Abstract

Significant advancements in various research and technological fields have contributed to remarkable findings on the physiological dynamics of the human body. To more closely mimic the complex physiological environment, research has moved from two-dimensional (2D) culture systems to more sophisticated three-dimensional (3D) dynamic cultures. Unlike bioreactors or microfluidic-based culture models, cells are typically seeded on polymeric substrates or incorporated into 3D constructs which are mechanically stimulated to investigate cell response to mechanical stresses, such as tensile or compressive. This review focuses on the working principles of mechanical stimulation devices currently available on the market or custom-built by research groups or protected by patents and highlights the main features still open to improvement. These are the features which could be focused on to perform, in the future, more reliable and accurate mechanobiology studies.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Contextualization

The adult human body is composed of approximately 37 trillion cells, all synchronized to maintain equilibrium [1]. Cells reside in a complex and dynamic microenvironment containing biological, chemical, physical, and mechanical cues which often regulate cell proliferation, migration, differentiation, and function, and ultimately, may be responsible for the development of disease [2]. To study and understand how cells respond to mechanical stimuli or how host cells will behave upon the implantation of biomaterials, researchers use mechanical stimulation devices. These devices subject biomaterials to a particular mechanical stress with the aim of stimulating cells through deformation of the biomaterials. Devices which are currently commercially available offer limited customization and restricted force measurement capabilities [3, 4]. As a consequence, a wide variety of apparatuses, with varying levels of sophistication, design, functionality, and precision, have been custom-built by research groups to meet particular needs, while others are protected by patents. This review focuses on the working principles, functionality, and main operational features of a number of mechanical stimulation devices developed over the past years, and highlights the main features still open to improvement.

The cellular microenvironment

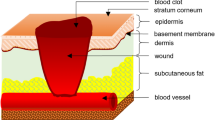

All cells are in permanent interaction with the surrounding microenvironment, including the extracellular matrix (ECM) and neighbouring cells. That interaction is based on a combination of multiple cues, including biological and physical cues able to influence cell behaviour [5, 6]. Cells are constantly and cyclically subjected to external forces whose type and magnitude are highly variable and dependent on location [7]. These forces are crucial from the beginning of cell life: throughout the development of embryos, and in everyday activities, in which cells experience shear stress during breathing and blood flow, or tensile and compressive stresses from skeletal muscle contraction, joint loading, and tendon/ligament stretching [8,9,10,11]. Their ability to sense externally imposed forces and mechanical properties of the surrounding ECM is denominated “cell mechanosensing” [12]. These signals are later converted into changes in intracellular biochemistry and gene expression, a process often referred to as “mechanotransduction” [13]. Mechanical stimuli include not only externally imposed forces (namely tensile, compressive, and shear forces), but also intrinsic cellular tensions generated by active cell contraction [7]. In fact, besides the intracellular response to dynamic modifications of the ECM, cells are also able to influence the environment, leading to a reciprocal interaction [7, 11]. Both outside-in and inside-out pathways exist in mechanotransduction processes, and are able to trigger signalling cascades [14, 15]. In this sense, the environment plays an important role in many cellular processes, such as cellular adhesion, migration, proliferation, differentiation, and apoptosis [15]. Given the importance of mechanical interactions in cellular behaviour, mechanobiology has emerged as a novel interdisciplinary field combining biology, mechanics, and engineering, which aims to understand how cells sense and behave in response to mechanical stimuli [7, 11, 16, 17]. Over the past few decades, researchers have developed systems to control the cellular microenvironment and, while some focus on improving cell culture conditions, others aim to study the effects of a particular mechanical stimulus on cells by using unique cells or biomaterial-based constructs.

Moving from 2D to 3D models

Biological systems are organized into several levels of structural organization, becoming more complex as the length scale increases. Beginning at the micrometre scale, cells assemble to form tissues, which are organized into organs, which together form the organism, the highest level of organization, on the metre scale. Biological model systems range from simplified two-dimensional (2D) cell cultures to more complex three-dimensional (3D) cell cultures, organoids, tissue explants, and model organisms, such as the mouse [2]. As the complexity rises, the associated cost and physiological relevance increase, while experimental accessibility decreases [2].

The 2D and 3D cell culture systems discussed below are illustrated in Fig. 1, in both static and dynamic modes. In conventional and static cell cultures, the nutrient supply is maintained by frequently changing the culture medium. Primary cells or established cell lines may be cultured as a 2D monolayer, in the case of an adherent culture, or as a cell suspension known as a “suspension culture”. Although monolayer cultures are easily manipulated, used worldwide in life-science research, and still accepted as the gold standard, cells are highly anisotropic. This is why it has been experimentally observed that even within a particular cell line, cellular responses may differ for an identical mechanical input [18]. Moreover, it has been reported that cells may lose some differentiated characteristics [19] and that conventional 2D culture models, whether in Petri dishes or culture flasks, do not replicate the dynamic in vivo 3D microenvironment [2]. As a consequence, over the past decades, researchers have focused on more complex cell culture models which include cell seeding on prefabricated scaffolds or incorporate cells into 3D scaffolds (usually hydrogels made of synthetic polymers). These materials allow cellular spatial organization into functional cell-based constructs. In order to keep up with continuously more complex and demanding research, bioreactor systems were developed for numerous applications, for example, in the context of cell biology research and regenerative medicine therapies. While the absence of media mixing or circulation in a static aqueous environment leads to limited diffusion of fluids or gases and contributes to cell-waste accumulation and nutrition depletion [5, 20], 3D models with continuously mixed media in a dynamic culture allow homogeneous media and cell dispersion, better reproducing the in vivo spatial and biomechanical complexity [19]. Three-dimensional culture systems, particularly bioreactors, are not the scope of this review, but extensive works on this topic may be easily found in the literature [2, 20,21,22,23]. Briefly, fluid-flow-induced bioreactors are designed to enhance nutrient supply to cell cultures and replicate tissue-specific conditions [24]. They are often grouped into fed-batch [25], spinner-flask [26], rotating [24, 27], and perfusion bioreactors [21, 28]. Despite the continuous media agitation in bioreactors, an efficient supply of gases and nutrients is not always assured and sample handling and maintenance of sterility are challenging. Because of the constraints related to bioreactor size, cost, and time consumption when running parallel multiple experiments, the reactor volumes in microfluidic systems can be reduced down to picolitres, while assuring a laminal-flow pattern [29, 30]. In addition to the decrease in reagent consumption, the culture environment is particularly controlled, because cell shape, dimensionality, and density are tightly regulated in 10–100 μm channels [31, 32]. In the category of micro-engineered devices, lab-on-a-chip-based devices are commonly used for point-of-care diagnostics and are characterized by easy handling and high performance of body fluid analyses [33]. Organ-on-a-chip devices can be used for culturing cells, spheroids, organoids, and tissue biopsies and, among their final applications, can be used for drug screening and development, disease modelling, and the study of human physiology, due to their capability of closely replicating the dynamic microenvironment of living organs [30, 34]. However, the resultant fluid-flow-induced shear stresses may induce cell damage, and current devices lack automation and well-defined protocols [34]. In contrast to bioreactors, microfluidic-based culture models (or bioreactors on a chip) offer optimized culture conditions and precise control over the chemical and physical cellular environment through the integration of sensors [29].

