Abstract

In an effort towards affordable availability of chromatographic 188W/188Re generators for widespread clinical use, we report the mechanochemical synthesis of mesoporous alumina as an advanced sorbent material for preparation of the generator. The synthesized material exhibits remarkably high sorption capacity (550 ± 12 mg W/g), which is adequate for preparation of clinical-scale generators using low specific activity (LSA) 188W produced in medium flux research reactors. Sorption of 188W in mesoporous alumina follows Freundlich adsorption isotherm and pseudo second order kinetics, indicating that the process is chemisorption. A clinical-scale (~ 14.0 GBq) 188W/188Re generator was developed and its performance was evaluated over a period of 6 months. Rhenium-188 could be consistently obtained from the generator with high yield (> 80%) and it met all the requirements for clinical use. The present strategy is expected to increase the scope of separation chemistry for availing clinical-grade 188Re for the benefit of millions of cancer patients world over.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Radionuclide generators continue to play an imperative role in providing radioisotopes for use in nuclear medicine. Efficiency, reliability, safety and cost-effectiveness are the key parameters that govern the development of next-generation radionuclide generators for regular usage in clinical context. To a large extent, progress in design of improved radionuclide generators is dependent on the advancements in separation science and technology [1]. Owing to its simplicity and convenience to use in hospital radiopharmacies, the column chromatographic separation technique has found the widest application in development of radionuclide generators. Basically, the ‘heart’ of any column chromatographic separation process is the sorbent and hence progress in this field is related to evolution of materials chemistry towards synthesis of advanced sorbent materials.

Synthesis of advanced sorbent materials with high capacity and improved performance towards development of radionuclide generators has now become a continuing object of research with potential for clinical translation [2]. In this regard, sorbent materials with regular and relatively large mesopores tend to become indispensable. There have been numerous reports of synthesis of mesoporous materials over the last several years [3,4,5,6,7]. Driven by the need for new, cleaner, scalable, highly efficient and more sustainable synthetic methodologies, solid state mechanochemical approaches for synthesis of mesoporous materials has seen a reawakening during the past few years [8, 9]. These techniques have not only been demonstrated as feasible alternatives to conventional solution-based syntheses, but they have also received consideration for their ability to enable high mesoporosity and thus develop novel sorbents for radionuclide generators. The solid-state synthesis route is easily amenable for scale up for synthesis of large quantities of sorbents required for the preparation of multiple radionuclide generators in order to meet the demands of the nuclear medicine community.

Rhenium-188 (T½ = 16.9 h, Emax = 2.12 MeV, 155 keV γ-ray) is an established therapeutic radioisotope that can be obtained in a no-carrier-added (NCA) form via 188W/188Re generator for preparation of a wide variety of radiopharmaceuticals [10]. The parent 188W can be produced with adequate specific activity by double neutron capture i.e. 186W (n,γ) 187 W (n,γ) 188W reaction on enriched 186W target in high flux research reactors (> 1015 n·cm−2·s−1) [10]. There are only very few operational high flux research reactors in the world. As a result, the widespread and cost-effective availability of clinically useful 188 W/188Re generators is compromised. In order to enhance the scope of utilization of 188Re in clinical domain, it is essential to utilize relatively LSA 188 W produced in medium flux research reactors for the preparation of 188 W/188Re generators. According to the International Atomic Energy Agency—Research Reactor Database (IAEA-RRDB), there are more than 50 operational medium flux research reactors world over and they are located in good geographical distribution to meet the supply logistics [11]. Utilization of LSA 188W produced in these research reactors mandates the need for high capacity advanced sorbent materials for preparation of clinically useful 188W/188Re generators. In the past, many high capacity sorbent materials such as polymeric zirconium compound, polymeric titantium oxychloride, synthetic alumina, polymer embedded nanocrystalline titania, nanocrystalline zirconia and nanocrystalline alumina, etc., have been reported for preparation of chromatographic 188W/188Re generators [10, 12,13,14,15,16,17,18,19]. Despite their high sorption capacity, most of these generators used high specific activity 188W produced in high flux research reactors. In fact, the development of clinical-scale generators using LSA 188W produced in medium flux reactors is yet to commence in commercial settings.

