Abstract

The depletion of renewable source of energy and wastewater treatment are one of the concerning issues for the growing population. To overcome these problems, algae can be acts as one of the potent sources for biofuels feedstocks as well as biosorbents for wastewater treatment. The cultivation of microalgae leads to the removal of nutrients, heavy metals, dyes, and pharmaceutical waste from wastewater. Extracted lipids from microalgae are utilized for biodiesel production and lipid extracted microalgae can act as feedstocks for the production of bioethanol, biobutanol, and biogas. Biochar formed from microalgae can act as biosorbents. Several factors like temperature, the intensity of light, CO2, nutrient concentration, and inoculum size affect the cultivation of microalgae. Dynamic models are proposed for algal growth kinetics in raceway ponds and photobioreactors. Similarly, biomass concentration, initial pH, contact time, temperature, initial metal and dyes concentration, etc. affect the biosorption process. Biosorption isotherm kinetics are employed for heavy metals and dyes removal from wastewater. Energy sustainability of microalgal biodiesel production is evaluated by the life cycle energy balance equation, circular economy, and life cycle assessment (LCA) analysis.

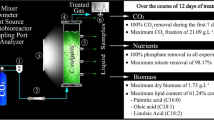

Graphic Abstract

Similar content being viewed by others

Abbreviations

- FTIR:

-

Fourier transform infrared spectroscopy

- SEM:

-

Scanning electron microscopy

- EDX:

-

Energy-dispersive X-ray spectroscopy

- XPS:

-

X-ray photoelectron spectroscopy

- XRD:

-

X-ray powder diffractometer

- XAS:

-

X-ray absorption spectroscopy

- AAS:

-

Atomic absorption spectrophotometry

- SAA:

-

Surface area analyzer

- TGA:

-

Thermogravimetric analyzer

- ICP-AES:

-

Inductively coupled plasma atomic emission spectroscopy

- ICP-AES:

-

Inductively coupled plasma optical emission spectrometry

- ICP-MS:

-

Inductively coupled plasma mass spectrometry

- TG:

-

Triglyceride

- MG:

-

Monoglyceride

- DG:

-

Diglyceride

- Gly:

-

Glycerol

- ME:

-

Methyl ester

- MeOH:

-

Methanol

- TMP:

-

Trans-membrane pressure (bar)

- EER:

-

Energy efficiency ratio

- LCA:

-

Life cycle assessment

- HTC:

-

Hydrothermal carbonization

- RCF:

-

Relative centrifugal force

- FAME:

-

Fatty acid methyl ester

- μ:

-

Specific growth rate (h−1)

- \(X_{1}\) :

-

Dry weight concentration (g L−1) at a time \(t_{1}\)

- \(X_{2}\) :

-

Dry weight concentration (g L−1) at a time t2

- \(I_{0}\) :

-

Incident photon flux density (PFD) (μ mole m−2 s−1)

- \(I\) :

-

Transmitted light over the layer thickness (μ mole m−2 s−1)

- cx :

-

Concentration of cell dry weight (g L−1)

- ɛ:

-

Specific extinction co-efficient (L g−1 cm−1)

- l:

-

Layer thickness at a random point (cm)

- NCO2 :

-

Carbon dioxide mass transfer rate (g CO2 m−3 h−1)

- Cco2 :

-

Dissolved carbon dioxide concentration in liquid phase

- \(C_{{CO_{2} }}^{*}\) :

-

Dissolved carbon dioxide concentration at equilibrium with the gas phase

- XA :

-

Mass concentration of microalgae

- XB :

-

Mass concentration of bacteria

- V:

-

Volume of the solution

- C 0 :

-

Inlets solute concentrations at any time (t)

- C :

-

Effluent solute concentrations at any time (t)

- k Th :

-

Thomas model constant (mL m−1 mg−1)

- q 0 :

-

Maximum solid-phase concentration of solute (mg g−1)

- m :

-

Total mass of the adsorbent (g)

- t :

-

Bed depth service time (h)

- N 0 :

-

Adsorption capacity (mg cm−3)

- Z :

-

Height of column (cm)

- C b :

-

Breakthrough sorbate concentration (mg L−1)

- ϑ :

-

Linear velocity (cm h−1)

- K a :

-

Rate constant (L mg−1 h−1) at time t.

- kAB :

-

Kinetic constant(L mg−1 min)

- kYN :

-

Rate of constant (L min−1)

- τ:

-

Time required for 50% adsorbate breakthrough (min)

- q e :

-

Biosorption capacity at equilibrium (mg g−1)

- q m :

-

Maximum uptake capacity of the biosorbent

- b :

-

Langmuir biosorption constant (L mg−1)

- c e :

-

Equilibrium metal ions concentration (mg L−1)

- \(X_{DR}\) :

-

Measure of adsorption capacity

- \(K_{DR}\) :

-

Activity coefficient (mol2 K J2)

- \(\varepsilon\) :

-

Polanyi potential respectively

- R:

-

Ideal gas constant (8.314 J mol−1 K−1)

- T:

-

Absolute temperature (K)

- q t,:

-

Amounts of metal or dye adsorbed at time t (mg g−1)

- k1 :

-

Rate constant of the pseudo-first-order kinetic model

- k2 :

-

Rate constant of the pseudo-second-order kinetic model

- t1/2 :

-

Half-life time in second

- Kdiff :

-

Rate constant of intraparticle diffusion(mg g−1 min1/2)

- α:

-

Initial adsorption rate (mg g−1 min−1)

- β:

-

Extent of surface coverage and activation energy for adsorption (g mg−1)

- ∆G0 :

-

Gibb’s energy(J mol−1)

- ∆S0 :

-

Adsorption entropy (J mol−1 K)

- ∆H0 :

-

Adsorption enthalpy (J mol−1)

- \(S\) :

-

Sedimentation rate

- \(v\) :

-

Particle velocity (m s−1)

- \(d_{p}\) :

-

Diameter of the particle

- \(\rho_{p}\) :

-

Density of the particle

- \(\rho\) :

-

Density of the fluid,

- \(\omega\) :

-

Aangular velocity in (rad s−1)

- \(r\) :

-

Distance between the central axis and the sphere

- \(J\) :

-

Permeate flux (L m−2 h−1)

- \(\eta\) :

-

Viscosity of permeate (Pa s)

- \(R_{m}\) :

-

Membrane resistance (m−1)

- \(R_{c}\) :

-

Cake resistance (m−1)

- \(R_{f}\) :

-

Resistance from pore blocking and absorption (m−1)

- A :

-

Frequency or pre-exponential factor

- E a :

-

Activation energy of the reaction,

- X :

-

Cell concentration (g L−1)

- X 0 :

-

Initial cell concentration (g L−1)

- X max :

-

Maximum cell concentration (g L−1)

- μ m :

-

Maximum specific growth rate (h−1)

- P :

-

Ethanol concentration (g L−1)

- P max :

-

Maximum ethanol concentration (g L−1)

- r m :

-

Maximum cell production rate, (g L−1·h)

- r p.max :

-

Maximum ethanol production rate, (g L−1·h)

- t :

-

Fermentation time (h)

- t L :

-

Lag phase or lag time from the beginning of fermentation to exponential growth or ethanol production (h)

- Q:

-

Thermal energy (KJ)

- \(m_{i}\) :

-

Weight of reactant and solvent involved in the reaction (kg)

- \(C_{Pi}\) :

-

Specific heat capacity of reactant and solvent (kg kg−1 °C)

- \(\Delta T\) :

-

Change in temperature

- \(C_{s}\) :

-

Cost of utility

- \(m_{biodiesel}\) :

-

Weight of biodiesel produced (kg)

- \(f_{I}\) :

-

Light intensity factor

References

Khoo KS, Chew KW, Yew GY, Leong WH, Chai YH, Show PL, Chen WH (2020) Recent advances in downstream processing of microalgae lipid recovery for biofuel production. Bioresour Technol 304:122996. https://doi.org/10.1016/j.biortech.2020.122996

