Abstract

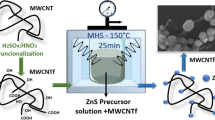

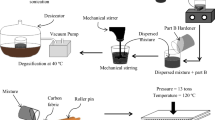

In this study, an extensive analysis on the mechanical properties of epoxy matrix, polyimide matrix, and PLA (polylactic acid) biopolymer matrix in association with carbon nanotubes (CNTs) (CNTs/epoxy, CNTs/polyimide, and CNTs/PLA) for different applied stresses and humidity levels has been performed. Results found showed that the fiber–matrix interface of the carbon nanotubes/epoxy nanocomposite material and the carbon nanotubes/PLA bionanocomposite material exhibit more resistance to applied mechanical stress and under a humid environment, compared to the carbon nanotubes/polyimide nanocomposite material (with an average interface damage difference up to 23%). These findings affirm and align precisely with a recent study conducted by Kucharczyk, which revealed that the incorporation of carbon nanotubes (CNTs) in epoxy nanocomposites enhances their stiffness and elasticity, leading to improved mechanical properties of the structure. As a result, the two most promising composites out of the three studied for use in a humid environment are the bionanocomposite carbon nanotubes/PLA and the nanocomposite carbon nanotubes/epoxy. Nevertheless, considering the need for environmentally friendly options, the bionanocomposite carbon nanotubes/PLA is the preferred choice due to the biodegradability of its biopolymer PLA matrix.

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are available within the paper.

Abbreviations

- CNTs:

-

Carbon nanotubes

- PLA:

-

Polylactic acid

- IoTs:

-

Internet of Things

- SEM:

-

Scanning electron microscopy

- \({G}_{m}\) :

-

Shear modulus of the matrix

- \({E}_{f}\) :

-

Young’s modulus of the fiber

- \(\varepsilon\) :

-

Deformation

- \({\sigma }_{f}\) :

-

Applied stress

- \({V}_{\mathrm{eff}}\) :

-

Matrix volume

- \(m\mathrm{ and}{ \sigma }_{0}\) :

-

Weibull parameters

- \({V}_{0}\) :

-

Initial volume of the matrix.

- \({\sigma }_{\mathrm{max}}^{f}\) :

-

The maximum stress applied to the fiber

- \({\sigma }_{0f}\) :

-

The initial stress applied to the fiber

- \({m}_{f}\) :

-

Weibull parameters

- \({A}_{f}\) :

-

π*a2

- \({L}_{\mathrm{equi}}\) :

-

The length of the fiber at equilibrium

- W i :

-

Weight of component i

- W c :

-

Total weight of the composite

- \({\rho }_{c}\) :

-

Density of composite

- \({\rho }_{f}\) :

-

Density of fiber

- \({\rho }_{m}\) :

-

Density of the matrix

References

N. Li, D. Qiao, S. Zhao, Q. Lin, B. Zhang, F. Xie, 3D printing to innovate biopolymer materials for demanding applications: a review. Mater. Today Chem. 20, 100459 (2021)

F. Samalens, M. Thomas, M. Claverie, N. Castejon, Y. Zhang, T. Pigot, S. Blanc, S.C.M. Fernandes, Progresses and future prospects in biodegradation of marine biopolymers and emerging biopolymer- based materials for sustainable marine ecosystems. Green Chem. 24, 1762 (2022)

K. Mohan, A.R. Ganesan, P.N. Ezhilarasi, K.K. Kondamareddy, D.K. Rajan, P.S. Kumar, J. Rajarajeswaran, L. Conterno, Green and eco-friendly approaches for the extraction of chitin and chitosan: A review. Carbohydr. Polym. 287, 119349 (2022)

A. Khanra, S. Vasistha, M.P. Rai, W.Y. Cheah, K.S. Khoo, K.W. Chew, L.F. Chuah, P.L. Show, Green bioprocessing and applications of microalgae-derived biopolymers as a renewable feedstock: circular bioeconomy approach. Environ. Technol. Innov. 28, 102872 (2022)

