Abstract

In this study, novel biocomposites composed of CO2-derived poly(propylene) carbonate and plant-based cellulose were developed employing solvent casting technique. An innovative and rapid strategy was employed, whereby pre-dissolving cellulose improves dramatically the compatibility of poly(propylene) carbonate with cellulose whilst pristine cellulose powder displays inhomogeneous distributions of cellulose within the biocomposite. Resulting biocomposites produce flat homogeneous surfaces with low cellulose content, whilst rougher surfaces and thicker cross sections were observed in films with higher cellulose content. Developed biocomposites outperformed biocomposites produced from pristine cellulose powder in terms of homogeneity, thermal stability, antioxidant activity and biocompatibility. Higher cellulose content samples show the formation of a new hydrogen bonding network between PPC and cellulose polymer chains and this contributes to improved thermal stability. TGA results reveal improved thermal stability for high cellulose content films and show enhanced water vapor permeability. A cell viability study shows that the developed materials are biocompatible. Curcumin, a natural antioxidant, was incorporated into optimized biocomposites to produce active biocomposites with antioxidant features to accelerate wound healing. Curcumin is shown to display a sustained release profile over a time period of 3 days, and this is ideal for would healing. The curcumin-functionalized biocomposites also contributed to enhanced thermal stability and water vapor permeability. Thus, these biocomposite films show promise as active biocomposites which can be used for biomedical applications such as wound healing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Despite the extensive works on the development of wound healing materials, there is still the need to discover sustainable, low-cost, homogeneous and active wound care materials due to increasing healthcare costs, plastic pollution, as well as the growing rates in the incidence of skin-related pathologies such as skin cancer [1, 2], congenital skin lesions [3] or burn scars [4]. Modern and plant-based wound healing materials have the ability to accelerate all stages of wound healing progress by improving tissue repair and restoration of lost tissue integrity. These advance performances arise from the bioactive nature [5, 6], biocompatibility, antioxidant property [7] and angiogenic effects of the components inside the patches [8, 9]. Hence, great attention has been focused on the development of biocomposites derived from silk [10, 11], cellulose [12], alginate [13], chitin [14], hyaluronic acid [15, 16], collagen [17,18,19] and gelatin [19, 20] for biomedical applications. In fact, these biocomposites show appropriate biodegradation rates and tunable release of bioactive molecules along with an efficient and long-lasting microbicidal effects [21, 22] indicating potential use of these biocomposites for wound healing applications and tissue repair in general. In particular, a cellulose-based bicomposite film with the present of natural antioxidant from oregano presented prolong antioxidant activity and started biodegrading after just 1 week in seawater [23].

Cellulose has attracted great attention in recent years thanks to its biodegradability, high biocompatibility, high tensile strength, drug releasing capability and moisture maintenance [24, 25]. It is the most abundant polysaccharide on Earth [26] and has been employed in the preparation of numerous biocomposites films in combination with various raw materials such as banana, sugar, beet, hems, softwood and hardwood pulps [27]. Due to its rigidity, often small molecule plasticizers, including sorbitol [28, 29] and glycerol [30], are used to achieve films with higher flexibility. However, the release of these water-soluble plasticizers into the surrounding environments creates potential risks to human health and the environment [31]. Cellulose has also been used for different wound healing applications. Firmanda et al. developed a wound dressing composed of cellulose and active ingredients from coffee and tea. The developed materials demonstrated antioxidant activity in clinical studies, including antimicrobial and antioxidant studies in scavenging the ABTS cation radical and DPPH free radical [32]. In another study, cellulose nanowhiskers were introduced into polyvinyl alcohol matrix to fabricate nanocomposites with controlled pore morphology. The thermal and mechanical properties of the obtained nanocomposites were enhanced in comparison with the pristine ones. Additionally, the water vapor transmission rate was in the range of wound dressing materials [33, 34].

Poly(propylene carbonate) (PPC) is a biodegradable aliphatic polycarbonate synthesized through copolymerization of propylene oxide and greenhouse gas carbon dioxide [35]. Good ductility and the biodegradation resulting in nontoxic compounds (water and CO2) make PPC as an ideal material for biomedical applications [23]. However, its poor thermal stability and relatively low mechanical strength strongly limit its effective implementation [36]. The incorporation of natural fibres into the biodegradable polymer matrix offers the advantages of the cost reduction and the more environmentally friendly benefit [37]. Therefore, great effort has been employed to improve these properties by chemical modification and blending, which involves compounding PPC with other materials. For instance, it has been reported the development of PPC and cellulose nanowhiskers (CNWs) films for medical applications. The results of this study showed that CNWs were uniformly dispersed in PPC matrix and the tensile strength, thermal stability, and storage modulus of PPC increased [38]. In addition, PPC has also been combined with different natural polymers including starch [39] and chitosan [40]. However, the resulting biocomposites showed big phase separation, loss of transparency, and the creation of non-uniform films due to the immiscible of hydrophobic PPC with other hydrophilic natural polymers [41]. Therefore, it is essential to develop the PPC-based biocomposites with high degree of miscibility between PPC and other components; hence, the mechanical strength and thermal stability of obtained biocomposites are improved and suitable for different practical applications.

Antioxidant materials assist the management of wound oxidative stress and, thus, accelerate wound healing [42]. Generally, materials such as silver nanoparticles [43], organic acids as benzoic acid or sorbates [44], natural active compounds (essential oil, biopolymer, and curcumin) [45, 46], and other functional ingredients were incorporated into polymers to develop active biomaterials for multiple applications [22, 34, 47,48,49,50,51,52,53,54]. The advantages shown in studies on active biocomposites for wound healing can have important implications on healthcare system since the wound healing process can be accelerated. Curcumin is a natural antioxidant substance with yellow-orange colour that can be found in the roots of Curcuma longa plant [55]. Owing to its excellent properties including antibacterial, anti-inflammatory, and antitumor activities, it is widely used in wound healing, as anticancer conjugate, inflammatory diseases, musculoskeletal [22] and cardiovascular disorders [44, 49, 50]. Liu et al. developed curcumin–chitosan films using solution casting technique, showing excellent antibacterial activity against Staphylococcus aureus and Rhizoctonia solani [56]. In other study, Li et al. reported methoxy poly(ethylene glycol)–graft–chitosan films with the incorporation of a curcumin nanoformulation. These films were successfully used for wound healing applications [34, 57].