Li H, Watson J, Zhang Y, Lu H, Liu Z (2020) Environment-enhancing process for algal wastewater treatment, heavy metal control and hydrothermal biofuel production: a critical review. Bioresour Technol 298:122421. https://doi.org/10.1016/j.biortech.2019.122421

Leong YK, Chang JS (2020) Bioremediation of heavy metals using microalgae: recent advances and mechanisms. Bioresour Technol 303:122886. https://doi.org/10.1016/j.biortech.2020.122886

Chin JY, Chng LM, Leong SS, Yeap SP, Yasin NHM, Toh PY (2020) Removal of synthetic dye by Chlorella vulgaris microalgae as natural adsorbent. Arab J Sci Eng. https://doi.org/10.1007/s13369-020-04557-9

Gita S, Shukla SP, Saharan N et al (2019) Toxic effects of selected textile dyes on elemental composition, photosynthetic pigments, protein content and growth of a freshwater chlorophycean alga Chlorella vulgaris. Bull Environ Contam Toxicol 102:795–801. https://doi.org/10.1007/s00128-019-02599-w

Rebello S, Anoopkumar AN, Aneesh EM, Sindhu R, Binod P, Pandey A (2020) Sustainability and life cycle assessments of lignocellulosic and algal pretreatments. Bioresour Technol 301:122678. https://doi.org/10.1016/j.biortech.2019.122678

Khan MI, Shin JH, Kim JD (2018) The promising future of microalgae: current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb Cell Factor 17(1):36. https://doi.org/10.1186/s12934-018-0879-x

Lee XJ, Ong HC, Gan YY, Chen WH, Mahlia TMI (2020) State of art review on conventional and advanced pyrolysis of macroalgae and microalgae for biochar, bio-oil and bio-syngas production. Energy Convers Manag 210:112707. https://doi.org/10.1016/j.enconman.2020.112707

Galès A, Bonnafous A, Carré C, Jauzein V, Lanouguère E, Le Floc’h E, Simier M (2019) Importance of ecological interactions during wastewater treatment using high rate algal ponds under different temperate climates. Algal Res 40:101508. https://doi.org/10.1016/j.algal.2019.101508

Zhu S, Feng S, Xu Z, Qin L, Shang C, Feng P, Yuan Z (2019) Cultivation of Chlorella vulgaris on unsterilized dairy-derived liquid digestate for simultaneous biofuels feedstock production and pollutant removal. Bioresour Technol 285:121353. https://doi.org/10.1016/j.biortech.2019.121353

Fazal T, Mushtaq A, Rehman F, Khan AU, Rashid N, Farooq W, Xu J (2018) Bioremediation of textile wastewater and successive biodiesel production using microalgae. Renew Sustain Energy Rev 82:3107–3126. https://doi.org/10.1016/j.rser.2017.10.029

Peng L, Fu D, Chu H, Wang Z, Qi H (2020) Biofuel production from microalgae: a review. Environ Chem Lett. https://doi.org/10.1007/s10311-019-00939-0

Menegazzo ML, Fonseca GG (2019) Biomass recovery and lipid extraction processes for microalgae biofuels production: a review. Renew Sustain Energy Rev 107:87–107. https://doi.org/10.1016/j.rser.2019.01.064

Guldhe A, Kumari S, Ramanna L, Ramsundar P, Singh P, Rawat I, Bux F (2017) Prospects, recent advancements and challenges of different wastewater streams for microalgal cultivation. J Environ Manag 203:299–315. https://doi.org/10.1016/j.jenvman.2017.08.012

Salama ES, Kurade MB, Abou-Shanab RA, El-Dalatony MM, Yang IS, Min B, Jeon BH (2017) Recent progress in microalgal biomass production coupled with wastewater treatment for biofuel generation. Renew Sustain Energy Rev 79:1189–1211. https://doi.org/10.1016/j.rser.2017.05.091

Cuellar-Bermudez SP, Aleman-Nava GS, Chandra R, Garcia-Perez JS, Contreras-Angulo JR, Markou G, Parra-Saldivar R (2017) Nutrients utilization and contaminants removal. A review of two approaches of algae and cyanobacteria in wastewater. Algal Res 24:438–449. https://doi.org/10.1016/j.algal.2016.08.018

Yu KL, Show PL, Ong HC, Ling TC, Lan JCW, Chen WH, Chang JS (2017) Microalgae from wastewater treatment to biochar—feedstock preparation and conversion technologies. Energy Convers Manag 150:1–13. https://doi.org/10.1016/j.enconman.2017.07.060

Mohan SV, Rohit MV, Chiranjeevi P, Chandra R, Navaneeth B (2015) Heterotrophic microalgae cultivation to synergize biodiesel production with waste remediation: progress and perspectives. Biores Technol 184:169–178. https://doi.org/10.1016/j.biortech.2014.10.056

Maheshwari N, Krishna PK, Thakur IS, Srivastava S (2019) Biological fixation of carbon dioxide and biodiesel production using microalgae isolated from sewage waste water. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-019-05928-y

Lakatos GE, Ranglová K, Manoel JC, Grivalský T, Kopecký J, Masojídek J (2019) Bioethanol production from microalgae polysaccharides. Folia microbiol. https://doi.org/10.1007/s12223-019-00732-0

Kareya MS, Mariam I, Nesamma AA, Jutur PP (2020) CO2 sequestration by hybrid integrative photosynthesis (CO2-SHIP): a green initiative for multi-product biorefineries. Mater Sci Energy Technol 3:420–428. https://doi.org/10.1016/j.mset.2020.03.002

Pires JC, Alvim-Ferraz MC, Martins FG (2017) Photobioreactor design for microalgae production through computational fluid dynamics: a review. Renew Sustain Energy Rev 79:248–254. https://doi.org/10.1016/j.rser.2017.05.064

Kroumov AD, Módenes AN, Trigueros DEG, Espinoza-Quiñones FR, Borba CE, Scheufele FB, Hinterholz CL (2016) A systems approach for CO2 fixation from flue gas by microalgae—theory review. Process Biochem 51(11):1817–1832. https://doi.org/10.1016/j.procbio.2016.05.019

Aziz MMA, Kassim KA, Shokravi Z, Jakarni FM, Lieu HY, Zaini N, Shokravi H (2020) Two-stage cultivation strategy for simultaneous increases in growth rate and lipid content of microalgae: a review. Renew Sustain Energy Rev 119:109621. https://doi.org/10.1016/j.rser.2019.109621

Eze VC, Velasquez-Orta SB, Hernández-García A, Monje-Ramírez I, Orta-Ledesma MT (2018) Kinetic modelling of microalgae cultivation for wastewater treatment and carbon dioxide sequestration. Algal Res 32:131–141. https://doi.org/10.1016/j.algal.2018.03.015

Chandra R, Iqbal HM, Vishal G, Lee HS, Nagra S (2019) Algal biorefinery: a sustainable approach to valorize algal-based biomass towards multiple product recovery. Technol Biores. https://doi.org/10.1016/j.biortech.2019.01.104

Laamanen CA, Scott JA (2020) Microalgae biofuel bioreactors for mitigation of industrial CO2 emissions. In: Singh L, Yousuf A, Mahapatra DM (eds) Bioreactors. Elsevier, pp 1–16. https://doi.org/10.1016/B978-0-12-821264-6.00001-2

Xu L, Weathers PJ, Xiong XR, Liu CZ (2009) Microalgal bioreactors: challenges and opportunities. Eng Life Sci 9(3):178–189. https://doi.org/10.1002/elsc.200800111

Nguyen LN, Truong MV, Nguyen AQ, Johir MAH, Commault AS, Ralph PJ, Nghiem LD (2020) A sequential membrane bioreactor followed by a membrane microalgal reactor for nutrient removal and algal biomass production. Environ Sci Water Res Technol 6(1):189–196. https://doi.org/10.1039/C9EW00851A

