Abstract

Purpose

Brake squeal as a dynamic instability phenomenon is a major comfort problem observed in automotive disc brake systems. Thus, it is aimed to investigate the effects of certain operational parameters on squeal initiation.

Methods

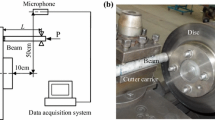

The problem is investigated both experimentally and mathematically from the perspective of system stability. Experimentally, a mass-sliding belt experiment is designed and built, with a focus on three key operational parameters. Experiments are conducted at a wide range of these operational parameters. Furthermore, the contact stiffness at the mass and sliding belt contact interface is evaluated via modal tests. Mathematically, a nonlinear mathematical model of the experiment is developed. The model is then linearized through certain assumptions, and the stability of the system is assessed through the linearized mathematical model via complex eigenvalue solution.

Results

Data measured from the experiments are processed in time and frequency domains. Time domain results reveal local dynamic amplifications in time histories of certain operational parameters, which lead to the emergence of super-harmonics in frequency domain. Furthermore, Stribeck type friction characteristic is observed at the mass and sliding belt contact interface. The critical values of dynamic friction coefficient and motor angular speed are obtained for the validation of predictions with experimental data.

Conclusion

A good correlation between the model predictions and experiments is achieved, thus the stability analysis based on linearized model is validated with the experimental data. An extensive understanding about the effects of key operational parameters on system stability is obtained.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Chen F (2009) Automotive disk brake squeal: an overview. Int J Veh Des 51(1–2):39–72. https://doi.org/10.1504/IJVD.2009.027115

Kinkaid NM, O’Reilly OM, Papadopoulos P (2003) Automotive disc brake squeal. J Sound Vib 267(1):105–166. https://doi.org/10.1016/S0022-460X(02)01573-0

Papinniemi A, Lai JC, Zhao J, Loader L (2002) Brake squeal: a literature review. Appl Acoust 63(4):391–400. https://doi.org/10.1016/S0003-682X(01)00043-3

Ouyang H, Mottershead JE, Cartmell MP, Friswell MI (1998) Friction-induced parametric resonances in discs: effect of a negative friction–velocity relationship. J Sound Vib 209(2):251–264. https://doi.org/10.1006/jsvi.1997.1261

Eriksson M, Jacobson S (2001) Friction behaviour and squeal generation of disc brakes at low speeds. Proc Inst Mech Eng Part D J Automob Eng 215(12):1245–1256. https://doi.org/10.1243/0954407011528789

Gagnon L, Morandini M, Ghiringhelli GL (2020) A review of friction damping modeling and testing. Arch Appl Mech 90:107–126. https://doi.org/10.1007/s00419-019-01600-6

Leine RI, Van Campen DH, De Kraker A, Van Den Steen L (1998) Stick-slip vibrations induced by alternate friction models. Nonlinear Dyn 16(1):41–54. https://doi.org/10.1023/A:1008289604683

Spurr RT (1961) A theory of brake squeal. Proc Inst Mech Eng Automob Div 15(1):33–52. https://doi.org/10.1243/PIME_AUTO_1961_000_009_02

Hoffmann N, Gaul L (2004) A sufficient criterion for the onset of sprag-slip oscillations. Arch Appl Mech 73:650–660. https://doi.org/10.1007/s00419-003-0315-4

Jarvis RP, Mills B (1963) Vibrations induced by dry friction. Proc Inst Mech Eng 178(1):847–857. https://doi.org/10.1177/0020348363178001124

Keitzel H, Hoffmann N (2006) Influence of the contact model on the onset of sprag‐slip. In PAMM: Proceedings in Applied Mathematics and Mechanics 6(1):311-312. https://doi.org/10.1002/pamm.200610137

Hultén J, Flint J (1999) An assumed modes method approach to disc brake squeal analysis. SAE Technical Paper 1:1335. https://doi.org/10.4271/1999-01-1335

Ouyang H, Mottershead JE, Brookfield DJ, James S, Cartmell MP, Kaster T, Treyde T, Hirst B, Allen R (1999) Dynamic instabilities in a simple model of a car disc brake. SAE Technical Paper 1:3409. https://doi.org/10.4271/1999-01-3409