L.M. Koh, S.M. Khor, Current state and future prospects of sensors for evaluating polymer biodegradability and sensors made from biodegradable polymers: a review. Anal. Chim. Acta. 1217, 339989 (2022)

K.L. Law, R. Narayan, Reducing environmental plastic pollution by designing polymer materials for managed end-of-life. Nat Rev Mater. 7, 104–116 (2002)

P. Sánchez-Cid, M. Jiménez-Rosado, A. Romero, V. Pérez-Puyana, Novel trends in hydrogel development for biomedical applications: a review. Polymers 14(15), 3023 (2022)

A.H. MdYusop, A. Al Sakkaf, H. Nur, Modifications on porous absorbable Fe-based scaffolds for bone applications: a review from corrosion and biocompatibility viewpoints. J Biomed Mater Res B. 110(1), 18–44 (2022)

D. Matveev, V. Vasilevsky, V. Volkov, T. Plisko, A. Shustikov, A. Volkov, A. Bildyukevich, Fabrication of ultrafiltration membranes from non-toxic solvent dimethylsulfoxide: benchmarking of commercially available acrylonitrile co-polymers. J. Environ. Chem. Eng. 10(1), 107061 (2022)

L. Pierau, C. Elian, J. Akimoto, Y. Ito, S. Caillol, D.L. Versace, Bio-sourced monomers and cationic photopolymerization–the green combination towards eco-friendly and non-toxic materials. Prog. Polym. Sci. 127, 101517 (2002)

M. Nodehi, Epoxy, polyester and vinyl ester based polymer concrete: a review. Innov. Infrastruct. Solut. 7, 64 (2022)

S. Kopf, D. Åkesson, M. Skrifvars, Textile fiber production of biopolymers – a review of Spinning techniques for Polyhydroxyalkanoates in biomedical applications. Polym Rev. (2022)

S.G. Alamdari, A. Alibakhshi, M. de la Guardia, B. Baradaran, R. Mohammadzadeh, M. Amini, P. Kesharwani, A. Mokhtarzadeh, F. Oroojalian, A. Sahebkar, Conductive and semiconductive nanocomposite-based hydrogels for cardiac tissue engineering. Adv. Healthcare Mater. 11, 2200526 (2022)

N.P. Simelane, J.K.O. Asante, P.P. Ndibewu, A.S. Mramba, L.L. Sibali, Biopolymer composites for removal of toxic organic compounds in pharmaceutical effluents – a review. Carbohydr. Polym. Techno. App. 4, 100239 (2022)

M.Y. Khalid, Z.U. Arif, Novel biopolymer-based sustainable composites for food packaging applications: a narrative review. Food Packag. Shelf Life. 33, 100892 (2022)

F. Razmjoo, E. Sadeghi, M. Alizadeh-Sani, R. Noroozi, M. Azizi-Lalabadi, Fabrication and application of functional active packaging material based on carbohydrate biopolymers formulated with Lemon verbena/Ferulagoangulata extracts for the preservation of raw chicken meat. J. Food Process. Preserv. 46, e16830 (2022)

Q. Wang, W. Chen, W. Zhu, D.J. McClements, X. Liu, F. Liu, A review of multilayer and composite films and coatings for active biodegradable packaging. NpjSci Food 6, 18 (2022)

P.R. Yaashikaa, P. Senthil Kumar, S. Karishma, Review on biopolymers and composites – evolving material as adsorbents in removal of environmental pollutants. Environ. Res. 212(A), 113114 (2022)

N. Fijoł, A. Aguilar-Sánchez, A.P. Mathew, 3D-printable biopolymer-based materials for water treatment: a review. Chem. Eng. J. 430(3), 132964 (2022)

A. Balakrishnan, S. Appunni, M. Chinthala, D.V.N. Vo, Biopolymer-supported TiO2 as a sustainable photocatalyst for wastewater treatment: a review. Environ ChemLett. 20, 3071–3098 (2022)

