Abstract

In the present study, the different weight ratios of 7-hydroxy-4-methyl coumarin (7H4MC) mixed polyvinyl alcohol (PVA)/oxidized maize starch (OMS) blend films were achieved by the solvent casting method and coded as PSC. The prepared film samples were characterized by employing techniques such as FTIR, UTM, and SEM. The film samples were also subjected to their wettability, biodegradation and migration rate studies. Experimental outcomes showed that strong intermolecular hydrogen bonding between components of the blend films contribute to increase the mechanical properties, smoother surface morphology, increase in surface hydrophobicity, improvement in biodegradability, and exhibited migration rates below the overall migration limit (OML). Furthermore, moisture content, density, optical properties, water absorption, water solubility, water vapour transmission rate and antioxidant properties are discussed in detail. With all these properties, PVA/OMS/7H4MC blend films have the potential to use as packaging material.

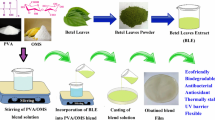

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the recent decades, increasing use of petroleum based plastics and their non-biodegradability have raised genuine environmental pollution, and hence, there is a demand for the development of environmentally friendly degradable polymer materials [1]. Therefore, the current trends encourage the improvement of active biodegradable plastics from renewable materials to exchange non biodegradable polymers in various applications. Polyvinyl alcohol and polysaccharides viz starch, pectin, and alginate are biopolymers, which are advantageous for the expansion of packaging films [2].

Polymer blends have become prominent in scientific research and practical applications, as they offer a key option in solving emerging application requirements. Polymer blending can be illustrated as a physical combination of two or more different polymers which interact through secondary forces and result in the formation of new material with improved mechanical and physicochemical properties [3]. Solution casting is a simple and inexpensive technique to prepare polymer blends because it requires easy tools and without contain any complicated process [4].

Starch is a naturally occurring biodegradable biopolymer. It is non-toxic and is of low cost. It consists of two main polysaccharides linear amylose and branched amylopectin (about 72% in wheat and maize starch). However, starch is modified to overcome its weak film-forming capacity, hydrophilicity and less compatibility with other polymers [5]. The hydroxyl groups of native starch can be readily involved in different types of the modification process, such as esterification, oxidation, and etherification [6]. Oxidation generally involves the chemical modification in which carboxyl and carbonyl group functional groups can be introduced to the starch chain by subsequent depolymerisation of starch [7]. The oxidized starch is more advantageous due to low viscosity, more stability, high transparency, good film forming and binding properties [8, 9]. Polyvinyl alcohol (PVA) is a synthetic, non-ionic water soluble, biodegradable and biocompatible polymer [10, 11], with good film forming capacity, flexibility [12], non-toxicity [13], transparency [14], and barrier properties [15]. In view of all these PVA is widely used in various fields such as packaging industry [16], pharmacy [17], and biosensor [18].

Coumarins are the class of compounds of both natural and synthetic origin [19]. The polymers containing coumarin are well studied and broadly applied in various fields such as medicinal, biochemical, electrooptical materials, and liquid crystalline materials [20, 21]. Organic compounds containing coumarin moiety exhibit useful and diverse pharmaceutical and biological activities such as anticoagulant, anti-inflammatory, antibacterial, antifungal, antiviral, anticancer, antihypertensive, antitubercular, and antioxidant properties [22]. 7-hydroxy coumarins have great implection as natural fragrances possess a characteristic odour like vanilla beans and their hydroxyl group at 7th position has importance in biosynthesis [23].

Both PVA and starch are hydrophilic, biodegradable and readily dominate by microorganisms in the natural environment. Starch/PVA blend plastics have been one of the most popular biodegradable plastics widely used in packaging and agricultural applications [24,25,26]. Blending of 7H4MC in PVA/OMS a biodegradable blend is favorable because, all of them have polar hydroxyl and carbonyl groups in their chemical structure. These highly polar hydroxyl groups tend to form intermolecular and intramolecular hydrogen bonds and hence promote the properties of the blend films [27].

To the best of our knowledge, this is the first report in the literature relevant to 7-Hydroxy 4-methylcoumarin (4-Methylumbelliferone) is used to prepare polymer blend with PVA/OMS. In this regard, we have undertaken this study to evaluate the effect of different amount of 7H4MC on the blend film for their mechanical, morphological, optical, biodegradation, migration, water vapour transmission rate, and antioxidant properties.

2 Experimental

2.1 Materials

Oxidized maize starch (OMS) was obtained from Millennium Starch India Pvt. Ltd., Athani, Karnataka, India. Polyvinyl alcohol (Degree of polymerization 1700 ± 50, 99% hydrolysed, and Molecular weight 1,15,000) was procured from Loba Chemie Pvt.Ltd., Mumbai, India. Resorcinol, ethylacetoacetate, sulphuric acid were purchased from Sigma Aldrich. All the chemicals used are analytical grade.

2.1.1 Synthesis of 7-Hydroxy 4-methylcoumarine

The 7-Hydroxy 4-methylcoumarin is synthesized according to method described by Kiskan et al. [28] Conc. sulphuric acid (20 mL) taken in RB flask was cooled in an ice bath at 0 °C. A solution of resorcinol (1) (2.0 g, 18.16 mmol) in ethylacetoacetate (2) (2.4 mL, 19 mmol) was added dropwise to the flask with constant stirring at 0 °C. Then the mixture was stirred overnight at room temperature. After completion of the reaction (TLC), the reaction mixture was poured into crushed ice with vigorous stirring. The white solid separated was filtered and washed with cold water. The crude product was recrystallized from absolute ethanol to obtain the pure white solid of 7-Hydroxy-4-methylcoumarin (3) with an approximately 75% yield.

2.1.2 7-Hydroxy-4-methyl-2H-chromen-2-one (3)

Yield: 85%, mp 189–190 °C, IR (KBr, cm−1): (C=O), (O–H); 1H-NMR (DMSO-d6, 400 MHz) δppm: 2.32 (s, 3H, –CH3), 6.08 (s, 1H), 6.65 (d, 1H, Ar–H, J = 2.4 Hz), 6.74–6.77 (dd, 1H, Ar–H, Ja = 2.8 Hz, Jb = 9.2 Hz), 7.54–7.57(d, 1H, Ar–H J = 8.8 Hz), 10.57 (s, 1H, –OH).

13C-NMR (DMSO-d6, 75 MHz) δ ppm: 18.65, 102.67, 110.74, 112.55, 113.41, 127.21, 154.21, 155.32, 160.91, 161.65.

2.2 Preparation PVA/OMS/7-Hydroxy 4-methylcoumarine (PSC) Blend Films

Polyvinyl alcohol was dissolved in double-distilled water at 90 °C by stirring on magnetic stirrer to obtain a clear solution (2%). The Oxidized maize starch was added in of double-distilled water (50 mL) at 95 °C with constant stirring to obtain a clear solution. The various weight ratio of 7-hydroxy 4-methylcoumarin viz 0.002, 0.004, 0.006, and 0.008 g were dissolved in suitable quantities of hot water and stirred up to get a clear solution (Table 1).