Chu F, Cheng J, Zhang X, Ye Q, Zhou J (2019) Enhancing lipid production in microalgae Chlorella PY-ZU1 with phosphorus excess and nitrogen starvation under 15% CO2 in a continuous two-step cultivation process. Chem Eng J 375:121912. https://doi.org/10.1016/j.cej.2019.121912

Fu J, Huang Y, Liao Q, Xia A, Fu Q, Zhu X (2019) Photo-bioreactor design for microalgae: a review from the aspect of CO2 transfer and conversion. Biores Technol. https://doi.org/10.1016/j.biortech.2019.121947

Zhang B, Li W, Guo Y, Zhang Z, Shi W, Cui F, Tay JH (2020) Microalgal-bacterial consortia: from interspecies interactions to biotechnological applications. Renew Sustain Energ Rev 118:109563. https://doi.org/10.1016/j.rser.2019.109563

Wu W, Chang JS (2019) Integrated algal biorefineries from process systems engineering aspects: a review. Biores Technol. https://doi.org/10.1016/j.biortech.2019.121939

Gonçalves AL, Pires JC, Simões M (2017) A review on the use of microalgal consortia for wastewater treatment. Algal Res 24:403–415. https://doi.org/10.1016/j.algal.2016.11.008

Tiron O, Bumbac C, Manea E, Stefanescu M, Lazar MN (2017) Overcoming microalgae harvesting barrier by activated algae granules. Sci Rep 7(1):1–11. https://doi.org/10.1038/s41598-017-05027-3

Passos F, Gutiérrez R, Uggetti E, Garfi M, García J, Ferrer I (2017) Towards energy neutral microalgae-based wastewater treatment plants. Algal Res 28:235–243. https://doi.org/10.1016/j.algal.2017.11.006

Sharma J, Kumar V, Kumar SS, Malyan SK, Mathimani T, Bishnoi NR, Pugazhendhi A (2020) Microalgal consortia for municipal wastewater treatment—lipid augmentation and fatty acid profiling for biodiesel production. J Photochem Photobiol B 202:111638. https://doi.org/10.1016/j.jphotobiol.2019.111638

Hu X, Meneses YE, Stratton J, Wang B (2019) Acclimation of consortium of micro-algae help removal of organic pollutants from meat processing wastewater. J Clean Prod 214:95–102. https://doi.org/10.1016/j.jclepro.2018.12.255

Fan J, Chen Y, Zhang TC, Ji B, Cao L (2020) Performance of Chlorella sorokiniana-activated sludge consortium treating wastewater under light-limited heterotrophic condition. Chem Eng J 382:122799. https://doi.org/10.1016/j.cej.2019.122799

Makut BB, Das D, Goswami G (2019) Production of microbial biomass feedstock via co-cultivation of microalgae-bacteria consortium coupled with effective wastewater treatment: a sustainable approach. Algal Res 37:228–239. https://doi.org/10.1016/j.algal.2018.11.020

Chen X, Hu Z, Qi Y, Song C, Chen G (2019) The interactions of algae-activated sludge symbiotic system and its effects on wastewater treatment and lipid accumulation. Biores Technol 292:122017. https://doi.org/10.1016/j.biortech.2019.122017

Huo S, Chen J, Zhu F, Zou B, Chen X, Basheer S, Qian J (2019) Filamentous microalgae Tribonema sp. cultivation in the anaerobic/oxic effluents of petrochemical wastewater for evaluating the efficiency of recycling and treatment. Biochem Eng J 145:27–32. https://doi.org/10.1016/j.bej.2019.02.011

Hernández-García A, Velásquez-Orta SB, Novelo E, Yáñez-Noguez I, Monje-Ramírez I, Ledesma MTO (2019) Wastewater-leachate treatment by microalgae: biomass, carbohydrate and lipid production. Ecotoxicol Environ Saf 174:435–444. https://doi.org/10.1016/j.ecoenv.2019.02.052

Larsen C, Yu ZH, Flick R, Passeport E (2019) Mechanisms of pharmaceutical and personal care product removal in algae-based wastewater treatment systems. Sci Total Environ 695:133772. https://doi.org/10.1016/j.scitotenv.2019.133772

Urrutia C, Yañez-Mansilla E, Jeison D (2019) Bioremoval of heavy metals from metal mine tailings water using microalgae biomass. Algal Res 43:101659. https://doi.org/10.1016/j.algal.2019.101659

Marzari F, Bellucci M, Fornaroli R, Bani A, Ficara E, Mezzanotte V (2019) Lab-scale testing of operation parameters for algae based treatment of piggery wastewater. J Chem Technol Biotechnol. https://doi.org/10.1002/jctb.5972

Dhaouefi Z, Toledo-Cervantes A, Ghedira K, Chekir-Ghedira L, Muñoz R (2019) Decolorization and phytotoxicity reduction in an innovative anaerobic/aerobic photobioreactor treating textile wastewater. Chemosphere. https://doi.org/10.1016/j.chemosphere.2019.06.106

Cheng P, Cheng JJ, Cobb K, Zhou C, Zhou N, Addy M, Ruan R (2019) Tribonema sp. and Chlorella zofingiensis co-culture to treat swine wastewater diluted with fishery wastewater to facilitate harvest. Biores Technol. https://doi.org/10.1016/j.biortech.2019.122516

Piligaev AV, Sorokina KN, Shashkov MV, Parmon VN (2018) Screening and comparative metabolic profiling of high lipid content microalgae strains for application in wastewater treatment. Biores Technol 250:538–547. https://doi.org/10.1016/j.biortech.2017.11.063

Das C, Ramaiah N, Pereira E, Naseera K (2018) Efficient bioremediation of tannery wastewater by monostrains and consortium of marine Chlorella sp and Phormidium sp. Int J Phytoremediat 20(3):284–292. https://doi.org/10.1080/15226514.2017.1374338

Shi X, Yeap TS, Huang S, Chen J, Ng HY (2018) Pretreatment of saline antibiotic wastewater using marine microalga. Biores Technol 258:240–246. https://doi.org/10.1016/j.biortech.2018.02.110

Vuppaladadiyam AK, Merayo N, Blanco A, Hou J, Dionysiou DD, Zhao M (2018) Simulation study on comparison of algal treatment to conventional biological processes for greywater treatment. Algal Res 35:106–114. https://doi.org/10.1016/j.algal.2018.08.021

Bello M, Ranganathan P, Brennan F (2017) Dynamic modelling of microalgae cultivation process in high rate algal wastewater pond. Algal Res 24:457–466. https://doi.org/10.1016/j.algal.2016.10.016

Rangabhashiyam S, Balasubramanian P (2019) Characteristics, performances, equilibrium and kinetic modeling aspects of heavy metal removal using algae. Bioresour Technol Rep 5:261–279. https://doi.org/10.1016/j.biteb.2018.07.009

Cheng SY, Show PL, Lau BF, Chang JS, Ling TC (2019) New prospects for modified algae in heavy metal adsorption. Trends Biotechnol. https://doi.org/10.1016/j.tibtech.2019.04.007

Sun X, Huang H, Zhao D, Lin J, Gao P, Yao L (2020) Adsorption of Pb2+ onto freeze-dried microalgae and environmental risk assessment. J Environ Manag 265:110472. https://doi.org/10.1016/j.jenvman.2020.110472

Saravanan A, Kumar PS, Yaashikaa PR, Kanmani S, Varthine RH, Muthu CMM, Yuvaraj D (2019) Modelling on the removal of dye from industrial wastewater using surface improved Enteromorpha intestinalis. Int J Environ Res 13(2):349–366. https://doi.org/10.1007/s41742-019-00181-0

Nicomel NR, Otero-Gonzalez L, Arashiro L, Garfí M, Ferrer I, Van Der Voort P, Du Laing G (2020) Microalgae: a sustainable adsorbent with high potential for upconcentration of indium (iii) from liquid process and waste streams. Green Chem 22(6):1985–1995. https://doi.org/10.1039/C9GC03073E

