Abstract

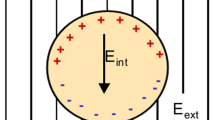

Large surface to volume ratio in zero dimension core/shell quantum dots makes lattice mismatch induced interfacial strain vital in determining structural and optical properties of nanostructures. In this study, changes in lattice mismatch induced strain from different compressive shell (CdS–ZnS) with different thicknesses (thin and thick) are evaluated and its effect on capped core diameter is theoretically calculated. Capped core squeeze amount is compared with its initial (bare) diameter obtained from transmission electron microscopy. The capped core diameter is first calculated theoretically using effective mass approximation. Then, same diameter is obtained from modified version of effective mass approximation method that considers interfacial strain amount. Comparison of the results with bare core size obtained from transmission electron microscopy revealed effect of shell thickness imposed on capped core diameter. Results show, larger lattice mismatch between core and shell induces higher strain amount on the core thereby larger squeezes the core. At the meantime, it is shown that, thicker compressive shell enforces lower stress on core as it widens its distance from core due to lattice relaxation. Hence, core is squeezes less under thicker shell.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Semiconductors have attracted huge interest in different aspects like source of light and lasers [1,2,3,4] with engineering their band structure. The nanoscale semiconductor heterostructures amd for instance core/shell quantum dots (QDs) with diameters smaller than the bulk exciton Bohr radius are new class of materials intermediates between molecular and bulk solid forms. CdSe based core–shell type quantum dots (QDs) exhibit novel properties making them attractive from both experimental and theoretical point of view [5,6,7,8,9,10,11,12]. It has been shown that coating core semiconductor with larger band gap of its kind, improve properties of nanocrystals (NCs) [13, 14]. However, it is believed that lattice mismatch between the core and shell affects structural and optical properties such as band gap energy and size in core and shell [15,16,17,18]. It has been shown that, when a compressive (tensile) stress is applied on QD, their size and band gap energy decreases (increase) [19].

In this study, modified version of effective mass approximation equation, suggested in our previous works [15,16,17,18], will be applied in calculating capped core size of type I core/shell semiconductors. Subsequently, compressive shell thickness effect on capped core size in CdSe/Cd(Zn)S QDs are evaluated. In aforementioned method, which we choose to cite as modified effective mass approximation (MEMA), capped core diameter is calculated after considering the effect of interfacial lattice mismatched strain amount in the structure, induced by shell. In our previous reports, accuracy of this method is examined in different type I and II structures with different band alignments. As an example for type II semiconductors, ZnSe core is capped with thin shell of CdS and Cd1−xZnxS [15, 16] and capped core diameter was calculated with MEMA method. In another study, CdSe core is capped with Cd1−xZnxS (0 ≤ x ≤ 1) forming type I core/shell structure and MEMA was used to obtain squeezed core diameter after compressive shell deposition [17, 18].

Here, with the MEMA method, the effect of lattice mismatch strain imposed by shell thickness on core size changes is evaluated. Influence of thin and thick compressive shell of Cd(Zn)S on CdSe core size is investigated. Comparing the calculated capped core size with the initial bare core from transmission electron microscopy (TEM) reveals core size squeeze after shell coating process. To quantitatively show this phenomenon, capped CdSe diameter is calculated using two theoretic methods; the well-known and used conventional effective mass approximation method (EMA) suggested by Brus [20] and its modified version MEMA.

2 Synthesis of CdSe/Cd(Zn)S core/shell nanocrystals

2.1 Chemicals used

Cadmium oxide (CdO, 99.5%), Selenium powder (Se, 99.99%), Sulfur powder (S, purum, 99.5%) and Tributylphosphine (TBP) were purchased from Aldrich. Paraffin liquid (chemical pure), Stearic acid (analytical grade) and Zinc acetate dihydrate (Zn(OAc)2.2H2O, analytical grade) were obtained from Sinopharm chemical. Methanol (analytical reagent), n-Hexane (analytical reagent) and Acetone (analytical grade) were also brought from Merck Chemicals. Chemical elements were used without any refinement in our synthesis.

