Abstract

In a recent publication, my group discussed a directive second order parameter that hypothetically could form micrometer large structures that influence the rheological behavior of a bicontinuous microemulsion. For this, the viscosities of two microemulsions with the non-ionic surfactants C10E4 and C8E3 were determined over the wide frequency and shear rate range. Contrarily to our previous publications there are no elevated viscosities towards slowest motions of the rheometer. Thus, no micrometer large structures form in microemulsions. However, we argue and confirm that there are compartments with the size of several correlation lengths. This finding supports the development of a directional order parameter in microemulsions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Microemulsions [1] consist of two immiscible liquids oil and water that are mediated by a surfactant. They are thermodynamically stable and form spontaneously. On the nanometer length scales the two liquids are still immiscible and form domains that are separated by the surfactant film. If mixing equal amounts of oil and water, then mostly bicontinuous microemulsions form [2]. Each of the liquids develops a sponge structure that hosts the other liquid. The surfactant film has the shape of minimal surfaces with a mean curvature zero and many stalks that connect the membrane network. The bicontinuous phase is very close to the phase inversion temperature \(\tilde{T}\) (for non-ionic surfactants) where the spontaneous curvature changes sign. Furthermore, a minimum of surfactant \(\tilde{\gamma }\) is needed to warrant the thermodynamic stability of this bicontinuous one-phase system. The critical point (\(\tilde{\gamma },\tilde{T}\)) in this phase diagram (temperature versus surfactant amount) is called fish tail point, because the fish body with a three phase coexistence is found towards lower surfactant amounts, and the fish tail with a one-phase region (predominantly with the bicontinuous structure) towards higher surfactant amounts. Below and above of these phase boundaries, two-phase coexistence is found with expelled oil and water, respectively. A review on microemulsions is found in Ref. 1, chapter 1.

When bicontinuous microemulsions are exposed to external surfaces the near surface structure can change. One understandable example is the formation of lamellar structures [3] at hydrophilic surfaces that decay towards the bulk by an increasing number of stalks. But also cubic structures may be aligned by the external interface [4]. All of these structures display longer persistence into the bulk than the predominant correlation length that is observed in the bulk. This would point to a second directional order parameter that is needed to describe microemulsions. While the scalar order parameter describes the alternating bulk structure of oil and water, the directional order parameter builds up from locally rather stable domains. Such building blocks or compartments would build up the whole liquid with an interaction between them depending on their orientation. This finding was discussed for the first time in Ref. [4].

A second hypothesis [4] was built on the finding of elevated viscosities at very low shear rates. Hypothetically, micrometer large chains of domains would build. In this manuscript we prove that this observation was made by deficient measurements.

However, we measure the viscosities and diffusion constants of two microemulsions with non-ionic surfactants and discuss the experimental findings in this context. We confirm the formation of compartments, i.e. a local formation of domains that are a basis for the liquid structure. So a directional order parameter can develop on this basis.

2 Experimental

2.1 Chemicals

The surfactans decyl tetraethylene glycol ether (C10E4) and octyl triethylene glycol ether (C8E3) were purchased form Bachem, Weil am Rhein, Germany and used without further purification. Heavy water (D2O) was purchased from Armar Chemicals, Döttingen, Switzerland and used without further purification. Sodium chloride and n-decane were purchased from Sigma Aldrich, Taufkirchen, Germany and used as delivered. Normal water (H2O) was desalinated according to standard lab procedures. The aqueous fraction was mixed with 1 and 1.1 wt% NaCl in light/heavy water. The bicontinuous microemulsions were mixed using 17/41.5/41.5 vol% fractions of C10E4/D2O/decane and 27/36.5/36.5 vol% fractions of C8E3/H2O/decane. The mixtures formed one-phase systems spontaneously after short shaking at a temperature of 25 and 21.5 °C (close to the phase inversion temperature) where all experiments were conducted. The bulk phase is forming a bicontinuous structure [1, 4].