P. Rekhi, M. Goswami, S. Ramakrishna, M. Debnath, Polyhydroxyalkanoates biopolymers toward decarbonizing economy and sustainable future. Crit. Rev. Biotechnol. 42(5), 668–692 (2022)

U.Z. Husna, K.A. Elraies, J.A.B.M. Shuhili, A.A. Elryes, A review: the utilization potency of biopolymer as an eco-friendly scale inhibitors. J Petrol Explor Prod Technol. 12, 1075–1094 (2022)

A.A. Mohan, A.R. Antony, K. Greeshma, J.H. Yun, R. Ramanan, H.S. Kim, Algal biopolymers as sustainable resources for a net-zero carbon bioeconomy. Bioresour. Technol. 344(B), 126397 (2022)

M. Stoica, D. Stoica, A.S. Ivan, C.M.B. Dragomir, Biopolymers: regulatory and legislative issues. (eds) Biopolymers. Springer Series on Polymer and Composite Materials, Book series, Chap. 55–71 (2022)

V.M. Kuimov, A.N. Kryazhov, A.I. Yagupov, A.A. Elagin, M.A. Mironov, Biopolymer-based membranes: green technologies for the separation of oil–water mixtures and the reduction of oil pollution. Clean. Techn. Environ. Policy. 24, 1961–1985 (2022)

L. Wang, F. Zhang, Y. Liu, J. Leng, Shape memory polymer fibers: materials, structures, and applications. Adv. Fiber Mater. 4, 5–23 (2022)

R.A. Ilyas, N.M. Nurazzi, M.N.F. Norrrahim, Fiber-reinforced polymer nanocomposites. Nanomaterials 12(17), 3045 (2022)

R. Hsissou, R. Seghiri, Z. Benzekri, M. Hilali, M. Rafik, A. Elharfi, Polymer composite materials: a comprehensive review. Compos. Struct. 26, 211364 (2021)

R.A. Ilyas, S.M. Sapuan, M.M. Harussani, M.Y.A.Y. Hakimi, M.Z.M. Haziq, M.S.N. Atikah, M.R.M. Asyraf, M.R. Ishak, M.R. Razman, N.M. Nurazzi, M.N.F. Norrrahim, H. Abral, M. Asrofi, Polylactic acid (PLA) biocomposite: processing, additive manufacturing and advanced applications. Polymers 13(8), 1326 (2021)

M.Y. Khalid, Z.A. Arif, R. Noroozi, A. Zolfagharian, M. Bodaghi, 4D printing of shape memory polymer composites: a review on fabrication techniques, applications, and future perspectives. J Manuf Process. 81, 759–797 (2022)

D.K. Rajak, P.H. Wagh, E. Linul, A review on synthetic fibers for polymer matrix composites: performance, failure modes and applications. Mater. 15(14), 4790 (2022)

J. Praveenkumara, P. Madhu, T.G. YashasGowda, M.R. Sanjay, S. Siengchin, A comprehensive review on the effect of synthetic filler materials on fiber-reinforced hybrid polymer composites. J. Text. Inst. 113(7), 1231–1239 (2022)

F. Alam, M. Elsherif, A.E. Salih, H. Butt, 3D printed polymer composite optical fiber for sensing applications. Addit. Manuf. 58, 102996 (2022)

R. Dhilip Kumar, S. Nagarani, V. Sethuraman, S. Andra, V. Dhinakaran, Investigations of conducting polymers, carbon materials, oxide and sulfide materials for supercapacitor applications: a review. Chem. Pap. 76, 3371–3385 (2022)

N.A. Lahmann, U. Müller-Werdan, S. Kuntz, J. Klingehöfer-Noe, F. Jaenicke, S. Strube-Lahmann, Conception and evaluation of a washable multimodal smart textile. Health Technol. 12, 69–81 (2022)

