Abstract

In this paper, the pH value effect of phosphating solution on the formed phosphate conversion coatings (CCs) has been studied for the corrosion behavior of AZ91D. The electrochemical tests have been processed on the CCs fabricated under different pH values of phosphating solution. Morphological evolution and composition of the coatings, as a function of pH value, were examined by scanning electron microscope (SEM) and X-ray photoelectron spectroscopy (XRD). The width and distribution area of micro-cracks on the surfaces were measured and statistical analyzed by an image-pro-plus software. Moreover, potentiodynamic polarization test, electrochemical impedance spectroscopy analysis, and immersion test were used to evaluate the corrosion property of the phosphate CCs in 3.5% NaCl solution. The dimension of the micro-cracks decreased with the increase of the value of pH. The CCs fabricated under the pH value of 4.0 showed the best corrosion resistance and the width and distribution area of micro-crack on the CCs were the minimum (0.78 (± 0.08) μm and 1253 (± 140) μm2, respectively). The self-corrosion current of the CCs was the minimum (2.85 μA/cm2), and the radius of capacitance arc in the electrochemical impedance spectroscopy was the maximum. The corrosion rate in immersion test also was the lowest. This study shows an alternative for the metal corrosion.

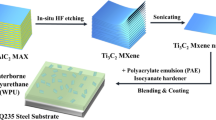

Graphical abstract

Different pH values of phosphating solution on corrosion behaviors of phosphate conversion coatings on AZ91D were investigated.

Similar content being viewed by others

References

Ishizaki T, Masuda Y, Teshima K (2013) Composite film formed on magnesium alloy AZ31 by chemical conversion from molybdate/phosphate/fluorinate aqueous solution toward corrosion protection. Surf Coat Technol 217:76–83

Yan W, Zhang Y, Sun H, Liu S, Chi Z, Chen X, Xu J (2014) Polyimide nanocomposites with boron nitride-coated multi-walled carbon nanotubes for enhanced thermal conductivity and electrical insulation. J Mater Chem 2(48):20958–20965

Pan D, Zhang X, Yang G, Sahng Y, Su F, Hu Q, Patil RR, Liu C, Guo Z (2020) Thermally conductive anticorrosive epoxy nanocomposites with tannic acid-modified boron nitride nanosheets. Ind Eng Chem Res. https://doi.org/10.1021/acs.iecr.0c04510

Das TK, Ghosh P, Das NC (2019) Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review. Adv Compos Hybrid Mater 2:214–233

Hornberger H, Virtanen S, Boccaccini AR (2012) Biomedical coatings on magnesium alloys—a review. Acta Biomater 8(7):2442–2455

Jayaraj J, Amruth Raj S, Srinivasan A, Ananthakumar S, Pillai UTS, Dhaipule NGK, Mudali UK (2016) Composite magnesium phosphate coatings for improved corrosion resistance of magnesium AZ31 alloy. Corros Sci 113:104–115

Liu B-s, Kuang Y-f, Chai Y-s, Fang D-q, Zhang M-g, Wei Y-h (2016) Degradation research of protective coating on AZ91D Mg alloy components via simulated contamination. J Magnes Alloy 4(3):220–229

Cui X-j, Liu C-h, Yang R-s, Fu Q-s, Lin X-z, Gong M (2013) Duplex-layered manganese phosphate conversion coating on AZ31 Mg alloy and its initial formation mechanism. Corros Sci 76:474–485

Song Y, Shan D, Chen R, Zhang F, Han E-H (2009) Formation mechanism of phosphate conversion film on Mg–8.8Li alloy. Corros Sci 51(1):62–69

Zhou W, Shan D, Han E-H, Ke W (2008) Structure and formation mechanism of phosphate conversion coating on die-cast AZ91D magnesium alloy. Corros Sci 50(2):329–337

Van Phuong N, Gupta M, Moon S (2017) Enhanced corrosion performance of magnesium phosphate conversion coating on AZ31 magnesium alloy. T Nonferr Metal Soc 27(5):1087–1095