Taking all the considerations into the account, in the present study, the biocomposites composed of poly(propylene) carbonate and cellulose in various proportions were obtained using rapid and simple solvent casting technique, which does not require further mechanical or thermal processing steps to obtain the final products [58]. The obtained free-standing films (both with and without curcumin) were thoroughly characterized with scanning electron microscopy (SEM) for morphological properties, Fourier transform infrared (FTIR) spectroscopy for chemical characteristics, and thermogravimetric analysis (TGA) for thermal stability studies. Furthermore, water absorption and water vapor permeability, swell ability, transparency by UV–Vis spectroscopy, biocompatibility, release, and antioxidant properties were also intensively analysed. To highlight the superior performance of the films made of cellulose in formic acid solution, the PPC/cellulose powder biocomposites were also studied for comparative purposes.

2 Experimental

2.1 Materials

Poly(propylene carbonate) (PPC) with molecular weight of 50,000 was obtained from Merck (Ireland). Cellulose fibres (medium), curcumin powder, trypsin, Trypan Blue, phosphate-buffered saline (PBS), Dulbecco’s modified Eagle’s medium, 2,2-diphenyl-1-picrylhydrazyl (DPPH), vitro toxicology assay kit — resazurin based, acetone, and formic acid were obtained from Merck (Ireland). Potassium chloride (Br < 0,005%) was purchased from Fluka Analytical, Ireland. All chemicals were used without any further purification.

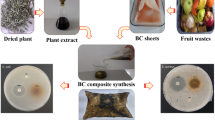

2.2 Preparation of PPC/cellulose biocomposites

Firstly, 10% (w/v) PPC in acetone solution was prepared by stirring for 1 h at room temperature. Meanwhile, 10% (w/v) cellulose in formic acid solvent solution was obtained by dissolving cellulose powder in formic acid for 3 days at 50 °C and stirring speed of 350 rpm. Subsequently, the two polymeric solutions were combined in various proportions to obtain final dried films of 500 mg, which was the optimized weight to obtain thin films of 89.77 ± 2.22 µm thickness once the mixture was cast into the 6-cm-diameter Teflon dish. The solutions composed of different weight percentage of PPC and cellulose (95/05, 90/10, 80/20, 70/30, 60/40, 50/50, 30/70) were prepared. Subsequently, PPC/cellulose mixtures were vortexed using IKA Vortex Mixer Genius 3 for 30 s and then sonicated by Soniprep 150 for 1 min. After that, they were cast into a Teflon mould and placed under a fume hood to allow solvent evaporation. After 24 h, the free-standing films were reversed and allowed for further drying of 24 h before collection and characterization.

For comparison, the biocomposites made of raw cellulose powder were also fabricated by directly incorporate appropriate amounts of cellulose powder into the 10% (w/v) PPC in acetone solutions, resulting in 90/10 PWD, 80/20 PWD, and 70/30 PWD. Finally, 5 mL PPC and 0.5 mL formic acid (PPC + F.A.), 100% PPC in acetone solvent (100/0), and 100% cellulose in formic acid (0/100) biocomposites were made as control samples.

2.3 Preparation of PPC/cellulose/curcumin films

The solution of 0.1% (w/v) curcumin in acetone solvent was firstly prepared. Afterwards, PPC solution and 0.2%, 0.5%, and 1% curcumin solution were mixed using IKA Vortex Mixer Genius 3 for 1 min. Subsequently, cellulose in formic acid solution was added in various proportions. The mixtures were blended using IKA Vortex Mixer Genius 3 for 1 min and following by 1-min sonication on Soniprep 150. The mixtures were then cast into the moulds and left under fume hood to let the solvent evaporate. After 24 h, the biocomposite films were collected, reversed, and left into a dish for another day to let the solvent to completely evaporate. The free-standing films were then ready for further use.

2.4 Characterization

Morphological analysis

Scanning electron microscopy (SEM) imaging was obtained by HITACHI SU-70 Scanning Electron Microscope with acceleration voltage of 5 kV to investigate surface and cross-section morphologies of the samples. Specimens for cross-section observation were obtained by cryo-fracture. The samples were coated with 10 nm gold using Emitech K550. The thickness of each biocomposite film was analysed via ImageJ software. The data are presented as averages ± standard deviation of three measurements.

Chemical analysis

PPC/cellulose and PPC/cellulose/curcumin films were characterized by Fourier transform infrared (FTIR) spectrometry using Spectrum 100 PerkinElmer scanner. Spectra were averaged on three different repetitions and recorded between the 4000 and 600 cm–1 range with eight repetitive scans on folded film.

Thermal stability

Thermogravimetric (TGA) analysis was conducted using TGA 4000 and StartPyris software. The measurements were carried out from 30 to 800 °C with a heating rate of 20 °C/min under nitrogen atmosphere.

Water vapor permeability test

Water vapor permeability test was performed as follow. Each film was placed between a perforated cap (1.4 cm of internal diameter) and a rubber sealing ring. The cap with attached film was then sealed on a vial containing 22 mL distilled water. Each container was weighted and placed into desiccator at room temperature (21 °C). The mass of each vial was monitored every hour for the first 6 h and then once a day for 2 weeks. Water vapor permeability was calculated using the following formula [57]:

where WVP is the water vapor permeability calculated in g/(m∙s∙Pa); Δm/Δt is the sample weight loss in time in grams per second (calculated with a linear fitting); e is the film thickness in meter; A is the permeability area (1.539 × 10−4 m2); and Δp is the pressure difference under the film and outside, in Pascal (3167 Pa) [57].

