Abstract

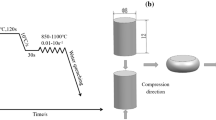

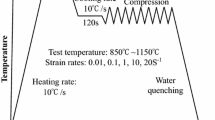

In order to determine the safe region of 42CrMo4 steel during hot working and obtain excellent workability, the hot deformation behavior at the temperatures of 850–1150 °C and the strain rates of 0.01–10 s−1 was investigated through single-pass compression test of thermo-simulation. Through observing and analyzing the true stress–strain curves, the conclusion may be drawn that the flow stress value increases with the decrease in deformation temperature and the increase in strain rate. Raising temperature and reducing strain rate are conductive to dynamic recrystallization (DRX) nucleating and growing, but adiabatic heating caused by higher strain rate can also promote it. Since the Zener–Hollomon (Z) value and dynamic recrystallized grain size (DDRX) have completely opposite trends with deformation condition parameters, the expression of Z value and DDRX can be determined as: \(D_{{{\text{DRX}}}} = 15,567.645Z^{ - 0.2174}\). The processing map and instability map constructed at a strain of 0.9 show that the suitable window for hot working with a true strain of 0.9 is in the temperature range of 970–1150 °C and strain rate range of 0.01–0.25 s−1, as well as at the temperature of 1150 °C and strain rate range of 0.25–10 s−1. The instability phenomenon appears in the process interval of 850–1096 °C and 0.22–10 s−1.

Similar content being viewed by others

References

P. Stark, U. Fritsching, M. Hunkel, D. Hansmann, Materialwissenschaft Und Werkstofftechnik 43 (2012) 56–62.

R. Pandiyarajan, K. Arumugam, M.P. Prabakaran, K.V. Kumar, Materialtoday Proceed. 37 (2021) 1957–1962.

H.J. McQueen, C.A.C. Imbert, J. Alloy. Compd. 378 (2004) 35–43.

R. Kaspar, J.S. Distl, O. Pawelski, Steel Res. 59 (1988) 421–425.

C. Wu, S. Han, Acta Metall. (Sin. Engl.) 31 (2018) 963–974.

S.K. Rajput, G.P. Chaudhari, S.K. Nath, J. Mater. Process. Technol. 237 (2016) 113–125.

Y.C. Lin, G. Liu, Comput. Mater. Sci. 48 (2010) 54–58.

M.S. Chen, Y.C. Lin, X.S. Ma, Mater. Sci. Eng. A 556 (2012) 260–266.

Z.W. Zhu, Y.S. Lu, Q.J. Xie, D.Y. Li, N. Gao, Mater. Des. 119 (2017) 171–179.

F.C. Qin, H.P. Qi, C.Y. Liu, H.Q. Qi, Z.B. Meng, Adv. Mater. Sci. Eng. 2021 (2021) 6638505.

H.C. Ji, H.L. Duan, Y.G. Li, W.D. Li, X.M. Huang, W.C. Pei, Y.H. Lu, J. Mater. Res. Technol. 9 (2020) 7210–7224.

A. Belyakov, H. Miura, T. Sakai, Mater. Sci. Eng. A 255 (1998) 139–147.

E. Brünger, X. Wang, G. Gottstein, Scripta Mater. 38 (1998) 1843–1849.

B. Derby, M.F. Ashby, Scripta Metall. 21 (1987) 879–884.

S.L. Wang, M.X. Zhang, H.C. Wu, B. Yang, Mater. Charact. 118 (2016) 92–101.

G.Z. Quan, G.S. Li, T. Chen, Y.X. Wang, Y.W. Zhang, J. Zhou, Mater. Sci. Eng. A 528 (2011) 4643–4651.

C.M. Li, L. Huang, M.J. Zhao, X.T. Zhang, J.J. Li, P.C. Li, Mater. Sci. Eng. A 797 (2020) 139925.

H. Jiang, J.X. Dong, M.C. Zhang, Z.H. Yao, J. Alloy. Compd. 735 (2018) 1520–1535.

Y.G. Yang, W.Z. Mu, X.Q. Li, H.T. Jiang, M. Wang, Z.L. Mi, X.P. Mao, J. Iron Steel Res. Int. 29 (2022) 316–326.

S. Mandal, M. Jayalakshmi, A.K. Bhaduri, V. Subramanya Sarma, Metall. Mater. Trans. A 45 (2014) 5645–5656.

H. Jiang, J.X. Dong, M.C. Zhang, Z.H. Yao, Metall. Mater. Trans. A 47 (2016) 5071–5087.

J.J. Jonas, C.M. Sellars, W.J.M.G. Tegart, Metall. Rev. 14 (1969) 1–24.

W.M. Xiong, R.B. Song, P. Yu, Z.J. Liu, S. Qin, Y.C. Zhang, S.Y. Quan, W.F. Huo, Z.Y. Zhao, S.R. Su, C. Wei, Steel Res. Int. 92 (2021) 2000225.

C. Zener, J.H. Hollomon, J. Appl. Phys. 15 (1944) 22–32.

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, D.R. Barker, Metall. Trans. A 15 (1984) 1883–1892.

S.V.S. Narayana Murty, B. Nageswara Rao, J. Mater. Sci. Letter. 17 (1998) 1203–1205.

Y.P. Wu, X.M. Zhang, Y.L. Deng, C.P. Tang, L. Yang, Y.Y. Zhong, Trans. Nonferrous Metal. Soc. China 25 (2015) 1831–1839.

W.L. Cheng, Y. Bai, S.C. Ma, L.F. Wang, H.X. Wang, H. Yu, J. Mater. Sci. Technol. 35 (2019) 1198–1209.

Y.H. Guo, Y.D. Xuanyuan, X. Ly, S. Yang, Materials 13 (2020) 312.

S. Ramanathan, R. Karthikeyan, M. Gupta, J. Mater. Process. Technol. 183 (2007) 104–110.

A. Chiba, S.H. Lee, H. Matsumoto, M. Nakamura, Mater. Sci. Eng. A 513–514 (2009) 286–293.

A. Hor, F. Morel, J. Lou Lebrun, G. Germain, Int. J. Mech. Sci. 67 (2013) 108–122.

C.M. Li, Y. Liu, Y.B. Tan, F. Zhao, Metals 8 (2018) 846.

Acknowledgements

This study was funded by the National High-tech R&D Program (863 Program) (2015AA03A501) and the Fundamental Research Funds for the Central Universities (N2107013).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qi, M., Wu, Hy., Dong, Y. et al. On hot deformation behavior and workability characteristic of 42CrMo4 steel based on microstructure and processing map. J. Iron Steel Res. Int. 30, 537–547 (2023). https://doi.org/10.1007/s42243-022-00857-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00857-6