In this study, we report the synthesis of mesoporous alumina sorbent by solid state mechanochemical approach and its utilization as a chromatographic sorbent in preparation of 188W/188Re generator using LSA 188W produced in a medium flux research reactor. The sorption characteristics of the material were investigated and conditions were optimized for chromatographic separation of 188Re from 188W. Detailed quality assessment tests were carried out over a period of 6 months to analyze the suitability of 188Re obtained from the 188W/188Re generator for clinical use. To the best of our knowledge, this is the first study on detailed investigation of tungsten-sorption characteristics of mesoporous alumina and its utilization as a chromatographic sorbent for preparation of a clinical-scale 188W/188Re generator using 188W produced in a medium flux research reactor.

2 Experimental

Enriched (99.9% in 186W) tungsten oxide was purchased from Isoflex, Russia. All other chemicals were purchased from Sigma-Aldrich and used as received.

Mesoporous alumina was synthesized by mechanical grinding of aluminum isopropoxide and glucose taken in different molar ratios (1:1, 1:1.25, 1:1.5, 1:1.75 and 1:2) in an agate mortar at room temperature for 1 h. After grinding, the reaction mixture was calcined in a furnace at 500 °C for 2 h. The lump obtained after calcination was crushed and sieved to get free flowing particles of 50–100 mesh size. The detailed procedure for optimization of the synthesis protocol and thorough characterization of the synthesized material are described in the Supporting Information.

For understanding the sorption of tungsten on mesoporous alumina synthesized under the optimized conditions, 187W produced via natW (n,γ) 187W reaction by irradiation of natural tungsten oxide powder in the Dhruva reactor at a flux of 1 × 1014 n.cm−2.s−1 for 7 d was used as radiotracer. For this, neutron irradiated natWO3 powder was dissolved in 4 M NaOH solution in presence of few drops of 30% H2O2 to convert it into [187W]Na2WO4. The distribution coefficients (Kd) values of tungstate and perrhenate ions for the sorbent matrix were measured at different pH, using 187W and 188Re as radiotracers, as per the procedure described in the Supporting Information. Sorption studies were carried out both by batch equilibration method as well as under dynamic (column flow) condition. In batch equilibration method, an accurately weighed amount of sorbent (50 mg) was taken in a stoppered glass conical flask and equilibrated with 10 mL of the tungstate solution of varying concentration (1, 2.5, 3.7, 5.6, 7.4 mg W / mL), spiked with ~ 370 kBq (10 μCi) of 187W for 4 h at pH 3. Subsequently, the contents were filtered and the activity of the filtrate was compared with that of the standard solution taken from the equilibrium mixture before incubation with the sorbent. Similarly, kinetic studies were carried out by taking 3.7 mg W/mL solution (pH ~ 3) spiked with ~ 370 kBq (10 μCi) of 187 W and sorption capacities were determined at different time intervals as described above. The dynamic sorption capacity was determined by passing 10 mg W/mL solution spiked with ~ 370 kBq (10 μCi) of 187W through a chromatographic column packed with 1 g of mesoporous alumina at a flow rate of 1 mL/min, as per the reported procedure [9].

The theoretical specific activity of 188W produced by double neutron capture reaction on 186W target at different flux conditions was calculated by simplified Bateman equations as detailed in the Supporting Information. Under the optimized conditions, 188W was produced by irradiation of enriched (99.9% in 186W) tungsten oxide (1.25 g) at a flux of 1.5 × 1014 n.cm−2.s−1 for 6 months. Post irradiation, the neutron irradiated 186WO3 powder was converted to [188W]Na2WO4 by dissolving it in 20 mL of 4 M NaOH containing few drops of 30% H2O2. The 188W/188Re generator was prepared by taking 4 g of mesoporous alumina in a chromatographic column placed in a lead shielded assembly. The activity was loaded in the column by passing 188W solution (14.1 GBq, 100 mL at pH ~ 3) through the column at a flow rate of 1 mL/min. Rhenium-188 was regularly eluted from the 188W/188Re generator in saline solution [0.9% NaCl (w/v) solution prepared in deionized water] and the performance of the generator was evaluated over a period of 6 months. The details regarding preparation of the 188W/188Re generator and its quality control are provided in the Supporting Information.