2.2 Synthesis of CdSe core QDs

The synthesis of CdSe QDs was carried out according to Chang-Qing Zhu et al. method [21]. Briefly, Cadmium stearate was prepared by heating the mixture of CdO and stearic acid as Cd precursor. Then Se powder was added to Cd precursor mixture and heated for growth of CdSe QDs.

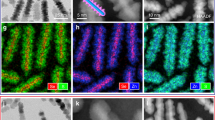

2.3 Synthesis of CdSe/Cd(Zn)S core/shell QDs

Process of capping CdSe with ZnS was carried out through Zhu et al. method [21]. Shortly, the as produced core solution (reaction for 50 min), Zn(OAc)2. 2H2O (0.01866 g) and S powder (0.00272 g) were mixed together in the reaction vessel. Under flow of N2 and heat ZnS shell starts capping CdSe in vessel. To monitor the reaction, aliquots were taken at different time intervals. CdSe NCs was capped with CdS shell using Yordanov et al. [22] method. Briefly, TBP-S was injected to the solution of CdSe QDs dispersed in cadmium stearate and paraffin under moderate stir and heat. Methanol and acetone, in sequences, added to mixture and centrifuged. Thick shell layer was deposited on the core/shell structure under the same method and conditions. Quantum dots were separated by decantation of the solution waste and applied in characterization analysis.

3 Characterization of CdSe/Cd(Zn)S core/shell QDs

3.1 Absorption and fluorescence measurements

The absorption spectra of the synthesized CdSe core and CdSe/Cd(Zn)S core/shell NCs diluted in n-Hexane is measured using the Schimadzu UV-3600 UV–Vis spectrometer. The fluorescence spectra (PL) of the QDs is also measured with the Varian Cary eclipse fluorescence spectrometer that excites with UV-light of λ = 350 nm. All characterization techniques took place at room temperature, unless stated otherwise. Figures 1 and 2 show the normalized absorption spectra for thin and thick capped layer of CdS and ZnS shell on CdSe, respectively. After deposition, CdS shell results in about 7 nm and 18 nm of red shift at its absorption peak wavelength. Red shift of 26 nm and 32 nm is observed in CdSe/ZnS after deposition of thin and thick layer of ZnS shell. Tunneling of electrons to shell and extension of electron wave function into the Cd(Zn)S shell is the reason for red shift of band gap energy in absorption spectra. This phenomenon can be explained with low energy barrier between core and shell [23, 24] and defects in the core/shell interface structure. Raise in red shift amount after second layer of shell deposition is due to thicker deposited shell.

Normalized PL spectra of CdSe/Cd(Zn)S core/shell QDs related to capping of thin and thick shell layer are given in Fig. 3. Distinct exciton peaks and red shift in both absorption and PL spectra of the synthesized CdSe/Cd(Zn)S NCs, exhibit type I heterostructure, in which exciton pairs are confined in the core. As it is mentioned earlier, when stress is applied on QD, its band gap energy changes [19]. Same phenomena repeats when core is coated with shell of different lattice parameter. Core is exposed to this stress, hence its band gap energy is modulated. Decrease in exciton energy of the coated CdSe with thicker shell is because of change in diameter of core which endures stress under compressive Cd(Zn)S shell. Thicker the shell, lower the stress on the core. In discussion section, exciton energy from absorption spectra will be substituted in EMA and MEMA in order to calculate capped core diameter. Obtained capped core diameter should be accurate by virtue of the fact that it considers both interfacial strain and shell thickness effect in MEMA method.

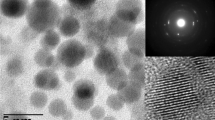

3.2 Transmission electron microscopy (TEM) characterization.

TEM measurement was carried out using JEM-ARM200F electron microscope at an acceleration voltage of 200 kV, cold FEG emitter and 0.27 eV energy spread. A drop of diluted core QDs in n-Hexane was dropped on a copper grid of 400 meshes placed over an amorphous carbon substrate for taking image. Figure 4 shows TEM image with size of initial bare CdSe (3.9 nm). Shell layers of Cd(Zn)S is capped on CdSe QDs at this size.

