Abstract

Amorphous SiZnSnO (a-SZTO) thin film transistors (TFTs) have been reported with transparent Si–In–Zn–O/Ag/Si–In–Zn–O (SIZO OMO) source/drain (S/D) electrodes. The characteristics of ITO and SIZO OMO electrodes were compared with conventional metal electrode of Ti/Al. The SZTO TFT with SIZO OMO electrode showed high field effect mobility of 17.69 cm2/Vs, threshold voltage of 4.05 V and low sub-threshold swing of 0.33 V/decade. The stability of a-SZTO TFTs with SIZO OMO electrode was measured ∆VTH = 1.4 V at 333 K, and − 20 V for 7200 s under negative bias temperature stress (NBTS).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recent developments in transparent thin film transistors (TTFT) show great progress in emerging transparent electronics. In 2003, Hoffman et al. [1] showed the first fully transparent ZnO thin film transistor. Many important studies have been proven [2, 3]. General applications include active matrix displays, wearable devices, biosensors, logic circuits, and electronic skins [4,5,6]. Mechanical optical transparency, low power consumption, flexibility, low production cost, light weight and, above all, high electrical performance have made this device widely popular in the academy and industry. To implement a transparent electronic device, it is necessary to maintain low resistivity and energy band matching while maintaining the transparency of the source/drain (S/D) electrodes. Transparent conductive oxides (TCO), such as indium zinc oxide (IZO), indium tin oxide (ITO), and aluminum zinc oxide (AZO) have been widely reported for electrodes in transparent electronic devices [7,8,9]. TAOS is a promising alternative to poly-Si and a-Si, as the active channel layer shows good electrical properties including good uniformity, high field effect mobility (µFE), and good sub-threshold swing (S.S). Zn-based oxide TFTs (e.g. InGaZnO (IGZO), ZnSnO (ZTO), HfInZnO (HIZO), etc.) exhibited transparency in the visible region due to a large band gap of 3.37 eV or more [10,11,12]. Among them, IGZO TFT shows excellent electrical properties with a high carrier concentration of about 1020 cm−3, and is the most widely used TAOS material because of the high mobility and transparency compared to a-Si [13].

In this report, the electrical properties of a-SZTO TFTs with SiInZnO/Ag/SiInZnO electrodes to replace metal electrodes were studied. Such transparent conducting electrodes are of high transparency and low resistivity.

2 Experiment

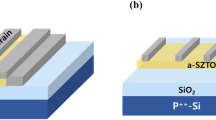

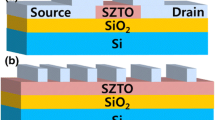

The a-SZTO thin film transistors were fabricated on Si substrates with thickness of 200 nm SiO2 as a gate insulator. The SZTO active layer was deposited by radio frequency magnetron sputtering using a target made of 0.5 wt% Si-incorporated SZTO. A magnetron sputtering power of 60 W and a process pressure of 3 mTorr were used for the deposition. The Ar:O2 gas ratio was used about 40:1 at room temperature. Post annealing treatment of the devices was performed at 500 °C for 2 h in air. By using photolithography and wet-etching processes, the width/length (W/L) of the active layer was patterned to be 250/50 µm. Finally, the source and the drain electrodes were deposited with Ti/Al (10/40 nm) by using an e-beam and thermal evaporation, ITO (50 nm) by using DC sputtering, and SIZO/Ag/SIZO (20/10/20 nm) by using RF sputtering and DC sputtering, respectively followed by lift off method. The electrical performance and the stability were measured in the dark using a semiconductor parameter analyzer (EL 423, ELECS Co.) and a vacuum probe station (HP4145B, Hewlett-Packard Co.).

3 Results and Discussion

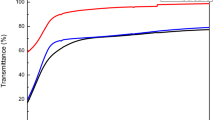

Figure 1 shows the transmittance of 0.5SZTO, Ti/Al, ITO, SIZO OMO on glass. The average optical transmittance of the 0.5SZTO, Ti/Al, ITO, SIZO OMO over the visible range of the average transmittance (380 ~ 780 nm) is approximately 94.2, 1.1, 64.4, 71.2%. As a result, the SIZO OMO electrode showed higher transmittance than Ti/Al which is a metal electrode, and ITO which is a widely used transparent electrode.

