with the input materials (CMA), formulation (CFV), and manufacturing process (CPP), then implement the QbD tools to optimize the potential factors to control the source of variability. The commonly used QbD tools like Risk assessment, Design of Experiment (DoE), and Process Analytical Technology (PAT), etc., enable us to create a design space and to arrive at the control strategies to address the variability associated with input materials, formulation, and process. The fishbone diagram or Ishikawa diagram is a cause-and-effect diagram for QbD prospects of pharmaceuticals application of double emulsion method for PLGA loaded nanoparticles (Fig. 6) [26].

5.4 Risk assessment

Risk assessment is a systematic process of identifying and analyzing the potential events that may negatively impact the outcome and make a judgment on the risk-based risk analysis's tolerability. Risk assessment consists of various steps like risk identification, risk analysis, risk evaluation, risk control, risk reduction, and risk acceptance [ICH Q9]. ICH Q9 provides a non-exhaustive list of risk assessment tools. Cause and Effect Diagrams (Ishikawa fishbone diagram) and Failure Mode Effects Analysis (FMEA) models are popularly used for risk assessment. An example of risk assessment for PLGA nanosuspension is given below for reference, as shown in Table 3 [131].

6 Design of experiment (DoE) and design space

DoE is a structured and organized approach to establish a relationship between factors affecting the CQA of the drug product. Based on risk assessment, the potential factors affecting CQA must be listed for further study. An excellent study design is based on a comprehensive understanding of the product and effective management of the whole process. DoE helps identify the potential factors (CMAs, CFVs, and CPPs) affecting CQA and optimal conditions for these factors in a structured manner called design space. As per ICH Q8, design space is a three-dimensional combination and interaction of input variables and process parameters that have been demonstrated to assure quality. Design space determines the edge of failure for process parameters or material attributes, beyond which the relevant quality attributes cannot be met. Any change within the design space is not considered a change and does not impact the CQA of the drug product. It is always recommended to explore a screening model (Fractional factorial or Placket Burman design) to identify the potential factors (if the no. of consideration is more than 5) and then an optimization design (Box Behnken, Central Composite, or any Optimal design) to arrive at design space. Finally, control strategies to be designed for each material attribute, formulation variables, and process parameters to ensure that a product of required quality will be produced consistently through the life cycle [26, 27].

7 Peptides and proteins loaded PLGA nanoparticles using the double emulsion method

Priwitaningrum DL et al., 2020 prepared a Smac-CPP-loaded PLGA nanoparticles by a double emulsion solvent evaporation method as follows; The internal water phase, which was 100 µL of 10 mg/mL Smac-CPP solution in buffered sodium chloride solution (NaCl 8.2 g, NaH2PO4.12H2O 3.1 g, NaH2PO4.2H2O 0.3 g in 1L of water for injection, pH 7.4), was emulsified in 2 mL ethyl acetate containing 30% (w/w) mPEG2000-PLGA blended with PLGA (lactide/glycolide molar ratio 50:50, IV = 0.4 dL/g, molecular weight of 44,000 Da), the total polymer concentration was 2.5% w/v. The emulsification was performed in an ice-bath using an ultrasonic homogenizer for 30 s at 10% power output. Subsequently, the formed w/o emulsion was added to an external aqueous phase of 2 ml of 2% PVA (w/v) (Mw 30,000–70,000 Da). A water-in-oil-in-water (w/o/w) emulsion was subsequently formed by sonication for 1 min at 10% power output. Next, the double emulsion was transferred into 45 mL of 0.3% PVA (w/v), and stirred overnight at room temperature to allow evaporation of ethyl acetate and to solidify the emulsified droplets. Nanoparticles were collected by centrifugation for 20 min at 20,000 rpm, and the supernatant was discarded. Finally, the particles were washed with 30 mL of PBS and water, and lyophilized. To prepare empty NPs and Cyanine 3 dye (Cy3)-labeled Smac-CPP loaded NPs, 100 µl PBS solution and 100 µl of Cy3-Smac-CPP were added as 7 internal water phase, respectively. Lyophilized Smac-CPP-loaded NPs were subsequently labeled with Cy3 for in vitro uptake study [132].