2.2 Rheometry

The rheometric measurements are performed on a MCR-702 from Anton Paar, Ostfildern, Germany. As tools we used the Couette cell devoted to small angle neutron scattering (SANS) measurements. The advantage is a large active surface and the geometry being suitable for easily wetting fluids. The inner diameter of the static outer cylinder is 50 mm and the outer diameter of the moved inner cylinder 49 mm. The active height is 60 mm. Gaps for the fluid below and above of about 5 mm are kept for minimal interference to the actual rheometric measurement. Further states of fillings with the fluid meniscus close to the upper rim of the inner cylinder are discussed later in the manuscript. The oscillatory shear experiments are conducted between frequencies of ω = 600 and 0.001 s−1 with growing amplitudes (both on logarithmic scales) between γ = 1 and 1000%. The microemulsions were all in the linear range. The steady shear experiments investigated shear rates of \(\dot{\gamma } = 1000\) and 0.001 s−1. The temperatures were kept constant at 25 and 21.5 °C for the C10E4 and C8E3 systems using a cooled air flow against heating.

2.3 Viscometry

Using the Malvern Zetasizer Nano the automated procedure measures the scattered intensity at one angle (173 °C) with a wavelength of 633 nm. The protocol directly delivers sizes of hydrodynamic radii that we reverted to the raw diffusion constants because they are the original magnitudes of the measurement. For that conversion, we used the provided viscosities of their calibrated water.

3 Results and Discussion

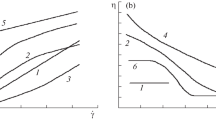

The results of the complex viscosity in an oscillatory shear experiment on the microemulsion containing C10E4 as surfactant are depicted in Fig. 1 as black symbols. Starting from highest shear frequencies ω, the inertia of the moved cylinder leads to an overestimation of the viscosity by a factor of up to approx. 5. Only at about ω = 40 s−1, the viscosity stays constant close to the average of 0.01 Pa s. The measured deviations from that average stay in the instrumental limit and are thus negligible. Similarly, does the steady shear viscosity (red symbols in Fig. 1) display a constant value at around 0.01 Pa s over a wide shear rate \(\dot{\gamma }\) range. Only at lowest shear rates \(\dot{\gamma } < 0.05\;{\text{s}}^{ - 1}\), a noise develops that is growing with even lower shear rates. This ‘trumpet’ indicates the limit of precision of the rheometer. The quite same behavior is found for the microemulsion containing C8E3 as surfactant (Fig. 2). Interestingly, the obtained viscosity takes the same constant value of 0.01 Pa s within experimental errors. This constant result deviates from our former publications [4, 5] where systematic increases of the steady shear viscosity were found towards lower shear rates.

Rheology measurements on the (complex) viscosity as a function of oscillatory shear frequency (black squares) and steady shear rate (red circles) for the microemulsion containing n-decane/D2O/C10E4. The solid lines indicate the mean values at 0.01 Pa s that should hold for the entire range. Deviations from those lines are artefacts of the measurements

Rheology measurements on the (complex) viscosity as a function of oscillatory shear frequency (black squares) and steady shear rate (red circles) for the microemulsion containing n-decane/H2O/C8E3. The solid lines indicate the mean values at 0.01 Pa s that should hold for the entire range. Deviations from those lines are artefacts of the measurements

While the abovementioned rheology experiments were conducted in the Couette shear cell with a safely covered inner rotating cylinder (Fig. 3a), the following experiments display experimental deficiencies caused by filling that ends approximately at the upper rim of the inner cylinder (Fig. 3b, c). In the latter case, the filling can be quite straight (Fig. 3b) or uneven or even air bubbles might be captured below the inner cylinder (Fig. 3c). The next example measurement on a microemulsion containing C10E4 as surfactant was conducted with a meniscus close to the upper rim of the inner cylinder and from high to low shear rates (Fig. 4) [6, 7]. First, a bump of viscosities is found around 20 s−1 indicating first effects of surface tension from the liquid between the two cylinders. Then, due to the evaporation the meniscus is lowered between the two cylinders and an uneven filling might be caused. The viscosity increases at around 1 s−1, and drops suddenly when the filling was completed by more liquid. Later, the evaporation of the liquid continues and was left undisturbed. The steep increase of viscosities to approx. 30 Pa s was observed that purely due to the meniscus between the two cylinders. While the slope 1 in the log–log scale indicates the clear effect of surface tension [7], the intermediate shoulder at around 0.2 s−1 is due to uneven filling of the liquid at the rim. A similar ‘pure’ shoulder is observed when the inner cylinder was completely covered but an air bubble was captured below the inner cylinder. So, the sliding of the boundary causes a weaker slope (but stronger effect) than the surface tension which tries to keep the boundary minimal.