Z. Li, F. Wang, L. Liu, Y. Liu, X. Chen, J. Yao, Highly sensitive, breathable and durable E-textiles integrated by graphene ink via scalable aerodynamics assisted screen printing. Cellulose 29, 4661–4671 (2022)

C.R.S. Oliveira, J.A.H. da Silva, A.P.S. Immich, J. Fiates, Use of advanced materials in smart textile manufacturing. Mater. Lett. 316, 132047 (2022)

A. Angelucci, M. Cavicchioli, I.A. Cintorrino, G. Lauricella, C. Rossi, S. Strati, A. Aliverti, Smart textiles and sensorized garments for physiological monitoring: a review of available solutions and techniques. Sens. 21(3), 814 (2021)

Y. Wu, L. Zhong, J. Yuan, W. Xiang, X. Xin, H. Liu, H. Luo, L. Li, M. Chen, D. Zhong, X. Zhang, N. Zhong, H. Chang, Photocatalytic optical fibers for degradation of organic pollutants in wastewater: a review. Environ ChemLett. 19, 1335–1346 (2021)

B. Parveez, M.I. Kittur, I.A. Badruddin, S. Kamangar, M. Hussien, M.A. Umarfarooq, Scientific advancements in composite materials for aircraft applications: a review. Polymers. 14(22), 5007 (2022)

N.S. Ali, S.K. Shihab, M.T. Mohamed, Mechanical and physical characteristics of hybrid particles/fibers-polymer composites: a review. Mater. Today: Proc. 62(1), 178–183 (2022)

A. García, G.D. Valbuena, A. García-Tuero, A. Fernández-González, J.L. Viesca, A.H. Battez, Compatibility of automatic transmission fluids with structural polymers used in electrified transmissions. Appl. Sci. 12(7), 3608 (2022)

A.K. Sharma, R. Bhandari, C. Sharma, S.K. Dhakad, C. Pinca-Bretotean, Polymer matrix composites: a state of art review. Mater. Today: Proc. 57(5), 2330–2333 (2022)

A. Felix Sahayaraj, M. Muthukrishnan, Experimental investigation on the effect of fiber volume fraction of sponge gourd outer skin fiber reinforced epoxy composites. Polym. Compos. 43(10), 6932–6942 (2022)

A. Felix Sahayaraj, M. Muthukrishnan, M. Ramesh, Experimental investigation on physical, mechanical, and thermal properties of jute and hemp fibers reinforced hybrid polylactic acid composites. Polym. Compos. 43(5), 2854–2863 (2022)

N.J. Kanu, S. Bapat, H. Deodhar, E. Gupta, G.K. Singh, U.K. Vates, G.C. Verma, V. Pandey, An insight into processing and properties of smart carbon nanotubes reinforced nanocomposites. Smart Sci. 10(1), 40–55 (2022)

R.R. Hasan, A.M. Saleque, A.B. Anwar, M.D. AbdurRahman, Y.H. Tsang, Multiwalled carbon nanotubes-based on-body patch antenna for detecting COVID-19 affected lungs. ACS Omega. 7(32), 28265–28274 (2022)

H. Song, H. Jeon, D. Im, N. Çakmakçı, K.Y. Shin, Y. Jeong, Free-standing carbon nanotubes film for high efficiency monopole antenna. Carbon 187, 22–28 (2022)

D. Suzuki, Y. Takida, Y. Kawano, H. Minamide, N. Terasaki, Carbon nanotubes-based, serially connected terahertz sensor with enhanced thermal and optical efficiencies. SciTechnolAdv Mater. 23(1), 424–433 (2022)

A. Amaro, S. Adrian, T. Alessio, T. Jose, M. Fabrizio, P.A. Martinez, G. Begoña, S. Neus, V. Jorge, A. Alcarria, EMI shielding effectiveness study for innovative carbon nanotubes materials in the 5G frequency region. IEEE Trans. Electromagn. Compat. 65(1), 177–185 (2023)