Prepared OMS solution was added slowly to the previously prepared polyvinyl alcohol solution with constant stirring and kept it for 30 min with constant stirring on a magnetic stirrer. Then the different ratio of the 7-hydroxy 4-methylcoumarin solution was added to the PVA/OMS (PS) blend. The blend solution was stirred for 24 h to get a clear and homogeneous solution. The solution is cast on a petri dish and placed in a hot air oven at 30 °C. After evaporation of the solvent, the films were peeled out carefully and stored in a desiccator.

3 Characterizations

3.1 Moisture content

Film specimens of size 2 cm × 2 cm were weighed (Wi) then kept in a hot air oven at 105 °C for 3 h to attain a constant weight. Then the sample was removed from hot air oven and stored in a desiccator for uniform cooling, and then the weight of the film was re-determined (Wf). Three measurements were made from each film specimen and the moisture content of the film was determined as follows [29].

where \({\text{W}}_{\text{i}}\) is the initial weight of the sample, and \({\text{W}}_{\text{f}}\) is the final weight of the sample.

3.2 Density

Films density was determined directly by taking film weight and dimensions using the following equation [30]

where M is the mass (g), A is the area (cm2), T is the thickness of the film (cm).

3.3 Water solubility

To evaluate solubility percentage of all the film in water, the film samples were cut into 2 × 3 cm and these film pieces were stored in desiccators (silica gel, approximately 0% RH) for 7 days. All the samples were initially weighed and placed in a glass beaker containing of deionised water (80 mL). The samples were continuously stirred over magnetic stirrer about one hour at room temperature. Then the contents of beakers were filtered using Whatman No.1 filter paper and the residue is dried in the oven at 60 °C to obtain constant weight. The percentage of the total solubility of films was calculated as follows [31]

3.4 Water absorption (WA) capacity

The water absorption capacity of all films samples was performed as described by Ismail et al. [32] Dried films were immersed in deionised water at room temperature (25 °C). After 24 h the film is removed from the water and the final weight of the film is recorded after removing water on the films surface using tissue paper. The amount of water absorbed by all films was calculated using the formula given below:

where WF is the final weight film at equilibrium, and WI is the initial weight of film.

3.5 Fourier transform infrared (FTIR) spectroscopy

The Infrared spectra of all films were recorded between 450 and 4000 cm−1 by placing the films over sample holder with a resolution of 4 cm−1 by using attenuated total reflection (ATR) equipped IR spectrometer at room temperature in air (FT-IR-ATR, Perkin Elmer spectrum version 10.5.4).

3.6 Mechanical properties

In this study, mechanical properties like tensile strength (Ts), young modulus (Ym), and elongation at break (Eb) of pure PVA, PS blend film and PSC blended films were evaluated by using Dak system universal testing method (UTM) according to ASTM D882-91 (ASTM, 2009). All the tests were carried out under cross-head speed 1 mm/min−1 at room temperature in air. Prior to the measurement of tensile strength, the thickness of the films was measured by digital micrometer (Mitutoyo made in Japan) at five different places and the average thickness is considered for testing.

3.7 Water contact angle (WCA) measurement

The water contact angle of pure and blended films was analyzed by using contact angle meter (Kyowa Interface Science Co. Ltd., Tokyo, Model DMs-401). All the measurements are carried out under room temperature. For all the measurement size of the water drop was uniform. From two different places, three measurements per test point were taken and averaged.

3.8 Scanning Electron Microscopy (SEM)

Film specimens of size 2 × 2 mm were cut from Pure PVA, PS blend, and PSC blended films and placed on metal stub using a dual sided gum carbon tape. Then all film specimens were laminate with a conductive layer of noble metal (10 nm thickness) to avoid charging to the high electron beam. Surface morphology and internal structure of all specimens were examined using a JEOL JSM-6360 scanning electron microscopy (SEM) at an acceleration voltage of 10 kV. SEM micrographs were taken at different magnification.

3.9 Water vapor transmission rate (WVTR)

To determine WVTR of all prepared films, the glass bottle having inside diameter 17 mm was taken and 10 ml of deionised water is poured into it, and the mouth of the bottle is capped with prepared films and tightened using Teflon tape then the initial weight (W1) of the bottle was recorded and kept in an oven at 400 C for 24 h. The bottle was removed from the oven and the final weight (W2) of a bottle is recorded, after 24 h [33]

where A is the area of circular mouth of the bottle in mm2, W1 initial weight of the bottle, W2 is the final weight of the bottle.

3.10 Optical properties

UV–Visible spectroscopy (Model V-670) was used to determine the transparency and opacity of pure PVA, PS blend and PSC composite films. Each specimen of size 3 cm × 1 cm were cut from pure PVA, PS blend and PSC blended films and directly placed into quartz cuvette and absorbance spectra were recorded in the range of 200 to 600 nm using air as reference. The analysis was done in triplicates and the average was calculated. Obtained results have been expressed in percentage transmission. The transparency of the film is determined by measuring % transmission at 600 nm and was calculated using the following equation [34]

where \(\% \,{\text{T}}\) percentage transmittance and b is is the film thickness in mm.

The opacity of the film was determined according to the method reported by Kannat et al. [35]. using the following formula

3.11 Biodegradation test

The biodegradation test of pure PVA, PS blend, and PSC blended films was investigated according to Riyajan et al. [36]. For this; sample of size 2 × 2 cm was taken and buried under soil at a depth of 5 cm from the surface. The soil was kept moist by sprinkling water at every 3 days for 4 weeks. The weight loss of sample was determined by removing sample and carefully cleaned with distilled water and dried at 45 °C. The degradation of the specimens was calculated according to equation given below:

where W1 is the initial dry weight of the sample and W2 dry weight of the sample after biodegradation test in soil.

3.12 Food compatibility

The analysis of overall migration rate of prepared films into different food simulants like distilled water (A), 50% ethanol (B) and 3% acetic acid (C) (employed to mimic aqueous foods, alcoholic beverages and acidic foods, respectively) was investigated according to IS: 9845-1998 specifications [37]. For this study, approximately 1 cm × 1 cm film samples were immersed into food simulants and kept it in hot air oven at 40 °C up to 10 days. After incubation period the samples were evacuated from food simulants and the simulants were evaporated and the residues were dried overnight at 100 °C and reweighed after cooling to room temperature. The rates of overall migration of components of all the films were estimated gravimetrically. The results were expressed as per kilogram (Fig. 1).