Biocompatibility study

Biocompatibility test was performed through vital dye Alamar Blue to quantify cell number and viability of cells once they were placed on PPC/cellulose and PPC/cellulose/curcumin films. DITNC1 0410712022 (astrocyte) cell line was used, and the initial number of living cells was obtained through optical microscope using the following formula: [59]

where \({c}_{n}\) is the number of counted cells in each square, and \({f}_{d}\) is the dilution factor.

Afterwards, cell solution was placed on each sample and the number of living cells was calculated by Synergy Mx Biotek in the 540–590-nm wavelength range. Consequently, data were normalized upon the maximum value and since three repetitions for each biocomposite were studied. Data are plotted as averaged ± standard deviation.

Release profile

Of each biocomposite, 0.2 g was placed in a vial with 10 mL of 1:1 water:ethanol mixture. All the tested vials were kept in an incubator at 37 °C to mimic the body temperature. At fixed time points (30 min, 1, 2, 3, 4, 5, 6, 24, 48, 72 h), 2 mL of the solution from each vial was withdrawn and put into different cuvettes. Fresh solution (2 mL) was added back to the vials. UV–Vis spectroscopy analysis was conducted on each cuvette. In addition, the calibration curve of curcumin in water:ethanol solutions at different concentrations was obtained as absorbance versus concentration.

Antioxidant characteristic

Antioxidant activity was studied using scavenging of DPPH• free radical assay [57]. Of DPPH, 1.2 mL (0.1 mM) in water:ethanol solution was added in each cuvette from the release experiment above. After 30 min of reaction time, the UV–Vis spectra were recorded. Additionally, the antioxidant of different curcumin solutions dissolving in water:ethanol was also investigated using identical protocol. The obtained absorbances were used to calculate antioxidant activity against DPPH• free radical according to Eq. (3): [60]

where \({A}_{1}\) is the absorbance of the reaction solution, and \({A}_{2}\) is the absorbance of DPPH• control solution, both determined at 516 nm.

3 Results and discussion

3.1 Morphological analysis

PPC/cellulose film surface and cross-section morphologies were characterized by SEM (Fig. 1.a1). PPC/cellulose 100/0 (the pure PPC film) presented a smooth surface (Fig. 1.a1) and compact cross-section. On the other hand, the pure cellulose film, named PPC/cellulose 0/100, exhibited a rougher surface (Fig. 1.b1) and a thicker cross-section (Fig. 1.b2). PPC/cellulose biocomposite films from formic solution showed relatively flat and homogeneous surfaces with low cellulose content. With the incorporation of curcumin (Supporting Information SI, Fig. S1), the obtained films also presented uniform morphologies and well-distributed cellulose within PPC matrix. Meanwhile, PPC/cellulose films made directly from cellulose powder show some agglomeration of cellulose and a gap appears between cellulose filler and PPC matrix, as seen in 90/10 PWD sample (Fig. 1.f2 and Fig. 1.f3). Hence, the developed fabrication technique, where cellulose was pre-dissolved, resulted in more homogeneous and uniform biocomposite films.

The transparency study by UV–Vis (SI, Fig. S2) is in good agreement with SEM results. With higher cellulose percentage, corresponding to reduced transparency of films, pure PPC films (PPC/cellulose 100/0) show the highest transparency.

3.2 Chemical interactions

FTIR spectra of pure polymers and PPC/cellulose biocomposites were characterized and presented in the region of 4000–650 cm−1 (Fig. 2). In the spectrum of pure PPC film (PPC/cellulose 100/0) (Fig. 2a), the C = O stretching vibration was located at 1737 cm−1, while the O–C–O stretching bond gave rise to a characteristic peak at 1223 cm−1 [61]. The 1064 cm−1 and 785 cm−1 peaks correspond to \({\text{CO}}\) stretching and \({\text{CH}}\) bending, respectively. FTIR spectra of pure cellulose film, named PPC/cellulose 0/100, were also characterized by a high intensity peak of \({\text{CO}}\) centred at 1029 cm−1. The \({\text{OH}}\) stretching band of cellulose was found at 3334 cm−1 [62].

In the FTIR spectra of PPC/cellulose biocomposite, all the characteristic chemical bands from both PPC and cellulose were observed with the changes in peak positions. In particular, C = O stretching peak were found around 1737 cm−1, indicating no intensity shift in comparison with PPC/cellulose 100/0 (pure PPC) sample. Moreover, with the increasing of cellulose content in the biocomposites, the intensities of O–C–O stretching peak around 1223 cm−1 and C–H bending peak around 785 cm−1 decreased. PPC/cellulose powder biocomposite FTIR spectra were also studied (SI, Fig.S3).

The chemical compositions of the films containing curcumin were also investigated by FTIR measurements. Pure curcumin powder (PURE CUR) spectrum (Fig. 2b) shows the phenolic \({\text{OH}}\) stretching band at 3501 cm−1 [63]. The peak at 1626 cm−1 was due to C = O stretching. The peaks at 1601 cm−1 correspond to C = C stretching in the benzene ring [64]. Finally, the bands in the region of 960–806 cm−1 belong to C–H bending and aromatic stretching [65]. The addition of curcumin into the biocomposites did not result in significant changes in FTIR spectra (Fig. 2a and b).