Nishiwaki M (1993) Generalized theory of brake noise. Proc Inst Mech Eng Part D J Automob Eng 207(3):195–202. https://doi.org/10.1243/PIME_PROC_1993_207_180_02

Von Wagner U, Spelsberg-Korspeter G (2011) Minimal models for squealing of railway block brakes. Arch Appl Mech 81:503–511. https://doi.org/10.1007/s00419-010-0422-y

Chen F, Chern J, Swayze J (2002) Modal coupling and its effect on brake squeal. SAE Technical Paper 1:0922. https://doi.org/10.4271/2002-01-0922

Chan SN, Mottershead JE, Cartmell MP (1994) Parametric resonances at subcritical speeds in discs with rotating frictional loads. Proc Inst Mech Eng C J Mech Eng Sci 208(6):417–425. https://doi.org/10.1243/PIME_PROC_1994_208_147_02

Rhee SK, Tsang PHS, Wang YS (1989) Friction-induced noise and vibration of disc brakes. Wear 133(1):39–45. https://doi.org/10.1016/0043-1648(89)90111-7

Cunefare KA, Graf AJ (2002) Experimental active control of automotive disc brake rotor squeal using dither. J Sound Vib 250(4):579–590. https://doi.org/10.1006/jsvi.2001.3909

Oberst S, Lai JCS (2015) A statistical approach to estimate the Lyapunov spectrum in disc brake squeal. J Sound Vib 334:120–135. https://doi.org/10.1016/j.jsv.2014.06.025

Giannini O, Akay A, Massi F (2006) Experimental analysis of brake squeal noise on a laboratory brake setup. J Sound Vib 292(1–2):1–20. https://doi.org/10.1016/j.jsv.2005.05.032

Akay A, Giannini O, Massi F, Sestieri A (2009) Disc brake squeal characterization through simplified test rigs. Mech Syst Signal Process 23(8):2590–2607. https://doi.org/10.1016/j.ymssp.2009.03.017

Felske A, Hoppe G, Matthäi H (1978) Oscillations in squealing disk brakes-analysis of vibration modes by holographic interferometry. SAE Technical Paper 780333, pp 1576–1595

Abendroth H (1999) Advances in brake NVH test equipment. Automot Eng. https://doi.org/10.4271/982241

Krupka R, Walz T, Ettemeyer A (2000) New techniques and applications for 3D-brake vibration analysis. SAE Technical Paper 1:2772. https://doi.org/10.4271/2000-01-2772

Bloch C, Treimer M, Müller G (2021) Linear and nonlinear energy analysis of a minimal model for brake squeal. J Sound Vib 508:116–188. https://doi.org/10.1016/j.jsv.2021.116188

Denimal E, Sinou JJ, Nacivet S (2019) Influence of structural modifications of automotive brake systems for squeal events with kriging meta-modelling method. J Sound Vib 463:114938. https://doi.org/10.1016/j.jsv.2019.114938

Lou G, Wu TW, Bai Z (2004) Disk brake squeal prediction using the ABLE algorithm. J Sound Vib 272(3–5):731–748. https://doi.org/10.1016/S0022-460X(03)00416-4

Dias AL, do Nascimento Rodriguesde Araújo Bezerra R, RR (2021) Heavy duty automotive drum brake squeal analysis using the finite element method. J Vib Eng Technolog 9:2019–2034. https://doi.org/10.1007/s42417-021-00346-2

Oberst S, Lai JCS (2015) Squeal noise in simple numerical brake models. J Sound Vib 352:129–141. https://doi.org/10.1016/j.jsv.2015.05.005

Ghorbel A, Zghal B, Abdennadher M, Walha L, Haddar M (2019) A new approach considering the brake pad geometry in brake squeal. Arch Appl Mech 89:2075–2088. https://doi.org/10.1007/s00419-019-01563-8

Kruse S, Tiedemann M, Zeumer B, Reuss P, Hetzler H, Hoffmann N (2015) The influence of joints on friction induced vibration in brake squeal. J Sound Vib 340:239–252. https://doi.org/10.1016/j.jsv.2014.11.016

Shin K, Brennan MJ, Oh JE, Harris CJ (2002) Analysis of disc brake noise using a two-degree-of-freedom model. J Sound Vib 254(5):837–848. https://doi.org/10.1006/jsvi.2001.4127