In many reports, deposited shell layer thickness is obtained via subtracting core/shell crystal size from bare core size using TEM images of both cases [25, 26]. Since, TEM images does not show squeezed or stretched core after being capped, it would be questionable and severely limited to predict shell thickness, as the capped core size has already changed during shell deposition [27]. We showed it earlier that with considering interfacial strain amount, capped core diameter and shell layer thickness can be obtained with high accuracy [15,16,17,18].

3.3 X-ray diffraction (XRD) measurements

X'Pert3 MRD (XL) X-ray diffractometer device is used to measure XRD pattern of the quantum dots, operating at 45 kV/40 mA using Copper Kα line (λ = 1.5406 Å).

As it is showed in Fig. 5, the XRD pattern exhibits broad peaks at \(2\theta\) values of 25° related to <111>, 42° to <220> and 49° to <311> crystalline planes for low temperature synthesized zinc-blende CdSe (Joint Committee on Powder Diffraction Standards file No. 77–2100) and any reflection pattern from wurtzite lattice structure (< 1 0 2> at 2θ≈35° and <1 0 3> at 2θ≈46°) were noticed in NCs XRD pattern. Growth of ZnS and CdS shells on CdSe led in a slight shift in the XRD pattern towards larger degrees that are indicated with red arrows in Fig. 5. When a uniform compressive strain is applied to a grain at right angles to the reflecting planes, their spacing becomes narrower and the corresponding diffraction line shifts toward larger angles [28].

4 Discussion

In this section, the capped core diameter of CdSe/Cd(Zn)S QDs is calculated after deposition of thin and thick shells. \(E_{g}^{nc} (d)\) as an excitation energy of type I quantum dots is calculated, using [29]

where \(\lambda_{\max }\) is the wavelength of the first maxima in absorption spectra and c denotes the speed of light. Using the \(E_{g}^{nc} (d)\), core size of the CdSe/Cd(Zn)S QDs is obtained from the well-known effective mass approximation (EMA) which is proposed and used for the first time by Brus [20]. At the mean time and as it was discussed elsewhere [15,16,17,18], interfacial strain amount is considered in EMA equation using the following thermodynamic relation as

Which is used in core/shell structures. Here, \(m_{e}^{*}\), \(m_{h}^{*}\) and \(\varepsilon_{\infty }\) are the effective mass of free electrons, holes and optical dielectric constant of bulk semiconductor, respectively. \(m_{cv}^{*} = (m_{e}^{*} m_{h}^{*} /(m_{e}^{*} + m_{h}^{*} )\) is the reduced effective mass of electron–hole pair (\(m_{n}^{*} = 0.13m_{ \circ }\), \(m_{p}^{*} = 0.43m_{ \circ }\) and \(\varepsilon_{\infty } = 6.2\varepsilon_{ \circ }\) for CdSe in bulk [30]). \(a_{gi} = - B(\partial E_{gi} /\partial P)\) is the bandgap deformation potential at \(i = \Gamma ,L,X\) symmetry points of core in bulk. On the other hand, \(E_{g}^{b} (T)\) is the bulk CdSe QD’s temperature dependent part for the unstrained direct bandgap energy. At the meantime and for Eq. (2), second, third and fourth terms are the strain contribution to the bulk CdSe. Hydrostatic interface strain in the core region can be written as

using continuum elastic theory (CET) [31]. In this equation,\(\varepsilon_{rr}\), \(\varepsilon_{\theta \theta }\) and \(\varepsilon_{\phi \phi }\) are the strain components in spherical coordinates. \(B_{ \circ }^{c}\) and \(\mu_{s}\) are the elastic bulk modulus of core and shear modulus of shell semiconductors, in order. \(\varepsilon_{m}\) is defined as the average lattice difference at the core/shell interface and is obtained as follow [32]:

Here \(a_{c}\) and \(a_{s}\) denote the lattice constants for core and shell in their bulk form, respectively. Form Eq. 3, 3.3% and 7.9% of compressive strain is obtained for CdSe/CdS and CdSe/ZnS, respectively. It is noteworthy to mention that the deposited shell thickness shows its effect on exciton energy in core/shell QDs as core endures stress where its band gap energy is modulated with the applied stress. Hence, aforementioned stress is considered in exciton energy from absorption spectra.