3.13 Antioxidant properties

Antioxidant activities of the pure PVA, PS and PSC blended film samples were determined by radical scavenging activity using the 2, 2-diphenyl-1-picrylhydrazyl (DPPH) method. The stock solution of DPPH was prepared by dissolving 3.9432 mg of DPPH in 100 ml of methanol and stored at 4 °C until further use. 2 ml of DPPH was mixed with 1 ml of five various concentrations (20, 40, 60, 80 and 100 mg mL−1) of the samples. Ascorbic acid was used as a standard reference. The reaction mixture was mixed and kept in the dark for 30 min to prevent photochemical reaction and incubated at room temperature. The absorbanceof reaction mixture (sample absorbance) was recorded spectrophotometrically at 517 nm. An antioxidant activity was calculated by the following equation

4 Results and discussion

4.1 Characterization of synthesized 7H4MC

1HNMR spectrum (Fig. 2a) showed the six different types of proton signals. The chemical shift at 2.32 ppm represents the methyl protons. The chemical shifts 6.08, 6.65, 6.74 and 7.54 ppm represent the aromatic protons and the chemical shift at 10.57 ppm represent the proton of the hydroxyl (-OH) group. 13CNMR spectrum (Fig. 2b) showed the 10 carbon signals which are equal to the number of carbon atoms present in the 7-hydroxy-4-methyl-2H-chromen-2-one. The signal at 18.65 ppm represents the methyl carbon, 102.67, 110.74, 112.55, 113.41, 127.21, 154.21, 155.32 and 160.91 signals represents the aromatic carbons and signal at 161.65 ppm represents the carbonyl carbon. Thus, of the spectroscopy characterizations confirmed the structure of 7H4MC.

4.2 The effect of 7H4MC on density and moisture content of PVA/OMS

In order to prevent the spoilage of food, it is expected that the film must be waterproof. In recent days, there is a need to develop biofilms which can reduce moisture sensitivity of the material. Moisture content and density of all the prepared film samples are presented in Table 2. The moisture content of PVA film decreases slightly after embodiment with OMS. This is due to both PVA and OMS are polar polymers containing OH groups [38]. After incorporation of different quantity of 7H4MC in PS blend film, a decrease in the moisture content was observed as compared to the control PS blend film. This may be due to the fact that 7H4MC results in the formation of strong hydrogen bonding with starch and PVA and the phenomenon are well supported by the FTIR results that the stretching frequency OH groups in PS blend film are decreased to a lower value after addition of 7H4MC. From the Table 2, it is observed that PS and PSC blend films shown density values lower as compared to pristine PVA this may be due to the interaction between components of the blend films which can reduce the hydroxyl groups per unit mass of the sample causes the reduction in density of the film [39].

4.3 The interaction of 7H4MC with PVA/OMS

The polar groups of PVA, OMS and 7H4MC play an extensive role in the formation of strong interaction among the components of the blend film through hydrogen bonding. The FTIR spectrum (Fig. 3) of 7H4MC showed vibration of OH groups at 3500 cm−1 corresponds to stretching vibration of =C–H, a sharp band at 1671 cm−1 corresponds to C=O stretching vibration and medium intensity bands at the peaks at 1602 cm−1 and 1394 cm−1 are associated with vibration of C=C vibration of symmetrical deformation of methyl group. The spectral data of PVA, PS and PSC blend films are shown in Fig. 3. The broad absorption peaks observed at 3371 cm−1 in neat PVA spectra was assigned to -OH stretching frequency, bands at 2917 cm−1, 1086 cm−1, and 1438 cm−1 were ascribed to C-H stretching, C-O stretching, and C-H bending, vibrations of PVA respectively, characteristic peak observed at 1723 cm−1 in PVA was attributed to acetate group exists from hydrolysis of polyvinyl acetate during manufacturing of polyvinyl alcohol. Obtained FTIR data are in good relevant with literature [40, 41].

In the spectrum of OMS, the absorption peaks at 3307 cm−1 and 2912 cm−1 are correspond to OH and CH2 stretching vibration of glucose units respectively. The absorption peak observed at 1631 cm−1 was attributed to the H2O bending vibration [42]. The peak located at 1736 cm−1 was ascribed to the carbonyl (C=O) stretching vibration [43]. The bands observed at 1011 cm−1 and 1153 cm−1 were the stretching vibration of C–O in C–O–H groups, and the peak located at 1346 cm−1 is ascribed to the angular deformation of C–H [44]. The peak at 928 cm−1 was ascribed to stretching vibration of C–O in C–O–C groups.

After the blending of OMS with PVA, the IR spectra of PS film shows all the specific bands of OMS and PVA with some variations. The position of OH stretching vibration in PVA shifts to lower frequency by the addition of OMS by around 3282 cm−1 indicating that strong hydrogen bonding interaction occurred between hydroxyl groups of OMS and PVA [45] (Fig. 4). The intensity of carbonyl groups peak observed at 1737 cm−1 in OMS decreased in PS blend films indicating that carbonyl groups are also involved in the hydrogen bonding with PVA (Fig. 4).

The IR spectra of the PS blend film reflect the modification with the addition of 7H4MC. The absorption peak of OH groups at 3282 cm−1 in the PS spectra shifts to lower stretching frequency at 3266 cm−1, 3256 cm−1 and 3211 cm−1 in PSC II, PSC III and PSC IV blend films respectively. This indicated that the 7H4MC has interacted with PS matrix (Fig. 4) and destructed the hydrogen bonding between PVA and OMS, due to which the -OH peaks are shifted to lower wave numbers [46, 47]. From spectral studies, it can be concluded that 7H4MC can forms hydrogen bonding with the OMS and PVA and miscible over the entire composition.

4.4 The effect of 7H4MC on mechanical properties of PVA/OMS

Mechanical properties of films are essential for the proper function of polymer materials and may be altered by the interaction between the components of the polymer blend [48]. Tensile properties such as tensile strength (TS), elongation at break (Eb) and young’s modulus (Ym) of pure PVA, PS and PSC blended films were measured at room temperature in air and stress–strain curves are shown in Fig. 5a and data obtained from stress–strain curves are presented in Table 3. Due to more hydroxyl group and flexible nature of carbon–carbon backbone, neat PVA film exhibited good mechanical properties [49].

Incorporation of OMS in the PVA matrix revealed weak compatibility between PVA and OMS leads to a decrease in the TS and increase in the Eb of PS blend film. Since water is a pervasive plasticizer, higher the water content in the blend enhances the elongation of the film [50]. With increase in the content of 7H4MC in PS blend, TS and Eb increases in PSC I and PSC II films. These observations are in good agreement with the results reported by Domene-Lopez et al. [51]. These maxima in both TS and Eb could be attributed to the strong interaction between the hydroxyl groups of PVA and OMS with the hydroxyl groups of 7H4MC intermolecular hydrogen bonding (Fig. 4). The Ym of the blend films varies from 148.85 MPa to 177.89 MPa. However, at a higher content of 7H4MC reduction in both TS and Eb was observed and this could be explained by the thixotropic behaviour of 7H4MC, which causes to reduce the viscosity of the film forming solution [52]. These satisfying results illustrate that the addition of 7H4MC improved the TS and Eb of the blend films.

4.5 The effect of 7H4MC on surface morphology of PVA/OMS

Scanning Electron Microscope (SEM) analysis is a very effective and well known technique to evaluate the surface morphology of polymeric materials as the morphology is a key factor in achieving the desired material properties [53, 54]. Figure 6 shows the SEM micrographs of the surface of neat PVA, PS blend and PS/7H4MC blended films.