There are other several studies in the literature investigating in vitro and in vivo immunogenicities of PLGA based vaccine formulations loaded with single leishmanial antigen. Recently Tosyali OA, et al., 2021 prepared a nano-co-delivery of lipophosphoglycan with soluble and autoclaved leishmania antigens into PLGA nanoparticles vaccine formulations by encapsulation of SLA-LPG and ALA-LPG dual antigens, characterize synthetized nanoparticles with different methods and evaluate their in vitro and in vivo immunostimulatory activities against visceral leishmaniasis and examining vaccine efficacies of PLGA nanoparticles carrying dual Leishmania antigens. PLGA nanoparticles by this method also improved the humoral and cellular immune responses without leading to any side effects, no toxicity against macrophages and produce nitric oxide and cytokines, and reduced the parasite burdens in murine visceral organs following to infection challenge [133].

8 Conclusions and future perspectives

Over the years, PLGA has gained much attention for drug encapsulation to prepare polymeric nanoparticles for complete range applications. Like the US FDA and European Medicine Agency, many regulatory agencies have also accepted the use of PLGA due to its biocompatibility and biodegradability. The double emulsion method for the preparation of nanocrystals for hydrophilic drugs is a complicated approach. PLGA nanoparticles by double emulsion (W/O/W) is a promising vehicle, which targets to encapsulate the hydrophilic drugs to enhance their therapeutic effectiveness, prolong the drug release, and tissue targeting. The double emulsion method is used to encapsulate several anticancer hydrophilic medicines, proteins, and peptides because oral delivery of these hydrophilic drugs is challenging due to their extensive fast pass metabolism enzymatic degradation. The significance of stable nanoparticles in drug delivery for enhancing therapeutic effectiveness or tissue targeting and its medical application has been of great interest. The polymer, stabilizer, other composition components, and process parameters play a significant role in establishing a stable nanoparticle by the double emulsion method. Therefore, the preparation of stable double emulsions with highly controllable properties has become challenging. In this review, the double emulsion process has been described along with the components. An attempt has been made to describe the QbD approach to prepare PLGA nanoparticles by the double emulsion method. Starting from Quality Target Product Profile, selection of components of double emulsion (PLGA, stabilizer), stabilization process, and identification of CMAs, CFVs, and CPPs have been discussed in detail in this review. With the QbD approach and using suitable statistical designs to screen and optimize the potential factors affecting the critical quality attributes of stable nanosuspension with an optimal composition for PLGA nanoparticles. With the traditional product development method, the quality of the drug product is ensured by end-product testing. However, for complex formulation like PLGA nanoparticles, where many factors influence the quality of the product, the end product testing is not sufficient to define quality. QbD approach enables the manufacturer to understand and identify the variability induced by any factors during any unit operation of the product and subsequently helps to establish the controls to deliver consistent product quality. The ICH and many regulatory agencies like US FDA, EMEA, etc., have encouraged pharmaceutical industries to use more systematic and scientific tools during product development by the QbD approach. The ultimate goal of the QbD approach is to develop a pharmaceutical product with desired and consistent quality throughout its life cycle, fewer rejections, decreasing costs, and shortening review time for approval.

Abbreviations

- CFVs:

-

Critical formulation variables

- CMAs:

-

Critical material attributes

- CPPs:

-

Critical process parameters

- CQAs:

-

Critical quality attributes

- HPH:

-

High-pressure homogenization

- O/W/O:

-

Oil in water in oil emulsion

- O/W:

-

Oil-in-water

- PDI:

-

Polydispersity index

- PGA:

-

Poly-glycolic acid

- PLA:

-

Poly-lactic acid

- PLGA:

-

Poly-(lactide-co-glycolide)

- QTP:

-

Quality target product profile

- QTPP:

-

Quality target product profile

- W/O/W:

-

Water in oil in water emulsion

References

Kola Srinivas NS, Verma R, Pai Kulyadi G, Kumar L (2017) A quality by design approach on polymeric nanocarrier delivery of gefitinib: formulation, in vitro, and in vivo characterization. Int J Nanomed 12:15–28

Soni G, Yadav KS, Gupta MK (2020) QbD based approach for formulation development of spray dried microparticles of erlotinib hydrochloride for sustained release. J Drug Deliv Sci Technol 57:101684

Gad A, Kydd J, Piel B, Rai P (2016) Targeting cancer using polymeric nanoparticle mediated combination chemotherapy. Int J Nanomed Nanosurg. https://doi.org/10.16966/2470-3206.116

Doppalapudi S, Jain A, Domb AJ, Khan W (2016) Biodegradable polymers for targeted delivery of anti-cancer drugs. Expet Opin Drug Deliv 13:891–909

