Abstract

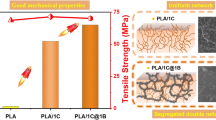

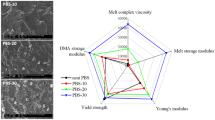

Biodegradable poly(glycolic-co-lactic acid) (PGLA) fiber was used as a reinforcing agent, and sustainable composites based on poly(propylene carbonate) (PPC) were prepared by melting mixing. The morphology, mechanical properties, rheological properties, and heat resistance were investigated. SEM revealed the uniform distribution of fiber in PPC matrix and good interfacial adhesion between PPC and fibers. With the addition of PGLA fibers, PPC composites showed obviously improvement of storage modulus, yield strength, and tensile modulus, while the toughness was still retained at room temperature. However, neat PPC and the composites gradually transformed into a brittle material with decrease of temperature, but the strength and modulus were improved. Moreover, the melt strength of PPC composites was improved with the incorporation of fibers due to the restriction of the chain mobility of PPC by the network-like structure of fibers. Finally, the vicat softening temperature of the composites was improved because of incorporation of PGLA fibers.

Graphical Abstract

Similar content being viewed by others

References

Tao J, Song CJ, Cao MF, Hu D, Liu L, Liu N, Wang SF (2009) Thermal properties and degradability of poly(propylene carbonate)/poly(β-hydroxybutyrate-co-β-hydroxyvalerate) (PPC/PHBV) blends. Polym Degrad Stab 94:575–583

Di Lorenzo ML, Longo A, Androsch R (2019) Polyamide 11/poly(butylene succinate) bio-based polymer blends. Materials 12:2833

Yu YL, Xu PF, Jia SL, Pan HW, Zhang HL, Wang DM, Dong LS (2019) Exploring polylactide/poly(butylene adipate-co-terephthalate)/rare earth complexes biodegradable light conversion agricultural films. Int J Biol Macromol 127:210–221

Inoue S, Koinuma H, Tsuruta T (1969) Copolymerization of carbon dioxide and epoxide. J Polym Sci B Polym Lett 7:287–292

Peng SW, Wang XY, Dong LS (2010) Special interaction between poly (propylene carbonate) and corn starch. Polym Compo 26:37–41

Meereboer KW, Pal AK, Misra M, Mohanty AK (2021) Green composites from a bioplastic blend of poly(3-hyroxybutyrateco-3-hydroxyvalerate) and carbon dioxide-derived poly(propylene carbonate) and filled with a corn ethanol-industry co-product. ACS Omega 6:20103–20111

Xing CY, Wang HT, Hu QQ, Xu FF, Cao XJ, You JC, Li YJ (2013) Mechanical and thermal properties of eco-friendly poly (propylene carbonate)/cellulose acetate butyrate blends. Carbohyd Polym 92:1921–1927

Li X, Hu CY, Pang X, Duan RL, Chen XS (2018) One-pot copolymerization of epoxides/carbon dioxide and lactide using a ternary catalyst system. Catal Sci Technol 8:6452–6457

Song PF, Ran BC, Shang YQ, Kang L, Chen YL, Sun LY (2019) A facile strategy for the preparation of end-capped and cross-linkable poly(propylene carbonate) with high performance. Adv Ind Eng Polym Res 4:161–166

Jiang G, Feng J, Zhang MD, Zhang SD, Huang HX (2016) Structure, and thermal and mechanical properties of poly(propylene carbonate) capped with different types of acid anhydride via reactive extrusion. RSC Adv 6:107547–107555

Wang DX, Li JY, Zhang XC, Zhang JM, Yu J, Zhang J (2020) Poly(propylene carbonate)/clay nanocomposites with enhanced mechanical property, thermal stability and oxygen barrier property. Comp Comm 22:100520

Dong XY, Liu L, Wang Y, Li T, Wu ZG, Yuan H, Ma PM, Shi DJ, Chen MQ, Dong WF (2021) The compatibilization of poly (propylene carbonate)/poly (lactic acid) blends in presence of core-shell starch nanoparticles. Carbohyd Polym 254:117321