Experimentally deficient viscosity measurements with steady shear when the meniscus of the liquid is close to the upper rim of the inner cylinder. All measurements were conducted from high to low shear rates. Open symbols: While the liquid is evaporating, refilled at 1 s−1 and dried further. Filled symbols: While an air bubble was below the inner cylinder

4 Discussion

While non-constant viscosities left room for micrometer structures in microemulsions that would build from the nanometer domains with a directional order parameter [4], the correct measurements state that the microemulsions behave like a Newtonian fluid in the considered shear rate (and frequency) range. The viscosities are 0.01 Pa s for both systems of this study. In dynamic light scattering studies we measured the diffusion constants D of the liquids: 1.21 and 1.63 (± 0.06) × 10–11 m2/s for the C10E4 and the C8E3 system at their respective temperatures. In terms of the mean viscosities of water (η1 = 0.887 (at 25 °C) and 0.968 × 10–3 Pa s (at 21.5 °C)) and n-decane (η2 = 0.850 and 0.899 × 10–3 Pa s, all according to Malvern tables) we arrive at hydrodynamic radii Rh of 20.8 and 14.2 (± 1) nm for the two microemulsions using the Einstein diffusion formula D = kBT/(6πηRh) (with the Boltzmann constant kB and the absolute temperature T). The correlation lengths at the fish tail points [8, 9] are 15.5 and 7.3 nm that translate according to the inverse proportionality to the surfactant amount to actual correlation lengths of 11.2 and 6.1 (± 0.5) nm. The correlation length in microemulsions is usually the approximate single domain size of oil or water. This means that the calculated hydrodynamic radii are approximately double the correlation length, and so compartments of 4 × 4 × 4 domains may form on short time scales. So, there are structures of correlated domains that diffuse as a whole in the microemulsion at shortest times. They do not reach micrometer sizes at all. At long time scales the effective viscosity takes ten times the solvent viscosities and so the underlying structures are at about 1 nm size (1.4 and 0.7 nm to be more precise) which correlates with the membrane thickness of the respective surfactants. So on large time scales, the only visible structure is the surfactant membrane and no initial domains anymore.

Just for the C10E4 system we compare the measured viscosity with the bare viscosities according to the formula [5]:

For the in plane viscosity η3 of the surfactant we take a value measured for lipids of 7.6 × 10–3 Pa s [10]. Thus, the value α must take a value of 8.0. This order of magnitude indicates that whole domains are moved by the shear experiment at short time scales. The exact number of connected correlation volumes that may form 4 × 4 × 4 compartments in the size of the hydrodynamic radius is a little vague. For sure the building blocks in a bicontinuous microemulsion are the correlation volumes that give room for a directional order parameter [4] for further alignment near surfaces.

5 Conclusions

While most attempts to describe the behavior of bicontinuous microemulsions base on a single order parameter [11,12,13], there are hints that a hidden directional order parameter may appear [4]. This finding supports the developed structures near planar surfaces. Secondly, elevated viscosities were found at very low shear rates, and speculations about micrometer chains of correlation volume compartments arised.

In this manuscript, the viscosity and diffusion constants in two microemulsions with the non-ionic surfactants C10E4 and C8E3 were determined. The viscosities were constant at 0.01 Pa s all over the wide frequency and shear rate range. Thus, no elevated viscosities appear in a correct measurement towards slowest motions. All previously measured elevated viscosities were artefacts of the fluid boundary conditions or due to polymer addition. This means, there are no micrometer large objects in a microemulsion forming. However, on the size of correlation volumes the microemulsion displays compartments that leave room for a directional order parameter. If the hydrodynamic radii are determined correctly, the compartments may reach sizes of 4 × 4 × 4 domains that diffuse at short time scales. At large time scales, the only visible structure is the surfactant membrane with ten times shorter length scales. Whatever the detailed size of the short time scale compartments is exactly, the directional order parameter in microemulsions is reality. Thus, near surface ordering extends over larger ranges than expected from the bulk correlation length. These findings [14] are essential for lubrication applications of microemulsions [15].