Wei D, Wang W, Wang B (2021) Bifurcation and chaotic behaviors of vehicle brake system under low speed braking condition. J Vib Eng Technolog 9:2107–2120. https://doi.org/10.1007/s42417-021-00350-6

Wei D, Ruan J, Zhu W, Kang Z (2016) Properties of stability, bifurcation, and chaos of the tangential motion disk brake. J Sound Vib 375:353–365. https://doi.org/10.1016/j.jsv.2016.04.022

Xu H, Jin X, Huang Z (2020) Random response of spring-damper-mass-belt system with coulomb friction. J Vib Eng Technol 8:685–693. https://doi.org/10.1007/s42417-019-00168-3

Sen OT, Singh R (2021) Dynamics of a simplified nonlinear model offering insights into the hammering type brake squeal initiation process. Noise Control Eng J 69(3):243–261. https://doi.org/10.3397/1/376924

Hochlenert D (2009) Nonlinear stability analysis of a disc brake model. Nonlinear Dyn 58:63–73. https://doi.org/10.1007/s11071-008-9461-0

Sinou JJ (2010) Transient non-linear dynamic analysis of automotive disc brake squeal on the need to consider both stability and nonlinear analysis. Mech Res Commun 37:96–105. https://doi.org/10.1016/j.mechrescom.2009.09.002

Zhang Z, Oberst S, Lai JCS (2016) On the potential of uncertainty analysis for prediction of brake squeal propensity. J Sound Vib 377:123–132. https://doi.org/10.1016/j.jsv.2016.05.023

Meziane A, Baillet L, Laulagnet B (2010) Experimental and numerical investigation of friction induced vibration of a beam-on-beam in contact with friction. Appl Acoust 71:843–853. https://doi.org/10.1016/j.apacoust.2010.04.012

Aronov V, D’Souza AF, Kalpakjian S, Shareef I (1984) Interactions among friction, wear, and system stiffness-Part 1: effect of Normal load and system stiffness. J Tribol 106:54–59. https://doi.org/10.1115/1.3260867

Wang H, Liu X, Shan Y, He T (2014) Nonlinear behavior evolution and squeal analysis of disc brake based on different friction models. J Vibroeng 16(5):2593–2609

Liu N, Ouyang H (2020) Friction-induced vibration considering multiple types of nonlinearities. Nonlinear Dyn 102:1–19. https://doi.org/10.1007/s11071-020-06055-x

Li Z, Ouyang H, Guan Z (2016) Nonlinear friction-induced vibration of a slider-belt system. J Vib Acoust 138(4):041006. https://doi.org/10.1115/1.4033256

Ghorbel A, Zghal B, Abdennadher M, Walha L, Haddar M (2020) Investigation of friction-induced vibration in a disk brake model, including mode-coupling and gyroscopic mechanisms. Proc Inst Mech Eng Part D J Automob Eng 234(2–3):887–896. https://doi.org/10.1177/095440701984572

Wang XC, Huang B, Wang RL, Mo JL, Ouyang H (2020) Friction-induced stick-slip vibration and its experimental validation. Mech Syst Signal Process 142:106705. https://doi.org/10.1016/j.ymssp.2020.106705

Pilipchuk V, Olejnik P, Awrejcewicz J (2015) Transient friction-induced vibrations in a 2-DOF model of brakes. J Sound Vib 344:297–312. https://doi.org/10.1016/j.jsv.2015.01.028

Sawczuk W, Ulbrich D, Kowalczyk J, Merkisz-Guranowska A (2021) Evaluation of wear of disc brake friction linings and the variability of the friction coefficient on the basis of vibroacoustic signals. Sensors 21(17):5927. https://doi.org/10.3390/s21175927

Sawczuk W, Ulbrich D, Kowalczyk J, Rilo Cañás A (2021) Modeling the average and instantaneous friction coefficient of a disc brake on the basis of bench tests. Materials 14(16):4766. https://doi.org/10.3390/ma14164766

Olsson H, Åström KJ, De Wit CC, Gäfvert M, Lischinsky P (1998) Friction models and friction compensation. Eur J Control 4(3):176–195. https://doi.org/10.1016/S0947-3580(98)70113-X

Bhushan B, Jahsman WE (1978) Propagation of weak waves in elastic-plastic and elastic-viscoplastic solids with interfaces. Int J Solids Struct 14(1):39–51. https://doi.org/10.1016/0020-7683(78)90063-X