Cell culture models may be in a static or dynamic mode. In 2D monolayer cultures, adherent cells are in contact with the culture vessel, neighbouring cells, and the culture medium. In non-adherent plates, 3D spheroids are grown in suspension, either without or with medium agitation (fed-batch bioreactor). In spinner-flask bioreactors, cell dispersion or cell-based constructs attached to a needle are in contact with a homogeneous medium due to agitation and medium perfusion. Rotating wall vessels enable cell culture mixing without an internal stirring mechanism by definition of a proper rotation speed. Perfusion bioreactors use continuous and fresh medium perfusion through cell-based constructs, provided by peristaltic pumps. Microfluidic systems are used for culturing and monitoring of both adherent and non-adherent cells. The fluid dynamics is represented by the red arrow

Two-dimensional culture models are based on a cell monolayer in which cells are forced to adapt to an artificial, flat, and rigid surface [27], and thus do not provide meaningful information regarding the real dynamics that living cells and tissues experience. Therefore, 3D culture models have greatly increased in number and sophistication, and have the capability of more closely replicating the dynamic microenvironment. They are also more experimentally tractable than model organisms. Despite the fact that bioreactors and microfluidic-based platforms are attractive devices for transporting nutrients and thus improving overall cell culture conditions [2, 35], fluid-flow-induced shear stresses cannot be measured in this setting; thus, although this shear stress is considered an important contribution to cell metabolism, it cannot be considered as a mechanical input for mechanotransduction studies.

In the context of mechanobiology, external force can be applied through direct methods such as micropipette aspiration [36,37,38], atomic-force microscopy [38,39,40,41], and substrate deformation [32, 42,43,44]. Indirect methods can also be used, in which cells are, for example, subjected to optical or magnetic fields [45,46,47]. In direct methods, a generated and controlled force is applied directly on cells, leading, in some cases, to a large global cell strain. On the other hand, indirect methods allow researchers to monitor deformation in different regions of a cell, but not to precisely control or measure the applied stress [32, 47].

Mechanical stimulation devices have been developed to study cellular response to an externally applied mechanical stimulus or to mimic physiological dynamics to perform more reliable studies. For example, one can apply compressive or tensile forces on cells in a controlled way via biomaterials, as illustrated in Fig. 2. Typically, these devices consist of a culture medium vessel, a specific space for the cell-based construct/substrate, and clamping parts to apply tensile or compressive loading in a controlled computed way [21]. Furthermore, some devices allow real-time monitoring by the use of chambers composed of light-transparent materials and multi-chamber configurations for parallel experiments [21]. Individual components, such as biomaterials, ECM, and soluble and mechanical cues, may be integrated in these systems to closely mimic the in vivo environment and study physiology and screen therapeutics.

Examples of mechanical stimulation devices used for mechanobiology studies. The commonly studied mechanical stresses are compressive and tensile stresses, either applied to cells incorporated inside 3D constructs (left) or cells seeded on a flexible substrate (right). The movement imposed on the biomaterials is represented by the red arrow

Emerging mechanical stimulation devices

Mechanical stimulation devices have gained interest due to their potential for replicating mechanical cues observed in the in vivo microenvironment, controlling mechanical and physical properties with precision, and in some cases, allowing simultaneous analysis [48, 49]. Mechanical strains in a given material obtained by applying either tensile or compressive stresses in any direction and at controlled loading features, such as strain magnitude and frequency, create a mechanical strain environment around the cultured cells. The strain profile obtained by such substrate deformation may occur in one of the three different modes illustrated in Fig. 3.

Novel and more complex devices have been developed to assure optimal cellular conditions during manipulation (e.g., application of a particular mechanical stimulus) and analyse the corresponding cellular behaviour in small-scale volumes. Some of the operational features of these mechanical stimulation devices are summarized in Table 1.

Depending on the goal of a particular study and consequently of the experimental design, cells may be seeded directly on the substrate or incorporated in functional constructs. Scaffolds or cell-based constructs are 3D structures often used to regulate the environment of cells, and in this sense, cells can be manipulated by controlling the mechanical properties of the scaffold, such as elasticity, rigidity, and strain. Natural scaffolds are made of naturally derived materials, namely collagen, fibrin, and components of decellularized tissues, whereas fully synthetic matrices are often composed of poly(dimethylsiloxane) (PDMS) and poly(L-lactide-co-glycolide) (PLGA) [27]. One of the most common materials used in mechanobiology research is PDMS, because it is non-cytotoxic, autoclavable, and flexible. Furthermore, it has high optical transparency and low auto-fluorescence, which allows cell analysis by fluorescence and optical imaging techniques [7, 50]. Hydrogels are biocompatible and biomimetic 3D structures which, once again, facilitate imaging because the cellular behaviour in their interior can be monitored. Moreover, hydrogels are typically used to apply mechanical stimuli on cells because they allow a uniform distribution of stresses throughout the structure [21].

One of the most important concerns in mechanobiology studies is to ensure aseptic conditions during experiments. Therefore, all parts of the mechanical stimulation device are assembled inside a laminal-flow biosafety cabinet and then the complete and mounted device along with its electronic components is placed in a typical culture incubator, allowing maximally sterile conditions and, when required, a long-term experiment. As already mentioned, confocal imaging is often preferable to upright microscopy techniques, mainly to overcome issues related to device size constraints. Therefore, the design of some devices considers the overall device dimensions to ensure that it fits in the microscope chamber, and the incorporation of a glass coverslip or other materials with similar optical properties to allow high-magnification imaging of the cultured or encapsulated cells, for example, for performing live imaging studies [32, 42, 51, 52]. Other developments are intended to produce high-throughput capabilities, such as by increasing the number of wells/chambers which can be loaded simultaneously [51, 53,54,55,56,57].