References

Stubenrauch C (ed) (2009) Microemulsions: background, new concepts, applications, perspectives. Wiley, New York. https://doi.org/10.1002/9781444305524

Davis HT, Bodet JF, Scriven LE, Miller WG (1989) Microstructure and transport in midrange microemulsions. Phys A 157:470–481. https://doi.org/10.1016/0378-4371(89)90345-2

Kerscher M, Busch P, Mattauch S, Frielinghaus H, Richter D, Belushkin M, Gompper G (2011) Near-surface structure of a bicontinuous microemulsion with a transition region. Phys Rev E 83:R030401. https://doi.org/10.1103/PhysRevE.83.030401

Kerscher M, Lipfert F, Frielinghaus H (2020) Exploring hidden local ordering in microemulsions with a weak directive second order parameter. Chem Afr. https://doi.org/10.1007/s42250-020-00126-7

Gvaramia M, Mangiapia G, Pipich V, Appavou MS, Jaksch S, Holderer O, Rukhadze MD, Frielinghaus H (2019) Tunable viscosity modification with diluted particles: when particles decrease the viscosity of complex fluids. Colloid Polym Sci 297:1507–1517. https://doi.org/10.1007/s00396-019-04567-6

Oliveira MS, Yeh R, McKinley GH (2006) Iterated stretching, extensional rheology and formation of beads-on-a-string structures in polymer solutions. J Nonnewton Fluid Mech 137:137–148. https://doi.org/10.1016/j.jnnfm.2006.01.014

Johnston MT, Ewoldt RH (2013) Precision rheometry: Surface tension effects on low-torque measurements in rotational rheometers. J Rheol 57:1515–1532. https://doi.org/10.1122/1.4819914

Choi SM, Chen SH, Sottmann T, Strey R (1997) Measurement of interfacial curvatures in microemulsions using small-angle neutron scattering. Phys B Condens Matter 241–243:976–978. https://doi.org/10.1016/S0921-4526(97)00770-9

Sottmann T, PhD thesis (1998) Mikroemulsionen: Eigenschaften von internen Grenzflächen. Cuvillier, Göttingen

Jaksch S, Holderer O, Gvaramia M, Ohl M, Monkenbusch M, Frielinghaus H (2017) Nanoscale rheology at solid-complex fluid interfaces. Sci Rep 7:1–7. https://doi.org/10.1038/s41598-017-04294-4

Teubner M, Strey R (1987) Origin of the scattering peak in microemulsions. J Chem Phys 87:3195–3200. https://doi.org/10.1063/1.453006

Gompper G, Schick M (1990) Correlation between structural and interfacial properties of amphiphilic systems. Phys Rev Lett 65:1116–1119. https://doi.org/10.1103/PhysRevLett.65.1116

Gompper G, Kroll DM (1988) Monte Carlo study of nonuniversal wetting behavior in (2+1) dimensions. Phys Rev B 37:R3821–R3824. https://doi.org/10.1103/PhysRevB.37.3821

Lipfert F, Kerscher M, Mattauch S, Frielinghaus H (2019) Stability of near-surface ordering of bicontinuous microemulsions in external shear-fields. J Colloid Interface Sci 534:31–36. https://doi.org/10.1016/j.jcis.2018.09.014

Dong C, Sun J, Cheng Z, Hou Y (2019) Preparation and tribological properties of a microemulsion for magnesium alloy warm rolling. Ind Lubr Tribol. https://doi.org/10.1108/ILT-06-2018-0222

Acknowledgements

Open Access funding provided by Projekt DEAL. I thank Christian Lang from my group for very detailed discussions about rheology experiments and data analysis.

Funding

None.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declares that he has no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Frielinghaus, H. Addendum to: Exploring Hidden Local Ordering in Microemulsions with a Weak Directive Second Order Parameter. Chemistry Africa 3, 711–715 (2020). https://doi.org/10.1007/s42250-020-00156-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-020-00156-1