3 Results and discussion

3.1 Synthesis and characterization of the sorbent

The sorbent, mesoporous alumina, was synthesized by solid state mechanochemical reaction of aluminum isopropoxide with glucose, followed by calcination at 500 °C. The glucose acted as template which could be removed during calcination leading to formation of gases which resulted in creation of mesopores in the sorbent matrix [8, 9]. The balanced chemical equation for this process can be written as:

As predicted from this equation, 2 molecules of aluminum isopropoxide reacts with 1 molecule of glucose for getting 1 molecule of aluminum oxide product. However, in order to obtain higher mesoporosity and hence higher sorption capacity of mesoporous alumina, higher amount of glucose content (than the amount predicted from the balanced chemical equation) was required in the reaction mixture. For maximizing the sorption capacity, the molar ratios of the aluminum isopropoxide to glucose in the reaction mixture were varied and the reactions were carried out under identical conditions, as detailed in the Supporting Information. Based on the mesoporosity (Figure S1, Figure S2 and Table S1) and sorption capacity (Table S2) studies, the material synthesized by maintaining aluminum isopropoxide to glucose molar ratio in the reaction mixture as 1:1.5 was identified as the optimal material for preparation of the 186W/188Re generator. The material synthesized under the optimized synthetic condition was free flowing and exhibited adequate mechanical strength for use as a sorbent matrix in a chromatographic procedure.

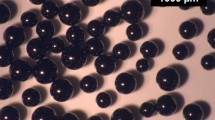

The X-ray diffraction (XRD) pattern of mesoporous alumina indicated that the material is nanocrystalline, with peaks assigned to (3 1 1), (4 0 0) and (4 4 0) planes of cubic alumina (Fig. 1a). From the XRD pattern, the average crystallite size of the material was determined to be 2.4 ± 0.1 nm, using the standard Debye Scherrer’s equation. The scanning electron microscopy (SEM) of the material showed worm-hole like structure which gives an idea that it is porous (Fig. 1b). The energy dispersive spectroscopy (EDS) showed peaks corresponding to Al and O. The SEM image of the overall particles is shown in Figure S3A. The transmission electron microscopy (TEM) of the mesoporous alumina showed that the material is nanosized but highly agglomerated (Fig. 1c). Agglomeration is essential in order to use a nanomaterial as a sorbent matrix in a chromatographic column [20]. The crystallite size of the material as evident from the TEM micrograph was in the range of 2–4 nm, which substantiated the results obtained from the XRD studies. The size distribution of the agglomerated particles as determined by laser diffraction technique is shown in Figure S3B and the mean particle size was determined to be 57.3 ± 1.6 μm.

Characterization of mesoporous alumina (a) XRD pattern, (b) SEM micrograph. Inset shows the EDS spectrum, (c) TEM micrograph, (d) Combined SAXS and MSANS profile. MSANS profiles are scaled to SAXS data in the overlapping q range, (e) Pore size distribution obtained from the SAXS-MSANS profile, (f) Pore size distribution from nitrogen adsorption desorption isotherm. Inset shows the type IV isotherm

The porous structure of the material was investigated by combined small angle X-ray scattering (SAXS) and medium resolution small-angle neutron scattering (MSANS) techniques, using a laboratory based SAXS and nuclear reactor based MSANS facility for accessing a wide q range [8, 9]. The scattering profile did not show any diffraction peak, indicating the absence of ordered pores in the material (Fig. 1d). From the SAXS-MSANS study, the pore size distribution showed that the average pore diameter of the material was 3.4 ± 0.2 nm, proving that it is mesoporous (Fig. 1e). This was further corroborated by conventional nitrogen adsorption–desorption method, which showed type IV isotherm characteristic of mesoporous materials and the average pore diameter was determined to be 3.6 ± 0.3 nm (Fig. 1f).

The surface charge on mesoporous alumina was analyzed at different pH environments by determining the zeta potential (Table 1). Under the acidic conditions, the material showed positive zeta potential with maximum value (48.5 ± 3.7 mV) at pH 3. On increase of pH beyond 6, the zeta potential became increasingly negative. The isoelectric point was attained between pH 6 and 7.