Bhushan B, Jahsman WE (1978) Measurement of dynamic material behavior under nearly uniaxial strain conditions. Int J Solids Struct 14(9):739–753. https://doi.org/10.1016/0020-7683(78)90032-X

Bhushan B (1996) Tribology and mechanics of magnetic storage devices, 2nd edn. Springer-Verleg, New York

Blau PJ (1996) Friction Science and Technology. Marcel Dekker, New York

Sen OT, Dreyer JT, Singh R (2012) Order domain analysis of speed-dependent friction-induced torque in a brake experiment. J Sound Vib 331(23):5040–5053. https://doi.org/10.1016/j.jsv.2012.06.011

Sen OT, Dreyer JT, Singh R (2013) Envelope and order domain analyses of a nonlinear torsional system decelerating under multiple order frictional torque. Mech Syst Signal Process 35(1–2):324–344. https://doi.org/10.1016/j.ymssp.2012.09.008

Kim TC, Rook TE, Singh R (2003) Effect of smoothening functions on the frequency response of an oscillator with clearance non-linearity. J Sound Vib 263(3):665–678. https://doi.org/10.1016/S0022-460X(02)01469-4

Tonazzi D, Massi F, Salipante M, Baillet L, Berthier Y (2019) Estimation of the normal contact stiffness for frictional interface in sticking and sliding conditions. Lubricants 7(7):56. https://doi.org/10.3390/lubricants7070056

Oestreich M, Hinrichs N, Popp K (1996) Bifurcation and stability analysis for a non-smooth friction oscillator. Arch Appl Mech 66:301–314. https://doi.org/10.1007/BF00795247

Millner N (1978) An analysis of disc brake squeal. SAE technical paper 1565–1575

Eriksson M (2000) Friction and contact phenomena of disc brakes related to squeal, Ph.D. Dissertation. Acta Universitatis Upsaliensis, Uppsala, Sweden.

Bergman F, Eriksson M, Jacobson S (1996) Influence of disc topography on generation of brake squeal. Wear 225:621–628. https://doi.org/10.1016/S0043-1648(99)00064-2

Acknowledgements

The authors gratefully acknowledge the support from the Scientific and Technological Research Council of Turkey (3001 Starting R&D Projects Funding Program, Project No. 115M002) and Scientific Research Projects Coordination Unit at Istanbul Technical University (Project No. MGA-2018-41304).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

The change of \(\mu\) and \({\mu }_{c}\) with respect to \({F}_{\mathrm{pre}}\) at \({\omega }_{\mathrm{m}}=200 \, \mathrm{rpm}\) is shown in Fig. 25 for \({\theta }_{1}{=\theta }_{2}=27\pi /36 \, \mathrm{rad}\). As in Fig. 19, the system exhibits unstable dynamics in the shaded region. Thus, at the points shown with solid circle in Fig. 25, the system is in stable state. Though, the point given with solid square corresponds to an unstable regime. The experimental time histories and corresponding frequency spectra for these points are shown in Fig. 26. As seen in Fig. 26, the claims related to the stability of the system at the given points are experimentally validated.

Average dynamic friction coefficient and critical friction coefficient with respect to \({F}_{\mathrm{pre}}\) at \({\omega }_{\mathrm{m}}=200 \, \mathrm{rpm}\) and \({\theta }_{1}{=\theta }_{2}=27\pi /36 \, \mathrm{rad}\). Key: black solid line, \(\mu\); black dashed line, \({\mu }_{c}\) black circle, Stable operating point; black square, Unstable operating point; black times, Bifurcation point

Time and frequency domain representations of experimental data for the stable and unstable operating points at \({\omega }_{\mathrm{m}}=200 \, \mathrm{rpm}\) and\({\theta }_{1}{=\theta }_{2}=27\pi /36 \, \mathrm{rad}\). a Acceleration time history, b frequency spectra. Key: blue solid line, Stable operating point at \({F}_{\mathrm{pre}}=50 \, \mathrm{N}\); red solid line, Unstable operating point at \({F}_{\mathrm{pre}}=100 \, \mathrm{N}\) (color figure online)

As seen in Figs. 27 and 28, which are given for the angular configuration of \({\theta }_{1}{=\theta }_{2}=30\pi /36 \, \mathrm{rad}\) and \({\omega }_{\mathrm{m}}=200 \, \mathrm{rpm}\), the model is again validated with the experimental data. Though the system is always in stable state.