Afshariani F, Roosta A (2019) Experimental study and mathematical modeling of biosorption of methylene blue from aqueous solution in a packed bed of microalgae Scenedesmus. J Clean Prod 225:133–142. https://doi.org/10.1016/j.jclepro.2019.03.275

Patel H (2019) Fixed-bed column adsorption study: a comprehensive review. Appl Water Sci 9(3):45. https://doi.org/10.1007/s13201-019-0927-7

Daneshvar E, Zarrinmehr MJ, Kousha M, Hashtjin AM, Saratale GD, Maiti A, Bhatnagar A (2019) Hexavalent chromium removal from water by microalgal-based materials: adsorption, desorption and recovery studies. Biores Technol 293:122064. https://doi.org/10.1016/j.biortech.2019.122064

Brion-Roby R, Gagnon J, Nosrati S, Deschênes JS, Chabot B (2018) Adsorption and desorption of molybdenum (VI) in contaminated water using a chitosan sorbent. J Water Process Eng 23:13–19. https://doi.org/10.1016/j.jwpe.2018.02.016

Devi S, Murugappan A, Rajesh Kannan R (2016) Textile dye wastewater treatment using freshwater algae in packed-bed reactor: modeling. Desalin Water Treat 57(38):17995–18002. https://doi.org/10.1080/19443994.2015.1085910

Jerold M, Joseph D, Patra N, Sivasubramanian V (2016) Fixed-bed column studies for the removal of hazardous malachite green dye from aqueous solution using novel nano zerovalent iron algal biocomposite. Nanotechnol Environ Eng 1(1):8. https://doi.org/10.1007/s41204-016-0007-2

Tukarambai M, Venakateswarlu P (2019) A study of lead removal using sargassum tenerrimum (brown algae): biosorption in column study. Mater Today Proc. https://doi.org/10.1016/j.matpr.2019.11.254

Beni AA, Esmaeili A (2020) Biosorption, an efficient method for removing heavy metals from industrial effluents: a review. Environ Technol Innov 17:100503. https://doi.org/10.1016/j.eti.2019.100503

Moreira VR, Lebron YAR, Freire SJ, Santos LVS, Palladino F, Jacob RS (2019) Biosorption of copper ions from aqueous solution using Chlorella pyrenoidosa: optimization, equilibrium and kinetics studies. Microchem J 145:119–129. https://doi.org/10.1016/j.microc.2018.10.027

da Rosa ALD, Carissimi E, Dotto GL, Sander H, Feris LA (2018) Biosorption of rhodamine B dye from dyeing stones effluents using the green microalgae Chlorella pyrenoidosa. J Clean Prod 198:1302–1310. https://doi.org/10.1016/j.jclepro.2018.07.128

Gül ÜD, Taştan BE, Bayazıt G (2019) Assessment of algal biomasses having different cell structures for biosorption properties of acid red P-2BX dye. S Afr J Bot 127:147–152. https://doi.org/10.1016/j.sajb.2019.08.047

Jiang X, Wang H, Hu E, Lei Z, Fan B, Wang Q (2020) Efficient adsorption of uranium from aqueous solutions by microalgae based aerogel. Microporous Mesoporous Mater. https://doi.org/10.1016/j.micromeso.2020.110383

Jayakumar V, Govindaradjane S, Rajasimman M (2019) Isotherm and kinetic modeling of sorption of cadmium onto a novel red algal sorbent, Hypnea musciformis. Model Earth Syst Environ 5:793–803. https://doi.org/10.1007/s40808-018-0566-2

Montazer-Rahmati MM, Rabbani P, Abdolali A, Keshtkar AR (2011) Kinetics and equilibrium studies on biosorption of cadmium, lead, and nickel ions from aqueous solutions by intact and chemically modified brown algae. J Hazard Mater 185(1):401–407. https://doi.org/10.1016/j.jhazmat.2010.09.047

Sebeia N, Jabli M, Ghith A, Elghoul Y, Alminderej FM (2019) Production of cellulose from Aegagropila linnaei macro-algae: chemical modification, characterization and application for the bio-sorptionof cationic and anionic dyes from water. Int J Boil Macromol 135:152–162. https://doi.org/10.1016/j.ijbiomac.2019.05.128

Dulla JB, Tamana MR, Boddu S, Pulipati K, Srirama K (2020) Biosorption of copper (II) onto spent biomass of Gelidiella acerosa (brown marine algae): optimization and kinetic studies. Appl Water Sci 10(2):1–10. https://doi.org/10.1007/s13201-019-1125-3

Mirghaffari N, Moeini E, Farhadian O (2015) Biosorption of Cd and Pb ions from aqueous solutions by biomass of the green microalga, Scenedesmus quadricauda. J Appl Phycol 27:311–320. https://doi.org/10.1007/s10811-014-0345-z

Birungi ZS, Chirwa EMN (2015) The adsorption potential and recovery of thallium using green micro-algae from eutrophic water sources. J Hazard Mater 299:67–77. https://doi.org/10.1016/j.jhazmat.2015.06.011

Dirbaz M, Roosta A (2018) Adsorption, kinetic and thermodynamic studies for the biosorption of cadmium onto microalgae Parachlorella sp. J Environ Chem Eng 6(2):2302–2309. https://doi.org/10.1016/j.jece.2018.03.039

Shen Y, Li H, Zhu W, Ho SH, Yuan W, Chen J, Xie Y (2017) Microalgal-biochar immobilized complex: a novel efficient biosorbent for cadmium removal from aqueous solution. Biores Technol 244:1031–1038. https://doi.org/10.1016/j.biortech.2017.08.085

Kayalvizhi K, Vijayaraghavan K, Velan M (2015) Biosorption of Cr (VI) using a novel microalga Rhizoclonium hookeri: equilibrium, kinetics and thermodynamic studies. Desalin Water Treat 56(1):194–203. https://doi.org/10.1080/19443994.2014.932711

Suganya S, Saravanan A, Senthil Kumar P, Yashwanthraj M, Sundar Rajan P, Kayalvizhi K (2017) Sequestration of Pb (II) and Ni (II) ions from aqueous solution using microalga Rhizoclonium hookeri: adsorption thermodynamics, kinetics, and equilibrium studies. J Water Reuse Desalin 7(2):214–227. https://doi.org/10.2166/wrd.2016.200

Saber M, Takahashi F, Yoshikawa K (2018) Characterization and application of microalgae hydrochar as a low-cost adsorbent for Cu (II) ion removal from aqueous solutions. Environ Sci Pollut Res 25(32):32721–32734. https://doi.org/10.1007/s11356-018-3106-8

Jiang X, Zhou X, Li C, Wan Z, Yao L, Gao P (2019) Adsorption of copper by flocculated Chlamydomonas microsphaera microalgae and polyaluminium chloride in heavy metal-contaminated water. J Appl Phycol 31(2):1143–1151. https://doi.org/10.1007/s10811-018-1636-6

Shen L, Wang J, Li Z, Fan L, Chen R, Wu X, Zeng W (2020) A high-efficiency Fe2O3@ microalgae composite for heavy metal removal from aqueous solution. J Water Process Eng 33:101026. https://doi.org/10.1016/j.jwpe.2019.101026

Wei C, Huang Y, Liao Q, Xia A, Zhu X, Zhu X (2019) Adsorption thermodynamic characteristics of Chlorella vulgaris with organic polymer adsorbent cationic starch: effect of temperature on adsorption capacity and rate. Bioresour Technol 293:122056. https://doi.org/10.1016/j.biortech.2019.122056

Kadir WNA, Lam MK, Uemura Y, Lim JW, Lee KT (2018) Harvesting and pre-treatment of microalgae cultivated in wastewater for biodiesel production: a review. Energy convers Manag 171:1416–1429. https://doi.org/10.1016/j.enconman.2018.06.074