A.H.M. Ismail, F.M. AL-Oqla, M.S. Risby, S.M. Sapuan, On the enhancement of the fatigue fracture performance of polymer matrix composites by reinforcement with carbon nanotubes: a systematic review. Carbon Lett. 32, 727–740 (2022)

H. Qifa, S. Kai, W. Zongxiang, W. Zhongyang, Y. Pengtao, J. Tian, D. Wenxin, F. Runhua, Epsilon-negative behavior and its capacitance enhancement effect on trilayer-structured polyimide–silica/multiwalled carbon nanotubes/polyimide–polyimide composites. J. Mater. Chem. C. 10(11), 4286–4294 (2022)

X. Li, J. Wang, Y. Tian, X. Jiang, X. Zhang, Thermal enhancement by constructing ordered-orienting hybrid network with modified boron nitride, graphene and carbon nanotubes in epoxy composite coatings. Prog. Org. Coat. 172, 107078 (2022)

Y. Wang, C. Yang, Z. Xin, Y. Luo, B. Wang, X. Feng, Z. Mao, X. Sui, Poly(lactic acid)/carbon nanotubes composites with enhanced electrical conductivity via a two-step dispersion strategy. Compos. Commun. 30, 101087 (2022)

D.C. Ngyen, Fibre/matrix interface characterization : application to hemp fiber/ polypropylene composites (PhD Thesis, UTT TROYES, Troyes, 2016)

Y. Li, K. Pickering, R. Farrell, Determination of interfacial shear strength of white rot fungi treated hemp fibre reinforced polypropylene. Compos. Sci. Technol. 69, 1165–1171 (2009)

R. El Guerjouma, I. Goujon, H. Nachad, A. Faiz, B.M. Godin, M.J.C. Baboux, Linear and nonlinear ultrasonics for material damage evaluation and health monitoring. Mater. et Tech. 90, 48–52 (2002)

R. El Guerjouma, M. Deschamps, A. Gérard, Acoustoelasticity under variable of incidence: a determination of the third order of the elastic constants. Acustica. 77, 183–192 (1992)

K.E. Van Den Abeele, Elastic pulsed wave propagation in media with second or higher-order nonlinearity. Part I. Theoretical frame work. J. Acoust. Soc. Am. 99(6), 3334–3345 (1996)

K. Van Den Abeele, P.A. Johnson, Elastic pulsed wave propagation in media with second or higher-order nonlinearity. Part II. Simulation of experimental measurement on Berea Sandstone. J. Acoust. Soc. Am. 99(6), 3346–3352 (1996)

F.A. Belhadj, M. Belkheir, A. Mokaddem, B. Doumi, A. Boutaous, Numerical characterization of the humidity effect on the fiber-matrix interface damage of hybrid composite material based on vinyl ester polymer matrix for engineering applications. Emergent Mater. 5, 591–600 (2022). https://doi.org/10.1007/s42247-022-00353-3

W. Weibull, A statistical theory of the strength of materials. Roy. Swe. Aca. Eng. Sci. Proc. 151, 1–45 (1939)

M. Belkheir, M. Rouissat, A. Mokaddem et al., Using genetic algorithm for studying the effect of polymethyl methacrylate (PMMA) polymer matrix on composites materials interface based on carbon, glass and aramid fibers for engineering and telecommunication applications. Part. Mech. Comp. (2022). https://doi.org/10.1007/s40571-022-00504-7

M. Belkheir, M. Alami, A. Mokaddem et al., An investigation on the effect of humidity on the mechanical properties of composite materials based on polymethyl methacrylate polymer optical fibers (POFs). Fibers Polym 23, 2897–2906 (2022). https://doi.org/10.1007/s12221-022-4164-6

A. Mokaddem, A. Alami, N. Ziani, N. Beldjoudi, A. Boutaous, Prediction by a genetic algorithm of the fiber–matrix interface damage for composite material. Part 2. Study of shear damage in graphite/epoxy nanocomposites. Strength Mater. 46(4), 548–552 (2014)

S. Grange, J.L. Prensier (2006), Annexe : détermination des paramètres de Weibull. Le modèle de Weibull : un critère de rupture probabiliste. http://eduscol.education.fr/sti/si-ens-cachan/ (accessed on 08/03/2022).