Figure 2 shows the transfer curve of a-SZTO TFTs with Ti/Al, ITO, SIZO OMO S/D electrodes. The electrical performance was measured at the gate voltage from − 20 to 40 V and the drain voltage (VDS) of 5.1 V. The electrical characteristics, such as threshold voltage (VTH), ION/OFF ratio, field effect mobility (µFE), and a threshold swing (S.S) were measured and summarized in Table 1. The SIZO OMO electrode device exhibited threshold voltage (VTH), ION/OFF ratio, field effect mobility (µFE), and a threshold swing (S.S) of 4.05 V, 1.57 × 109, 17.81 cm2/V s, and 0.33 V/decade, respectively. In addition, the curves exhibit low hysteresis (0.93 V) properties between forward and reverse sweeps shown in Fig. 2. The hysteresis value is smaller than other electrodes include Ti/Al (1.42 V) and ITO (0.94 V) [14]. Hysteresis is mainly caused by the charge-trapping between the channel and the gate insulator. The charge can be trapped or de-trapped and the hysteresis width can be changed depending on the VGS and defect density. The defect density can be considered to dependent mainly on the defect state in terms of instability. In experiment, the SIZO OMO device indicates low defect density at in the channel interface.

Figure 3 shows a plot of Rc and Rsh of a-SZTO TFT with Ti/Al, ITO, SIZO OMO S/D electrodes. The total resistance measured by the transmission line method (TLM) is a function of the sheet resistance of the channel and the contact resistance at channel/electrodes interfaces. The total resistance was calculated by using formula (1): [15]

where d is the separation of the electrodes, RTotal is the sheet resistance of the semiconducting layer outside the contact, Rc is the contact resistance between channel and S/D electrodes, and Rsh is the sheet resistance, and W is the electrodes width of fixed 250 \({{\upmu }}\) m. Figure 3 shows a plot of Rc and Rsh extracted from formula (1) as a function of Vgs, Rc, and Rsh obtained from the intercept of RTotal and the slope of the RTotal versus Lch plot. SIZO OMO electrode showed similar resistance as Ti/Al and ITO electrodes. As a result, SIZO OMO showed high transparency and low resistivity. Barquinha et al. [16] indicated an improvement on the electrical performance which was caused by some electron-diffusion between the S/D electrode and semiconductor interface.

Figure 4 shows the transfer curve of a-SZTO TFT with various electrodes under negative bias temperature stress (NBTS). The a-SZTO TFT was stressed under the following condition, such as the temperature and negative bias. VGS, and VDS were fixed, − 20, and 0.1 V at the temperature of to 60 °C during 120 min. A low negative ΔVTH shift of 1.401 V was observed as increasing stress time in a-SZTO TFTs with OMO electrodes. Compared to commonly used metal electrode Ti/Al with 2.783 V and the transparent conductive electrode ITO with 1.604 V, the SIZO OMO electrode showed excellent stability. At negative gate bias, the VTH moves in the negative direction due to the hole carrier trapping model near the gate insulator/channel layer interface. This means that the mechanism of NBTS, which is thermally excited electrons, is released at the trap site [17] and hole trapping is observed at the channel interface of the a-SZTO TFT [18]. And using Hall measurement, the resistance of SIZO OMO was measured as 5.38 × 10−5 Ω cm−3 and the resistance of ITO was measured to be 8.37 × 10−4 Ω cm−3. SIZO OMO, which has a small resistance, has a fast time for the charge of the channel layer to be trapped in the gate insulator and the channel/gate insulator interface [19]. Therefore, small VTH of SZTO TFT with SIZO/Ag/SIZO OMO electrode was measured because the SIZO OMO electrode diffused more electrons into the SZTO layer and had fewer trap sites than the other electrodes.

4 Conclusions

In conclusion, we studied a-SZTO TFT using Ti/Al, ITO, and SIZO OMO electrode. We measured the characteristics of a-SZTO TFT under negative bias temperature stress. Also, the observed average transmittance of Ti/Al, ITO, and SIZO OMO is 1.1, 64.4, and 71.2%. By using SIZO OMO electrode, a-SZTO TFT has good electrical properties such as \(\upmu\)FE (17.81 cm2/V s) and ION/OFF (1.57 × 109) and better stability (∆VTH = 1.401 V). Thus, applications as transparent thin film transistors with SIZO/Ag/SIZO OMO electrode are possible in next generation flexible or transparent displays, wearable devices, biosensors, logic circuits, and electronic skins.