Mosiałek M, Mordarski G, Nowak P, Simka W, Nawrat G, Hanke M, Socha RP, Michalska J (2011) Phosphate–permanganate conversion coatings on the AZ81 magnesium alloy: SEM, EIS and XPS studies. Surf Coat Technol 206(1):51–62

Zucchi F, Frignani A, Grassi V, Trabanelli G, Monticelli C (2007) Stannate and permanganate conversion coatings on AZ31 magnesium alloy. Corros Sci 49(12):4542–4552

Yang KH, Ger MD, Hwu WH, Sung Y, Liu YC (2007) Study of vanadium-based chemical conversion coating on the corrosion resistance of magnesium alloy. Mater Chem Phys 101(2–3):480–485

Wang C, Zhu S, Jiang F, Wang F (2009) Cerium conversion coatings for AZ91D magnesium alloy in ethanol solution and its corrosion resistance. Corros Sci 51(12):2916–2923

Liu Q, Liu Y, Lei T, Tan Y, Wu H, Li J (2015) Preparation and characterization of nanostructured titanate bioceramic coating by anodization–hydrothermal method. Appl Surf Sci 328:279–286

Fan X, Yin X (2018) Progress in research and development on matrix modification of continuous fiber-reinforced silicon carbide matrix composites. Adv Compos Hybrid Mater 1:685–695

Van Phuong N, Moon S, Chang D, Lee KH (2013) Effect of microstructure on the zinc phosphate conversion coatings on magnesium alloy AZ91. Appl Surf Sci 264:70–78

Chen X-B, Zhou X, Abbott TB, Easton MA, Birbilis N (2013) Double-layered manganese phosphate conversion coating on magnesium alloy AZ91D: Insights into coating formation, growth and corrosion resistance. Surf Coat Technol 217:147–155

Pan D, Ge S, Tian J, Shao Q, Guo L, Liu H, Wu S, Ding T, Guo Z (2019) Research progress in the field of adsorption and catalytic degradation of sewage by hydrotalcite-derived materials. Chem Rec 20:355–369

Chen XB, Birbilis N, Abbott TB (2012) Effect of [Ca2+] and [] levels on the formation of calcium phosphate conversion coatings on die-cast magnesium alloy AZ91D. Corros Sci 55:226–232

Amini R, Sarabi AA (2011) The corrosion properties of phosphate coating on AZ31 magnesium alloy: the effect of sodium dodecyl sulfate (SDS) as an eco-friendly accelerating agent. Appl Surf Sci 257(16):7134–7139

Chen XB, Birbilis N, Abbott TB (2011) A simple route towards a hydroxyapatite–Mg(OH)2 conversion coating for magnesium. Corros Sci 53(6):2263–2268

Han EH, Zhou WQ, Shan DY, Ke W (2003) Corrosion and protection of magnesium alloy AZ31D by a new conversion coating. Mater Sci Forum 419:879–882

Zhou WQ, Tang W, Zhao Q, Wu SW, In HEH (2011) Influence of additive on structure and corrosion resistance of manganese phosphate film on AZ91 magnesium alloy. Mater Sci Forum 686:176–180

Giri A, Hopkins PE (2019) A review of experimental and computational advances in thermal boundary conductance and nanoscale thermal transport across solid interfaces. Adv Funct Mater 30(8):1903857

Guo SQ, Hou LF, Guo CL, Wei YH (2017) Characteristics and corrosion behavior of nickel-phosphorus coatings deposited by a simplified bath. Mater Corros 68(4):468–475

Zou Z, Li N, Li D, Liu H, Mu S (2011) A vanadium-based conversion coating as chromate replacement for electrogalvanized steel substrates. J Alloy Compound 509(2):503–507

Wu Q-H, Thissen A, Jaegermann W, Liu M (2004) Photoelectron spectroscopy study of oxygen vacancy on vanadium oxides surface. Appl Surf Sci 236(1–4):473–478