Yin Z, Zhu L, Li S, Hu T, Chu R, Mo F, Li B (2020) A comprehensive review on cultivation and harvesting of microalgae for biodiesel production: environmental pollution control and future directions. Bioresour Technol 301:122804. https://doi.org/10.1016/j.biortech.2020.122804

Roselet F, Vandamme D, Muylaert K, Abreu PC (2019) Harvesting of microalgae for biomass production. In: Wang Z (ed) Asraful Alam Md. Microalgae biotechnology for development of biofuel and wastewater treatment. Springer, Singapore, pp 211–243. https://doi.org/10.1007/978-981-13-2264-8_1

Mofijur M, Rasul MG, Hassan NMS, Nabi MN (2019) Recent development in the production of third generation biodiesel from microalgae. Energy Procedia 156:53–58. https://doi.org/10.1016/j.egypro.2018.11.088

Pérez L, Salgueiro JL, Maceiras R, Cancela Á, Sánchez Á (2017) An effective method for harvesting of marine microalgae: pH induced flocculation. Biomass Bioenergy 97:20–26. https://doi.org/10.1016/j.biombioe.2016.12.010

Gupta SK, Ansari FA, Bauddh K, Singh B, Nema AK, Pant KK (2017) Harvesting of microalgae for biofuels: comprehensive performance evaluation of natural, inorganic, and synthetic locculants. In: Singh R, Kumar S (eds) Green technologies and environmental sustainability. Springer, Cham, pp 131–156. https://doi.org/10.1016/B978-0-12-817388-6.00002-7

Hawari AH, Alkhatib AM, Das P, Thaher M, Benamor A (2020) Effect of the induced dielectrophoretic force on harvesting of marine microalgae (Tetraselmis sp.) in electrocoagulation. J. Environ Manag. 260:110106. https://doi.org/10.1016/j.jenvman.2020.110106

Patel A, Matsakas L, Sartaj K, Chandra R (2020) Extraction of lipids from algae using supercritical carbon dioxide. In: Green sustainable process for chemical and environmental engineering and science. Elsevier, pp 17–39. https://doi.org/10.1016/B978-0-12-817388-6.00002-7

Alhattab M, Kermanshahi-Pour A, Brooks MSL (2019) Microalgae disruption techniques for product recovery: influence of cell wall composition. J Appl Phycol 31(1):61–88. https://doi.org/10.1007/s10811-018-1560-9

Pan J, Muppaneni T, Sun Y, Reddy HK, Fu J, Lu X, Deng S (2016) Microwave-assisted extraction of lipids from microalgae using an ionic liquid solvent [BMIM][HSO4]. Fuel 178:49–55. https://doi.org/10.1016/j.fuel.2016.03.037

Zhou X, Jin W, Tu R, Guo Q, Han SF, Chen C, Wang Q (2019) Optimization of microwave assisted lipid extraction from microalga Scenedesmus obliquus grown on municipal wastewater. J Clean Prod 221:502–508. https://doi.org/10.1016/j.jclepro.2019.02.260

Anto S, Mukherjee SS, Muthappa R, Mathimani T, Deviram G, Kumar SS, Pugazhendhi A (2020) Algae as green energy reserve: technological outlook on biofuel production. Chemosphere 242:125079. https://doi.org/10.1016/j.chemosphere.2019.125079

Tang X, Zhang C, Yang X (2020) Optimizing process of hydrothermal liquefaction of microalgae via flash heating and isolating aqueous extract from bio-crude. J Clean Prod 258:120660. https://doi.org/10.1016/j.jclepro.2020.120660

Mathimani T, Mallick N (2019) A review on the hydrothermal processing of microalgal biomass to bio-oil-knowledge gaps and recent advances. J Clean Prod 217:69–84. https://doi.org/10.1016/j.jclepro.2019.01.129

Ma G, Mu R, Capareda SC, Qi F (2020) Use of ultrasound for aiding lipid extraction and biodiesel production of microalgae harvested by chitosan. Environ Technol. https://doi.org/10.1080/09593330.2020.1745288

Ranjith Kumar R, Hanumantha Rao P, Arumugam M (2015) Lipid extraction methods from microalgae: a comprehensive review. Front Energy Res 2:61. https://doi.org/10.3389/fenrg.2014.00061

Garcia-Vaquero M, Rajauria G, Tiwari B (2020) Conventional extraction techniques: solvent extraction. In: Torres MD, Kraan S, Dominguez H (eds) Sustainable seaweed technologies. Elsevier, pp 171–189. https://doi.org/10.1016/B978-0-12-817943-7.00006-8

Shin HY, Shim SH, Ryu YJ, Yang JH, Lim SM, Lee CG (2018) Lipid extraction from Tetraselmis sp. microalgae for biodiesel production using hexane-based solvent mixtures. Biotechnol Bioprocess Eng 23(1):16–22. https://doi.org/10.1007/s12257-017-0392-9

Hena S, Fatimah S, Tabassum S (2015) Cultivation of algae consortium in a dairy farm wastewater for biodiesel production. Water Resour Ind 10:1–14. https://doi.org/10.1016/j.wri.2015.02.002

Ling Y, Sun LP, Wang SY, Lin CSK, Sun Z, Zhou ZG (2019) Cultivation of oleaginous microalga Scenedesmus obliquus coupled with wastewater treatment for enhanced biomass and lipid production. Biochem Eng J 148:162–169. https://doi.org/10.1016/j.bej.2019.05.012

Bélanger-Lépine F, Tremblay A, Huot Y, Barnabé S (2018) Cultivation of an algae-bacteria consortium in wastewater from an industrial park: effect of environmental stress and nutrient deficiency on lipid production. Bioresour Technol 267:657–665. https://doi.org/10.1016/j.biortech.2018.07.099

Tan XB, Zhao XC, Zhang YL, Zhou YY, Yang LB, Zhang WW (2018) Enhanced lipid and biomass production using alcohol wastewater as carbon source for Chlorella pyrenoidosa cultivation in anaerobically digested starch wastewater in outdoors. Bioresour Technol 247:784–793. https://doi.org/10.1016/j.biortech.2017.09.152

Rinna F, Buono S, Cabanelas ITD, Nascimento IA, Sansone G, Barone CMA (2017) Wastewater treatment by microalgae can generate high quality biodiesel feedstock. J Water Process Eng 18:144–149. https://doi.org/10.1016/j.jwpe.2017.06.006

Lam MK, Yusoff MI, Uemura Y, Lim JW, Khoo CG, Lee KT, Ong HC (2017) Cultivation of Chlorella vulgaris using nutrients source from domestic wastewater for biodiesel production: growth condition and kinetic studies. Renew Energy 103:197–207. https://doi.org/10.1016/j.renene.2016.11.032

Guldhe A, Ansari FA, Singh P, Bux F (2017) Heterotrophic cultivation of microalgae using aquaculture wastewater: a biorefinery concept for biomass production and nutrient remediation. Ecol Eng 99:47–53. https://doi.org/10.1016/j.ecoleng.2016.11.013

Mousavi S, Najafpour GD, Mohammadi M, Seifi MH (2018) Cultivation of newly isolated microalgae Coelastrum sp. in wastewater for simultaneous CO2 fixation, lipid production and wastewater treatment. Bioprocess Biosyst Eng 41(4):519–530. https://doi.org/10.1007/s00449-017-1887-7

Di Caprio F, Altimari P, Pagnanelli F (2018) Integrated microalgae biomass production and olive mill wastewater biodegradation: optimization of the wastewater supply strategy. Chem Eng J 349:539–546. https://doi.org/10.1016/j.cej.2018.05.084

Cheah WY, Show PL, Juan JC, Chang JS, Ling TC (2018) Enhancing biomass and lipid productions of microalgae in palm oil mill effluent using carbon and nutrient supplementation. Energy Convers Manag 164:188–197. https://doi.org/10.1016/j.enconman.2018.02.094

Hena S, Znad H, Heong KT, Judd S (2018) Dairy farm wastewater treatment and lipid accumulation by Arthrospira platensis. Water Res 128:267–277. https://doi.org/10.1016/j.watres.2017.10.057

