Abstract

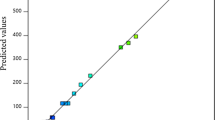

The effect of electrodeposition parameters on the synthesis of new nanocomposite coating formulations of zinc reinforced with calcium oxide nanoparticles (CaOnp) from oyster shells was studied. The g/l calcium oxide nanoparticles (CaOnp), current density, deposition temperature, and times were the stir electrodeposition parameters, while electrical conductivity, hardness values, and corrosion rate were used as the multi-responses for the study. The experimental results were in good accordance with model prediction values. The optimium conditions were obtained at 10g/lCaOnp, 80 °C deposition temperature, 1.5A/cm2 current density, and 15-min deposition time. The smaller crystallite size of the deposited sample is the main reason for the lower corrosion resistance and higher hardness values obtained. It was established that waste oysters can be used for the electrodeposition of mild steel to enhance corrosion resistance and hardness values.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting this study's conclusions is included in the publication.

References

V.S. Aigbodion, Explicit simultaneous enhancement of adhesion strength and wear resistance of functional value-added epoxy-functionalized rice husk ash nanoparticle composite coating. Inter. J. of Adva. Manuf. Techno 109, 2205–2214 (2020). https://doi.org/10.1007/s00170-020-05758-0

V.S. Aigbodion, S.I. Neife, I.Y. Suleiman, Surface modification of mild steel by co-deposition using Zn-ZnO-Ant hill particulate composite coating in simulated seawater, Proceed. of the Instit. of Mech. Eng., Part M: J. of Eng. for the Marit. Envir. (2019). https://doi.org/10.1177/1475090218792382

R. Winand, in Modern electroplating, 5th edn.. Electrodeposition of zinc and zinc alloys (JohnWiley & Sons, Inc., Hoboken, NJ, USA, 2011), pp. 285–307

L.M. Muresan, in Handbook of nanoelectrochemistry. Electrodeposited Zn-nanoparticles composite coatings for corrosion protection of steel (Springer International Publishing, Cham, Switzerland, 2016), pp. 333–353

P.A.I. Popoola, N. Malatji, O.S. Fayomi, in Applied Studies of Coastal and Marine Environments. Fabrication and properties of zinc composite coatings for mitigation of corrosion in coastal and marine zone, vol 32 (InTech, London, UK, 2016), pp. 137–144

B.M. Praveen, T.V. Venkatesha, Generation and corrosion behavior of Zn-nano sized carbon black composite coating. Int. J. Electrochem. Sci. 4, 258–266 (2009)

M.K. Punith Kumar, M.P. Singh, C. Srivastava, Electrochemical behavior of Zn–graphene composite coatings. RSC Adv. 5, 25603–25608 (2015)

M.Y. Rekha, C. Srivastava, Microstructure and corrosion properties of zinc-graphene oxide composite coatings. Corros. Sci. 152, 234–248 (2019)

N. Malatji, A.P.I. Popoola, O.S.I. Fayomi, C.A. Loto, Multifaceted incorporation of Zn-Al2O3/Cr2O3/SiO2 nanocomposite coatings: anti-corrosion, tribological, and thermal stability. Int. J. Adv. Manuf. Technol. 82, 1335–1341 (2016)

K. Vathsala, T.V. Venkatesha, Zn–ZrO2 nanocomposite coatings: electrodeposition and evaluation of corrosion resistance. Appl. Surf. Sci. 257, 8929–8936 (2011)

G. Roventi, Electrodeposition of Zn-Ni-ZrO2, Zn-Ni-Al2O3 and Zn-Ni-SiC nanocomposite coatings from an alkaline bath. Int. J. Electrochem. Sci. 663–678 (2017)

F.Z. ZhuanghuaYu, J. Wang, Q. Shao, A.A. Gaber, A.M. Mersal, M.M. Ibrahim, Z.M. El-Bahy, Y. Li, M. Huang, Z. Guo, Waterborne acrylic resin co-modified by itaconic acid and γ-methacryloxypropyl triisopropoxidesilane for improved mechanical properties, thermal stability, and corrosion resistance. Prog. Org. Coat. 168, 106875 (2022)