Commercially available cell-stimulation devices

In vitro mechanical stimulation devices have been developed to apply specific mechanical stimuli to biomaterials and, in this way, stimulate cells, for example, as they would be stimulated by external cues typically observed in physiological conditions. Some tension and compression devices are available on the market, and the most well-known companies are FLEXCELL International Corporation, TA Instruments, CellScale, IonOptix, BISS, and Strex. Some features of their commercially available products, including the type of mechanical stimulus and the maximum strain and frequency that can be applied, are summarized in Table 2. Figure 4 is a graphical representation of the maximum strain/displacement and frequency provided by the device models.

Some of the commercialized devices may be used to evaluate a variety of specimens, including cells seeded in monolayers, 3D cell-seeded constructs (e.g. hydrogels), natural tissues, or bioartificial tissue samples. Stretching devices commercialized by FLEXCELL use regulated vacuum pressure and positive air pressure to deform flexible-bottomed culture plates. Depending on the type of culture plate, equibiaxial or uniaxial tension may be applied. Flexcell FX-2000 and FX-4000 created by FLEXCELL International Corporation, and recently upgraded to FX-6000 T, were used to promote tensile loading [58,59,60,61].

The Flexcell FX-2000 cell-strain unit is composed of a circular silicone rubber membrane at the bottom of each well of the culture plate, in which biaxial strain is regulated by applying vacuum, promoting a multi-radial uniform stretch. One group exposed flexor tendon cells to biaxial tensile strain of 0.0075% at 1 Hz and analysed the formation and organization of the actin stress-fibre network and cell–cell adherent junctions under loading [58]. In another study, the same Flexcell unit was used to apply an equibiaxial cyclic strain of 3% at 0.25 Hz (2 s on, 2 s off) to human mesenchymal stem cells (hMSCs) for 16 days, which decreased proliferation and stimulated matrix mineralization over unstrained cells (Figs. 5a–5c) [59]. Human embryonic stem cells (hESCs) were cultured on BioFlex culture plates coated with Matrigel and exposed to a biaxial 10% membrane strain for 10 cycles/min using the FX-4000 device [61]. The mechanical strain inhibited hESC differentiation, but self-renewal was promoted compared to an unstrained control [61]. Porcine valve interstitial cells and bone-marrow-derived hMSCs (bm-hMSCs) were cultured on BioFlex culture plates and exposed to a biaxial (radial and circumferential) tensile strain of 7%, 10%, 14%, and 20% respectively at 0.6 Hz for 4 days [62]. The strain magnitudes, which were homogenously distributed throughout the membrane, had an impact on collagen production [62]. More recently, the FX-6000 T Tension System was used on vascular smooth muscle cells derived from human-induced pluripotent stem cells (hiPSCs-VSMCs) [63]. Uniaxial cyclic tensile strain of 2.5% at 2.75 Hz applied for a period of 48 h enhanced the expression of VSMC and ECM markers and also the formation of phalloidin, mostly in a perpendicular direction to the tensile loading direction [63]. A Flexcell FX-4000 strain unit was used by Sumanasinghe et al. to apply an uniaxial cyclic tensile strain to bm-hMSCs seeded on linear 3D type I collagen matrices [60]. Cyclic tensile strains of 10% and 12% at 1 Hz induced osteogenic differentiation compared to unstrained controls after 1 and 2 weeks, without osteogenic supplements [60].

Cellular results of studies which made use of commercially available devices. Von Kossa staining of cell layers after 16 days in culture showed that compared to the unstrained condition (a), hMSCs that underwent mechanical strain imposed by Flexcell FX-2000 had greater matrix mineralization (b), as corroborated by measurement of matrix-deposited calcium (c) (reproduced from [59], Copyright 2003, with permission from Elsevier). d Sarcomere length analysis by actin (ACTN, red) and nuclei (DAPI, cyan) staining of samples: non-conditioned (NC), electrically conditioned (E), mechanically conditioned by an IonOptix C-stretch (M), and electromechanically conditioned (EM) (scale bar: 25 mm). Results for different conditioning procedures (1 Hz 3 d, 2 Hz 3 d, and 1 Hz 7 d) are shown in a boxplot (e) (reproduced from [64], Copyright 2017, with permission from Elsevier). Empty and non-loaded scaffolds were loaded by a TA Instruments BioDynamic device coupled with an Electroforce testing machine, then cut into cross sections and stained with Sirius red (for collagen) (f) and alizarin red (for calcium) (g). Absorbance of MTS (for cell-viability assessment), alizarin red, and Sirius red per loaded scaffold at day 20 was normalized to a paired non-loaded scaffold (mean±SD) (h), and showed an increase of matrix mineralization after loading (reproduced from [66], Copyright 2009, with permission from Elsevier). i Expression of gremlin-1 (Grem1) protein (green) in mouse primary chondrocytes increased 24 h after tensile stress loading (stress+) was applied with the Strex STB-140 system, compared to the unloading condition (stress−) (scale bar: 50 μm). j An acceleration of mouse osteoarthritis development after surgical induction was observed through safranin O staining and gremlin-1 immunofluorescence. Scale bars: 100 μm and 50 μm, respectively (reproduced from [69] authored by Chang et al. under the Creative Commons license CC BY 4.0). hMSCs: human mesenchymal stem cells

Commercialized by IonOptix, C-Pace EM is a multi-mode electromechanical stimulator which can be coupled to the C-Stretch system. This stimulator was used to apply electrical, mechanical, and combined electromechanical stimulation to human-induced pluripotent stem-cell-derived cardiomyocytes (hiPSC-CMs) cultured on fibronectin-coated PDMS [64]. A uniaxial cyclic tensile strain of 5% was applied at 1 Hz for 3 or 7 days and, with regard to electromechanical stimulation, cells were also stimulated with an electrical field of 3 V/cm and 4 ms biphasic pulse duration at the end of the mechanical stimulus hold phase to mimic the isovolumetric contraction. All three stimulus modes resulted in stress-fibre formation and sarcomeric length shortening, but upon electromechanical stimulus the transmembrane calcium current significantly decreased (Figs. 5d and 5e) [64].