Pandey A, Srivastava S, Kumar S (2019) Isolation, screening and comprehensive characterization of candidate microalgae for biofuel feedstock production and dairy effluent treatment: a sustainable approach. Biores Technol 293:121998. https://doi.org/10.1016/j.biortech.2019.121998

Kumar AK, Sharma S, Shah E, Parikh BS, Patel A, Dixit G, Divecha JM (2019) Cultivation of Ascochloris sp. ADW007-enriched microalga in raw dairy wastewater for enhanced biomass and lipid productivity. Int J Environ Sci Technol 16(2):943–954. https://doi.org/10.1007/s13762-018-1712-0

Passos F, Felix L, Rocha H, de Oliveira Pereira J, de Aquino S (2016) Reuse of microalgae grown in full-scale wastewater treatment ponds: thermochemical pretreatment and biogas production. Biores Technol 209:305–312. https://doi.org/10.1016/j.biortech.2016.03.006

Chen CY, Kuo EW, Nagarajan D, Ho SH, Dong CD, Lee DJ, Chang JS (2020) Cultivating Chlorella sorokiniana AK-1 with swine wastewater for simultaneous wastewater treatment and algal biomass production. Biores Technol 302:122814. https://doi.org/10.1016/j.biortech.2020.122814

Amini M, Khoei ZA, Erfanifar E (2019) Nitrate (NO3−) and phosphate (PO43−) removal from aqueous solutions by microalgae Dunaliella salina. Biocatal Agric Biotechnol 19:101097. https://doi.org/10.1016/j.bcab.2019.101097

Bolognesi S, Bernardi G, Callegari A, Dondi D, Capodaglio AG (2019) Biochar production from sewage sludge and microalgae mixtures: properties, sustainability and possible role in circular economy. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-019-00572-5

Sekar M, Mathimani T, Alagumalai A, Chi NTL, Duc PA, Bhatia SK, Pugazhendhi A (2021) A review on the pyrolysis of algal biomass for biochar and bio-oil—bottlenecks and scope. Fuel 283:119190. https://doi.org/10.1016/j.fuel.2020.119190

Sharma S, Kundu A, Basu S, Shetti NP, Aminabhavi TM (2020) Sustainable environmental management and related biofuel technologies. J Environ Manag 273:111096. https://doi.org/10.1016/j.jenvman.2020.111096

Wu W, Lei YC, Chang JS (2019) Life cycle assessment of upgraded microalgae-to-biofuel chains. Biores Technol 288:121492. https://doi.org/10.1016/j.biortech.2019.121492

Khan MI, Shin JH, Kim JD (2018) The promising future of microalgae: current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb Cell Fact 17(1):36. https://doi.org/10.1186/s12934-018-0879-x

Milledge JJ (2011) Commercial application of microalgae other than as biofuels: a brief review. Rev Environ Sci Biotechnol 10(1):31–41. https://doi.org/10.1007/s11157-010-9214-7

Turkkul B, Deliismail O, Seker E (2020) Ethyl esters biodiesel production from Spirulina sp. and Nannochloropsis oculata microalgal lipids over alumina-calcium oxide catalyst. Renew Energy 145:1014–1019. https://doi.org/10.1016/j.renene.2019.06.093

Khan SA, Hussain MZ, Prasad S, Banerjee UC (2009) Prospects of biodiesel production from microalgae in India. Renew Sustain Energ Rev 13(9):2361–2372. https://doi.org/10.1016/j.rser.2009.04.005

Nguyen TT, Lam MK, Uemura Y, Mansor N, Lim JW, Show PL, Lim S (2020) High biodiesel yield from wet microalgae paste via in-situ transesterification: effect of reaction parameters towards the selectivity of fatty acid esters. Fuel 272:117718. https://doi.org/10.1016/j.fuel.2020.117718

Teo SH, Islam A, Taufiq-Yap YH (2016) Algae derived biodiesel using nanocatalytic transesterification process. Chem Eng Res Des 111:362–370. https://doi.org/10.1016/j.cherd.2016.04.012

Nautiyal P, Subramanian KA, Dastidar MG (2014) Kinetic and thermodynamic studies on biodiesel production from Spirulina platensis algae biomass using single stage extraction–transesterification process. Fuel 135:228–234. https://doi.org/10.1016/j.fuel.2014.06.063

Singh J, Tiwari ON, Dhar DW (2019) Overview of carbon capture technology: microalgal biorefinery concept and state-of-the-art. Front Mar Sci 6:29. https://doi.org/10.3389/fmars.2019.00029

Ahmad I, Sharma AK, Daniell H, Kumar S (2015) Altered lipid composition and enhanced lipid production in green microalga by introduction of brassica diacylglycerol acyltransferase 2. Plant Biotechnol J 13(4):540–550. https://doi.org/10.1111/pbi.12278

Rajvanshi S, Sharma MP (2012) Micro algae: a potential source of biodiesel. J Sustain Bioenergy Syst 2(03):49. https://doi.org/10.4236/jsbs.2012.23008

Akubude VC, Nwaigwe KN, Dintwa E (2019) Production of biodiesel from microalgae via nanocatalyzed transesterification process: a review. Mater Sci Energy Technol 2(2):216–225. https://doi.org/10.1016/j.mset.2018.12.006

Smachetti MES, Coronel CD, Salerno GL, Curatti L (2020) Sucrose-to-ethanol microalgae-based platform using seawater. Algal Res 45:101733. https://doi.org/10.1016/j.algal.2019.101733

Kumar AN, Chatterjee S, Hemalatha M, Althuri A, Min B, Kim SH, Mohan SV (2020) Deoiled algal biomass derived renewable sugars for bioethanol and biopolymer production in biorefinery framework. Bioresour Technol 296:122315. https://doi.org/10.1016/j.biortech.2019.122315

de Carvalho JC, Magalhães AI Jr, de Melo Pereira GV, Medeiros ABP, Sydney EB, Rodrigues C, Soccol CR (2020) Microalgal biomass pretreatment for integrated processing into biofuels, food, and feed. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.122719

Phwan CK, Chew KW, Sebayang AH, Ong HC, Ling TC, Malek MA, Show PL (2019) Effects of acids pre-treatment on the microbial fermentation process for bioethanol production from microalgae. Biotechnol Biofuels 12(1):191. https://doi.org/10.1186/s13068-019-1533-5

El-Dalatony MM, Kurade MB, Abou-Shanab RA, Kim H, Salama ES, Jeon BH (2016) Long-term production of bioethanol in repeated-batch fermentation of microalgal biomass using immobilized Saccharomyces cerevisiae. Bioresour Technol 219:98–105. https://doi.org/10.1016/j.biortech.2016.07.113

Phukoetphim N, Salakkam A, Laopaiboon P, Laopaiboon L (2017) Kinetic models for batch ethanol production from sweet sorghum juice under normal and high gravity fermentations: logistic and modified Gompertz models. J Biotechnol 243:69–75. https://doi.org/10.1016/j.jbiotec.2016.12.012

Wang Y, Ho SH, Yen HW, Nagarajan D, Ren NQ, Li S, Chang JS (2017) Current advances on fermentative biobutanol production using third generation feedstock. Biotechnol Adv 35(8):1049–1059. https://doi.org/10.1016/j.biotechadv.2017.06.001

Ibrahim MF, Kim SW, Abd-Aziz S (2018) Advanced bioprocessing strategies for biobutanol production from biomass. Renew Sustain Energ Rev 91:1192–1204. https://doi.org/10.1016/j.rser.2018.04.060

Yeong TK, Jiao K, Zeng X, Lin L, Pan S, Danquah MK (2018) Microalgae for biobutanol production—technology evaluation and value proposition. Algal Res 31:367–376. https://doi.org/10.1016/j.algal.2018.02.029