The pure PVA film (Fig. 6a) exhibits smooth and homogeneous surface whereas the surface of PVA/OMS blend films (Figure 6b) was found to be rough and irregular surface. The blend film at lower content of 7H4MC (Fig. 6c) exhibits rough surface with short fiber like particles of 7H4MC along with agglomeration of starch particles in the blend films. Further, the agglomeration of starch particles decreases with an increase in the content of 7H4MC in the PS matrix. This implies the addition of the 7H4MC in the PS matrix improves the compatibility with PVA/OMS and this could be due to strong intermolecular interaction between PVA/OMS. This evidence is good relevance with results reported by Jianga et al. [55].

Among all the blend films PSCII and III [Fig. 6d, e] blend films presented smooth surface. The results were correlated with higher values of TS and Eb of these blends films [56]. From the surface morphology of all blend films, it was observed that the PSC blend films were smoother than that PS blend film, this could be due to the better compatibility and strong adhesion between the 7H4MC and PS matrix. These findings have good agreement with the other researchers [57, 58]. These conclusions obtained from SEM are also comparable and in good agreement with FTIR studies.

4.6 The effect of 7H4MC on wettability of PVA/OMS

Water contact angle (WCA) measurement is the main criteria to understand the effect of the interaction between the components of the blend on the film hydrophilicity. For the food packaging application of PVA based materials surface hydrophobicity of film is an important property [59]. The wettability between film surface and liquid can be expressed by contact angle θ. When the value of θ is smaller than 90° referred to as film is hydrophilic and if the θ is greater than 90° correspond to film is hydrophobic [60]. If the film is hydrophilic the liquid can moisturize the surface but in the hydrophobic situation, the liquid can travel on the surface of the film. WCA and the pictures of water drops on the surface of the films of neat PVA, PS and PSC blended films were shown in Fig. 7.

By observing Fig. 7 it is clearly confirmed that all the blended films showed a higher contact angle as compared to neat PVA. PVA film presented fully hydrophilic behaviour with contact angle 54.5° due to water has a stronger interaction with PVA [61]. Moreover the WCA of PS blend film increases by the addition of OMS into PVA, this might be due to interaction between the OMS and PVA reduces the content of hydrophilic groups of PVA film [62]. After incorporation of 7H4MC in PS the matrix a remarkable improvement observed in the WCA. From the figure, we can see that samples with more quantity of 7H4MC found to be hydrophobic. This fact is due to polar groups of PVA and OMS are involving strong hydrogen bonding with 7H4MC (Fig. 4). These consequences are associated with the surface morphology of the films (SEM) that the films with rougher surface shown the higher values of contact angle whereas smoother surface films showed the lower values of contact angle and similar results are reported by Kubiak et al. [63] From the above observation it should be concluded that incorporation of 7H4MC into PVA and OMS blend can change the film wettability from hydrophilic to hydrophobic.

4.7 The effect of 7H4MC on water absorption capacity of PVA/OMS

A water absorption test is carried out to evaluate the percentage of water absorbed by the film under specified situation. It can also give information about the water resistance properties of the films. Reducing water sensitivity and developing water resistance of the starch based material is a highly important concept [64]. Percentage of water absorption capacity of pure PVA, PS and 7H4MC incorporated PVA/OMS blend films are tabulated in Table 3. The incorporation of OMS in the PVA matrix can enhance the percentage of water absorption as compared to pure PVA film. This may due to loading of starch molecules in between PVA chain cause to increase the discontinuity and free volume in the PVA matrix so that water could easily penetrate in the blend through the voids and absorbed by the starch resulting in the higher water uptake [39]. It can be also observed that water absorption of PS blend films decreases after addition of 7H4MC. This observation is attributed to combining 7H4MC with PVA and OMS prevented the water molecule from dissolving and improve the water resistance of the blend film. On the other hand the strong intermolecular hydrogen bonding between 7H4MC, PVA/OMS blend film which forms the network structure that could reduce the penetration of water molecules in a polymer matrix [65, 66].

4.8 The effect of 7H4MC on WVTR of PVA/OMS

For food packaging film water vapour transmission rate is an important criterion that is used to determine the capacity of the moisture getting inside from, surrounding environment of the film. To maintain the freshness of the foods, the value of water vapour transmission should be as low as possible. WVTR across the films takes place through two processes viz adsorption followed by diffusion steps [67]. The calculated values of water vapour transmission of neat PVA and PS, PSC blend films are summarised in Table 3. The neat polyvinyl alcohol film showed WVTR at 31.22 g/m2h.32 With the addition of OMS in the PVA matrix, we observed there was an increase in the water vapour transmission rate of PS blend film. This could be mainly due to hydrophilic behaviour of PVA and water sensitivity of OMS that would cause to enhance the interchain spacing and mobility of water molecules through the films which made positive contributions to increase the WVTR [68, 69]. The incorporation of 7H4MC in PS blend films lowers the WVTR. It might be due to the strong interaction between hydroxyl group of 7H4MC with polar groups of PVA and OMS via hydrogen bonding which made different lanes of direct diffusion of water molecules which creates tortuous path in blend film and thus they blocked the moisture and water vapours passing through the blend film (shown in Fig. 8). The results obtained are good relevance with Fahma et al. [70]. As the percentage of 7H4MC increases in the blend the hydrophilicity of the film is decreases. From the above observation, it can be concluded that the incorporation of 7H4MC in PS caused to decrease in the WVTR of the film up to 20.20 g/m2h. All the blend films showed the WVTR value in the range of 31–20 g/m2h which are similar to the some polymer used in packaging field (low-density polyethylene–LDPE = 16–23 g/m2.day, polyethylene terephthalate—PET = 15–20 g/m2.day) [57].

4.9 The Effect of 7H4MC on solubility of PVA/OMS

The percentage of solubility of the film in the aqueous phase is an important criterion to investigate the biodegradability of the films. Lower solubility would indicate high water resistance and vice versa. In some cases the lower the solubility of the film is very useful in the storage applications, higher solubility of the films leads to higher biodegradability [31, 71]. Table 2 shows the solubility values of pure and blend films. Due to the blending of OMS with PVA the solubility of PS blend film increases as compare to polyvinyl alcohol, this result illustrates that strong interaction between the hydroxyl group of PVA and OMS occurred via hydrogen bonding which enhanced the solubility of PS blend film. Furthermore, 7H4MC doped blend films exhibited the reduction in water solubility as compared to PS blend film which is due to improvement in the interfacial adhesion between components of the blend films caused to reduces the water sensitivity of the film [72, 73]. These findings coincided with the decrease in water absorption and water vapour transmission rate of the films.

4.10 The effect of 7H4MC on optical properties of PVA/OMS

The optical properties are one of the important characteristics of packaging films, since it influences the appearance of the product. Generally, a transparent packaging material is desirable for viewing the packed product [74]. In another situation, it is important to protect food from the light, especially from UV radiation in order to reduce catalytically deteriorations [56]. The films were scanned at 200–600 nm wavelength range and the percentage of light transmittance was recorded. The percentage of light transmittance indicates the transparency of films and their structural homogeneity, more the transmittance percentage associated with, more the structural homogeneity and high transparency [75].