Desai N (2012) Challenges in development of nanoparticle-based therapeutics. AAPS J 14:282–295

Soni G, Yadav KS, Gupta MK (2019) Design of experiments (DoE) approach to optimize the sustained release microparticles of gefitinib. Curr Drug Deliv 16:364–374

Guideline ICH (2005) Pharmaceutical development Q8. Curr Step 4:11

Esma ND (2020) Development of a method for industrial production of PLGA nanoparticles with quality by design (QbD) approach. In: Nano Congress 2020, 32nd nano congress for future advancements; Webinar- June 12–13

Shirsat AE, Chitlange SS (2015) Quality by design approach to optimization of tacrolimus loaded PLGA nanoparticles. Int J Pharm Sci Res 6:4342–4353

Soni G, Kale K, Shetty S, Gupta MK, Yadav KS (2020) Quality by design (QbD) approach in processing polymeric nanoparticles loading anticancer drugs by high pressure homogenizer. Heliyon 6:e03846

Yajun L, Steven P (2012) Schwendeman. mapping microclimate pH distribution inside protein-encapsulated PLGA microspheres using confocal laser scanning microscopy. Mol Pharm 9:1342–1350

Qi F, Wu J, Hao D, Yang T, Ren Y, Ma G, Su Z (2014) Comparative studies on the influences of primary emulsion preparation on properties of uniform-sized exenatide-loaded PLGA microspheres. Pharm Res 31:1566–1574

Pistner H, Harald S, Ralf G et al (1994) Poly (l-Lactide): a long-term degradation study in vivo: part ii: physico-mechanical behaviour of implants. Biomaterials 15:439–450

Li S, McCarthy S (1999) Further investigations on the hydrolytic degradation of poly (DL-Lactide). Biomaterials 20:35–44

Astete C, Sabliov C (2006) Synthesis and characterization of PLGA nanoparticles. J Biomater Sci Polym Ed 17:247–289

Chaubal M (2002) Polylactides/glycolides-excipients for injectable drug delivery and beyond. Drug Deliv Tech 2:34–36

Biondi M, Ungaro F, Quaglia F et al (2008) Controlled drug delivery in tissue engineering. Adv Drug Del Rev 60:229–242

Gao L, Zhang D, Chen M (2008) Drug nanocrystals for the formulation of poorly soluble drugs and its application as a potential drug delivery system. J Nanopart Res 10:845–862

Song CX, Labhasetwar V, Murphy H et al (1997) Formulation and characterization of biodegradables nanoparticles for intravascular local drug delivery. J Controlled Release 43:197–212

Jalil R, Nixon JR (1990) Biodegradable poly (lactic acid) and poly-(lactide-co-glycolide) microcapsules: problems associated with preparative techniques and release properties. J Microencapsul 7:297–325

Bodmeier R, Mcginity JW (1987) The preparation and evaluation of drug poly-(DL-lactide) on drug release from biodegradable poly-(D1-lactide) drug delivery systems. Int J Pharm 51:1–8

Fong JW, Nazareno JP, Pearson J et al (1986) Evaluation of biodegradable microcapsules prepared by solvent evaporation process using sodium oleate as emulsifier. J Controlled Release 3:119–130

Garti N, Bisperink C (1998) Double emulsions: progress and applications. Curr Opin Colloid Interface Sci 3:657–667

Schuch A, Deiters P, Henne J et al (2013) Production of W/ O/W (water-in-oil-in-water) multiple emulsions: droplet breakup and release of water. J Colloid Interface Sci 402:157–164

Xu X, Khan MA, Burgess DJ (2011) A quality by design (QbD) case study on liposomes containing hydrophilic API: I. Formulation, processing design and risk assessment. Int J Pharm 419:52–59

Beg S, Swain S (2021) Introduction to the experimental designs: basic fundamentals. In: Beg S (ed) Design of experiments for pharmaceutical product development. Springer, Singapore. https://doi.org/10.1007/978-981-33-4717-5_1

International conference on harmonization (ICH) of technical requirements for registration of pharmaceuticals for human use. Quality risk management, ICH Q9, 2005. https://database.ich.org/sites/default/files/Q9%20Guideline.pdf

International conference on harmonization (ICH) of technical requirements for registration of pharmaceuticals for human use, Pharmaceutical quality system, ICH Q10, 2008. https://database.ich.org/sites/default/files/Q10%20Guideline.pdf