PPC/cellulose 100/0 to 0/100 were analysed further. There was an FTIR decreasing shift in the transmittance of (a) 88 cm−1 in \({\text{CH}}\) stretching peak, (b) 30 cm−1 \({\text{CO}}\) stretching peak, and (c) 140 cm−1 \({\text{OH}}\) stretching peak, while (d) an increasing shift of 9 cm−1 is shown for the O–C–O stretching peak as shown in Fig. 3. These shifting bands correspond to the formation of a new hydrogen bonding network in the biocomposite structure which plays a significant role in subsequent film properties.

3.3 Thermal stability

Thermal stability of all biocomposites were investigated by thermal gravimetric analysis (TGA) and shown in Fig. 4. Pure cellulose films (PPC/cellulose 0/100) display a decomposition temperature of 323 °C. Considering PPC/cellulose films, the thermal decomposition temperature (Fig. 4a) increased with higher cellulose content. No significant variations were noticed between the temperature range of 0 °C and 200 °C, confirmed through derivative thermogravimetry (DTG) in Fig. 4b. However, the onset temperatures of thermal degradation were 309 °C (10% cellulose), 319 °C (30% cellulose), and 320 °C (50% cellulose). Thus, PPC/cellulose 50/50 biocomposite shows the highest thermal stability with the decomposition temperature 11 °C higher than that of 90/10. When increasing cellulose content, the carbonization products were higher, and this is evident in the 500–800 °C range. At 800 °C, pure cellulose film (PPC/cellulose 0/100) presented a remained weight of around 15%, with 50/50 around 3%, 70/30 around 1.5%, and 90/10 around 0.2%. This is due to the propensity of cellulose to form carbonization products [66]. Moreover, from DTG (Fig. 4b), it could be seen that the temperature at the maximum weight loss rate was steadily increased as a function of increasing the cellulose content.

In addition, the biocomposite developed with 90% PPC and 10% of cellulose powder was also studied (SI, Fig. S4). It was observed that biocomposites from acid formic solution exhibited better thermal stability displaying a 5 °C higher degradation temperature compared to powder-based one. This is attributed to the more uniformly dispersed cellulose.

With respect to PPC/cellulose/curcumin films containing 1 wt% curcumin, the 50/50/1 and 70/30/1 biocomposites present the highest thermal stability as shown in Fig. 4c. In particular, the onset temperatures of thermal degradation were 313 °C, 321 °C, and 322 °C for the 90/10/1, 70/30/1, and 50/50/1 biocomposites, respectively. Furthermore, the remaining weight at 800 °C was 14% for PPC/cellulose 0/100, 1.19% for PPC/cellulose/curcumin 50/50/1, 0.12% for PPC/cellulose/curcumin 70/30/1, and 0% for PPC/cellulose/curcumin 90/10/1. In addition, from DTG graphs shown in Fig. 4d, the temperature at maximum weight loss rate was improved with increasing cellulose content as described previously.

3.4 Water vapor permeability test

Water vapor permeability (WVP) measurements were carried out to investigate the water barrier ability of the developed biocomposites an important property for wound healing films as shown in Fig. 5. The WVP of PPC/cellulose films were higher with increasing cellulose content. This enhancement of PPC/cellulose biocomposites in water permeability as shown in Fig. 5 is attributed to the hydrophilicity of cellulose [67, 68] and the more porous structure of the obtained biocomposites with higher cellulose content (SEM, Fig. 1); these pores may act as a conduit for water molecules to travel through the films of 89.77 ± 2.22 µm thickness. For PPC/cellulose/curcumin biocomposites, films containing higher cellulose percentage also featured better WVP. The incorporation of curcumin did not significantly affect WVP of resulting films. This feature is beneficial for breathable wound healing materials [69,70,71]; moreover, it could be also significant for stretchable [72] and bacterial resistance properties of the material [73]. In fact, the average water vapor permeability of the human skin is estimated to be around 10−10 g/(m s Pa). Thus, WVP of the developed PPC/cellulose biocomposites was higher than that of the skin; hence, these films were highly permeable to water vapour and potentially an ideal solution for wound healing applications.

3.5 Biocompatibility studies

Pure PPC 100/0 and pure cellulose 0/100 films present high cell viability of 96.1 ± 3.8% and 92.7 ± 4.50%, respectively, indicating good biocompatibility of these films (Fig. 6). All of PPC/cellulose biocomposite presented higher cell viability compared to controls indicating high biocompatibility of the developed biocomposites. Furthermore, among PPC/cellulose biocomposites, with a percentage of 143.8 ± 8.6%, the cell growth on PPC/cellulose film 70/30 reached the highest cell viability. This could be explained by the homogeneous surface of 70/30 sample (SEM, Fig. 1), the presence of high cellulose content leading to more hydrophilic surface; thus, the cell attachment on the films was improved resulting in high cell growth and viability [74]. In addition, the active biocomposites containing curcumin also exhibited high cell viability. Overall, the obtained PPC/cellulose biocomposite films show good biocompatibility, essential for would healing materials.

3.6 Sustained release of antioxidant curcumin

In the dynamic release test (details in SI, Figs. S5, S6), considering the biocomposites containing identical curcumin content, the release of curcumin increases in the biocomposites containing higher cellulose percentage. With greater cellulose content, the films were more hydrophilic due to the hydrophilicity of cellulose and the films were less dense (SEM, Fig. 1). This helped the penetration of the solvent media into the structure of the biocomposites, resulting in a greater curcumin diffusion throughout the film and ease of its subsequent release to the surrounding environment. The concentration of released curcumin from the biocomposites to surrounding media was calculated and depicted in Fig. 7 as a function of release time. As can be seen from the graphs in the first line of Fig. 7 of the films with curcumin content of 0.2%, a slight increase in released curcumin concentration was observed with increase in cellulose percentage in the films. The similarly increasing curcumin release was also obtained in the films containing 0.5% and 1% curcumin, as shown in the second and third lines of Fig. 7, respectively. The maximum concentration of release curcumin was 3.56 × 10–3 mg/ mL after 72 h of release test with the PPC/cellulose/curcumin 50/50/1 biocomposite film, as it contained the highest cellulose content and the highest curcumin loading. With the films containing identical content of cellulose (the samples in one column of Fig. 7), the greater release of curcumin was observed in the biocomposite films with higher loaded curcumin.