3.2 Sorption characteristics of mesoporous alumina

In order to understand the sorption characteristics of mesoporous alumina, the distribution coefficients (Kd) of tungstate and perrhenate ions were determined at different pH and the results are summarized in Table 1. Under all conditions, the Kd values for tungstate ions are much higher than that of perrhenate ions, indicating the high affinity of the sorbent towards tungstate ions. The maximum Kd value was obtained at pH 3, indicating that this is the most favorable condition for sorption of 188W in the generator column. At pH < 6, tungstate ions polymerize to form highly negative polytungstate [HW6O21]5− ions [21]. It is pertinent to note that the zeta potential to the sorbent was maximum positive at pH 3, resulting in high sorption of negatively charged [HW6O21]5− ions on mesoporous alumina. In saline solution, the Kd value for tungstate ions is appreciably high (15,521 ± 231) and that for perrhenate ions is negligibly low (0.2 ± 0.1). Therefore, saline is a suitable medium for selective elution of 188Re from the generator column.

The uptake of polytungstate ions on mesoporous alumina under acidic conditions is expected to occur in two steps. The first step is due to electrostatic attraction of negatively charged polytungstate ions on the positively charged surface of alumina under acidic conditions. In the second step, thermodynamically stable complexes of tetrahedrally coordinated aluminum atoms and WO42− tetrahedrons are formed, resulting in strong binding as evident from the high Kd values [22]. On the other hand, perrhenate ions cannot form complex with the alumina matrix and therefore manifests low Kd values.

The tungstate sorption isotherm was analyzed at room temperature (298 K) by the following three models [23]:

Langmuir model:

A linear form of this equation is:

where, Q0 and b are Langmuir constants that are related to the maximum sorption capacity and sorption energy, respectively.

Freundlich model

Equation (4) can be rewritten as:

where, KF is Freundlich constant and n is Freundlich exponent (dimensionless).

Dubinin–Radushkevich (D–R) Isotherm

where, Xm is the maximum sorption capacity, β is the activity coefficient related to the mean sorption energy, and ε is the Polanyi potential, which can be written as

where, R is the universal gas constant [expressed in units of kJ/(mol.K)] and T is the temperature (in K). In all these models, qe is the amount of tungstate ions adsorbed on mesoporous alumina at equilibrium (expressed in terms of mg/g), Ce is the equilibrium concentration of metal ions (expressed in terms of mg/L). From the fittings (Fig. 2a, Figure S4), it could be inferred that the equilibrium data could be fitted well with Freundlich model with R2 = 0.99, which implied that adsorption occurred on a heterogeneous surface, where the adsorption energy exponentially reduced with decrease in number of adsorption sites [24]. The values of KF and 1/n were determined to be 47.01 mg g−1(mg L−1)−1/n and 0.24, respectively. Because the value of 1/n is less than unity, it indicates a favorable adsorption [23].

The kinetics for tungstate sorption by mesoporous alumina was analyzed at room temperature (298 K) by two kinetic models [23].

Pseudo-first-order reaction

Pseudo-second-order reaction

where, k1 and k2 are the rate constants for the pseudo-first-order and pseudo-second-order reactions respectively, qe is the amount of metal ion adsorbed at equilibrium time (expressed in units of mg/g) and q is the amount of metal ion adsorbed at any time (also expressed in units of mg/g). Integrating Eq. (9) for the boundary conditions of t = 0, q = 0 gives the linear equation:

From the fittings (Fig. 2b, Figure S5), it could be inferred that the sorption process follows pseudo-second-order kinetics indicating that the process is chemisorption and irreversible [25]. The kinetic parameters k2, qe and h were determined to be 3.07 × 10−4 g min−1 mg−1, 312.5 mg g−1 and 30.1 mg g−1 min, respectively. It is pertinent to mention here that adsorption mechanisms cannot be accurately assigned based on observing simple kinetic experiments or by fitting kinetic models [26, 27]. They can only be established by using several analytical techniques [27]. However, such studies have not been pursued as they were outside the scope of the present work.

Under dynamic conditions, the breakthrough capacity of the sorbent was determined to be 550 ± 12 mg W/g (Fig. 3), which is ~ 10 times higher than the conventionally used bulk alumina [28]. A comparative evaluation of the breakthrough capacity of mesoporous alumina determined under dynamic conditions with that of other high capacity sorbents reported for the preparation of 188W/188Re generator is provided in Table 2. It can be seen from the table that the breakthrough capacity of mesoporous alumina is much higher than that of other reported materials, which demonstrates its suitability for preparation of clinical-scale 188W/188Re generator.