Muhammad I, Nadiah Z, Hatem F et al (2015) Double emulsion solvent evaporation techniques used for drug encapsulation. Int J Pharm 496:173–190

Seifriz W (1925) Studies in emulsions. J Phys Chem 29:587–600

Florence AT, Whitehill D (1985) Stability and stabilization of water-in-oil-in-water multiple emulsions. In: ACS symposium series, American Chemical Society, pp 359–380

Aserin A (2007) Multiple emulsions. Wiley Subscription Services Inc, Hoboken

Clegg PS, Tavacoli JW, Wilde PJ (2016) One-step production of multiple emulsions: microfluidic, polymer-stabilized and particle-stabilized approaches. Soft Matter 12:998–1008

Matsumoto S, Kita Y, Yonezawa D (1976) An attempt at preparing water-in-oil-in-water multiple-phase emulsions. J Colloid Interface Sci 57:353–361

Frenkel M, Shwartz R, Garti N (1983) Multiple emulsions. I. Stability: inversion, apparent and weighted HLB. J Colloid Interface Sci 94:174–178

Garti N (1997) Double emulsions-scope, limitations and new achievements. Colloid Surf A 123(124):233–246

Grigoriev D, Miller R (2009) Mono- and multilayer covered drops as carriers. Curr Opin Colloid Interface Sci 14:48–59

Goubran R, Garti N (1988) Stability of water in oil emulsions using high molecular weight emulsifiers. J Dispersion Sci Tech 9:131–148

Mora-Heuretas CE, Fessi H, Elaissari A (2010) Polymer based nanocapsules for drug delivery. Int J Pharm 385:113

Ubrich N, Bouillot P, Pellerin C et al (2004) Preparation and characterization of propanolol hydrochloride nanoparticles: a comparative study. J Controlled Release 291–300

Arshady R (1991) Preparation of biodegradable microspheres and microcapsules: 2. Polyactides and related polyesters. J Controlled Release 17:1–21

Chaisri W, Hennink WE, Okonogi S (2009) Preparation and characterization of cephalexin loaded PLGA microspheres. Curr Drug Deliv 6:69–75

Mao S, Xu J, Cai C et al (2007) Effect of WOW process parameters on morphology and burst release of FITC-dextran loaded PLGA microspheres. Int J Pharm 334:137–148

Hans ML, Lowman AM (2002) Biodegradable nanoparticles for drug delivery and targeting. Curr Opin Solid State Mater Sci 6:319–327

Hillaireau H, Couvreur P (2009) Nanocarriers entry into the cell: relevance to drug delivery. Cell Mol Life Sci 66:2873–2896

Frank A, Rath S, Venkatraman S (2005) Controlled release from bioerodible polymers: effect of drug type and polymer composition. J Controlled Rel 102:333–344

Siegel S, Kahn J, Metzger K et al (2006) Effect of drug type on the degradation rate of PLGA matrices. Eur J Pharm Biopharm 64:287–293

Li S, Girod-Holland S, Vert M (1996) Hydrolytic degradation of poly (DL-lactic acid) in the presence of caffeine base. J Controlled Release 40:41–53

D’Souza S, Faraj JA, Dorati R et al (2015) Enhanced degradation of lactide-co-glycolide polymer with basic nucleophilic drugs. Adv Pharm. https://doi.org/10.1155/2015/154239

Weiler W, Gogolewski S (1996) Enhancement of the mechanical properties of polylactides by solid-state extrusion: I. Poly (D-lactide). Biomaterials 17:529–535

Tang Y, Singh J (2008) Controlled delivery of aspirin: effect of aspirin on polymer degradation and in vitro release from PLGA based phase sensitive systems. Int J Pharm 357:119–125

Hurrell S, Cameron RE (2002) The effect of initial polymer morphology on the degradation and drug release from polyglycolide. Biomaterials 23:2401–2409

Klose D, Siepmann F, Elkharraz K et al (2008) PLGA-based drug delivery systems: Importance of the type of drug and device geometry. Int J Pharm 354:95–103

Cabezas LI, Gracia I, de Lucas A et al (2014) Validation of a mathematical model for the description of hydrophilic and hydrophobic drug delivery from biodegradable foams: experimental and comparison using indomethacin as released drug. Ind Eng Chem Res 53:8866–8873