3.7 Antioxidant characteristic

The antioxidant capacity of the developed active biocomposites was obtained from the extract solutions of the release test, and was evaluated by DPPH• free radical scavenging activity test [75]. The detailed UV–Vis spectra of the test are shown in Figs. S7, S8, and S9. As shown in Fig. 8, the DPPH• free radical scavenging (FRS) activity increased with higher curcumin content, indicating greater antioxidant capacity. PPC/cellulose/curcumin 70/30/1 shows the highest scavenging activity. In particular, the percentage of DPPH FRS activity was 93.9%. and 95.8% at 30 min and 1 h of testing, respectively. After that, the FRS reached the maximum of 96.6% after 6 h and, at last time points, the scavenging activity slightly decreased to 96.03% after 64 h. This is due to a loss of activity over time, and these results are supported by the reports of Hossain et al. [76] and Villaño et al. [77]. All the active biocomposites presented efficient, prolonged, and sustained antioxidant activities which are beneficial for wound healing treatment [78].

4 Conclusions

In this study, homogeneous and free-standing biocomposites made of CO2-based PPC and cellulose were successfully developed. The compatibility between PPC and cellulose from formic acid solution increased, and performance in terms of homogeneity, thermal stability, antioxidant activity and biocompatibility of the obtained biocomposites improved in comparison to ones produced with pristine cellulose powder Biocomposite films with low cellulose content show smoother surfaces with a more transparent appearance. With higher cellulose content, the surface became rougher, and the thickness also increased. Well-dispersed curcumin and cellulose within the active biocomposites result in homogeneous active films. Newly formed hydrogen bonding networks between PPC and cellulose polymer chains result in significant improvement in thermal stability of the biocomposites, and this plays role in the biological properties of the films as it allows a degree of control over curcumin release. High cell viability was shown by PPC/cellulose 90/10 s and 70/30 s biocomposites compared to 50/50 s and pure cellulose (0/100) or pure PPC (100/0) films. These active biocomposites feature effective antioxidant capacity which is suitable for wound healing application. These active biocomposites could be considered an important starting point for future studies to proceed with in vivo tests for wound healing treatment.

Data Availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

Meg Watson, Dawn M. Holman, and Maryellen Maguire-Eisen, Ultraviolet radiation exposure and its impact on skin cancer risk, in Seminars in Oncology Nursing (Elsevier, 2016), xxxii, 241–54.

Yun Zhu et al., Atopic dermatitis and skin cancer risk: a systematic review. Dermatol Ther 12(5), 1167–79 (2022). https://doi.org/10.1007/s13555-022-00720-2

A. Indrieri, B. Franco, Linear Skin Defects with Multiple Congenital Anomalies (LSDMCA): an unconventional mitochondrial disorder. Genes 12(2), 263 (2021)

Zhi Wei, Kenny Low et al., Recent innovations in artificial skin. Biomater Sci 8(3), 776–797 (2020). https://doi.org/10.1039/C9BM01445D

A. Gaspar-Pintiliescu, A.-M. Stanciuc, O. Craciunescu, Natural composite dressings based on collagen, gelatin and plant bioactive compounds for wound healing: a review. Int. J. Biol. Macromol. 138, 854–865 (2019). https://doi.org/10.1016/j.ijbiomac.2019.07.155

Yu. Rui, Hualei Zhang, Baolin Guo, Conductive biomaterials as bioactive wound dressing for wound healing and skin tissue engineering. Nano-Micro Lett 14(1), 1 (2022). https://doi.org/10.1007/s40820-021-00751-y

Alina Hadi et al., Physical, mechanical, optical, barrier, and antioxidant properties of sodium alginate–aloe vera biocomposite film (2021) J Food Process Preserv, 45(5) https://doi.org/10.1111/jfpp.15444.

R.A. Osmani et al., Biopolymers and Biocomposites: Nature’s Tools for Wound Healing and Tissue Engineering, in Applications of Advanced Green Materials. (Elsevier, 2021), pp.573–630. https://doi.org/10.1016/b978-0-12-820484-9.00023-4

Chengwei Gu et al., Angiogenic effect of mesenchymal stem cells as a therapeutic target for enhancing diabetic wound healing. Int. J. Low. Extrem. Wounds 13(2), 88–93 (2014). https://doi.org/10.1177/1534734614534977

Ane Escobar et al., Electroconductive poly(3,4-ethylenedioxythiophene) (PEDOT) nanoparticle-loaded silk fibroin biocomposite conduits for peripheral nerve regeneration. Adv. Compos. Hybrid Mater. 6(3), 118 (2023). https://doi.org/10.1007/s42114-023-00689-2

Cataldo Pignatelli et al., Electrospun silk fibroin fibers for storage and controlled release of human platelet lysate. Acta Biomater. 73, 365–376 (2018). https://doi.org/10.1016/j.actbio.2018.04.025

H.M.N. Iqbal et al., Iqbal and others, Poly(3-hydroxybutyrate)-ethyl cellulose based bio-composites with novel characteristics for infection free wound healing application. Int. J. Biol. Macromol. 81, 552–559 (2015). https://doi.org/10.1016/j.ijbiomac.2015.08.040

A. Serafin, M. Culebras, M.N. Collins, Synthesis and evaluation of alginate, gelatin, and hyaluronic acid hybrid hydrogels for tissue engineering applications. Int. J. Biol. Macromol. 233, 123438 (2023). https://doi.org/10.1016/j.ijbiomac.2023.123438