The PS blend film shows the reduction in percentage transmission as compared to PVA this could be due to partial miscibility of PVA and OMS [65]. The transmission percentage of PSC blends decreases with an increase in the amount of 7H4MC. The good dispersion of 7H4MC in PS blend film enhances the transmittance (%) whereas the poor miscibility of 7H4MC in blend film reduces the transmission (%)[76]. Apparently, the films with higher content of 7H4MC led to rougher surface due to involvement of highly agglomerated OMS and 7H4MC particles, resulting in enhances the light scattering sites [77]. Lee et al. [78] demonstrated that the reduction in transmittance percentage is an advantage for food packaging application. However, a strong absorption peak arrived in the wavelength range of 240 to 310 nm, which could be attributed to dipole–dipole interaction between molecules or n → π* transition, because of unsaturated C=O bond break as reported earlier [79, 80].

The transparency and opacity of all the prepared films were calculated and shown in Fig. 9b. Transparency and opacity are inversly related and hence high transparency leads to a low opacity [35]. The transparency values of PS and PSC blend films decreases as compare to control PVA film. This might be due to the coagulation of 7H4MC in OMS and the PVA matrix creates a low miscibility and lowers the value of transparency. Similar results were reported in the PVA/starch films prepared by the incorporation of zinc oxide nanocomposites [66].

Generally, film colour and thickness have a direct effect on its opacity [81]. In the current study, the thickness values Table 3 of the films were different, therefore the thickness affects the opacity of films. The results indicated that blend films produced more opacity values as compared to neat PVA Fig. 9c. An increase in opacity may have been the result of contraction of the film matrix in which the polymer inter-chain spacing was decreased thus permitting less light to pass through the film [82].

4.11 The effect of 7H4MC on biodegradation of PVA/OMS

In order to evaluate the effect of 7H4MC on the biodegradation PVA and OMS blend films a soil burial biodegradation analysis was performed. The soil burial test is an outdoor experiment and provides a realistic environment, where soil humidity, temperature, and type, and the number of microorganisms are in less control and change with season [83].

Generally, it is demonstrated that two step degradation took place in soil burial biodegradation test first is the diffusion of water into the film samples, resulting in the swelling of the films and allowing the growth of microorganisms on the films. The second step involves enzymatic and other secreted degradation, causing a weight loss and disruption of the film samples [84]. The degradation percentage of neat PVA and PS, PSC blend films on 1st, 5th, 10th, 15th, 20th 25th, and 30th day were shown in Fig. 10.

In the present work, all the blend films showed the more weight loss as compared to neat PVA film. In contrast, the PVA film results in higher resistance against soil burial biodegradation because of the chemical structure of PVA (unknown stereoregularity of hydroxyl groups) or by the degree of polymerization (comparably high molecular weight) [85]. Further increase in the biodegradation rate is observed up to 56.79% after addition of OMS in PVA matrix (PS blend film) which might be due to the easier microorganism attack to OMS material then those of pure PVA [86]. Concerning biodegradability of PSC blend films, it was manifested that biodegradation rate was dropped after addition of 7H4MC to PS blend this could be attributed to hydrogen bond formation between 7H4MC and blend matrices so that water diffusion and infiltration speed of microorganism were restricted and similar phenomenon was observed in other results [65]. However the PSC IV blend film shown higher biodegradation rate among, PSC blend films because of agglomeration of 7H4MC in PS blend matrices [87]. The obtained results are related to the solubility and water absorption test.

4.12 The effect of 7H4MC on food compatibility of PVA/OMS

The food compatibility of the prepared pure PVA and blend films were carried out to investigate the total amount additives that might be migrated into foodstuffs from the matrix film [88]. Figure 11 represents migration rates in three different food stimulants like simulant A (distilled water), simulant B (50% ethanol) and simulant C (3% acetic acid). It was observed from the figure that the migration rate of PS blend film is higher for simulant A as compared to PSC blend films. Overall migration results obtained from simulant A have good vibes with the solubility of blend films, with the addition of the 7H4MC into PS matrix reduces the solubility of the blend films as discussed earlier and the similar findings were shown by Mauricio-Iglesias et al. [89]. Moreover, the strong interfacial adhesion between 7H4MC and blend matrix is another evidence for reduction in migration during contact with food stimulant.

While dealing with PSC blend films with respect to simulant B, the migration rate of the blend films were increased at lower dopent levels and subsequently decreases with higher a content of 7H4MC. Finally to mimic the acidic foodstuff the overall migration rates were recorded in stimulant C, which shows the increasing trends for overall migration rates.

The blend films possessed a higher sensitivity to water (simulant A), followed by ethanol (Simulant B) and then acetic acid (Simulant C). All the blend films show the migration rates below the overall migration limit (OML) of 60 mg/kg (European Union Commission Regulation (EU) No 10/2011) [90], and hence these films can be used for aqueous, lipophilic and acidic foodstuff packaging (Fig. 12).

4.13 The effect of 7H4MC on antioxidant properties of PVA/OMS

Antioxidant activity of all the prepared films was evaluated by the diphenylpicrylhydrazine (DPPH) scavenging assay. When an absorbance at 517 nm DPPH radical scavenging activity is a violet colour solution, but antioxidants can change the colour of DPPH radical to yellow colour with decrease in the absorbance value [91]. Table 4 represents the scavenging activity of the films. Pure PVA films did not show antioxidant activity [92]. The PS blend films exhibited a lower value of the antioxidant activity, but the addition of 7H4MC increases the DPPH radical scavenging activity of the blend films. Moreover, the activity of the PSC blend films increased with the increase of 7H4MC and similar results were reported by Qin et al. [93]. The antioxidant activity of the PSC blend films mainly due to the 7H4MC since hydroxycoumarins has property similar to phenol or quinol based antioxidants in which hydroxyl groups scavenge the free radicalds [94]. All the films have shown good scavenging activity as compared to the activity of ascorbic acid (standard) which indicates that the reported PSC blend films are useful as an antioxidant packaging.

5 Conclusion

In the present study, 7H4MC doped PVA/OMS blend films were fabricated successfully by using an inexpensive solution casting technique. The obtained blend films were characterized by using different instrumental techniques. The experimental finding indicates the incorporation of 7H4MC in the PS blend matrix enhances the mechanical properties due to changes in the structure of blend films. The blend films containing 0.004 and 0.006 g of 7H4MC showed increase tensile strength and elongation at break as compared to control blend film, this could be due to hydrogen bonding interaction between components of the blend films which is confirmed by FTIR spectroscopy. While the Surface morphological studies of 7H4MC doped blend films presented smoother surface as compared to PS blend film and those results are consistent with higher mechanical properties. The PSC IV blend film exposed the hydrophobic nature associated with the rougher surface morphology confirmed by the SEM analysis. The transmission (%) of the films in the UV region reduced after the addition of 7H4MC and also transparency decreases with an increase in opacity values. Meanwhile, the water vapour transmission rate of the films decreased with an increase in the content of 7H4MC and these results of the WVTR, are also in close agreement with reducing values of solubility and water absorption rate. The results obtained from the food compatibility test revealed that migration rates of all the blend films are below the overall migration limit (OML) of 60 mg/kg. All the fabricated blend films are biodegradable and presented good antioxidant properties as compared to the standard sample. An increase in the 7H4MC content in the blend matrix enhances the antioxidant property. Therefore the films with these types of properties have broad prospects in the application of active food packaging.