Ratner B, Horbelt T, Hoffman A (1975) Cell adhesion to polymeric materials: implication with respect to biocompatibility. J Biomed Mater Res 9:407–423

Locatelli E, Franchini MC (2012) Biodegradable PLGA-b-PEG polymeric nanoparticles: synthesis, properties, and nanomedical applications as drug delivery system. J Nanopart Res 14:1316

Ratzinger G, Agrawal P, Korner W et al (2010) Surface modification of PLGA nanospheres with Gd-DTPA and Gd-DOTA for high-relaxivity MRI contrast agents. Biomaterials 31:8716–8723

Danhier F, Ansorena E, Silva JM et al (2012) PLGA-based nanoparticles: an overview of biomedical applications. J Controlled Release 161:505–522

Mundargi R, Babu V, Rangaswamy V et al (2008) Nano/micro technologies for delivering macromolecular therapeutics using poly(D, L-lactide-co-glycolide) and its derivatives. J Controlled Release 125:193–209

Mohamed F, Van der Walle CF (2008) Engineering biodegradable polyester particles with specific drug targeting and drug release properties. J Pharm Sci 97:71–87

Gentile P, Chiono V, Carmagnola I et al (2014) An overview of poly (lactic-co-glycolic) acid (PLGA)-based biomaterials for bone tissue engineering. Int J Mol Sci 15:3640–3659

Wang ZY, Zhao YM, Wang F (2006) Syntheses of poly (Lactic acid-co-glycolic acid) serial biodegradable polymer materials via direct melt polycondensation and their characterization. J Appl Polym Sci 99:244–252

Graham P, Brodbeck K, Mchugh A (1999) Phase inversion dynamics of PLGA solutions related to drug delivery. J Controlled Release 58:233–245

Lamprecht A, Ubrich N, Perez M et al (2000) Influences of process parameters on nanoparticle preparation performed by a double emulsion pressure homogenization technique. Int J Pharm 196:177–182

Lu J, Wang X, Muller M et al (2009) Current advances in research and clinical applications of PLGA based nanotechnology. Expert Rev Mol Diagn 9:325–341. https://doi.org/10.1586/erm.09.15

Makadia H, Siegel S (2011) Poly lactic-co-glycolic acid (PLGA) as biodegradable controlled drug delivery carrier. Polymers (Basel) 3:1377–1397. https://doi.org/10.3390/polym3031377

Passerini N, Craig DQM (2001) An investigation into the effects of residual water on the glass transition temperature of polylactide microspheres using modulated temperature DSC. J Controlled Release 73:111–115

Wu L, Zhang J, Jing D et al (2006) Wet state mechanical properties of three dimensional polyester porous scaffolds. J Biomed Mater Res 76:264–271

Lee LY, Wang CH, Smith CH (2014) Micro-porous paclitaxel-loaded PLGA foams-a new implant material for controlled release of chemotherapeutic agent. http://hdl.handle.net/1721.1/35874

Wu H, Gopal J, Abdelhamid H et al (2012) Quantum dot applications endowing novelty to analytical proteomics. Proteomics 12:2949–2961

Dolenc A, Kristl J, Baumgartner S et al (2009) Advantages of celecoxib nanosuspension formulation and transformation into tablets. Int J Pharm 376:204–212

Gao L, Zhang D, Chen M et al (2007) Preparation and characterization of an oridonin nanosuspension for solubility and dissolution velocity enhancement. Drug Dev Ind Pharm 33:1332–1339

Ali HS, York P, Blagden N (2009) Preparation of hydrocortisone nanosuspension through a bottom-up nanoprecipitation technique using microfluidic reactors. Int J Pharm 375:107–113

Verma S, Huey BD, Burgess DJ (2009) Scanning probe microscopy method for nanosuspension stabilizer selection. Langmuir 25:12481–12487

Tanvir S, Qiao L (2012) Surface tension of nanofluid-type fuels containing suspended nanomaterials. Nanoscale Res Lett 7:226

Esfandi E, Ramezani V, Vatanara A et al (2014) Clarithromycin dissolution enhancement by preparation of aqueous nanosuspensions using sonoprecipitation technique. Iran J Pharm Res 13:809–818

Rachmawati H, Al Shaal L, Muller RH et al (2013) Development of curcumin nanocrystal: physical aspects. J Pharm Sci 102:204–214