Jiada Nie et al., Bio-based epoxidized natural rubber/chitin nanocrystals composites: self-healing and enhanced mechanical properties. Compos. B Eng. 172, 152–160 (2019). https://doi.org/10.1016/j.compositesb.2019.04.035

George Dan Mogoşanu, Alexandru Mihai Grumezescu, Natural and synthetic polymers for wounds and burns dressing. Int. J. Pharm. 463(2), 127–136 (2014). https://doi.org/10.1016/j.ijpharm.2013.12.015

M.B. Dreifke, A.A. Jayasuriya, A.C. Jayasuriya, Current wound healing procedures and potential care. Mater. Sci. Eng., C 48, 651–662 (2015). https://doi.org/10.1016/j.msec.2014.12.068

Mihaela Ghica et al., Development, optimization and in vitro/in vivo characterization of collagen-dextran spongious wound dressings loaded with flufenamic acid. Molecules 22(9), 1552 (2017). https://doi.org/10.3390/molecules22091552

Rui Guo et al., Collagen-cellulose nanocrystal scaffolds containing curcumin-loaded microspheres on infected full-thickness burns repair. J. Tissue Eng. Regen. Med. 11(12), 3544–3555 (2017). https://doi.org/10.1002/term.2272

Sirsendu Bhowmick et al., Nanofibrous artificial skin substitute composed of MPEG–PCL grafted gelatin/hyaluronan/chondroitin sulfate/sericin for 2nd degree burn care: in vitro and in vivo study. RSC Adv. 8(30), 16420–16432 (2018). https://doi.org/10.1039/C8RA01489B

Aleksandra Serafin et al., 3D printable electroconductive gelatin-hyaluronic acid materials containing polypyrrole nanoparticles for electroactive tissue engineering. Adv Compos Hybrid Mater 6(3), 109 (2023). https://doi.org/10.1007/s42114-023-00665-w

Elahe Chiani et al., Synthesis and characterization of gelatin/lignin hydrogels as quick release drug carriers for ribavirin. Int. J. Biol. Macromol. 224, 1196–1205 (2023). https://doi.org/10.1016/j.ijbiomac.2022.10.205

A. Serafin, M.C. Rubio, M. Carsi, P. Ortiz-Serna, M.J. Sanchis, A.K. Garg, J. Miguel Oliveira, J. Koffler, M.N. Collins, Electroconductive PEDOT nanoparticle integrated scaffolds for spinal cord tissue repair. Biomaterials Research 26(1), 63 (2023). https://doi.org/10.1186/s40824-022-00310-5

Dexiu Wang et al., Transparent bionanocomposites with improved properties from poly(propylene carbonate) (PPC) and cellulose nanowhiskers (CNWs). Compos. Sci. Technol. 85, 83–89 (2013). https://doi.org/10.1016/j.compscitech.2013.06.004

Viola Hospodarova et al., Characterization of cellulosic fibers by FTIR spectroscopy for their further implementation to building materials. Am. J. Anal. Chem. 09(06), 303–310 (2018). https://doi.org/10.4236/ajac.2018.96023

J. Ryan, Andrew E. Pelling, Cellulose biomaterials for tissue engineering. Front. Bioeng. Biotechnol. 7, 45 (2019). https://doi.org/10.3389/fbioe.2019.00045

P. Peças et al., Natural fibre composites and their applications: a review. J Compos Sci 2, 66 (2018). https://doi.org/10.3390/jcs2040066

A.E. Naas et al., Do rumen Bacteroidetes utilize an alternative mechanism for cellulose degradation? MBio 5(4), e01401-14 (2014). https://doi.org/10.1128/mBio.01401-14

M.A. Bertuzzi et al., Water vapor permeability of edible starch based films. J Food Eng 80(3), 972–978 (2007). https://doi.org/10.1016/j.jfoodeng.2006.07.016

Berenice González-Torres et al., Combination of sorbitol and glycerol, as plasticizers, and oxidized starch improves the physicochemical characteristics of films for food preservation. Polymers 13(19), 3356 (2021). https://doi.org/10.3390/polym13193356

Huafeng Tian et al., Effect of sorbitol plasticizer on the structure and properties of melt processed polyvinyl alcohol films: polyvinyl alcohol films. J. Food Sci. 82(12), 2926–2932 (2017). https://doi.org/10.1111/1750-3841.13950

T.N. Tran, K.T. Lim, F. Fiorentini, A. Athanassiou, Antioxidant and biocompatible CO2-based biocomposites from vegetable wastes for active food packaging. Advanced Sustainable Systems 6(6), 2100470 (2022)

Melissa Gurgel Adeodato. Vieira et al., Natural-based plasticizers and biopolymer films: a review. Eur. Polymer J. 47(3), 254–263 (2011). https://doi.org/10.1016/j.eurpolymj.2010.12.011

Afrinal Firmanda et al., Cellulose composites containing active constituents of coffee and tea: a prospective novel wound dressing. Mater Adv 3(20), 7463–7483 (2022). https://doi.org/10.1039/D2MA00642A

Aleksandra Serafin, Mario Culebras and Maurice N Collins (2023), Synthesis and evaluation of alginate, gelatin, and hyaluronic acid hybrid hydrogels for tissue engineering applications, Int. J. Biol. Macromol, 123438. https://doi.org/10.1016/j.ijbiomac.2023.123438

Jimena S. Gonzalez et al., Poly(vinyl alcohol)/cellulose nanowhiskers nanocomposite hydrogels for potential wound dressings. Mater. Sci. Eng., C 34, 54–61 (2014). https://doi.org/10.1016/j.msec.2013.10.006

T Nishino T Peijs A-C Composites 2014 Materials and Energy Handbook of Green Materials, Chapter 14 201 216 https://doi.org/10.1142/9789814566469_0028