A BioDynamic™ chamber mounted on an ELF3200 mechanical testing machine from the TA Instruments group was used in compressive loading studies [65, 66]. Five per cent global strain was applied by cyclic compressive loading (for 2 h on day 9 and then every 5 days up to and including day 19) to hMSCs cultured in 3D polyurethane (PU) scaffolds, and was found to promote osteogenic differentiation and mineralized matrix production [65]. MLO-A5 osteoblastic cells cultured on PU open-cell foam scaffolds were exposed to a compressive strain of 5% at 1 Hz (for 2 h per day on days 5, 10, and 15 of culture), which promoted the production of mineralized matrix (Figs. 5f–5h) [66]. Endothelial progenitor cells (EPCs) isolated from rat bone-marrow were seeded in demineralized bone matrix (DBM) scaffolds under cyclic compressive loading. Cell-based constructs were placed in a BioDynamic ELF5110 device, and after being subjected to 5% strain at 1 Hz for 4 h/day for 7 days, proliferation of EPCs increased [67].

Cell tensile loading systems from Strex are reported in the literature for diverse purposes, including the evaluation of cell adhesion and mechanotransduction studies. Meniscal root and horn cells were cultured on rat tail COL1-coated polydimethylsiloxane and subjected to 2 h and 4 h treatment with 5% and 10% uniaxial cyclic tensile strain at 0.5 Hz, using a STB-140 system. The density of both root and horn cells was reduced after mechanical treatment, whereas expression of the chondrocyte-associated genes SOX9 and COL2A1 was significantly enhanced [68]. Using the same loading system, mouse primary chondrocytes were seeded into silicon stretch chambers coated with fibronectin, and after 48 h were subjected to cyclic tensile loading (0.5 Hz, 10% elongation) for 30 min in a CO2 incubator. The excessive loading accelerated osteoarthritis development by inducing gremlin-1 (Figs. 5i and 5j) [69]. In a different study, Murali et al. seeded hMSCs onto silicone chambers coated with COL1 and subjected them to tensile loading at 1 Hz frequency and 8% strain for 6, 24, 48, and 72 h, using the ST-140 model. They suggested that when subjected to uniaxial loading, hMSCs underwent tenogenic differentiation through activation of epithelial sodium channels [70]. Takahashi et al. seeded normal human lung fibroblasts onto silicon chambers coated with COL1, and a uniaxial sinusoidal cyclic tensile loading of 30 cycles/min was applied for 10 min using the ST-140 model. The concentrations of ATP in the supernatant were significantly elevated by 20% strain, but not by 4% strain. The researchers also visualized ATP release during cell stretch in real time, using the NS-600 W model. Following a single uniaxial tensile strain of 22% for 1 s duration, the release of ATP continued and increased in intensity [71].

Besides application of tensile or compressive stresses, all models of TA Instruments presented in Table 2 include pulsatile stimulation. For example, the BioDynamic 5170 and BioDynamic 5270 test instruments permit a flow range of 17–1760 mL/min. These devices are computer-controlled, allowing a static, cyclic, or intermittent deformation in a range of frequencies, amplitudes, and waveforms. The substrates used for culture plates of commercialized mechanical stimulation devices are typically flexible and light-transparent materials that enable phase-contrast, fluorescence, or scanning confocal microscopy analysis. The design and material choices allow, in some cases, simultaneous and real-time visualization using inverted microscopes. While these are often preferred to upright microscopes because they do not limit the total height of the device, it is mandatory to ensure that the focal length is not compromised. Despite the notorious progress on the tensile and compressive loading devices available on the market, the main motivation for research groups to design and fabricate their own devices is related to these device-associated costs. The cost of these devices ranges from thousands to tens of thousands of dollars, and the total price may increase when considering maintenance and the need to purchase additional device-specific accessories (such as culture well plates) in order to maximize the number of samples that can be tested at the same time [3]. Moreover, the macroscopic dimensions of some devices limit their throughput, and it is usually difficult or impossible to adapt to particular experiments such as, for example, using other substrate materials than polymers, which restricts the utility of these devices in a research context [3, 51, 52, 72].

Custom-built cell-stimulation devices

Despite the focus on continuous innovation, mechanical stimulation systems available on the market present critical challenges. Consequently, numerous research groups have designed and developed custom-built devices to study the effects of tensile and compressive loading conditions on cellular behaviour.

Tensile loading devices

Several tensile loading devices with different designs and working principles have been developed in recent years. Table 3 lists uniaxial tensile loading studies in which devices were custom fabricated to meet research groups’ needs. The tensile loading working principles were divided into four major groups: four-point bending apparatuses, linear sliding rake systems, clamped samples connected to a tensile device, and vacuum-actuated tensile devices, as represented in Fig. 6. The tensile loading devices designed by research groups are graphically arranged in Fig. 7, according to the maximum strain/displacement and frequency under study.

Representation of four tensile working principles. In the four-point bending apparatus, the cell-based construct is supported by stationary supports and strain is distributed in the perpendicular plane to the applied load. However, the strain magnitude is not distributed uniformly between these horizontal planes because it increases from the central horizontal axis to the external medial and lateral faces (which are subjected to maximum tensile and compressive strains, respectively) [73]. Constructs can also be placed in cages and fixed at two opposite ends: one rigidly and the other to the rake attachment. The linear sliding rake is then controlled at the desired frequency and amplitude. Cell-based samples can also be clamped and connected to a tensile device (one end of the rectangular membrane is fixed while the other is connected to a computer-controlled movable frame). Finally, polymeric substrates may be exposed to uniaxial tensile loading with a vacuum-actuated tensile device. The movement imposed by the tensile loading device is represented by the red arrow

The majority of tensile loading devices involve cell culture on a circular flexible membrane (fixed along its periphery) or rectangular flexible membrane (fixed at opposite ends) (Fig. 7). Some of the results obtained by the studies mentioned in Table 3 are summarized in Fig. 8.

Graphical arrangement of the devices designed and produced by research groups according to the maximum tensile strain/displacement studied at a particular frequency. Observation: despite the fact that Subramanian et al. [57] applied 2% uniaxial tensile strain to cells encapsulated in collagen constructs, the device used in this study may operate at a loading strain up to 12% at cyclic frequencies of 0.01–1 Hz