O. Hammami, L. Dhouibi, P. Berçot, E.M. Rezrazi, E. Triki, Study of Zn-Ni alloy coatings modified by nano-SiO2 particles incorporation. Int. J. Corros. 2012, 301392 (2012)

J. Cai, V. Murugadoss, J. Jiang, X. Gao, Z. Lin, M. Huang, J. Guo, S.A. Alsareii, H. Algadi, M. Kathiresan, Waterborne polyurethane and its nanocomposites: a mini-reviewfor anti-corrosion coating, flame retardancy, and biomedicalapplications. Adv. Compos. 5(11). https://doi.org/10.1007/s42114-022-00473-8

L.M. Tavares, E.M. da Costa, J.J. de Oliveira Andrade, R. Hubler, B. Huet, effect of calcium carbonate on low carbon steel corrosion behavior in saline CO2 high pressure environments. Appl. Surf. Sci. 359, 143–152 (2015)

Z. Yan, S. Wang, J. Bi, Q. He, H. Song, I.H. El Azab, S.M. El-Bahy, A.Y. Elnaggar, M. Huang, M.H. Mahmoud, J. Wang, Strengthening waterborne acrylic resin modified with trimethylolpropane triacrylate and compositing with carbon nanotubes for enhanced anticorrosion. Adv. Compos. Hybrid Mater. 5, 2116–2130 (2022)

V.S. Aigbodion, E.T. Akinlabi, Explicit microstructural evolution and electrochemical performance of zinc eggshell particles composite coating on mild steel. Surf. Interf. 17, 100387 (2019). https://doi.org/10.1016/j.surfin.2019.100387

H. Du, X. Ren, D. Pan, Y. An, Y. Wei, X. Liu, Z. Guo, Effect of phosphating solution pH value on the formation of phosphate conversion coatings for corrosion behaviors on AZ91D. Adv. Compos. Mater. 4(2), 401–414 (2021). https://doi.org/10.1007/s42114-021-00222-3

Q. Zhu, Y. Huang, Y. Li, M. Zhou, S. Xu, X. Liu, Z. Guo, Aluminum dihydric tripolyphosphate/polypyrrole-functionalized graphene oxide waterborne epoxy composite coatings for impermeability and corrosion protection performance of metals. Adv. Compos 4(3), 780–792 (2021). https://doi.org/10.1007/s42114-021-00265-6

G. Qiao, S. Wang, X. Wang, X. Chen, X. Wang, H. Cui, Ni/Co/black phosphorus nanocomposites for Q235 carbon steel corrosion-resistant coating. Adv. Compos (2021). https://doi.org/10.1007/s42114-021-00268-3

M. Farahmandian, M. Saidi, S. Fazlinejad, Synthesis and characterization of nickel–cobalt spin coatings reinforced with carbon nanotubes: microstructural properties, microhardness, and corrosion resistance. Adv. Compos. 5(2), 1490–1507 (2021). https://doi.org/10.1007/s42114-021-00220-5

T.J. Tuaweri, Influence of process parameters on the cathode current efficiency of Zn/SiO2 electrodeposition. Int. J. Mech. Eng. Appl. 1, 93 (2013)

T.J. Tuaweri, G.D. Wilcox, Behaviour of Zn-SiO2 electrodeposition in the presence of N. Surf. Coat. Technol. 200, 5921–5930 (2006)

T. Ohgai, K. Ogushi, K. Takao, Morphology control of Zn-SiO2 composite films electrodeposited from aqueous solution containing quaternary ammonium cations. J. Phys. Conf. Ser. 417, 012006 (2013)

A.P.I. Popoola, O.S.I. Fayomi, Effect of some process variables on zinc coated low carbon steel substrates. Sci. Res. Essays 6(20), 4264–4272 (2011)

T.J. Tuaweri, E.M. Adigio, P.P. Jombo, A study of process parameters for zinc electrodeposition from a sulphate bath. Int. J. Eng. Sci. 2, 2319–6734 (2013)

O.S. Fayomi, V.R. Tau, A.P.I. Popoola, B.M. Durodola, O. Ajayi, C.A. Loto, O. Inegbenebor, A Influence of plating parameter and surface morphology on mild steel. J. Mater. Environ. Sci 2(3), 271–280 (2011)