References

Flavia D, Renata KTK, Gerson N, Luciano AP, Suzana M (2014) Biodegradable active packaging based on cassava bagasse, polyvinylalcohol and essential oils. Ind Crops Prod 52:664–670

Hassan B, Chatha S, Hussain A, Zia KM, Akhtar N (2018) Recent advances on polysaccharides, lipids and protein based edible films and coatings: a review. Int J Biol Macromol 109:1095–1107

Rao RV, Iatha P (1999) Viscometric and ultrasonic studies of blends of poly (vinyl pyrrolidone) and poly (vinyl alcohol). J Mater Sci Let 18:457–459

Mudigoudra B, Masti S, Chougale R (2012) Thermal behavior of poly (vinyl alcohol)/poly (vinyl pyrrolidone)/chitosan ternary polymer blend films. Res J Recent Sci 1:83–86

Zhaoyun L, Yuanyuan X, Guihua Y, Jiachuan C, Dexian J (2019) Improved film formability of oxidized starch-based blends through controlled modification with cellulose nanocrystals. Ind Crops Prod 140:111665

Maryam S, Rouhollah B, Mahmood M (2017) Effect of oxidized starch on morphology, rheological and tensile properties of low-density polyethylene/linear low-density polyethylene/thermoplastic oxidized starch blends. J Polym Environ 26:2219–2226

Zhang YR, Zhang SD, Wang XL, Chen RY, Wang YZ (2009) Effect of carbonyl content on the properties of thermoplastic oxidized starch. Carbohydr Polym 78:157–161

Paul BZF, Apolonio VT, Jose PG, Elsa BM, Luis ABP (2006) Films prepared with oxidized banana starch: mechanical and barrier properties. Starch/Stärke 58:274–282

Elizabeth AG, Javier SF, Rodolfo JRV, Francisco RG, Alfredo JP, Emmanuel FH (2014) Properties of edible films based on oxidized starch and zein. Int J Polym Sci 5:1687–9430

Chiellini E, Corti A, Solaro R (1999) Polym Degrad Stab 64:1346

Corti A, Solaro R, Chiellini E (2002) Polym Degrad Stab 75:447

Julinova MDM, Kupec JHJ, Kopcilova MHJ, Alexy PNA, Vaskova I (2008) Influence of technological process on biodegradation of PVA/WAXY starch blends in an aerobic and anaerobic environment. J Polym Environ 16:241–249

Oviedo IR, Meendez NAN, Gomez MPG, Rodriguez HC, Martinez AR (2008) Design of a physical and nontoxic cross-linked poly(vinyl alcohol) hydrogel. Int J Polym Mater 57:1095–1103

Podsiadlo P, Kaushik AK, Arruda EM, Waas AM, Shim BS, Xu J, Nandivada H, Pumplin BG, Lahann J, Ramamoorthy A, Kotov NA (2007) Ultrastrong and stiff layered polymer nanocomposites. Science 318:80–83

DeMerlis CC, Schoneker DR (2003) Review of the oral toxicity of polyvinyl alcohol. Food Chem Toxicol 41:319–326

Sapalidis AA, Katsaros FK, Romanos GE, Kakizis NK, Kanellopoulos NK (2007) Preparation and characterization of novel poly(vinyl alcohol)–Zostera flakes composites for packaging applications. Compos B 38:398–404

McGann MJ, Higginbotham CL, Geever LM, Nugent MJD (2009) The synthesis of novel pH-sensitive poly(vinyl alcohol) composite hydrogels using a freeze/thaw process for biomedical applications. Int J Pharm 372:154–161

Ren GL, Xu XH, Liu Q, Cheng J, Yuan XY, Wu LL, Wan YZ (2006) Electrospun poly(vinyl alcohol)/glucose oxidase biocomposite membranes for biosensor applications. React Funct Polym 66:1559–1564

Venugopala KN, Rashmi V, Odhav B (2013) Review on natural coumarin lead compounds for their pharmacological activity. Biomed Res Int 963248:14

Nursel A, Feride B, Kadir D (2012) Polymers based on methacrylate bearing coumarin side group: synthesis via free radical polymerization, monomer reactivity ratios, dielectric behavior, and thermal stabilities. Polym Sci 352759:13

Trenor R, Allan RS, Brian JL, Timothy EL (2004) Coumarins in polymers: from light harvesting to photo-cross-linkable tissue scaffolds. Scott Chem Rev 104:3059–3078

Mounir AIS, Magda IM, Azza ME (2016) Synthesis and characterization of some new coumarins with in vitro antitumor and antioxidant activity and high protective effects against DNA damage. Molecules 21:249

Mark MD, Balam SKK, Umamaheswara RN, Baktavathsala R, Manoj KS, Adeppa K, Syama SC, Cirandur SR, Krishna M (2015) Synthesis and bio-evaluation of novel 7-hydroxy coumarin derivatives via Knoevenagel reaction. Res Chem Intermed 41:1115

Jayasekara R, Harding I, Bowater I, Christie GBY, Lonergan GT (2004) Preparation, surface modification and characterisation of solution cast starch PVA blended films. Polym Test 23:17–27

Randal L, Shogren JW, Lawton KAF, Tiefen B, Liang C (1998) Starch–poly(vinyl alcohol) foamed articles prepared by a baking process. J Appl Polym Sci 68:2129–2140

Tudorachi N, Cascaval N, Rusu M, Pruteanu M (2000) Testing of polyvinyl alcohol and starch mixtures as biodegradable polymeric materials. Polym Test 19:785–799

Rahman L, Tin S, Rahma AR, Sama AA (2010) Thermal behaviour and interactions of cassava starch filled with glycerol plasticized polyvinyl alcohol blends. Carbohydr Polym 81:805–810

Baris K, Yusuf Y (2007) Thermally curable benzoxazine monomer with a photodimerizable coumarin group. J App Polym Sci Part A Polym Chem 45:1670–1676

Chen J, Long Z, Wang J, Wu M, Wang F, Wang B, Lv W (2017) Preparation and properties of microcrystalline cellulose/hydroxypropyl starch composite films. Cellulose 24:4449–4459

Salgado PR, Molina Ortiz SE, Petruccelli S, Mauri AN (2010) Biodegradable sunflower protein films naturally activated with antioxidant compounds. Food Hydrocoll 24:525–533

Nouri L, Mohammadi Nafchi A (2014) Antibacterial, mechanical, and barrier properties of sago starch film incorporated with betel leaves extract. Int J Biol Macromol 66:254–259

Ismail H, Zaaba NF (2011) Effect of additives on properties of polyvinyl alcohol (PVA)/tapioca starch biodegradable films. Polym Plast Technol Eng 50:1214–1219