Birgen C, Berglihn OT, Preisig HA, Wentzel A (2019) Kinetic study of butanol production from mixtures of glucose and xylose and investigation of different pre-growth strategies. Biochem Eng J 147:110–117. https://doi.org/10.1016/j.bej.2019.04.002

Birgen C, Dürre P, Preisig HA, Wentzel A (2019) Butanol production from lignocellulosic biomass: revisiting fermentation performance indicators with exploratory data analysis. Biotechnol Biofuels 12(1):167. https://doi.org/10.1186/s13068-019-1508-6

Li S, Huang L, Ke C, Pang Z, Liu L (2020) Pathway dissection, regulation, engineering and application: lessons learned from biobutanol production by solventogenic clostridia. Biotechnol Biofuels 13(1):1–25. https://doi.org/10.1186/s13068-020-01674-3

Nimbalkar PR, Khedkar MA, Kulkarni RK, Chavan PV, Bankar SB (2019) Strategic intensification in butanol production by exogenous amino acid supplementation: fermentation kinetics and thermodynamic studies. Bioresour Technol 288:121521. https://doi.org/10.1016/j.biortech.2019.121521

Azimi H, Tezel H, Thibault J (2019) Optimization of the in situ recovery of butanol from ABE fermentation broth via membrane pervaporation. Chem Eng Res Des 150:49–64. https://doi.org/10.1016/j.cherd.2019.07.012

Anwar M, Lou S, Chen L, Li H, Hu Z (2019) Recent advancement and strategy on bio-hydrogen production from photosynthetic microalgae. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.121972

Khetkorn W, Rastogi RP, Incharoensakdi A, Lindblad P, Madamwar D, Pandey A, Larroche C (2017) Microalgal hydrogen production—a review. Bioresour Technol 243:1194–1206. https://doi.org/10.1016/j.biortech.2017.07.085

Nagarajan D, Lee DJ, Kondo A, Chang JS (2017) Recent insights into biohydrogen production by microalgae—from biophotolysis to dark fermentation. Bioresour Technol 227:373–387. https://doi.org/10.1016/j.biortech.2016.12.104

Mona S, Kumar SS, Kumar V, Parveen K, Saini N, Deepak B, Pugazhendhi A (2020) Green technology for sustainable biohydrogen production (waste to energy): a review. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2020.138481

Sharma A, Arya SK (2017) Hydrogen from algal biomass: a review of production process. Biotechnol Rep 15:63–69. https://doi.org/10.1016/j.btre.2017.06.001

Wang J, Yin Y (2018) Fermentative hydrogen production using pretreated microalgal biomass as feedstock. Microb Cell Fact 17(1):22. https://doi.org/10.1186/s12934-018-0871-5

Bayro-Kaiser V, Nelson N (2017) Microalgal hydrogen production: prospects of an essential technology for a clean and sustainable energy economy. Photosynth Res 133(1–3):49–62. https://doi.org/10.1007/s11120-017-0350-6

Bolatkhan K, Kossalbayev BD, Zayadan BK, Tomo T, Veziroglu TN, Allakhverdiev SI (2019) Hydrogen production from phototrophic microorganisms: reality and perspectives. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2019.01.092

Show KY, Yan Y, Zong C, Guo N, Chang JS, Lee DJ (2019) State of the art and challenges of biohydrogen from microalgae. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.121747

Zabed HM, Akter S, Yun J, Zhang G, Zhang Y, Qi X (2020) Biogas from microalgae: technologies, challenges and opportunities. Renew Sustain Energ Rev 117:109503. https://doi.org/10.1016/j.rser.2019.109503

Ward AJ, Lewis DM, Green FB (2014) Anaerobic digestion of algae biomass: a review. Algal Res 5:204–214. https://doi.org/10.1016/j.algal.2014.02.001

Buswell AM, Boruff CS (1932) The relation between the chemical composition of organic matter and the quality and quantity of gas produced during sludge digestion. Sewage Works J 4:454–460

Gan YY, Ong HC, Chen WH, Sheen HK, Chang JS, Chong CT, Ling TC (2020) Microwave-assisted wet torrefaction of microalgae under various acids for coproduction of biochar and sugar. J Clean Prod. https://doi.org/10.1016/j.jclepro.2019.119944

Li F, Srivatsa SC, Bhattacharya S (2019) A review on catalytic pyrolysis of microalgae to high-quality bio-oil with low oxygeneous and nitrogenous compounds. Renew Sustain Energ Rev 108:481–497. https://doi.org/10.1016/j.rser.2019.03.026

Sotoudehniakarani F, Alayat A, McDonald AG (2019) Characterization and comparison of pyrolysis products from fast pyrolysis of commercial Chlorella vulgaris and cultivated microalgae. J Anal Appl Pyrolysis 139:258–273. https://doi.org/10.1016/j.jaap.2019.02.014

Plácido J, Bustamante-López S, Meissner KE, Kelly DE, Kelly SL (2019) Microalgae biochar-derived carbon dots and their application in heavy metal sensing in aqueous systems. Sci Total Environ 656:531–539. https://doi.org/10.1016/j.scitotenv.2018.11.393

Nagarajan D, Lee DJ, Chen CY, Chang JS (2020) Resource recovery from wastewaters using microalgae-based approaches: a circular bioeconomy perspective. Bioresour Technol 302:122817. https://doi.org/10.1016/j.biortech.2020.122817

Stegmann P, Londo M, Junginger M (2020) The circular bioeconomy: its elements and role in European bioeconomy clusters. Resour Conserv Recycl X. https://doi.org/10.1016/j.rcrx.2019.100029

Banu JR, Kavitha S, Gunasekaran M, Kumar G (2020) Microalgae based biorefinery promoting circular bioeconomy-techno economic and life-cycle analysis. Bioresour Technol 302:122822. https://doi.org/10.1016/j.biortech.2020.122822

Ubando AT, Felix CB, Chen WH (2020) Biorefineries in circular bioeconomy: a comprehensive review. Bioresour Technol 299:122585. https://doi.org/10.1016/j.biortech.2019.122585

Mohan SV, Hemalatha M, Chakraborty D, Chatterjee S, Ranadheer P, Kona R (2020) Algal biorefinery models with self-sustainable closed loop approach: trends and prospective for blue-bioeconomy. Bioresour Technol 295:122128. https://doi.org/10.1016/j.biortech.2019.122128

Lam MK, Lee KT (2014) Cultivation of Chlorella vulgaris in a pilot-scale sequential-baffled column photobioreactor for biomass and biodiesel production. Energy convers Manag 88:399–410. https://doi.org/10.1016/j.enconman.2014.08.063

Hossain N, Mahlia TMI, Zaini J, Saidur R (2019) Techno-economics and sensitivity analysis of microalgae as commercial feedstock for bioethanol production. Environ Progr Sustain Energy 38(5):13157. https://doi.org/10.1002/ep.13157

Kumar A, Saini K, Bhaskar T (2020) Hydochar and biochar: production, physicochemical properties and techno-economic analysis. Bioresour Technol. https://doi.org/10.1016/j.biortech.2020.123442

Pandit PR, Fulekar MH (2019) Biodiesel production from microalgal biomass using CaO catalyst synthesized from natural waste material. Renew Energy 136:837–845. https://doi.org/10.1016/j.renene.2019.01.047

Gonçalves AL, Alvim-Ferraz M, Martins FG, Simões M, Pires J (2016) Integration of microalgae-based bioenergy production into a petrochemical complex: techno-economic assessment. Energies 9(4):224. https://doi.org/10.3390/en9040224

Nhat PVH, Ngo HH, Guo WS, Chang SW, Nguyen DD, Nguyen PD, Guo JB (2018) Can algae-based technologies be an affordable green process for biofuel production and wastewater remediation? Biores Technol 256:491–501. https://doi.org/10.1016/j.biortech.2018.02.031

Figueroa-Torres GM, Mahmood WMAW, Pittman JK, Theodoropoulos C (2020) Microalgal biomass as a biorefinery platform for biobutanol and biodiesel production. Biochem Eng J 153:107396. https://doi.org/10.1016/j.bej.2019.107396