Results of studies performed with customized tensile loading devices. ALP staining at 24 h was higher for cells subjected to mechanical loading by a four-point bending device (a) compared to unstretched cells (b) and control cells (c) (reproduced from [43], Copyright 2008, with permission from Elsevier). d Scanning electron micrographs of 3D collagen constructs encapsulated with OB6, C2C12, or AC10 cells at day 3 either loaded by a linear sliding rake system or non-loaded (scale bar: 100 μm) indicated that the fibre orientation of loaded cells was parallel to the axis of load application (reproduced from [57], Copyright 2017, with permission from Wiley). e Staining of actin (green), sarcomeric z-lines (red), and nuclei (blue) of cardiomyocytes cultured on clamped samples connected to a tensile device revealed that after being subjected to 6 h of cyclic uniaxial tensile loading, the cells aligned in the direction of loading (white arrow) (reproduced from [3], Copyright 2018, with permission from ASME). f No significant differences in the average normalized total fluorescence of nuclei were found between non-stretched (control) and stretched groups, but F-actin fluorescence significantly increased with loading performed with a vacuum-actuated tensile device. The spatial distribution of per cent change between stretched and control average nuclei (g) and F-actin fluorescence (h) showed that expression of F-actin increased after tensile loading (reproduced from [52], Copyright 2018, with permission from Springer Science Business Media, LLC, part of Springer Nature)

Application of cyclic uniaxial (one direction) tensile strains sometimes leads to a heterogeneous biaxial strain profile, due to the Poisson effect. Therefore, custom-designed devices were developed to modulate equiaxial strains and generate a homogeneous strain environment [32, 44, 78, 79]. Other groups focused on reproducing a more complex physiological environment by applying biaxial strains [80, 81]. Tensile loading was also performed using piezoelectrically actuated pins of a Braille display [72]. Briefly, an elastomeric membrane of PDMS containing microwells was placed on top of an actuated pins array and deformed by the Braille pin movement. Each pin was independently computer-controlled and responsible for applying a cyclically radial strain (maximal 20%–25% radial and 12% tangential). Mouse myogenic C2C12 cells and human dermal microvascular endothelial cells (HDMECs) aligned to the loading direction at increasing frequencies of 0.2, 1, and 5 Hz, after 2, 4, and 12 h, in contrast to human lung adenocarcinoma epithelial A549 cells, which did not respond to tensile loading (Fig. 9) [72].

Schematic representation of the cross section of cells (represented in green) cultured on flexible membranes (a) and the deformation of the latter as the pin moves upwards (b). The alignment of C2C12 and HDMECs in response to loading is illustrated by fluorescent images of HDMECs (c, d), C2C12 myoblast cells (e, f), and A549 alveolar epithelial cells (g, h) stained with Calcein AM before loading (left column) and after being subjected to cyclical tensile loading (5 Hz for 12 h) (right column) (reproduced from [72], Copyright 2008, with permission from Elsevier). HDMECs: human dermal microvascular endothelial cells

Compressive loading devices

Microfabricated devices have been developed to apply compressive strain to cell-encapsulated constructs. Typically, the compression is achieved by loading pistons actuated by a pneumatic system. This type of compressive device can generate three types of compression: unconfined, semi-confined, and confined, all of which are illustrated in Fig. 10.

Unconfined compression was studied in the majority of compressive loading studies, as it represents the simplest microfabrication technique. One device was designed to study the influence of dynamic 10% compressive strain at 1 Hz for up to 3 weeks on chondrogenesis of goat bm-MSCs encapsulated in poly(ethylene glycol) diacrylate (PEGDA) hydrogels, as well as human embryonic body-derived (hEBd) cells encapsulated in tyrosine-glycine-aspartate-serine (YRGDS)-PEG-acrylate hydrogels [82]. The expression and synthesis of chondrocyte-specific matrix molecules were also studied, under the same loading conditions, with bovine bm-stromal cells encapsulated in agarose gels for 8 and 16 days [83]. Another group investigated the role of cyclical unconfined compression on osteogenesis by applying 10% and 20% compressive strains at 0.5 Hz for 4 h on rat pre-osteoblasts seeded into electrospun polycaprolactone (PCL) scaffolds [84]. Only the 10%-magnitude strain induced expression of osteogenic-related proteins and transcription factors, showing that elevated magnitudes may inhibit bone formation [84]. Ravichandran et al. designed a custom-fabricated device to apply a range of compressive strains to four independent chambers. hMSCs were seeded on polycaprolactone-β tricalcium phosphate (PCL-TCP) scaffolds using fibrin gel and then exposed to 0.22%, 0.88%, and 1.1% compressive strain at 1 Hz, 4 h/day for 4 weeks [85]. Cyclic physiological compression of 0.22% resulted in higher ALP activity compared to supra-physiological strains; it also up-regulated osteogenic markers and generated high mineralization levels [85]. C3H10T1/2 mouse MSCs were encapsulated in PEG hydrogels and exposed to 6%, 11%, 14%, and 26% compressive strains. Regardless of the strain magnitude, there was no significant difference in nuclear deformation, whereas cellular deformation only changed significantly at the highest strain levels [86]. The device proposed by Moraes et al. [86] consisted on an array of loading posts suspended over actuation cavities and was adopted and altered by Lee et al. to subject alginate-chondrocyte constructs to compressive strain [87]. These constructs were placed on PDMS balloons with different diameters and by varying only the cavity diameter (with the applied pressure remaining the same), it was possible to create a range of compressive strains. Because the balloons were inflated with pressurized air, compression on constructs was studied either in a static (14 kPa, 1 h) or dynamic (14 kPa, 1 Hz, 1 h) mode. Lee et al. found that the mean strain of chondrocytes was approximately 50% of the gel strain, with a permanent deformation of 9%–30% for static compression, and 0.5%–6% for dynamic compression. Finally, cell viability was found to be higher in dynamically loaded constructs, perhaps due to better nutrient transport [87]. Despite these findings, unconfined compression generates a heterogeneous strain distribution within the 3D construct. In contrast, confined compression generates a uniform strain, but challenges arise concerning its microfabrication. Semi-confined compression offers easier microfabrication, but uniform strains are only achieved in the central region of the biomaterial. These findings were obtained from the finite-element simulations (represented in Fig. 11), and the obtained strain fields for the three compression modes were compared [88].

Finite-element simulations of three compression modes all involved application of 10% compressive strain on PEG hydrogel (adapted from [88], Copyright 2011, with permission from IOP Publishing Ltd). Strain field within the hydrogel was generated for unconfined (a), confined (b), and semi-confined (c) compression modes and the radial, circumferential, and axial strains (mean and standard deviation) were plotted for the total axial thickness of the hydrogel

The same group fabricated a semi-confined compression device, which was used to generate nominal strains of 20%, 30%, 40%, and 45% on PEG and collagen hydrogels. The authors concluded that this compression model enables the study of cellular responses to precisely applied strains on a range of polymerizable biomaterials, improving the applicability and versatility of the device [88]. Zhang et al. [89] used a custom-designed dynamic-compression loading system with a stepper motor to apply a 10% compressive strain on PCL scaffolds encapsulated with hMSCs. PCL-based constructs subjected to both mechanical and biochemical stimulation supported a chondroprotective effect [89].