Sarwar MS, Bilal M, Niazi K, Jahan Z, Ahmad T, Hussain A (2017) Preparation and characterization of PVA/nanocellulose/Ag nanocomposite films for antimicrobial food packaging. Carbohydr Polym 184:453–464

Han JH, Floros JDJ (1997) Casting antimicrobial packaging films and measuring their physical properties and antimicrobial activity. Plast Film Sheet 13:287

Kanatt SR, Rao MS, Chawla SP, Sharma A (2012) Active chitosan–polyvinyl alcohol films with natural extracts. Food Hydrocoll 29:290–297

Riyajan SA, Patisat SJ (2018) A novel packaging film from cassava starch and natural rubber. Polym Environ 26:2845–2854

Oluwasina O, Olaleye FK, Olusegun SJ, Mohallem NDS (2019) Influence of oxidized starch on physicomechanical, thermal properties, and atomic force micrographs of cassava starch bioplastic film. Int J Biol Macromol 135:282–293

Ramaraj B (2007) Crosslinked poly(vinyl alcohol) and starch composite films: study of their physicomechanical, thermal, and swelling properties. J Appl Polym Sci 103:1127–1132

Ramaraj B (2007) Crosslinked poly(vinyl alcohol) and starch composite films. ii. physicomechanical, thermal properties and swelling studies. J Appl Polym Sci 103:909–916

Negim E, Rakhmetullayeva R, Yeligbayeva G, Urkimbaeva P, Primzharova S, Kaldybekov D, Khatib J, Mun G, Williams CD (2014) Improving biodegradability of polyvinyl alcohol/starch blend films for packaging applications. Int J Basic Appl Sci 3:263–273

Popescu MC, Dogaru BI, Goanta M, Timpu D (2018) Structural and morphological evaluation of CNC reinforced PVA/Starch biodegradable films. Int J Biol Macromol 116:385–393

Zhang YR, Wang XL, Zhao GM, Wang YZ (2012) Preparation and properties of oxidized starch with high degree of oxidation. Carbohydr Polym 87:2554–2562

Dang X, Chen H, Wang Y, Shan Z (2018) Freeze-drying of oxidized corn starch: electrochemical synthesis and characterization. Cellulose 25:2235–2247

Wang H, Wang W, Jiang S, Jiang S, Zhai L, Qin J (2011) Poly(vinyl alcohol)/oxidized starch fibres via electrospinning technique, fabrication and characterization. Iran Polym J English Ed 20:551–588

Yin Y, Li J, Liu Y, Li Z (2008) Starch crosslinked with poly(vinyl alcohol) by boric acid. J Appl Polym Sci 96:1394–1397

Amalvy J, Pardini O, González-Forte LJ (2016) Starch/polyvinyl alcohol blends containing polyurethane as plasticizer. Compos Biodegrad Polym 4:2–10

Yajuan Y, Changhua L, Chang PR, Chen Y, Debbie AP, Stumborg M (2010) Properties and structural characterization of oxidized starch/PVA/a-zirconium phosphate composites. J Appl Polym Sci 115:1089–1097

Chen Y, Cao X, Chang PR, Huneault MA (2008) Comparative study on the films of poly(vinyl alcohol)/pea starch nanocrystals and poly(vinyl alcohol)/native pea starch. Carbohydr Polym 73:8–17

Tian H, Yan J, Rajulu AV, Xiang A, Luo X (2017) Fabrication and properties of polyvinyl alcohol/starch blend films: effect of composition and humidity. Int J Biol Macromol 96:518–523

Rivero S, Garcia MA, Pinotti A (2010) Crosslinked capacity of tannic acid in plasticized chitosan films. Carbohydr Polym 82:270–276

Domene-López D, Guillén MM, Martin-Gullon I, García-Quesada JC, Montalbán MG (2018) Study of the behavior of biodegradable starch/polyvinyl alcohol/rosin blends. Carbohydr Polym. 202:299–305

Vanjeri VN, Goudar N, Kasai D, Masti SP, Chougale RB (2019) Thermal and tensile properties study of 4-hydroxycoumarin doped polyvinyl alcohol/chitosan blend films. Chem Data Collect 23:100257

Maiti S, Ray D, Mitra D (2012) Role of crosslinker on the biodegradation behavior of starch/polyvinylalcohol blend films. J Polym Environ 20:749–759

Luo X, Li J, Lin X (2012) Effect of gelatinization and additives on morphology and thermal behavior of corn starch/PVA blend films. Carbohydr Polym 90:1595–1600

Zhang X, Jiang X, Jiang T, Gan L, Zhang X, Dai H (2012) The plasticizing mechanism and effect of calcium chloride on starch/poly(vinyl alcohol) films. Carbohydr Polym 90:1677–1684

Guimarães M, Botaro VR, Novack KM, Teixeira FG (2015) Tonoli GHD (2015) Starch/PVA-based nanocomposites reinforced with bamboonanofibrils. Ind Crops Prod 70:72–83

Singha AS, Priya B, Pathania D (2015) Cornstarch/poly(vinyl alcohol) biocomposite blend films: mechanical properties, thermal behavior, fire retardancy, and antibacterial activity. Int J Polym Anal Charact 20:357–366

Priya B, Gupta VK, Pathania D, Singha AS (2014) Synthesis, characterization and antibacterial activity of biodegradable Starch/PVA composite films reinforced with cellulosic fibre. Carbohydr Polym 109:171–179

Li HZ, Chen SC, Wang YZ (2014) Thermoplastic PVA/PLA blends with improved processability and hydrophobicity. Ind Eng Chem Res 53:17355–17361

Abdullah ZW, Dong Y (2019) Biodegradable and water resistant poly(vinyl) alcohol (PVA)/starch (ST)/glycerol(GL)/halloysite nanotube (HNT) nanocomposite films for sustainable food packaging. Front Mater 6:1

Shahbazi M, Rajabzadeh G, Rafe A, Ettelaie R, Ahmadi SJ (2016) The physico-mechanical and structural characteristics of blend film of poly(vinyl alcohol) with biodegradable polymers as affected by disorder-to-order conformational transition. Food Hydrocoll 60:393–404

Wang Y, Jiang L, Duan J, Shao S (2013) Effect of the carbonyl content on the properties of composite films based on oxidized starch and gelatin. J Appl Polym Sci 130:3809–3815

Kubiak KJ, Wilson MCT, Mathia TG, Carval P (2011) Wettability versus roughness of engineering surfaces. Wear 271:523–528

Parvin F, Rahman MA, Islam JMM, Khan MA, Saadat AHM (2010) Preparation and characterization of starch/PVA blend for biodegradable packaging. Mater Adv Mater Res 351:123–125

Tang S, Zou P, Xiong H, Tang H (2008) Effect of nano-SiO2 on the performance of starch/polyvinyl alcohol blend film. Carbohydr Polym 72:521–526

Akhavan A, Khoylou F, Ataeivarjovi E (2017) Preparation and characterization of gamma irradiated Starch/PVA/ZnO nanocomposite films. Radiat Phys Chem 138:49–53