Jiang G, Yu L (2021) High strength and barrier properties of biodegradable PPC/PBSA blends prepared by reaction compatibilization for promising application in packaging. Macromol Mater Eng 306:2000723

Wang DX, Yu J, Zhang JM, He JS, Zhang J (2013) Transparent bionanocomposites with improved properties from poly(propylene carbonate) (PPC) and cellulose nanowhiskers (CNWs). Compos Sci Tech 85:83–89

Wang W, Han CY, Wang XH, Zhou GB, Xu MZ (2020) Enhanced rheological properties and heat resistance of poly (propylene carbonate) composites with carbon fiber. Comp Comm 21:100422

Chen FQ, Liu HY, Zhao YQ, Feng YH, Guo RB, Wu ZH, Chen HZ, Tang HL, Qu JP (2014) Caulis spatholobi residue fiber reinforced biodegradable poly (propylene carbonate) composites: the effect of fiber content on mechanical and morphological properties. Polym Compos 35:208–216

Li XH, Meng YZ, Wang SJ, Rajulu AV, Tjong SC (2004) Completely biodegradable composites of poly (propylene carbonate) and short, lignocellulose fiber Hildegardia populifolia. J Polym Sci B Polym Phys 42:666–675

Ju DD, Han LJ, Li F, Chen S, Dong LS (2014) Poly (ε-caprolactone) composites reinforced by biodegradablepoly (3-hydroxybutyrate-co-3-hydroxyvalerate) fiber. Int J Biol Macromol 67:343–350

Ju DD, Han LJ, Guo ZQ, Bian JJ, Li F, Chen S, Dong LS (2015) Effect of diameter of poly (lactic acid) fiber on the physical properties of poly (ε-caprolactone). Int J Biol Macromol 76:49–57

Ju DD, Han LJ, Li F, Chen S, Dong LS (2013) Crystallization, mechanical properties, and enzymatic degradation of biodegradable poly (e-caprolactone) composites with poly (lactic acid) Fibers. Polym Compos 34:1745–1752

Cooper JA, Lu HH, Ko FK, Freeman JW (2005) Fiber-based tissue-engineered scaffold for ligament replacement: design considerations and in vitro evaluation. Biomaterials 26:1523–1532

Tian HL, Wang ZP, Jia SL, Pan HW, Han LJ, Bian JJ, Li Y, Yang HL, Zhang HL (2022) Biodegradable foaming material of poly (butylene adipate-co-terephthalate) (PBAT)/poly(propylene carbonate) (PPC). Chin J Polym Sci 40:208–219

Huda MS, Mohanty AK, Drzal LT, Schut E, Misra M (2005) “Green” composites from recycled cellulose and poly(lactic acid): physico-mechanical and morphological properties evaluation. J Mater Sci 40:4221–4229

Zhao L, Jia SL, Wang ZP, Chen YJ, Bian JJ, Han LJ, Zhang HL, Dong LS (2021) Thermal, rheological and mechanical properties of biodegradable poly(propylene carbonate)/epoxidized soybean oil blends. Chin J Polym Sci 39:1572–1580

Bastida S, Eguiazábal JI, Nazábal J (1993) The vicat softening temperature as a method to assess the phase behaviour of amorphous polymer blends. Polym Testing 12:233–242

Li HB, Li Qi, Yan ML (2011) Influence of operation procedures on vicat softening temperature of thermoplastic materials. Adv Mater Res 9:1820–1824

Acknowledgements

The financial support from the Science and Technology Development Plan of Jilin Province (20210203199SF) and the Science and Technology Development Program of Yantai of China (2022ZDCX015) was greatly appreciated.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, C., Jia, S., Liu, C. et al. Green composite from carbon dioxide-derived poly (propylene carbonate) and biodegradable poly (glycolic-co-lactic acid) fiber. Colloid Polym Sci 301, 319–329 (2023). https://doi.org/10.1007/s00396-023-05068-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-023-05068-3