Review of patents

Given the promising outcomes from engineered mechanical stimulation devices in mechanobiology studies like those described above, many patent applications have been filed in the past few decades. We looked at both granted patents and patent applications, and conducted our research through the Derwent Innovation Index [90] and Google Patents [91] databases, which include European, USA, and World Patents (WIPO—World Intellectual Property Organization). The keywords were related to mechanical cell stimulation and resulted in a total of 369 records. We excluded inventions whose descriptions could not be automatically translated to English, those with unclear abstracts, and those not within the scope of this review.

A total of 44 patents of devices able to create different stimuli (tensile, compressive, shear stresses, and vibration) were comprehensively studied and selected, taking into account their in vitro cellular purposes. Table 4 summarizes the selected inventions. They are organized first by frequency level (low to moderate vs. high frequency), then by actuator type, as schematically illustrated in Fig. 12, and finally by the imposed stress state. Inventions that obey non-conventional actuation principles are in a separate category.

To better organize the resulting inventions, we grouped them according to their actuation principle. From low to high frequencies, the actuation may be pneumatic (either positive or negative pressure), motor-driven, or magnetic. However, some inventors disclosed more than one functionality principle. The invention of Sittampalam et al. [96] is a drug-screening device and system that attempts to impart strain to cells in a similar manner to physiological motion and rest. According to their description, different mechanical drive systems can be adopted to move the pins and thus exert mechanical strain on cells, including a linear actuator (Fig. 13a), an electromagnetic system, or a pneumatic system (Fig. 13b).

The device of invention number US 2013/0059324 AI may be operated (a) by a mechanical drive mechanism, in which the rotation of a non-circular shaft (218) moves the movable support (216), thereby pushing the push members (214) in respect to the pins (118); or (b) by a pressurized mechanism (220), in which the change of fluid volume moves the support (216), imparting mechanical strain to the cells located in the wells (112). Illustrations from [96]

The device invented by Shapiro et al. [118], defined in Table 3 as belonging to the motor-driven category has, in fact, more than one approach to achieving membrane mechanical displacement (Fig. 14). The elastic membrane upon which the cell culture is placed is securely held in place and moved by a displacement applicator located, for example, on the bottom surface. Then, it is cyclically moved upward and downward by a force generator, deforming the membrane. This membrane deformation imparts biaxial forces (either tensile or compressive) to the cells mounted thereon, and the strain profile may be either uniform or non-uniform. The electric motor drives an actuating apparatus, such as a cam (Fig. 14a), which revolves eccentrically about an axis, contacting the bottom surface of the rod and forcing the rod and displacement applicator to move upward to contact and deform the membrane. At the end of the upward stroke, the applicator moves to a lowered position out of contact with the membrane. The invention may also correspond to a mechanical actuated tensile apparatus which applies biaxial strain (Fig. 14b) or simultaneously applies tensile loading to several cell cultures (Fig. 14c). The removable and disposable wells are mounted above each available displacement applicator.

Illustrations of invention number US 5,348,879 of Shapiro et al., with three different displacement applicators (represented in the drawing by 24). In (a), a cam deforms the membrane, in (b), the membrane is secured by plates and is deformed by the displacement applicator moving upward, and in (c), each well is mounted above the displacement applicator. Schematics from [118]

Substrate deformation through the pneumatic actuation principle may be achieved by pressure [92, 98] or vacuum [93,94,95,96,97], and by pulling a portion of the flexible membrane upward or downward, respectively. Despite the simple set-up, in both modes the stimulus frequency is low and may not even be capable of creating dynamic cycles. However, vacuum pumps are slower than pressure inlet. Other inventions aim to deform the membrane through pressurization of the fluid (e.g., culture medium) [99, 102], or by creating hydrostatic pressure using a piston [100]. If not carefully designed, moving the flexible membrane upward through a displacement applicator, by pressure or manually (e.g. with a piston), may cause friction between the membrane of interest and the loading post of the device, as represented in Fig. 15.

Hydraulic actuators are comprised of a hollow cylinder with a piston, and due to unbalanced pressure applied to the piston, a force is generated that deforms the membrane equiaxially. Although these actuators are often limited in terms of frequency, invention number DE102009057698A1 of Kiesow et al. [98] allows cyclic testing in a frequency range of 0.001 to 200 Hz.

Still, either in low- or high-frequency mode, the culture liquid in contact with the cells may be pressurized and the generated hydrostatic pressure then exerts a compressive mechanical force on cells.

The motor-driven mechanism involves the conversion of a rotary motion of an electric motor into linear displacement. The selected motor may be a stepper motor [103, 104, 106,107,108,109,110,111, 117], a linear DC motor [105, 113, 114, 119, 128], a servo motor [126], or a voice-coil motor [105, 115]. Stepper motors, which are composed of multiple toothed electromagnets, were preferred for some of these inventions. Despite the possibility of miniaturization, precise rotation (ranging from step angles through full 360° rotation), easy set-up and control, this type of motor is frequently slow due to a low transmission ratio (from rotational to linear movement). Moreover, it may cause small vibrations, which will act as an external disturbance to the system and thus should be considered separately from the substrate’s deformation. Linear DC motors are two-wire continuous rotation motors with each pulse being so fast that the motor seems to be rotating constantly with no stuttering. Servo motors are also fast, with high torque, and can be precisely controlled because of their accurate rotation within a limited angle. This actuation principle is particularly suitable for uniaxial tensile loading and for larger engineered constructs. In addition, it allows multiple loading modes and precise control over the strain features, such as amplitude and frequency. On the other hand, some potential disadvantages are the risk of contamination and limitation of high-throughput capabilities [134].

The linear actuation principle may be preferable because it allows for automation, requires less maintenance, and offers a broader range of strain magnitudes, frequencies, and durations of mechanical stimulus. Invention number US10,421,955B2, assigned to IonOptix LLC in 2019 (Fig. 16), applies a tensile strain up to 50% (at 0.01–10 Hz) on a deformable rectangular culture dish made, for example, from silicone rubber [111]. A plurality of viewing ports are provided to enable cell culture observation by microscope and exchange of the culture medium, permitting long-term experiments to be performed.