P. Ladevèse, G. Lubineau, D. Marsal, Towards a bridge between the micro- and mesomechanics of delamination for laminated composites. Compos. Sci. Technol. 66(6), 898–712 (2006)

N. Lissart, J. Lamon, Damage and failure in ceramic matrix minicomposites: experimental study and model. Acta Mater. 45(3), 1025–1044 (1997)

P. Bonniau, A.R. Bunsell, A comparative study of water absorption theories applied to glass epoxy composites. J. Comp. Mater. 15(3), 272–293 (1981)

T.P. Hong, O. Lesaint, P. Gonon, Water absorption in a glass-mica-epoxy composite. IEEE Trans. Dielectric ElectrInsul. 16(1), 1–10 (2009)

P. Nogueira, C. Ramirez, A. Torres, M.A. Abad, J. Cano, J. Lopez, I. Lopezbueno, L. Barral, Influence of the curing cycle selection on the thermal degradation of an epoxy-diamide system. J. Polym. Sci. 80, 71880 (2001)

Y. Diamant, G. Marom, L. Broutman, The effect of network structure on moisture absorption of epoxy resins. J. Polym. Sci. 26, 3015–3025 (1931)

M.J. Adamson, Thermal expansion and swelling of cured epoxy resin used in graphite/epoxy composite material. J. Mater. Sci. 15, 1736–1745 (1980)

A. Apicella, L. Egiziano, L. Nicolais, V. Tucci, Environmental degradation of electrical and thermal properties of organic insulating materials. J. Mater. Sci. 23, 729–735 (1988)

Y. Menail, B. Redjel, A. EL Mah, M. Assarar, Impact de la fatigue et du vieillissement hygrothermique en eau douce sur un composite unidirectionnel verre-époxy. Rev. Sci. Technol. 24, 38–43 (2015)

M. Assarar, D. Scida, A. EL Mahi, C. Poilâne, R. Ayad, Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax–fibres and glass fibres. Mater. Des. 32, 788–79 (2011)

F.B. Boukhoulda, L. Guillaumat, J.L. Lataillade, E. Adda-Bedia, A. Lousdad, Aging-impact coupling based analysis upon glass/polyester composite material in hygrothermal environment. Mater. Des. 32, 4080–4087 (2011)

S. Iijima, Helical microtubules of graphitic carbon. Nature 354, 56–58 (1991)

S. Iijima, T. Ichihasi, Single-shell carbon nanotubes of 1-nm diameter. Nature 363, 603–605 (1993)

F. Laurent, Growth of carbon nanotubes on carbon fibres : application to composite materials (PhD Thesis. HAUTE-ALSACE University (UHA), Mulhouse, 2016)

J.B. Donnet, H. Oulanti, T. Le Huu, Mechanism growth of multiwalled CNT on carbon black. DiamRelatMater. 17, 1506–1512 (2008)

M. Yu, O. Lourie, M.J. Dyer, T.F. Kelly, R.S. Ruoff, Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Sci. 287, 637–677 (2000)

J.M. Berthelot, Matériaux composites. Comportement mécanique et analyse des structures. Book 5th Edition Lavoisier, 638 (2012)

T. Crochon, modeling of the viscoelastic behavior of a polyimide matrix at elevated temperature (PhDThesis, Ecole polytechnique de Montréal, Polypublie, 2014)

F. Li, G.L. Huang, Y. Shi, X. Jin, Z. Wu, Z. Shen, K.C. Chuang, R.E. Lyon, F.W. Harris, Z.D. Cheng, Thermal degradation mechanism and thermal mechanical properties of two high-performance aromatic polyimide fibers. J. Macromol. Sci. 38, 107–122 (1999)