3.3 Production of 188W and development of 188W/188Re generator

The theoretical specific activity of 188W calculated using simplified Bateman equation under different neutron flux conditions is shown in Figure S6. The specific activity of 188W increased with increase in flux and an irradiation period of ~ 6 months was required to get appreciable specific activity. On irradiation of 1.25 g of enriched (99.9% in 186W) tungsten oxide target at a flux of 1.5 × 1014 n.cm−2.s−1 for 6 months, 15.1 ± 0.4 GBq of 188W could be produced with a specific activity of 15.0 ± 0.3 GBq/g which is comparable to that obtained by theoretical calculation.

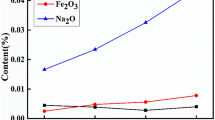

A 14.0 GBq 188W/188Re generator (Figure S7) was developed and its performance was evaluated over a period of 6 months. The elution profile of the generator was recorded at the beginning of every month and shown in Fig. 4a. The elution profiles are reasonably sharp and they gradually broadened with passage of time. The gradual broadening in elution profiles is not unexpected and is due to decay loss of 188W and repeated elution of 188Re from the same generator column over a prolonged period of time. Nevertheless, it can be seen from the elution profiles that 188Re could be quantitatively eluted in 8 mL of saline solution. In the conventional bulk alumina based 188W/188Re generators, a much larger volume of saline solution (> 15–20 mL) is required for elution of 188Re [29]. As evident from the elution profiles (Fig. 4a), the radioactive concentration of 188Re could be further increased by adopting fractionated elution approach. The elution yield of 188Re was initially ~ 90% and it marginally decreased over the period of 6 months of study (Fig. 4b). A typical γ-spectrum of 188Re eluted from the generator is shown in Figure S8. From the analyses of the decayed samples of 188Re, the level of 188W impurity could be quantified as < 10−4% over the 6 months of elution (Fig. 4c). The radiochemical purity of 188Re in the form of ReO4− was > 98%, as determined by the paper chromatographic study (Figure S9). Inductively coupled plasma—atomic emission spectroscopy (ICP-AES) analysis of the decayed samples revealed that the level of tungsten impurity was below detectable limit (< 0.01 ppm) and the level of Al ions was 0.11 ± 0.02 ppm. No other trace metal impurity could be detected in the 188Re samples indicating high chemical purity for preparation of radiopharmaceuticals. This performance remained consistent even after 6 months of usage of the 188W/188Re generator, indicating high stability of the mesoporous alumina sorbent even in intense radiation environment. If mesoporous alumina sorbent did not retain its stability over a prolonged period of time, deteriorating performance of the 188W/188Re generator in terms of increased 188W breakthrough and significant amounts of Al ions impurity would have been observed in the 188Re eluate.

In all the batches, the 188Re eluate was found to be sterile and the level of bacterial endotoxins was < 25 EU, which is within acceptable limit as per Indian Pharmacopeia [30]. Overall, it could be inferred from these quality control studies that 188Re obtained from this generator was amenable for use in clinical context.

4 Conclusions

In summary, solid state mechanochemistry has been found to be a viable method for synthesis of mesoporous alumina sorbent for preparation of chromatographic 188W/188Re generator using 188W produced in a medium flux research reactor. The sorbent exhibits high sorption capacity (~ 550 mg W/g), which is adequate for preparation of clinical-scale generator. The 188Re obtained from this chromatographic generator met all the requirements for clinical use. Adoption of this strategy would aid towards wider availability of 188W/188Re generators for clinical use at more affordable cost, since 188W produced in medium flux research reactors could be effectively utilized. This would be especially beneficial for developing countries which do not have access to high flux research reactors for radioisotope production.