Illustrations of invention number US10,421,955B2, assigned to IonOptix LLC. (a) is a side view of the electromechanical stage (28a) composed by a fixed support (32) and a moving support (36) connected to a stepper motor (42). (b) is a perspective view illustrating six culture dishes and supporting parts of the electromechanical stage. Figures from [111]

Muthiah et al. [115] developed a mechanical tensile device, invention number US 2012/0219981Al, with dimensions of 408 mm×150 mm (much larger than a 24-well plate). It is composed of two engagement areas located at opposite ends of a flexible substrate; each one connected to a movable element and a motor to promote opposite movements, as shown in Fig. 17. The device may include a temperature-control unit, such as a heating unit and/or a fan, to assure uniform distribution of heat and to maintain the temperature, a humidity reservoir unit, and a gas-control unit to control the gas parameters and supply. During or after tensile loading, the materials may also be imaged using a microscope base plate.

Schematics of invention number US 2012/0219981Al, assigned to Muthiah and Lane [115], in which each motor (denoted by 504 and 506) is connected to an opposite end of the cell culture device (502). The embodiment includes a water reservoir (512), an electric heating unit (508) and cooling fans (510), and computer interface connections (514). Figures from [115]

The magnetic actuation principle is an indirect method used to apply mechanical stresses on the substrate of interest. The actuating part is never in contact with the moveable one, which decreases the risk of contamination, but it is hard to control the strain and velocity. In addition, there is a potential unwanted magnetic effect on cells.

Looking further at low- to high-frequency range, some inventions apply fluid-flow-induced shear stress to cells. Despite the fact that this stimulus cannot be considered a mechanical cue for mechanotransduction studies given that it cannot be measured, Jiang et al.’s invention number CN10314657A also provides, according to the inventors, tensile stresses on cells [127], and Boronyak et al.’s invention number US 8,852,923 B2 may be adapted to impose cyclic flexural and/or tensile stresses [128].

The aforementioned inventions apply tensile, compressive, or shear stresses to cells, and some allow simultaneous electric stimulation. When cells are stimulated by deformation of the substrate on which they are cultured, those forces generate uniaxial, biaxial, or equiaxial strains (previously described in Fig. 3). In-plane substrate distension through frictionless platen displacement (by vacuum, pressure, or another means) creates biaxial strain traction on a flexible culture membrane and produces a uniform strain field [119]. This strain-profile output may be required for more accurate and controlled mechanotransduction studies, given that all cells cultured on the substrate are subjected to the same strain.

Actuation using piezoelectric or ultrasound elements was used to create vibration/oscillation. The main advantage is easy set-up, but the deformation created exhibits low amplitude and high frequency. In addition, the deformation of the piezo elements is not equal to the deformation of the substrate, and consequently of the cells, because losses are always present and, as the whole device vibrates, the vibrations can be even more attenuated.

Potential and future perspectives

Significant progress in research and technological fields has contributed to remarkable findings on the physiological dynamics of the human body. Basic life science research has moved from 2D culture systems to more complex 3D dynamic cultures, not only to improve cell culture conditions by promoting nutrient and oxygen flow to cells, but also to more closely mimic the complex physiological environment. Unlike bioreactors or microfluidic-based culture models, for the purpose of mechanobiology studies, cells are usually seeded on polymeric substrates or incorporated into 3D constructs and stimulated in mechanical force devices in order to investigate cell adaptation to different mechanical stresses, such as tensile or compressive stresses.

Regenerative medicine strategies involve the use of biomaterials whose mechanical properties and behaviour upon implantation may be studied in vitro by closely mimicking physiological conditions of, for example, bone [43, 74,75,76], heart muscle [42, 135], tendon [56], and lung [77]. By reproducing the physiological conditions to which the implants or biomaterials would be subjected, the need to perform in vivo animal testing would decrease. This would be in line with the European Directive 2010/63/EC which follows the “3Rs: reduction, refinement, and replacement” strategy to reinforce the importance of using alternative in vitro and in silico methods to obtain the maximal information from the intended product prior to clinical trials [136,137,138]. Despite more reliable studies conducted over the past years for multiple tissue-specific applications, there are still opportunities for further improvement. Mechanical stimulation devices should be designed (or integrated with other systems) to allow multiple and real-time assessment and evaluation of cell behaviour and responses at a microscale. One possibility is performing real-time imaging using non-invasive imaging techniques, fluorescence, or μCT. In order to assure optimal experimental conditions, mechanical stimulation devices could be coupled and assembled with sensors for monitor-based and cell-specific parameters, such as pH, temperature, oxygen, and secretion of small molecules and proteins.

References

Roy AL, Conroy RS (2018) Toward mapping the human body at a cellular resolution. Mol Biol Cell 29:1779–1785. https://doi.org/10.1091/mbc.E18-04-0260

Jackson EL, Lu H (2016) Three-dimensional models for studying development and disease: moving on from organisms to organs-on-a-chip and organoids. Integr Biol 8:672–683. https://doi.org/10.1039/c6ib00039h

Atcha H, Davis CT, Sullivan NR et al (2018) A low-cost mechanical stretching device for uniaxial strain of cells: a platform for pedagogy in mechanobiology. J Biomech Eng 140:1–9. https://doi.org/10.1115/1.4039949

Raveling AR, Theodossiou SK, Schiele NR (2018) A 3D printed mechanical bioreactor for investigating mechanobiology and soft tissue mechanics. MethodsX 5:924–932. https://doi.org/10.1016/j.mex.2018.08.001

Yi N, Cui H, Zhang LG et al (2019) Integration of biological systems with electronic-mechanical assemblies. Acta Biomater 95:91–111. https://doi.org/10.1016/j.actbio.2019.04.032

Gattazzo F, Urciuolo A, Bonaldo P (2014) Extracellular matrix: a dynamic microenvironment for stem cell niche. Biochim Biophys Acta Gen Subj 1840:2506–2519. https://doi.org/10.1016/j.bbagen.2014.01.010

Uto K, Tsui JH, Deforest CA et al (2017) Dynamically tunable cell culture platforms for tissue engineering and mechanobiology. Prog Polym Sci 65:53–82. https://doi.org/10.1016/j.progpolymsci.2016.09.004

Li L, Eyckmans J, Chen CS (2017) Designer biomaterials for mechanobiology. Nat Mater 16:1164–1168. https://doi.org/10.1038/nmat5049

Jansen KA, Donato DM, Balcioglu HE et al (2015) A guide to mechanobiology: where biology and physics meet. Biochim Biophys Acta Mol Cell Res 1853:3043–3052. https://doi.org/10.1016/j.bbamcr.2015.05.007

Orr AW, Helmke BP, Blackman BR et al (2006) Mechanisms of mechanotransduction. Dev Cell 10:11–20. https://doi.org/10.1016/j.devcel.2005.12.006