M. Kul, K.O. Oskay, F. Erden, E. Akça, R. Katırcı, E. Köksal, Evindar Akıncı Effect of Process Parameters on the Electrodeposition of Zinc on 1010 Steel: Central Composite Design Optimization. Int. J. Electrochem. Sci. 15, 9779–9795 (2020). https://doi.org/10.20964/2020.10.19

S. Tongwanichniyom, T. Pattamapitoon, Napimporn Sangvichien and Somkiat Phornphisutthimas Production of calcium oxide from waste oyster shells for a value-added application of antibacterial, Eco. Env. Cons. 27(2), 539–547 (2021)

S.M. Adams, E. Atikpo, V.S. Aigbodion, CaCO3 derived from eggshell waste for improving the hardness values and wear behavior of composite coating on mild steel via co-deposition. Int. J. Adv. Manuf. Technol. 119, 5483–5496 (2022)

H.M. Muzamma, H. Ma, H.M. Liang, Z. Gao, J. Cao, C. Wang, et al., Fabrication of cerium myristate coating for a mechanochemically robust modifier-free superwettability system to enhance the corrosion resistance on 316L steel by one-step electrodeposition. Surf. Coat. Technol. 125970 (2020). https://doi.org/10.1016/j.surfcoat.2020.1259

B. Stalin, P. Ramesh Kumar, M. Ravichandran, M. Siva Kumar, M. Meignanamoorthy, Optimization of wear parameters using Taguchi grey relational analysis and ANN-TLBO algorithm for Silicon Nitride filled AA6063 matrix composites. Mater. Res. Expr. (2019). https://doi.org/10.1088/2053-1591/ab3d90

S. Arora, B. Sharma, C. Srivastava, ZnCo-carbon nanotube composite coating with enhanced corrosion resistance behavior. Surf. Coat. Technol. 126083 (2020). https://doi.org/10.1016/j.surfcoat.2020.126083

Y.P. Deepthi, M. Krishna, Optimization of electroless copper coating parameters on graphite particles using Taguchi And grey relational analysis. Materials Today: Proceedings 5(5), 12077–12082 (2018). https://doi.org/10.1016/j.matpr.2018.02.183

S. Anwar, F. Khan, Y. Zhang, S. Caines, Zn composite corrosion resistance coatings: what works and what does not work? J. Loss Prev. Process Ind. 69 (2021)

J.H. Liu, J.X. Yan, Z.L. Pei, J. Gong, C. Sun, Effects of Mo content on the grain size, hardness and anti–wear performance of electrodeposited nanocrystalline and amorphous Ni–Mo alloys. Surf. Coat. Technol. 126476 (2020). https://doi.org/10.1016/j.surfcoat.2020.1264

A. Premkumar, A. Elayaperumal, S. Arulvel, M.S. Jagatheeshwaran, Partial dissolution of precipitated-calcium carbonate (P-CaCO3) in electroless nickel-phosphorus (Ni-P) coating and its surface characterization. Mater. Res. Expr. 6(6), 066409 (2019). https://doi.org/10.1088/2053-1591/ab0934

Acknowledgements

The authors hereby appreciate and acknowledge the Africa Centre of Excellence for Sustainable Power and Energy Development, ACE-SPED, University of Nigeria, Nsukka; the Energy materials research group, University of Nigeria, Nsukka, Nigeria; and the Faculty of Engineering and Built Environment, University of Johannesburg, Auckland Park, South Africa for their supports.

Author information

Authors and Affiliations

Contributions

They contribute 100% to the study work’s development, from experimentation to analysis.

Corresponding author

Ethics declarations

Ethics approval

Because this experiment does not involve people or animals, no ethics committee approval is required.

Consent to participate

Because this study does not include people or animals, no permission is required to participate.

Publishing permission

The writers grant their permission for the work to be published by the publisher.

Consent for publication

The authors give the publisher the consent to publish the work.

Competing interests

The authors declare no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Adams, S.M., Onyekachi, A.F. & Aigbodion, V.S. High-performance multi-response optimization of new nanocomposite coating formulation of zinc reinforced with calcium oxide nanoparticle synthesis from oyster shell via one-step electrodeposition approach. emergent mater. 6, 973–986 (2023). https://doi.org/10.1007/s42247-023-00458-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-023-00458-3