Average dynamic friction coefficient and critical friction coefficient with respect to \({F}_{\mathrm{pre}}\) at \({\omega }_{m}=200 \, \mathrm{rpm}\) and \({\theta }_{1}{=\theta }_{2}=30\pi /36 \, \mathrm{rad}\). Key: black solid line, \(\mu\); black dashed line, \({\mu }_{c}\); black circle, Stable operating point; black times, Bifurcation point

Time and frequency domain representations of experimental data for the stable and unstable operating points at \({\omega }_{\mathrm{m}}=200 \, \mathrm{rpm}\) and \({\theta }_{1}{=\theta }_{2}=30\pi /36 \, \mathrm{rad}\). a Acceleration time history at \({F}_{\mathrm{pre}}=50 \, \mathrm{N}\), b frequency spectra at \({F}_{\mathrm{pre}}=50 \, \mathrm{N}\), c acceleration time history at \({F}_{pre}=150 \, \mathrm{N}\), d frequency spectra at \({F}_{\mathrm{pre}}=150 \, \mathrm{N}\)

Appendix B

The change of \({\omega }_{\mathrm{m}}\) and \({\omega }_{\mathrm{mc}}\) with respect to \({F}_{\mathrm{pre}}\) is shown in Fig. 29 for \({\theta }_{1}{=\theta }_{2}=27\pi /36\mathrm{ rad}\). Again, the system exhibits unstable dynamics in the shaded region. Thus, the points shown with a solid circle and a solid square represent stable and unstable states, respectively. As evident from Fig. 30, experimental time histories and frequency spectra that correspond to these points validate the detected state by the linearized model. Furthermore, the critical speeds corresponding to \({F}_{\mathrm{pre}}=50 \, \mathrm{N}\) and \({F}_{\mathrm{pre}}=100 \, \mathrm{N}\) are \({\omega }_{mc}=73 \, \mathrm{rpm}\) and \({\omega }_{\mathrm{mc}}=278 \, \mathrm{rpm}\), respectively.

Time and frequency domain representations of experimental data for the stable and unstable operating points at\({ \theta }_{1}{=\theta }_{2}=27\pi /36 \, \mathrm{rad}\). a Acceleration time histories; b frequency spectra. Key: blue solid line, Stable operating point at \({F}_{\mathrm{pre}}=50 \, \mathrm{N}\) and \({ \omega }_{\mathrm{m}}=300 \, \mathrm{rpm}\); red solid line, Unstable operating point at \({F}_{\mathrm{pre}}=100 \, \mathrm{N}\) and \({ \omega }_{\mathrm{m}}=100 \, \mathrm{rpm}\) (color figure online)

As seen in Figs. 31 and 32, which are given for the angular configuration of \({\theta }_{1}{=\theta }_{2}=30\pi /36 rad\), the model is again validated with the experimental data. Though the system is always in stable state.

Time and frequency domain representations of experimental data for the stable and unstable operating points at \({\theta }_{1}{=\theta }_{2}=30\pi /36 \, \mathrm{rad}\). a Acceleration time history at \({F}_{\mathrm{pre}}=50 \, \mathrm{N}\) and \({\omega }_{\mathrm{m}}=200 \, \mathrm{rpm}\); b frequency spectra at \({F}_{\mathrm{pre}}=50 \, \mathrm{N}\) and \({\omega }_{\mathrm{m}}=200 \, \mathrm{rpm}\); c acceleration time history at \({F}_{\mathrm{pre}}=150 \, \mathrm{N}\) and \({\omega }_{\mathrm{m}}=100 \, \mathrm{rpm}\); d frequency spectra at \({F}_{\mathrm{pre}}=150 \, \mathrm{N}\) and \({\omega }_{\mathrm{m}}=100 \, \mathrm{rpm}\)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yavuz, A., Sen, O.T. Stability Analysis of a Mass-Sliding Belt System and Experimental Validation as Motivated by the Brake Squeal Problem. J. Vib. Eng. Technol. 12, 395–414 (2024). https://doi.org/10.1007/s42417-023-00849-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-023-00849-0