Yu KL, Chen WH, Sheen HK, Chang JS, Lin CS, Ong HC, Ling TC (2020) Bioethanol production from acid pretreated microalgal hydrolysate using microwave-assisted heating wet torrefaction. Fuel 279:118435. https://doi.org/10.1016/j.fuel.2020.118435

Wu H, Li J, Liao Q, Fu Q, Liu Z (2020) Enhanced biohydrogen and biomethane production from Chlorella sp. with hydrothermal treatment. Energy Convers Manag 205:112373. https://doi.org/10.1016/j.enconman.2019.112373

Yu KL, Chen WH, Sheen HK, Chang JS, Lin CS, Ong HC, Ling TC (2020) Production of microalgal biochar and reducing sugar using wet torrefaction with microwave-assisted heating and acid hydrolysis pretreatment. Energy Renew. https://doi.org/10.1016/j.renene.2020.04.064

Khoo CG, Lam MK, Mohamed AR, Lee KT (2020) Hydrochar production from high-ash low-lipid microalgal biomass via hydrothermal carbonization: effects of operational parameters and products characterization. Environ Res. https://doi.org/10.1016/j.envres.2020.109828

Giarola S, Forte O, Lanzini A, Gandiglio M, Santarelli M, Hawkes A (2018) Techno-economic assessment of biogas-fed solid oxide fuel cell combined heat and power system at industrial scale. Appl Energy 211:689–704. https://doi.org/10.1016/j.apenergy.2017.11.029

Hossain N, Zaini J, Mahlia TMI, Azad AK (2019) Elemental, morphological and thermal analysis of mixed microalgae species from drain water. Renew Energy 131:617–624. https://doi.org/10.1016/j.renene.2018.07.082

Purohit P, Chaturvedi V (2018) Biomass pellets for power generation in India: a techno-economic evaluation. Environ Sci Pollut Res 25(29):29614–29632. https://doi.org/10.1007/s11356-018-2960-8

Choi HI, Lee JS, Choi JW, Shin YS, Sung YJ, Hong ME, Sim SJ (2019) Performance and potential appraisal of various microalgae as direct combustion fuel. Biores Technol 273:341–349. https://doi.org/10.1016/j.biortech.2018.11.030

Bhushan S, Kalra A, Simsek H, Kumar G, Prajapati SK (2020) Current trends and prospects in microalgae-based bioenergy production. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2020.104025

Gupta S, Pawar SB, Pandey RA (2019) Current practices and challenges in using microalgae for treatment of nutrient rich wastewater from agro-based industries. Sci Total Environ 687:1107–1126. https://doi.org/10.1016/j.scitotenv.2019.06.115

Abdel-Raouf N, Al-Homaidan AA, Ibraheem IBM (2012) Microalgae and wastewater treatment. Saudi J Biol Sci 19(3):257–275. https://doi.org/10.1006/eesa.1995.1064

Khan S, Fu P (2020) Biotechnological perspectives on algae: a viable option for next generation biofuels. Curr Opin Biotechnol 62:146–152. https://doi.org/10.1016/j.copbio.2019.09.020

Kumar AN, Chatterjee S, Hemalatha M, Althuri A, Min B, Kim SH, Mohan SV (2020) Deoiled algal biomass derived renewable sugars for bioethanol and biopolymer production in biorefinery framework. Biores Technol 296:122315. https://doi.org/10.1016/j.biortech.2019.122315

Kim EJ, Kim S, Choi HG, Han SJ (2020) Co-production of biodiesel and bioethanol using psychrophilic microalga Chlamydomonas sp. KNM0029C isolated from Arctic sea ice. Biotechnol Biofuels 13(1):1–13. https://doi.org/10.1186/s13068-020-1660-z

Behera B, Dey B, Balasubramanian P (2020) Algal biodiesel production with engineered biochar as a heterogeneous solid acid catalyst. Biores Technol. https://doi.org/10.1016/j.biortech.2020.123392

Khoo CG, Lam MK, Mohamed AR, Lee KT (2020) Hydrochar production from high-ash low-lipid microalgal biomass via hydrothermal carbonization: effects of operational parameters and products characterization. Environ Res 188:109828. https://doi.org/10.1016/j.envres.2020.109828

Azizi K, Moraveji MK, Najafabadi HA (2018) A review on bio-fuel production from microalgal biomass by using pyrolysis method. Renew Sustain Energy Rev 82:3046–3059. https://doi.org/10.1016/j.rser.2017.10.033

Akbari M, Oyedun AO, Kumar A (2020) Techno-economic assessment of wet and dry torrefaction of biomass feedstock. Energy 207:118287. https://doi.org/10.1016/j.energy.2020.118287

Wang Y, Yang H, Zhang X, Han F, Tu W, Yang W (2020) Microalgal hydrogen production. Small Methods 4(3):1900514. https://doi.org/10.1002/smtd.201900514

Sun J, Xiong X, Wang M, Du H, Li J, Zhou D, Zuo J (2019) Microalgae biodiesel production in China: a preliminary economic analysis. Renew Sustain Energy Rev 104:296–306. https://doi.org/10.1016/j.rser.2019.01.021

Muhammad G, Alam MA, Mofijur M, Jahirul MI, Lv Y, Xiong W, Xu J (2020) Modern developmental aspects in the field of economical harvesting and biodiesel production from microalgae biomass. Renew Sustain Energy Rev 135:110209. https://doi.org/10.1016/j.rser.2020.110209

Saravanan AP, Pugazhendhi A, Mathimani T (2020) A comprehensive assessment of biofuel policies in the BRICS nations: implementation, blending target and gaps. Fuel 272:117635. https://doi.org/10.1016/j.fuel.2020.117635

Klein BC, Chagas MF, Watanabe MDB, Bonomi A, Maciel Filho R (2019) Low carbon biofuels and the New Brazilian National Biofuel Policy (RenovaBio): a case study for sugarcane mills and integrated sugarcane-microalgae biorefineries. Renew Sustain Energy Rev 115:109365. https://doi.org/10.1016/j.rser.2019.109365

Szulczyk KR, Cheema MA (2020) The economic feasibility and environmental ramifications of biobutanol production in Malaysia. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.124953

Mukherjee M, Goswami G, Mondal PK, Das D (2020) Biobutanol as a potential alternative to petroleum fuel: sustainable bioprocess and cost analysis. Fuel 278:118403. https://doi.org/10.1016/j.fuel.2020.118403

Theuerl S, Herrmann C, Heiermann M, Grundmann P, Landwehr N, Kreidenweis U, Prochnow A (2019) The future agricultural biogas plant in Germany: a vision. Energies 12(3):396. https://doi.org/10.3390/en12030396

Gu L, Zhang YX, Wang JZ et al (2016) Where is the future of China’s biogas? Review, forecast, and policy implications. Pet Sci 13:604–624. https://doi.org/10.1007/s12182-016-0105-6

Carrasco-Reinado R, Escobar A, Carrera C, Guarnizo P, Vallejo RA, Fernández-Acero FJ (2019) Valorization of microalgae biomass as a potential source of high-value sugars and polyalcohols. LWT 114:108385. https://doi.org/10.1016/j.lwt.2019.108385

Sanchez J, Curt MD, Robert N, Fernandez J (2019) Biomass resources. In: Lago C, Caldés N, Lechón Y (eds) The role of bioenergy in the bioeconomy. Academic Press, pp 25–111. https://doi.org/10.1016/B978-0-12-813056-8.00002-9

Acknowledgements

The author acknowledged the library support provided by Lovely Professional University, India.

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent for publication

Not applicable.

Rights and permissions

About this article

Cite this article

Kumar, A. Current and Future Perspective of Microalgae for Simultaneous Wastewater Treatment and Feedstock for Biofuels Production. Chemistry Africa 4, 249–275 (2021). https://doi.org/10.1007/s42250-020-00221-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-020-00221-9