Muppalla SR, Kanatt SR, Chawla SP, Sharma A (2014) Carboxymethyl cellulose–polyvinyl alcohol films with clove oil for active packaging of ground chicken meat, Food Packag. Shelf Life 2:51–58

Ooi XZ, Hanafi I, Nor AAA, Azhar AB (2011) Preparation and properties of biodegradable polymer film based on polyvinyl alcohol and tropical fruit waste flour. Polym Plastics Technol Eng 50:705–711

Ismail H, Zaaba NF (2014) Effects of poly (vinyl alcohol) on the performance of sago starch plastic films. J Vinyl Addit Technol 20:72–79

Fahma F, Sugiarto ST, Indriyani SM, Lisdayana N (2017) Thermoplastic cassava starch-PVA composite films with cellulose nanofibers from oil palm empty fruit bunches as reinforcement agent. Int J Polym Sci 27:45721

De Pauli RB, Quast LB, Demiate IM, Sakanaka LS (2011) Production and characterization of oxidized cassava starch (Manihot esculenta Crantz) biodegradable films. Starch/Staerke 63:595–603

Noshirvani N, Ghanbarzadeh B, Fasihi H, Almasi H (2016) Starch–PVA nanocomposite film incorporated with cellulose nanocrystals and MMT: a comparative study. Int J Food Eng 12:37–48

Kisku SK, Sarkar N, Dash S, Swain SK (2014) Preparation of starch/PVA/CaCO3 nanobiocomposite films: study of fire retardant, thermal resistant, gas barrier and biodegradable properties. Polym Plast Technol Eng 53:1664–1670

Marcel Dekker, Plastics in Food Packaging Properties. Design and Fabrication 539:8–10

Cano AI, Cháfer M, Chiralt A, González-Martínez (2015) Physical and microstructural properties of biodegradable films based on pea starch and PVA. C J Food Eng 167:59–64

Siddaramaiah RB, Somashekar R (2004) Structure–property relation in polyvinyl alcohol/starch composites. J Appl Polym Sci 91:630–635

Grunlan JC, Grigorian A, Hamilton CB, Mehrabi ARJ (2004) Effect of clay concentration on the oxygen permeability and optical properties of a modified poly(vinyl alcohol). Appl Polym Sci 93:1102–1109

Lee MH, Kim SY, Park HJ (2018) Effect of halloysite nanoclay on the physical, mechanical, and antioxidant properties of chitosan films incorporated with clove essential oil. Food Hydrocoll 84:58–67

Li X, Yushu Z, Haiqing P, Nan X, Changtong M, Haiyan M, Wenqing Z, Jiabin C, Changyan X (2020) Preparation and performance of radiata-pine-derived polyvinyl alcohol/carbon quantum dots fluorescent films. Materials 13:67

Baraker BM, Lobo BC (2017) Spectroscopic analysis of CdCl2 doped PVA-PVP blend films. J Phys 95:738–747

Sun Q, Sun C, Xiong L (2013) Mechanical, barrier and morphological properties of pea starch and peanut protein isolate blend films. Carbohydr Polym 98:630–637

Yang L, Paulson AT, Nickerson MT (2010) Mechanical and physical properties of calcium-treated gellan films. Food Res Int 43:1439–1443

Guohua Z, Ya L, Cuilan F, Min Z, Caiqiong Z, Zongdao C (2006) Water resistance, mechanical properties and biodegradability of methylated-cornstarch/poly(vinyl alcohol) blend film. Polym Degrad Stab 91:703–711

Hejri Z, Seifkordi AA, Ahmadpour A, Zebarjad SM, Maskooki A (2013) Biodegradable starch/poly (vinyl alcohol) film reinforced with titanium dioxide nanoparticles. Int J Miner Metall Mater 20:1001–1011

Huali T, Hanguo X, Tang S, Zou P (2009) A starch-based biodegradable film modified by nano silicon dioxide. J Appl Polym Sci 113:34–40

Cano AI, Cháfer M, Chiralt A, González-Martínez (2016) Biodegradation behavior of starch-PVA films as affected by the incorporation of different antimicrobials. C Polym Degrad Stab 132:11–20

Heidarian P, Behzad T, Sadeghi M (2017) Investigation of cross-linked PVA/starch biocomposites reinforced by cellulose nanofibrils isolated from aspen wood sawdust. Cellulose 24:3323–3339

Schmidt B, Katiyar V, Plackett D, Larsen EH, Gerds N, Koch CB, Petersen JH (2011) Migration of nanosized layered double hydroxide platelets from polylactide nanocomposite films. Food Addit Contam Part A Chem Anal Control Expo Risk Assess 28:956–966

Mauricio IM, Peyron S, Guillard V, Gontard N (2010) Wheat gluten nanocomposite films as food-contact materials: migration tests and impact of a novel food stabilization technology (high pressure). J Appl Polym Sci 116:2535–2658

European Standard EN 1186-1:2002 Materials and articles in contact with foodstuffs. Plastics. Guide to the selection of conditions and test methods for overall migration

Garrido-Miranda KA, Rivas BL, Pérez-Rivera MA, Sanfuentes EA, Peña-Farfal C (2018) Antioxidant and antifungal effects of eugenol incorporated in bionanocomposites of poly-(3-hydroxybutyrate)-thermoplastic starch. LWT Food Sci Technol 98:260–267

Gaikwad KK, Lee JY, Lee YS (2016) Development of polyvinyl alcohol and apple pomace bio-composite film with antioxidant properties for active food packaging application. J Food Sci Technol 53:1608–1619

Qin Y, Liu Y, Zhang X, Liu J (2020) Development of active and intelligent packaging by incorporating betalains from red pitaya (Hylocereus polyrhizus) peel into starch/polyvinyl alcohol films. Food Hydrocoll 100:105410

Morabito G, Trombetta D, Singh BK, Prasad AK, Parmar VS, Naccari C, Mancari F, Saija A, Cristani M, Firuzi O, Saso L (2010) Antioxidant properties of 4-methylcoumarins in in vitro cell-free systems. Biochimie 92:1101–1107

Acknowledgement

The authors wish to acknowledge, University Scientific Instrumentation Centre (USIC), DST Sophisticated Analytical Instrument Facilities (SAIF), DST PURSE Phase II,Karnatak University, Dharwad, Karnataka, India for providing an instrumental facilities. The authors wish to express their gratitude to Millennium Starch India Pvt. Ltd., Athani, Karnataka, India for a generous gift of oxidized maize starch. We also wish to thank Dr. Saraswati P. Masti, Principal Investigator, DST-SERB Project, No. SB/EMEQ-213/2014, Department of Chemistry, Karnatak Science College, Dharwad, Karnataka, India, for providing Dak system Universal Testing Machine (UTM) to study the mechanical properties.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hiremani, V.D., Sataraddi, S., Bayannavar, P.K. et al. Mechanical, optical and antioxidant properties of 7-Hydroxy-4-methyl coumarin doped polyvinyl alcohol/oxidized maize starch blend films. SN Appl. Sci. 2, 1877 (2020). https://doi.org/10.1007/s42452-020-03399-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-03399-2