References

Dash A, Chakravarty R (2014) Pivotal role of separation chemistry in the development of radionuclide generators to meet clinical demands. RSC Adv 4:42779–42803. https://doi.org/10.1039/C4RA07218A

Dash A, Chakravarty R (2017) Nanomaterial-based adsorbent: promises, opportunities, and challenges to develop column chromatography radionuclide generators for nuclear medicine. Sep Purif Rev 46:91–107. https://doi.org/10.1080/15422119.2016.1205089

Yamauchi Y, Nagaura T, Ishikawa A, Chikyow T, Inoue S (2008) Evolution of standing mesochannels on porous anodic alumina substrates with designed conical holes. J Am Chem Soc 130:10165–10170. https://doi.org/10.1021/ja7107036

Wu C-W, Yamauchi Y, Ohsuna T, Kuroda K (2006) Structural study of highly ordered mesoporous silica thin films and replicated Pt nanowires by high-resolution scanning electron microscopy (HRSEM). J Mater Chem 16:3091–3098. https://doi.org/10.1039/B604062D

Nandi M, Mondal J, Sarkar K, Yamauchi Y, Bhaumik A (2011) Highly ordered acid functionalized SBA-15: a novel organocatalyst for the preparation of xanthenes. Chem Commun 47:6677–6679. https://doi.org/10.1039/C1CC11007A

Malgras V, Henzie J, Takei T, Yamauchi Y (2018) Stable blue luminescent CsPbBr3 perovskite nanocrystals confined in mesoporous thin films. Angew Chem Int Ed Engl 57:8881–8885. https://doi.org/10.1002/anie.201802335

Jiang B, Guo Y, Kim J, Whitten AE, Wood K, Kani K, Rowan AE, Henzie J, Yamauchi Y (2018) Mesoporous metallic iridium nanosheets. J Am Chem Soc 140:12434–12441. https://doi.org/10.1021/jacs.8b05206

Chakravarty R, Chakraborty S, Shukla R, Bahadur J, Ram R, Mazumder S, Dev Sarma H, Tyagi AK, Dash A (2016) Mechanochemical synthesis of mesoporous tin oxide: a new generation nanosorbent for 68Ge/68Ga generator technology. Dalton Trans 45:13361–13372. https://doi.org/10.1039/C6DT01921H

Chakravarty R, Bahadur J, Lohar S, Sarma HD, Sen D, Mishra R, Chakraborty S, Dash A (2019) Solid state synthesis of mesoporous alumina: a viable strategy for preparation of an advanced nanosorbent for 99Mo/99mTc generator technology. Micropor Mesopor Mat 287:271–279. https://doi.org/10.1016/j.micromeso.2019.06.020

Dash A, Knapp FF Jr (2015) An overview of radioisotope separation technologies for development of 188W/188Re radionuclide generators providing 188Re to meet future research and clinical demands. RSC Adv 5:39012–39036. https://doi.org/10.1039/C5RA03890A

IAEA Research Reactor Database. Accessible online at: https://nucleus.iaea.org/RRDB/RR/ReactorSearch.aspx

Boschi A, Uccelli L, Pasquali M, Duatti A, Taibi A, Pupillo G, Esposito J (2014) 188W/188Re generator system and its therapeutic applications. J Chem 2014:529406. https://doi.org/10.1155/2014/529406

Lee JS, Lee JS, Park UJ, Son KJ, Han HS (2009) Development of a high performance 188W/188Re generator by using a synthetic alumina. Appl Radiat Isot 67:1162–1166. https://doi.org/10.1016/j.apradiso.2009.02.062

Matsuoka H, Hasimoto K, Hishinuma Y, Ishikawa K, Terenuma H, Tatenuma K, Uchida S (2005) Application of PZC to 188W/188Re generators. J Nucl Radiochem Sci 6:189–191

Chakravarty R, Shukla R, Ram R, Venkatesh M, Tyagi AK, Dash A (2011) Exploitation of nano alumina for the chromatographic separation of clinical grade 188Re from 188W: a renaissance of the 188W/188Re generator technology. Anal Chem 83:6342–6348. https://doi.org/10.1021/ac201232m

So LV, Nguyen CD, Pellegrini P, Bui VC (2009) Polymeric titanium oxychloride sorbent for 188W/188Re nuclide pair separation. Sep Sci Technol 44:1074–1098. https://doi.org/10.1080/01496390902728819