Tanaka Y, Inkyo M, Yumoto R, Nagai J, Takano M, Nagata S (2009) Nanoparticulation of poorly water soluble drugs using a wet-mill process and physicochemical properties of the nanopowders. Chem Pharm Bull 57(10):1050–1057

Ghosh I, Bose S, Vippagunta R et al (2011) Nanosuspension for improving the bioavailability of a poorly soluble drug and screening of stabilizing agents to inhibit crystal growth. Int J Pharm 409:260–268

O’Connor SM, Gehrke SH (1997) Synthesis and characterization of thermally-responsive hydroxypropyl methylcellulose gel beads. J Appl Polym Sci 66:1279–1290

Kesisoglou F, Panmai S, Wu YH (2007) Nano sizing-Oral formulation development and biopharmaceutical evaluation. Adv Drug Deliv Rev 59:631–644

Zhang ZP, Tan SW, Feng SS (2012) Vitamin-E TPGS as a molecular biomaterial for drug delivery. Biomaterials 33:4889–4906

Berglund KD, Przybycien TM, Tilton RD (2003) Co-adsorption of sodium dodecyl sulfate with hydrophobically modified nonionic cellulose polymers. 1 Role of polymer hydrophobic modification. Langmuir 19:2705–2713

Lee J, Lee SJ, Choi JY et al (2005) Amphiphilic amino acid copolymers as stabilizers for the preparation of nanocrystal dispersion. Eur J Pharm Sci 24(5):441–449

Daebis NAO, El-Massik M, Abdelkader H (2015) Formulation and characterization of itraconazole oral nanosuspension: methyl cellulose as promising stabilizer. Ely J Pharm Res 1:102

Muller RH, Jacobs C (2002) Buparvaquone mucoadhesive nanosuspension: preparation, optimization and long-term stability. Int J Pharm 237:151–161

Jacobs C, Kayser O, Muller RH (2000) Nanosuspensions as a new approach for the formulation for the poorly soluble drug tarazepide. Int J Pharm 196:161–164

Wang YC, Zhang DR, Liu ZP et al (2010) In vitro and in vivo evaluation of silybin nanosuspensions for oral and intravenous delivery. Nanotechnology 21:155

Verma S, Gokhale R, Burgess DJ (2009) A comparative study of top-down and bottom-up approaches for the preparation of micro/nanosuspensions. Int J Pharm 380:216–222

Freitas C, Muller RH (1998) Effect of light and temperature on zeta potential and physical stability in solid lipid nanoparticle (SLN (TM) dispersions. Int J Pharm 168:221–229

Papdiwal AP, Pande VV, Aher S (2014) Investigation of effect of different stabilizers on formulation of zaltoprofen nanosuspension. Int J Pharm Sci Rev Res 27:244–249

Sato T, Takeuchi H, Sakurai T et al (2015) Characterization of a riboflavin non-aqueous nanosuspension prepared by bead milling for cutaneous application. Chem Pharm Bull (Tokyo) 63:88–94

Tuomela A, Hirvonen J, Peltonen L (2016) Stabilizing agents for drug nanocrystals: effect on bioavailability. Pharmaceutics 8:16. https://doi.org/10.3390/pharmaceutics8020016

Garti N, Frenkel M, Shwartz R (1983) Multiple emulsions. Part II: proposed technique to overcome unpleasant taste of drugs. J Dispersion Sci Technol 4:237–252

Omotosho JA, Law TK, Whateley TL, Florence AT (1986) The stabilization of w/o/w emulsions by interfacial interaction between albumin and non-ionic surfactants. Colloids Surfaces 20:133–144

Liu P, Rong X, Laru J et al (2011) Nanosuspensions of poorly soluble drugs: preparation and development by wet milling. Int J Pharm 411:215–222

Tadros T (2006) General principles of colloid stability and the role of surface forces. Colloid stability. Wiley-VCH Verlag GmbH and Co. KGaA, pp 1–22

Ghosh I, Schenck D, Bose S et al (2012) Optimization of formulation and process parameters for the production of nanosuspension by wet media milling technique: effect of vitamin-E TPGS and nanocrystal particle size on oral absorption. Eur J Pharm Sci 47:718–728

Choi JY, Yoo JY, Kwak HS et al (2005) Role of polymeric stabilizers for drug nanocrystal dispersions. Curr Appl Phys 5(5):472–474

Pund S, Shete Y, Jagadale S (2004) Multivariate analysis of physicochemical characteristics of lipid based nanoemulsifying cilostazol-quality by design. Colloids Surf B Biointerfaces 115:29–36