References

R.L. Hoffman, B.J. Norris, J.F. Wager, Appl. Phys. Lett. 82, 733 (2003)

P.F. Carcia, R.S. McLean, M.H. Reilly, G. Nunes, Appl. Phys. Lett. 82, 1117 (2003)

K. Nomura, H. Ohta, A. Takagi, T. Kamiya, M. Hirano, H. Hosono, Nature 432, 488 (2004)

D. Karnaushenko, N. Munzenrieder, D.D. Karnaushenko, B. Koch, A.K. Meyer, S. Baunack, L. Petti, G. Troster, D. Makarov, O.G. Schmidt, Adv. Mater. 27, 6797–6805 (2015)

A.K. Tripathi, E.C.P. Smits, J.B.P.H. van der Putten, M. van Neer, K. Myny, M. Nag, S. Steudel, P. Vicca, K. O’Neill, E. van Veenendaal, J. Genoe, P. Heremans, G.H. Gelinck, Appl. Phys. Lett. 98, 162102 (2011)

J.S. Park, T.W. Kim, D. Stryahilev, J.S. Lee, S.G. An, Y.S. Pyo, D.B. Lee, Y.G. Mo, D.U. Jin, H.K. Chung, Appl. Phys. Lett. 95, 13503 (2009)

X. Jiang, F.L. Wong, M.K. Fung, S.T. Lee, Appl. Phys. Lett. 83, 1875 (2003)

M. Murugesan, D. Arjunraj, J. Mayandi, V. Venkatachalapathy, J.M. Pearce, Mater. Lett. 222, 50–53 (2018)

D.H. Kim, M.R. Park, H.J. Lee, G.H. Lee, Appl. Surf. Sci. 253, 409–411 (2006)

K. Hoshino, D. Hong, H.Q. Chiang, J.F. Wager, IEEE Trans. Electron. Dev. 56, 1365–1370 (2009)

H.Q. Chiang, J.F. Wager, R.L. Hoffman, J. Jeong, D.A. Keszler, Appl Phys Lett 86, 13503 (2005)

Y.R. Denny, H.C. Shin, S. Seo, S.K. Oh, H.J. Kang, D. Tahir, S. Heo, J.G. Chung, J.C. Lee, S. Tougaard, J. Electron Spectrosc. Relat. Phenom. 185, 18–22 (2012)

K. Nomura, H. Ohta, A. Takagi, T. Kamiya, M. Hirano, H. Hosono, Nature (London) 432, 488 (2004)

B. Li, C.Y. Han, P.T. Lai, W.M. Tang, Thin Solid Films 667, 28–33 (2018)

M. Spera, C. Miccoli, R.L. Nigro, C. Bongiorno, D. Corso, S.D. Franco, F. Iucolano, F. Roccaforte, G. Greco, Mater. Sci. Semicond. Process. 78, 111–117 (2018)

P. Barquinha, A.M. Vila, G. Goncalves, L. Pereira, R. Martins, J.R. Morante, E. Fortunato, IEEE Trans. Electron Dev. 55, 4 (2008)

B.H. Lee, S.Y. Lee, Trans. Electrical Electron. Mater. 18, 51–54 (2017)

M.Y. Tsai, T.C. Chang, A.K. Chu, T.Y. Hsieh, T.C. Chen, K.Y. Lin, W.W. Tsai, W.J. Chiang, J.Y. Yan, Appl. Phys. Lett. 103, 012101 (2013)

H.-S. Choi, W.-J. Cho, Phys. Status Solidi A 216, 1800653 (2018)

Acknowledgements

This work was supported by the Basic Science Research Program through the Korea Institute of Energy Technology Evaluation and Planning(KETEP) and the Ministry of Trade, Industry & Energy (MOTIE) of the Republic of Korea (No. 20172010104940).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hwang, J.Y., Lee, S.Y. Influence of Si–In–Zn–O/Ag/Si–In–Zn–O Electrode on Amorphous Si–Zn–Sn–O Thin Film Transistors. Trans. Electr. Electron. Mater. 22, 103–107 (2021). https://doi.org/10.1007/s42341-020-00277-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42341-020-00277-x