Thi Nga Tran et al., Transparent bioplastic derived from CO2-based polymer functionalized with oregano waste extract toward active food packaging. ACS Appl. Mater. Interfaces. 12(41), 46667–46677 (2020). https://doi.org/10.1021/acsami.0c12789

Mohsen Bahrami et al., Recent progress in hybrid biocomposites: mechanical properties, water absorption, and flame retardancy. Materials 13(22), 5145 (2020). https://doi.org/10.3390/ma13225145

C. Li, S. Jia, C. Liu, H. Tian, L. Han, D. Wang, H. Zhang, Green composite from carbon dioxide-derived poly(propylene carbonate) and biodegradable poly(glycolic-co-lactic acid) fiber. Colloid Polym. Sci. 301(4), 319–329 (2023)

Xin Jing et al., Electrospinning homogeneous nanofibrous poly(propylene carbonate)/gelatin composite scaffolds for tissue engineering. Ind. Eng. Chem. Res. 53(22), 9391–9400 (2014). https://doi.org/10.1021/ie500762z

Zhilong Quan et al., Synthesis and antimicrobial activities of chitosan/polypropylene carbonate-based nanoparticles. RSC Adv. 11(17), 10121–10129 (2021). https://doi.org/10.1039/D0RA09257F

Douaki Ali, Thi Nga Tran, Giulia Suarato, Laura Bertolacci, Luisa Petti, Paolo Lugli, Evie L. Papadopoulou, Athanassia Athanassiou, Thermo-responsive nanofibers for on-demand biocompound delivery platform. Chem Eng J 445, 136744 (2022)

E.L. Papadopoulou, U.C. Paul, T.N. Tran, G. Suarato, L. Ceseracciu, S. Marras, R. d’Arcy, A. Athanassiou, Sustainable active food packaging from poly (lactic acid) and cocoa bean shells. ACS Appl Mater Interfaces 11(34), 31317–31327 (2019)

Adeeb Shehzad et al., Curcumin in inflammatory diseases. BioFactors 39(1), 69–77 (2013). https://doi.org/10.1002/biof.1066

J. Liu et al., Effect of protocatechuic acid incorporation on the physical, mechanical, structural and antioxidant properties of chitosan film. Food Hydrocoll 73, 90–100 (2017). https://doi.org/10.1016/j.foodhyd.2017.06.035

Xiaocui Liu and others, Curcumin-releasing chitosan/aloe membrane for skin regeneration. Chem. Eng. J. 359, 1111–1119 (2019). https://doi.org/10.1016/j.cej.2018.11.073

Luis Bastarrachea and others, Engineering properties of polymeric-based antimicrobial films for food packaging: a review. Food Engineering Reviews 3(2), 79–93 (2011). https://doi.org/10.1007/s12393-011-9034-8

E.L. Papadopoulou, U.C. Paul, T.N. Tran, G. Suarato, L. Ceseracciu, S. Marras, R. d’Arcy, A. Athanassiou, Sustainable active food packaging from poly (lactic acid) and cocoa bean shells. ACS Appl Mater Interfaces 11(34), 31317–31327 (2019)

N. Xu, M. Li, P. Wang, S. Wang, H. Shi, Spectrum-effect relationship between antioxidant and anti-inflammatory effects of banxia baizhu tianma decoction: an identification method of active substances with endothelial cell protective effect. Front. Pharmacol. 13, 823341 (2022)

H. Tang et al., Curcumin polymers as anticancer conjugates. Biomaterials 31(27), 7139–7149 (2010). https://doi.org/10.1016/j.biomaterials.2010.06.007.7

A. Escobar, A. Serafin, M.R. Carvalho, M. Culebras, A. Cantarero, A. Beaucamp, R.L. Reis, J. Miguel Oliveira, M.N. Collins, Electroconductive poly (3, 4-ethylenedioxythiophene)(PEDOT) nanoparticle-loaded silk fibroin biocomposite conduits for peripheral nerve regeneration. Advanced Composites and Hybrid Materials 6(3), 118 (2023). https://doi.org/10.1007/s42114-023-00689-2

F. Zamboni, G. Ren, M. Culebras, J. O’Driscoll, J. O’Dwyer, E.J. Ryan, M.N. Collins, Curcumin encapsulated polylactic acid nanoparticles embedded in alginate/gelatin bioinks for in situ immunoregulation: characterization and biological assessment. Int. J. Biol. Macromol. 221, 1218–1227 (2022). https://doi.org/10.1016/j.ijbiomac.2022.09.014

A. Mehran, and Mahendra Rai., Recent progress in nanoformulations of silver nanoparticles with cellulose, chitosan, and alginic acid biopolymers for antibacterial applications. Appl. Microbiol. Biotechnol. 103, 8669–8676 (2019)

M. Alavi, M. Rai, Antibacterial and wound healing activities of micro/nanocarriers based on carboxymethyl and quaternized chitosan derivatives, in Biopolymer-based nano films. (Elsevier, 2021), pp.191–201

S.D. Fitzmaurice et al., Antioxidant therapies for wound healing: a clinical guide to currently commercially available products. Skin Pharmacol. Physiol. 24(3), 113–26 (2011). https://doi.org/10.1159/000322643

Yujia Liu et al., Molecular interactions, characterization and antimicrobial activity of curcumin–chitosan blend films. Food Hydrocoll 52, 564–572 (2016). https://doi.org/10.1016/j.foodhyd.2015.08.005

Xingyi Li et al., In vivo evaluation of curcumin nanoformulation loaded methoxy poly(ethylene glycol)-graft-chitosan composite film for wound healing application. Carbohyd. Polym. 88(1), 84–90 (2012). https://doi.org/10.1016/j.carbpol.2011.11.068