Shah B, Khunt D, Bhatt H et al (2015) Application of quality by design approach for intranasal delivery of rivastigmine loaded solid lipid nanoparticles: effect on formulation and characterization parameters. Eur J Pharm Sci 78:54–66

Amasya G, Badilli U, Aksu B et al (2016) Quality by design case study 1: design of 5-fluorouracil loaded lipid nanoparticles by the W/O/W double emulsion-solvent evaporation method. Eur J Pharm Sci 84:92–102

Zhang L, Shirui M (2017) Application of quality by design in the current drug development. Asian J Pharm Sci 12:1–8

Marto J, Gouveria LF, Gonçalves LM et al (2016) A quality by design (QbD) approach on starch-based nanocapsules: a promising platform for topical drug delivery. Colloids Surf B Biointerfaces 143:177–185

Vitorino C, Carvalho FA, Almeida AJ et al (2011) The size of solid lipid nanoparticles: an interpretation from experiment design. Colloids Surf B Biointerfaces 84:117–130

Kan S, Lu J, Liu J et al (2014) A quality by design (QbD) case study on enteric coated pellets: screening of critical variables and establishment of design space at laboratory scale. Asian J Pharm Sci 9:268–278

Merisko-Liversidge EM, Liversidge GG (2008) Drug nanoparticles: formulating poorly water-soluble compounds. Toxicol Pathol 36:43–48

Pinto Reis C, Neufeld RJ, Ribeiro AJ et al (2006) Nanoencapsulation I. Methods for preparation of drug-loaded polymeric nanoparticles. Nanomedicine 2:8–21

Emil J, Gautam S (2019) Multifunctional nanocrystals for cancer therapy: a potential nanocarrier nanomaterials for drug delivery and therapy, Chap 4, pp 91–116. https://doi.org/10.1016/B978-0-12-816505-8.00007-2

Ajeet K, Chandra KD (2017) Methods for characterization of nanoparticles advances in nanomedicine for the delivery of therapeutic nucleic acids, Chap 3, pp 43–58. https://doi.org/10.1016/B978-0-08-100557-6.00003-1

Ahmed SH (2012) Optimizing the process parameters for encapsulation of linamarin into PLGA nanoparticles using double emulsion solvent evaporation technique. Adv Polymer Technol 1–19

Lu Z, Bei J, Wang S (1999) A method for the preparation of polymeric nanocapsules without stabilizer. J Control Release 61:107–112

Zhu Y, Zhang G, Yang H et al (2005) Influence of surfactants on the parameters of polylactide nanocapsules containing insulin. J Surfactant Detergent 8:353–358

Khoee S, Yaghoobian M (2008) An investigation into the role of surfactants in controlling particle size of polymeric nanocapsules containing Penicillin-G in double emulsion. Eur J Med Chem. https://doi.org/10.1016/j.ejmech.2008.09.045

Kreuter J (1983) Physicochemical characterization of polyacrylic nanoparticles. Int J Pharm 14:43–58

Magenhein B, Levy MY, Benita S (1993) A new in vitro technique for the evaluation of drug release profile from colloidal carriers ultrafiltration technique at low pressure. Int J Pharm 94:115–123

Navya Sree KS, Ruchi V, Girish PK et al (2017) A quality by design approach on polymeric nanocarrier delivery of gefitinib: formulation, in vitro, and in vivo characterization. Int J Nanomed 12:15–28

Padmanabha RVR, Sanjeev RA, Niyati S et al (2015) Optimization of size controlled poly (lactide-co-glycolic acid) nanoparticles using quality by design concept. Asian J Pharm. https://doi.org/10.4103/0973-8398.160310

Masato K, Shin-ichiro K, Yukihiro G et al (2017) evaluating the properties of poly(lactic-co-glycolic acid) nanoparticle formulations encapsulating a hydrophobic drug by using the quality by design approach. Chem Pharm Bull 65:218–228

Lamprecht A, Ubrich N, Perez MH et al (1999) Biodegradable monodispersed nanoparticles prepared by homogenization-emulsification. Int J Pharm 184:97

Washington C, Prosper M, Louis LG et al (2015) Preparation and evaluation of pralidoxime-loaded PLGA nanoparticles as potential carriers of the drug across the blood brain barrier. J Nanomaterials. https://doi.org/10.1155/2015/692672