Chakravarty R, Dash A (2013) Nano structured metal oxides as potential sorbents for 188W/188Re generator: a comparative study. Sep Sci Technol 48:607–616. https://doi.org/10.1080/01496395.2012.713433

Chakravarty R, Dash A, Venkatesh M (2009) Separation of clinical grade 188Re from 188W using polymer embedded nanocrystalline titania. Chromatographia 69:1363–1372. https://doi.org/10.1365/s10337-009-1070-7

Chakravarty R, Shukla R, Tyagi AK, Dash A, Venkatesh M (2010) Nanocrystalline zirconia: a novel sorbent for the preparation of 188W/188Re generator. Appl Radiat Isot 68:229–238. https://doi.org/10.1016/j.apradiso.2009.10.031

Chakravarty R, Dash A (2013) Role of nanoporous materials in radiochemical separations for biomedical applications. J Nanosci Nanotechnol 13:2431–2450. https://doi.org/10.1166/jnn.2013.7349

Khalid M, Mushtaq A, Iqbal MZ (2001) Sorption of tungsten (VI) and rhenium (VII) on various ion-exchange materials. Sep Sci Technol 36:283–294. https://doi.org/10.1081/SS-100001079

Dadachova E, Mirzadeh S, Lambrecht RM (1995) Tungstate-ion-alumina interaction in a 188W/188Re biomedical generator. J Phys Chem 99:10976–10981. https://doi.org/10.1021/j100027a044

Saxena S, Prasad M, D’Souza SF (2006) Radionuclide sorption onto low-cost mineral adsorbent. Ind Eng Chem Res 45:9122–9128. https://doi.org/10.1021/ie060378r

Xiao X, Hayashi F, Shiiba H, Selcuk S, Ishihara K, Namiki K, Shao L, Nishikiori H, Selloni A, Teshima K (2016) Platy KTiNbO5 as a selective Sr ion adsorbent: crystal growth, adsorption experiments, and DFT calculations. J Phys Chem C 120:11984–11992. https://doi.org/10.1021/acs.jpcc.6b02422

Rathore E, Pal P, Biswas K (2017) Layered metal chalcophosphate (K-MPS-1) for efficient, selective, and ppb level sequestration of Pb from water. J Phys Chem C 121:7959–7966. https://doi.org/10.1021/acs.jpcc.7b00908

Kumar KV (2006) Comments on “Adsorption of acid dye onto organobentonite.” J Hazard Mater 137:638–639. https://doi.org/10.1016/j.jhazmat.2006.03.056

Lima ÉC, Adebayo MA, Machado FM (2015) Kinetic and equilibrium models of adsorption. In: Bergmann CP, Machado FM (eds) Carbon nanomaterials as adsorbents for environmental and biological applications. Springer, Cham, pp 33–69

Jeong JM, Knapp FF Jr (2008) Use of the Oak Ridge National Laboratory tungsten-188/rhenium-188 generator for preparation of the rhenium-188 HDD/lipiodol complex for trans-arterial liver cancer therapy. Semin Nucl Med 38:S19-29. https://doi.org/10.1053/j.semnuclmed.2007.10.003

Guhlke S, Beets AL, Oetjen K, Mirzadeh S, Biersack HJ, Knapp FF Jr (2000) Simple new method for effective concentration of 188Re solutions from alumina-based 188W–188Re generator. J Nucl Med 41:1271–1278

Indian Pharmacopoeia (2014) Test for Sterility (2.2.11), Test for Bacterial Endotoxin (2.2.3), Radiopharmaceutical Preparation, p 3393

Acknowledgements

The authors are grateful to Dr. P. K. Pujari, Director, Radiochemistry and Isotope Group, Bhabha Atomic Research Centre (BARC) for his valuable support to the Isotope Program. The Irradiation Coordination Group of Radiopharmaceuticals Division, BARC is gratefully acknowledged for facilitating irradiation of targets in the Dhruva reactors. Thanks are due to Analytical Chemistry Division, BARC for ICP-AES analysis of the samples.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chakravarty, R., Bahadur, J., Lohar, S. et al. Mechanochemically synthesized mesoporous alumina: a smart new-generation sorbent for preparation of chromatographic 188W/188Re generator. SN Appl. Sci. 3, 77 (2021). https://doi.org/10.1007/s42452-020-04053-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-04053-7