Table 1, shows the calculated CdSe core diameter after capping with compressive shells (CdS or ZnS) using Eq. 2. As it is expected, squeeze of core is noticeable from the results. Considering bare core size of 3.9 nm (TEM), deposited thin shell of ZnS and CdS, causes 6.8% and 1.8% squeeze on core, respectively. CdSe is squeezed more after capping with ZnS than CdS shell, due to larger lattice mismatch in former than the later. Growing thick shell of ZnS and CdS on CdSe core, shows less squeezed core in compare with thin shell.

However, the conventional EMA method points out stretch of the core after deposition of compressive shell in calculating capped core size (Table 2). Thereby one should be cautious in using EMA method for calculating capped core size without taking interfacial strain effect in consideration.

5 Conclusions

In this work, a comparative theoretical and experimental study to determine lattice mismatch induced strain amount on capped core diameter was presented. It was shown that, the core is squeezed after being capped with compressive shell. Induced stress amount is decreased with thicker shell deposition. Shell thickness changes shows its effect on the band gap energy and the exciton energy amount which is applied in the calculations. Capped core diameter, was calculated with considering interfacial strain effect obtained from CET in EMA method and the results were compared with bare core size obtained from TEM. It was shown that core in CdSe/ZnS structure squeezes more due to the greater lattice mismatch than CdSe/CdS. Introducing Zn(Cd)S shell on CdSe core causes 6.8% (1.8%) squeeze in core size. With our previously introduced theoretical method (MEMA), it is demonstrated that core undertakes less squeeze in case of thicker shell in both CdS and ZnS shells, due to lattice mismatch relaxation as it widens its gap between core shell interfaces.

References

Sheremet V, Genç M et al (2018) Two-step passivation for enhanced InGaN/GaN light emitting diodes with step graded electron injectors. Superlattices Microstruct 113:623–634

Sheremet V, Gheshlaghi N et al (2018) InGaN stress compensation layers in InGaN/GaN blue LEDs with step graded electron injectors. Superlattices Microstruct 116:253–261

Gundogdu S, Pisheh HS et al (2018) Time resolved Fabry-Perot measurements of cavity temperature in pulsed QCLs. Opt Expr 26(6):6572–6580

Gundogdu S, Demir A et al (2018) Low-loss regrowth-free long wavelength quantum cascade lasers. IEEE Photon Technol Lett 30(23):1997–2000

Liu GQ, Liu ZQ et al (2016) Modified spontaneous emission from CdSe/ZnS core–shell quantum dots in plasmonic–photonic crystals. Mater Lett 167:134

Davidowski SK, Lisowski CE, Yarger JL (2016) Characterizing mixed phosphonic acid ligand capping on CdSe/ZnS quantum dots using ligand exchange and NMR spectroscopy. Magn Reson Chem 54:234

Medintz IL, Uyeda HT, Goldman ER, Mattoussi H (2005) Quantum dot bioconjugates for imaging, labelling and sensing. Nat Mater 4:435–446

Michalet X, Pinaud FF et al (2005) Quantum dots for live cells, in vivo imaging, and diagnostics. Science 307:538–544

Resch-Genger U, Grabolle M et al (2008) Quantum dots versus organic dyes as fluorescent labels. Nat Methods 5:763–775

Algar WR, Susumu K, Delehanty JB, Medintz IL (2011) Semiconductor quantum dots in bioanalysis: crossing the valley of death. Anal Chem 83:8826–8837

Shi XB, Tu Y et al (2013) Photobleaching of quantum dots by non-resonant light. Phys Chem Chem Phys 15:3130–3132

Gheshlaghi N, Faraji M, Pisheh HS (2019) Structural dependent, dielectric and conduction analysis of CdSe based quantum dots. SN Appl Sci 1:401. https://doi.org/10.1007/s42452-019-0451-2

