Abstract

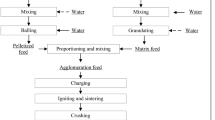

Effect of distribution of iron concentrates between pelletized and matrix feed on the preparation of blast furnace burdens from two different kinds of fine iron concentrates (magnetite and hematite) by composite agglomeration process (CAP) was explored. It was found that when the mass ratio of iron concentrate A (magnetite) to iron concentrate B (hematite) in the mixed feed was constant, the proportion of iron concentrate A in the pelletized and matrix feed significantly affected the quality of CAP products. Particularly, as the proportion of iron concentrate A in the pelletized feed increased from 0 to 100%, the yield decreased from 82.11% to 79.19% and the tumbler index decreased from 71.33% to 68.27%. The mineralization characterization results indicated that when 100% iron concentrate A was used as the pelletized feed, the crystallization styles of the outer layer and the inner layer of the pellet were different, and a lot of pores exist around hematite and magnetite phases in the pelletized part, with the weak connection of pelletized and matrix part, resulting in poor strength of agglomeration product.

Similar content being viewed by others

References

National Bureau of Statistics of China, National Pig Iron Output, http://data.stats.gov.cn/easyquery.htm?cn=C01&zb=A0E0H&sj=2018 (accessed: 2019-10-12).

M. Yellishetty, P.G. Ranjith, A. Tharumarajah, Resour. Conserv. Recycl. 54 (2010) 1084–1094.

S.L. Wu, Z.G. Que, K.L. Li, J. Iron Steel Res. Int. 25 (2018) 1017–1025.

X. Chen, J. Wang, X. Fan, M. Gan, Y. Zhou, W. Lv, Q. Chen, Z. Yu, in: T. Jiang, J.Y. Hwang, M.E. Schlesinger, O. Yucel, R. Padilla, P.J. Mackey, G. Zhou (Eds.), 5th International Symposium on High-Temperature Metallurgical Processing, John Wiley & Sons Inc., USA, 2014, pp. 401–408.

H. Han, L. Lu, Miner. Process. Extr. Metall. Rev. 39 (2018) 217-230.

H.M. Long, Q. Shi, H.L. Zhang, R.F. Wei, T.J. Chun, J.X. Li, J. Iron Steel Res. Int. 25 (2018) 357–365.

E.A. Mousa, D. Senk, A. Babich, H.W. Gudenau, Ironmak. Steelmak. 37 (2010) 219–228.

E.A. Mousa, A. Babich, D. Senk, Steel Res. Int. 84 (2013) 1085–1097.

D. Zhu, Z. Guo, J. Pan, F. Zhang, Ironmak. Steelmak. 43 (2016) 721–729.

L.H. Hsieh, ISIJ Int. 57 (2017) 1937–1946.

S.Z. He, H.L. Feng, X.J. Gan, M. Gan, J. Iron Steel Res. 28 (2016) No. 9, 10–16.

S.W. Kim, J.W. Jeon, I.K. Suh, S.M. Jung, Ironmak. Steelmak. 43 (2016) 500–507.

F.Q. Gu, Y.B. Zhang, G.H. Li, Q. Zhong, J. Luo, Z.J. Su, M.J. Rao, Z.W. Peng, T. Jiang, Ironmak. Steelmak. (2019). https://doi.org/10.1080/03019233.2019.1641681.

T. Jiang, G.H. Li, H.T. Wang, K.C. Zhang, Y.B. Zhang, Ironmak. Steelmak. 37 (2010) 1–7.

Y. Zhang, T. Jiang, G. Li, X. Fan, in: XXV Int. Miner. Process. Congress (IMPC), Australas. Inst. Min. Metall. AU, 2010, pp. 223–229.

G. Li, C. Liu, Z. Yu, M. Rao, Q. Zhong, Y. Zhang, T. Jiang, Energies 11 (2018) 2382.

Y.B. Zhang, B.B. Liu, L. Xiong, G.H. Li, T. Jiang, Ironmak. Steelmak. 44 (2017) 532–543.

G.H. Li, J.H. Zeng, T. Jiang, Q. Li, Y.B. Yang, R.J. Wang, H.L. Wu, J. Iron Steel Res. Int. 16 (2009) No. S2-1, 149–153.

T. Jiang, Z. Yu, Z. Peng, M. Rao, Y. Zhang, G. Li, ISIJ Int. 55 (2015) 1599–1607.

Y.B. Zhang, M.H. Du, Z.J. Su, G.H. Li, T. Jiang, Ironmak. Steelmak. 45 (2018) 566–575.

X. Lin, Z.W. Peng, F.Q. Gu, L. Ye, L.C. Wang, M.J. Rao, Y.B. Zhang, G.H. Li, T. Jiang, Powder Technol. 340 (2018) 131–138.

T. Jiang, Principle and technology of agglomeration of iron ores, Central South University Press, Changsha, China, 2016.

J. Pal, S. Ghorai, M.C. Goswami, S. Prakash, T. Venugopalan, ISIJ Int. 54 (2014) 620–627.

X. Ding, X.M. Guo, Metall. Mater. Trans. B 45 (2014) 1221–1231.

X. Ding, X.M. Guo, C.Y. Ma, K. Tang, Y.D. Zhao, Metall. Mater. Trans. B 46 (2015) 1146–1153.

Acknowledgements

This work was partially supported by the National Natural Science Foundation of China under Grant U1960114, 51774337, and U1660206, the Open Sharing Fund for the Large-scale Instruments and Equipments of Central South University under Grant CSUZC201905, and the Fundamental Research Funds for the Central Universities of Central South University under Grant 2018zzts220.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Gu, Fq., Zhang, Yb., Li, Gh. et al. Preparation of blast furnace burdens by composite agglomeration process: effect of distribution of magnetite and hematite concentrates in pelletized and matrix feed. J. Iron Steel Res. Int. 27, 1363–1371 (2020). https://doi.org/10.1007/s42243-020-00376-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00376-2