D. Garlotta, A literature review of poly(lactic acid). J. Polym. Environ. 9(2), 63–84 (2000)

Y. Ruksakulpiwat, P. Tonimit, J. Kluengsamrong, Mechanical properties of PLA-Jute composites by using natural rubber and epoxidized natural rubber as impact modifiers: effect of molding technique. Clean Technol. 310–313 (2010)

A. Akbari, M. Majumder, A. Tehrani, Handbook of Polymer Nanocomposites. Processing, Performance and Applicatio (Springer, Berlin, Heidelberg, 2015), pp.283–297

S. Jacobsen, H.G. Fritz, Plasticizing polylactide – the effect of different plasticizers on the mechanical properties. PolymEng Sci. 39, 1303–1310 (1999)

B. Benyamina, A. Mokaddem, B. Doumi et al., Study and modeling of thermomechanical properties of jute and Alfa fiber-reinforced polymer matrix hybrid biocomposite materials. Polym. Bull. 78, 1771–1795 (2021)

M.D. Isaac, O.Ishai, Engineering Mechanics of Composite Materials. 2nd ed. Oxford University Press. ISBN 978–0–19–532244–6 (2006)

A.K. Kaw, Mechanics of composite materials. 2nd ed. Taylor & Francis Group, LLC. ISBN 0-8493-1343-0 (2006)

A. Mokaddem, M. Alami, A. Boutaous, Stability condition for the evaluation of damage in three-point bending of a laminated composite. Steel. Compo. Struct. 15(2), 203–220 (2013)

N. Kaouche, M. Mebrek, A. Mokaddem, B. Doumi et al., Theoretical study of the effect of the plant and synthetic fibers on the fiber-matrix interface damage of biocomposite materials based on PHA (polyhydroxyalkanoates) Biodegradable Matrix. Polym. Bull. 79, 7281–7301 (2022)

A. Mokaddem, M. Alami, A. Boutaous, A study by a genetic algorithm for optimizing the arrangement of the fibers on the damage to the fiber–matrix interface of a composite material. J. Text. Inst. 103(12), 1376–1382 (2012)

I. Assaf, M. Belkheir, A. Mokaddem, B. Doumi, A. Boutaous, Effect of fiber-matrix interface decohesion on the behavior of thermoset and thermoplastic composites reinforced with natural fibers: a comparative study. J. Mater. Sci. 28(1), 93–100 (2021)

M. Belkheir, M. Rouissat, A. Mokaddem, B. Doumi, A. Boutaous, Studying the effect of polymethyl methacrylate polymer opticals fibers (POFs) on the performance of composite materials based on the polyether ether ketone (PEEK) polymer matrix. Emergent Mater. 5, 2075–2085 (2022)

M. Belkheir, B. Doumi, A. Mokaddem, A. Boutaous, Using genetic algorithm for investigating the performance of carbon-basalt / polyester hybrids composite material. Curr. Mater. Sci. 13, 120–128 (2020)

W. Kucharczyk, M. Bakar, W. Zurowski, O.T. BiałkowskaA, StawarzS, Influence of carbon nanotubes, resin matrix and technology of mixture homogenization on ablative and dynamic mechanical properties of epoxy nanocomposites. Compos. Struct. 280, 114801–1148014 (2022)

Funding

This work was supported by the General Direction of Scientific Research and Technological Development of the Ministry of Higher Education and Scientific Research of Algeria. (PRFU:A25N01CU320120230001).

Author information

Authors and Affiliations

Contributions

All authors have contributed equally. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Belkheir, M., Rouissat, M., Mokaddem, A. et al. Effect of carbon nanotube (CNT)-reinforced polymers and biopolymer matrix on interface damage of nanocomposite materials. emergent mater. 6, 1589–1602 (2023). https://doi.org/10.1007/s42247-023-00547-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-023-00547-3