Shambetova N, Chen Y et al (2016) Acid dissociation of 3-mercaptopropionic acid coated CdSe–CdS/Cd0.5Zn0.5S/ZnS core–multishell quantum dot and strong ionic interaction with Ca2+ Ion. J Phys Chem C 120:3519–3529

Tshangana C, Nyokong T (2015) Photophysical properties gallium octacarboxy phthalocyanines conjugated to CdSe@ZnS quantum dots. Spectrochim Acta Part A Mol Biomol Spectrosc 151:397–404

Pisheh HS et al (2017) The effects of strain and spacer layer in CdSe/CdS/ZnS and CdSe/ZnS/CdS core/shell quantum dots. Phys E 85:334–339. https://doi.org/10.1016/j.physe.2016.07.007

Pisheh HS et al (2017) Composition tuning of bandgap and diameter of CdSe/Cd1–xZnx S core/shell quantum dots. Mater Sci Semicond Process 68:295–301

Gheshlaghi N et al (2017) Composition and strain effects in type i and type ii heterostructure ZnSe/Cd (Zn) S and ZnSe/Cd1–xZnxS core/shell quantum dots. Superlattices Microstruct 111:156–165

Gheshlaghi N et al (2016) Interfacial strain effect on type-I and type-II core/shell quantum dots. Superlattices Microstruct 97:489–494

Smith A, Mohs A, Nie S (2009) Tuning the optical and electronic properties of colloidal nanocrystals by lattice strain. Nat Nanotech 4:56–63. https://doi.org/10.1038/nnano.2008.360

Brus LE (1984) Electron–electron and electron-hole interactions in small semiconductor crystallites: the size dependence of the lowest excited electronic state. J Chem Phys 80:4403

Zhu C-Q, Wang P, Wang X, Li Y (2008) Facile phosphine-free synthesis of CdSe/ZnS core/shell nanocrystals without precursor injection. Nanoscale Res Lett 3:213–220

Yordanov GG, Yoshimura H, Dushkin CD (2008) Synthesis of high-quality core–shell quantum dots of CdSe–CdS by means of gradual heating in liquid paraffin. Colloid Polym Sci 286:1097

Isarov M et al (2015) The effect of low temperature coating and annealing on structural and optical properties of CdSe/CdS core/shell QDs. Lith J Phys 55:297–304

Teitelboim A et al (2016) Colloidal double quantum dots. Acc Chem Res 49:902–910

Xie R, Kolb U, Li J, Basche T, Mews A (2005) Synthesis and characterization of highly luminescent CdSe–core CdS/Zn0.5Cd0.5S/ZnS multishell nanocrystals. J Am Chem Soc 127:7480–7488

Kang T, Um K et al (2016) Minimizing the fluorescence quenching caused by uncontrolled aggregation of CdSe/CdS core/shell quantum dots for biosensor applications. Sens Actuators B Chem 222:871–878

Reiss P, Protiere M, Li L (2009) Core/shell semiconductor nanocrystals. Small 5:154–168

Khorsand Zak A, Abd Majid WH et al (2011) X-ray analysis of ZnO nanoparticles by Williamson-Hall and size–strain plot methods. Solid State Sci 13:251–256

Suresh S (2014) Studies on the dielectric properties of CdS nanoparticles. Appl Nanosci 4:325–329

Sadao A (2005) Properties of semiconductor alloys: group-IV, III–V and II–VI semiconductors. In: Wiley series in materials for electronic and optoelectronic applications. Wiley, London.

Balasubramanian S, Ceder G, Kolenbrander KD (1996) Three-dimensional epitaxy: thermodynamic stability range of coherent germanium nanocrystallites in silicon. J Appl Phys 79:4132–4136

Sneed BT, Young AP, Tsung CK (2015) Building up strain in colloidal metal nanoparticle catalysts. Nanoscale 7:12248–12265

Acknowledgements

Technical assistance of Prof. Dr. M. Ali Gülgün for TEM measurements is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gheshlaghi, N., Faraji, M. & Sedaghat Pisheh, H. Interfacial strain and shell thickness effect on core squeeze/stretch in core/shell quantum dots. SN Appl. Sci. 2, 745 (2020). https://doi.org/10.1007/s42452-020-2540-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-2540-7