Yin S, Ren X, Lian P, Zhu Y, Mei Y (2020) Synergistic effects of black phosphorus/boron nitride nanosheets on enhancing the flame-retardant properties of waterborne polyurethane and its flame-retardant mechanism. Polymers (Basel) 12(7)

Yin J, Yu J, Li X, Li J, Zhou J, Zhang Z, Guo W (2015) Large single-crystal hexagonal boron nitride monolayer domains with controlled morphology and straight merging boundaries. Small 11(35):4497–4502

Lin CS, Fang SK (2005) Formation of cerium conversion coatings on AZ31 magnesium alloys. J Electrochem Soc 152(2):B54

Pan D, Su F, Liu H, Ma Y, Das R, Hu Q, Liu C, Guo Z (2020) The properties and preparation methods of different boron nitride nanostructures and applications of related nanocomposites. Chem Rec 20:1–25

Zhang M, Chen S, Dong M, Guo Z (2018) Slippery liquid-infused porous surface fabricated on aluminum maintains stable corrosion resistance at elevated temperatures. Eng Sci 3:67–76

Song Y, Shan D, Chen R, Han E-H (2009) Corrosion characterization of Mg–8Li alloy in NaCl solution. Corros Sci 51(5):1087–1094

Nautiyal A, Qiao M, Ren T, Huang T-S, Zhang X, Cook J, Bozack MJ, Farag R (2018) High-performance engineered conducting polymer film towards antimicrobial/anticorrosion applications. Eng Sci 4:70–78

Kirkland NT, Williams G, Birbilis N (2012) Observations of the galvanostatic dissolution of pure magnesium. Corros Sci 65:5–9

Ardelean H, Frateur I, Marcus P (2008) Corrosion protection of magnesium alloys by cerium, zirconium and niobium-based conversion coatings. Corros Sci 50(7):1907–1918

Galicia G, Pébère N, Tribollet B, Vivier V (2009) Local and global electrochemical impedances applied to the corrosion behaviour of an AZ91 magnesium alloy. Corros Sci 51(8):1789–1794

Jian S-Y, Chu Y-R, Lin C-S (2015) Permanganate conversion coating on AZ31 magnesium alloys with enhanced corrosion resistance. Corros Sci 93:301–309

Niu LY, Jiang ZH, Li GY, Gu CD, Lian JS (2006) A study and application of zinc phosphate coating on AZ91D magnesium alloy. Surf CoatTechnol 200(9):3021–3026

Li W, Song Z, Qian J, Tan Z, Chu H, Wu X, Nie W (2018) Largely enhanced dielectric and thermal conductive properties of novel ternary composites with small amount of nanofillers. Compos Sci Technol 163:71–80

Jiang X, Guo R, Jiang S (2015) Microstructure and corrosion resistance of Ce–V conversion coating on AZ31 magnesium alloy. Appl Surf Sci 341:166–174

Hong S, Lee C-S, Lee M-H, Lee Y, Ma KY, Kim G, Yoon SI, Ihm K, Kim K-J, Shin TJ, Kim SW, Jeon E-c, Jeon H, Kim J-Y, Lee H-I, Lee Z, Antidormi A, Roche S, Chhowalla M, Shin H-J, Shin HS (2020) Ultralow-dielectric-constant amorphous boron nitride. Nature 582(7813):511–514

Hamdy AS, Doench I, Möhwald H (2011) Smart self-healing anti-corrosion vanadia coating for magnesium alloys. Prog Organ Coat 72(3):387–393

Funding

This research was funded by the Key Scientific Research Project in Shanxi Province (Grant Nos. 20181101014, MC2016-06, 201603D111004, and 201805D121003), the Natural Science Foundation of Shanxi Province (201801D121090), and the College Science and Technology Innovation Project of Shanxi Province (2017115).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Du, H., Ren, X., Pan, D. et al. Effect of phosphating solution pH value on the formation of phosphate conversion coatings for corrosion behaviors on AZ91D. Adv Compos Hybrid Mater 4, 401–414 (2021). https://doi.org/10.1007/s42114-021-00222-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00222-3