I.R. Calori et al., Polymer scaffolds as drug delivery systems Eur. Polymer J. 129, 109621 (2020). https://doi.org/10.1016/j.eurpolymj.2020.109621

Sicheng Wang et al., Influences of mesoporous magnesium calcium silicate on mineralization, degradability, cell responses, curcumin release from macro-mesoporous scaffolds of gliadin based biocomposites. Sci Rep 8(1), 174 (2018). https://doi.org/10.1038/s41598-017-18660-9

Nusret Celik et al., Self-healing of biocompatible superhydrophobic coatings: the interplay of the size and loading of particles. Langmuir 39(9), 3194–3203 (2023). https://doi.org/10.1021/acs.langmuir.2c02795

Md.. Mahbubur Rahman et al., In vitro antioxidant and free radical scavenging activity of different parts of Tabebuia pallida growing in Bangladesh. BMC Res Notes 8(1), 621 (2015). https://doi.org/10.1186/s13104-015-1618-6

Thi Nga Tran, Uttam Paul, José Alejandro. Heredia-Guerrero, Ioannis Liakos, Sergio Marras, Alice Scarpellini, Farouk Ayadi, Athanassia Athanassiou, Ilker S. Bayer, Transparent and flexible amorphous cellulose-acrylic hybrids. Chem Eng J 287, 196–204 (2016)

Thi Nga Tran, Ilker S. Bayer, José Alejandro. Heredia-Guerrero, Michela Frugone, Marco Lagomarsino, Fabio Maggio, Athanassia Athanassiou, Cocoa shell waste biofilaments for 3D printing applications. Macro Mater Eng 302(11), 1700219 (2017)

Kalindu DC. Perera et al., Study of concentration dependent curcumin interaction with serum biomolecules using ATR-FTIR spectroscopy combined with principal component analysis (PCA) and partial least square regression (PLS-R). Vib. Spectrosc. 116, 103288 (2021). https://doi.org/10.1016/j.vibspec.2021.103288

M. Mohammadian-Kohol et al., A study of the effects of gamma irradiation on the structural and mechanical properties of polyvinyl butyral film. Radiat. Phys. Chem. 152, 1–5 (2018). https://doi.org/10.1016/j.radphyschem.2018.07.014

Y. Qiao, L. Duan, Curcumin-loaded polyvinyl butyral film with antibacterial activity. E-Polymers 20(1), 673–681 (2020). https://doi.org/10.1515/epoly-2020-0042

Paola Calcagnile et al., Biodegradable poly(lactic acid)/cellulose-based superabsorbent hydrogel composite material as water and fertilizer reservoir in agricultural applications. J. Appl. Polym. Sci 136(21), 47546 (2019). https://doi.org/10.1002/app.47546

Lihua Xie and others, Utilization of wheat straw for the preparation of coated controlled-release fertilizer with the function of water retention. J. Agric. Food Chem. 60(28), 6921–6928 (2012). https://doi.org/10.1021/jf3001235

Hamza Simsir et al., Effects of acidic and alkaline metal triflates on the hydrothermal carbonization of glucose and cellulose. Energy Fuels 33(8), 7473–7479 (2019). https://doi.org/10.1021/acs.energyfuels.9b01750

Xueting Liu et al., Breathable, stretchable and adhesive nanofibrous hydrogels as wound dressing materials. Eng Regen 2, 63–69 (2021). https://doi.org/10.1016/j.engreg.2021.05.001

W.J. Zheng et al., Waterproof and breathable wound dressing composited by expanded polytetrafluoroethylene backing and hydrogel. Macro Biosci 22(8), 2200131 (2022). https://doi.org/10.1002/mabi.202200131

Sihan Jiang et al., Breathable, Antifreezing, Mechanically skin-like hydrogel textile wound dressings with dual antibacterial mechanisms. Bioactive Materials 21, 313–323 (2023). https://doi.org/10.1016/j.bioactmat.2022.08.014

G. Perotto, L. Ceseracciu, R. Simonutti, U.C. Paul, S. Guzman-Puyol, T.N. Tran, I.S. Bayer, A. Athanassiou, Bioplastics from vegetable waste via an eco-friendly water-based process. Green Chem. 20(4), 894–902 (2018)

Zheng A. Tran, Thi Nga, Athanassia Athanassiou, Abdul Basit, Ilker S. Bayer, Starch-based bio-elastomers functionalized with red beetroot natural antioxidant. Food Chem 216, 324–333 (2017)

Mahsa Janmohammadi et al., Cellulose-based composite scaffolds for bone tissue engineering and localized drug delivery. Bioact Mater 20, 137–163 (2023)

M.A. Hossain et al., Response surface optimization for antioxidant extraction from jackfruit (Artocarpus Heterophyllus Lam.) seed and pulp. J Sci Res 12(3), 397–409 (2020). https://doi.org/10.3329/jsr.v12i3.44459

D. Villaño et al., Radical scavenging ability of polyphenolic compounds towards DPPH free radical. Talanta 71(1), 230–35 (2007). https://doi.org/10.1016/j.talanta.2006.03.050

Hasan Akgül et al., Total antioxidant and oxidant status and DPPH free radical activity of Euphorbia eriophora. Turk J Agric Food Sci Technol 10(2), 272–75 (2022). https://doi.org/10.24925/turjaf.v10i2.272-275.4685

Funding

Open Access funding provided by the IReL Consortium. This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No. 945168. This project is supported in part by a research grant from Science Foundation Ireland (SFI) under the grant number 12/RC/2278_P2.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dominici, S., Collins, M.N., Morris, M.A. et al. An innovative approach to develop plant-derived and CO2-based active biocomposite films towards antioxidant activity. emergent mater. (2024). https://doi.org/10.1007/s42247-024-00659-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42247-024-00659-4