Vining KH, Mooney DJ (2017) Mechanical forces direct stem cell behaviour in development and regeneration. Nat Rev Mol Cell Biol 18:728–742. https://doi.org/10.1038/nrm.2017.108

Chen Y, Ju L, Rushdi M et al (2017) Receptor-mediated cell mechanosensing. Mol Biol Cell 28:3134–3155. https://doi.org/10.1091/mbc.e17-04-0228

Wittkowske C, Reilly GC, Lacroix D et al (2016) In vitro bone cell models : impact of fluid shear stress on bone formation. Front Bioeng Biotechnol 4:1–22. https://doi.org/10.3389/fbioe.2016.00087

Ma S, Meng Z, Chen R et al (2019) The hippo pathway: biology and pathophysiology. Annu Rev Biochem 88:577–604. https://doi.org/10.1146/annurev-biochem-013118-111829

DuFort CC, Paszek MJ, Weaver VM (2001) Balancing forces: architectural control of mechanotransduction. Nat Rev Mol Cell Biol 12:308–319. https://doi.org/10.1038/nrm3112

Gasik M (2020) Biomechanical characterization of engineered tissues and implants for tissue/organ replacement applications. Biomaterials for organ and tissue regeneration. Elsevier, pp 599–627. https://doi.org/10.1016/B978-0-08-102906-0.00024-6

Melo-Fonseca F, Miranda G, Domingues HS et al (2020) Reengineering bone-implant interfaces for improved mechanotransduction and clinical outcomes. Stem Cell Rev Rep 16:1121–1138. https://doi.org/10.1007/s12015-020-10022-9

Desmaële D, Boukallel M, Régnier S (2011) Actuation means for the mechanical stimulation of living cells via microelectromechanical systems: a critical review. J Biomech 44:1433–1446. https://doi.org/10.1016/j.jbiomech.2011.02.085

Bhatia SN, Ingber DE (2014) Microfluidic organs-on-chips. Nat Biotechnol 32:760–772. https://doi.org/10.1038/nbt.2989

Adelaide Asnaghi M, Smith T, Martin I et al (2014) Bioreactors. Tissue engineering. Elsevier, pp 393–425. https://doi.org/10.1016/B978-0-12-420145-3.00012-2

Brunelli M, Perrault C, Lacroix D (2019) A review of bioreactors and mechanical stimuli. In: Lacroix D, Brunelli M, Perrault C et al (Eds.), Multiscale Mechanobiology in Tissue Engineering. Springer Singapore, Singapore, pp 1–22. https://doi.org/10.1007/978-981-10-8075-3_1

Eaker S, Abraham E, Allickson J et al (2017) Bioreactors for cell therapies: current status and future advances. Cytotherapy 19:9–18. https://doi.org/10.1016/j.jcyt.2016.09.011

Mckee C, Chaudhry GR (2017) Advances and challenges in stem cell culture. Colloids Surf B Biointerf 159:62–77. https://doi.org/10.1016/j.colsurfb.2017.07.051

Yeatts AB, Fisher JP (2011) Bone tissue engineering bioreactors: dynamic culture and the influence of shear stress. Bone 48:171–181. https://doi.org/10.1016/j.bone.2010.09.138

Berry JD, Godara P, Liovic P et al (2015) Predictions for optimal mitigation of paracrine inhibitory signalling in haemopoietic stem cell cultures. Stem Cell Res Ther 6:1–16. https://doi.org/10.1186/s13287-015-0048-7

King JA, Miller WM (2007) Bioreactor development for stem cell expansion and controlled differentiation. Curr Opin Chem Biol 11:394–398. https://doi.org/10.1016/j.cbpa.2007.05.034

Mazzoleni G, Di Lorenzo D, Steimberg N (2009) Modelling tissues in 3D: the next future of pharmaco-toxicology and food research? Genes Nutr 4:13–22. https://doi.org/10.1007/s12263-008-0107-0

Marijanovic I, Antunovic M, Matic I et al (2016) Bioreactor-based bone tissue engineering. In: Zorzi AR, Batistade Miranda J (Eds.), Advanced Techniques in Bone Regeneration. InTech. https://doi.org/10.5772/62546

van Noort D (2016) Bioreactors on a chip. In: Mandenius CF (Ed.), Bioreactors: Design, Operation and Novel Applications (1st Ed.). Wiley-VCH Verlag GmbH & Co, KGaA, pp 77–112

Sosa-Hernández JE, Villalba-Rodríguez AM, Romero-Castillo KD et al (2018) Organs-on-a-chip module: a review from the development and applications perspective. Micromachines 9:536. https://doi.org/10.3390/mi9100536

Whitesides GM (2006) The origins and the future of microfluidics. Nature 442:368–373. https://doi.org/10.1038/nature05058

Mann JM, Lam RHW, Weng S et al (2012) A silicone-based stretchable micropost array membrane for monitoring live-cell subcellular cytoskeletal response. Lab Chip 12:731–740. https://doi.org/10.1039/c2lc20896b

Haeberle S, Zengerle R (2007) Microfluidic platforms for lab-on-a-chip applications. Lab Chip 7:1094–1110. https://doi.org/10.1039/b706364b

Azizipour N, Avazpour R, Rosenzweig DH et al (2020) Evolution of biochip technology: a review from lab-on-a-chip to organ-on-a-chip. Micromachines 11:1–15. https://doi.org/10.3390/mi11060599

Brown TD (2000) Techniques for mechanical stimulation of cells in vitro: a review. J Biomech 33:3–14. https://doi.org/10.1016/S0021-9290(99)00177-3

Esteban-Manzanares G, González-Bermúdez B, Cruces J et al (2017) Improved measurement of elastic properties of cells by micropipette aspiration and its application to lymphocytes. Ann Biomed Eng 45:1375–1385. https://doi.org/10.1007/s10439-017-1795-7

González-Bermúdez B, Guinea GV, Plaza GR (2019) Advances in micropipette aspiration: applications in cell biomechanics, models, and extended studies. Biophys J 116:587–594. https://doi.org/10.1016/j.bpj.2019.01.004

Daza R, González-Bermúdez B, Cruces J et al (2019) Comparison of cell mechanical measurements provided by atomic force microscopy (AFM) and micropipette aspiration (MPA). J Mech Behav Biomed Mater 95:103–115. https://doi.org/10.1016/j.jmbbm.2019.03.031

Efremov YM, Wang WH, Hardy SD et al (2017) Measuring nanoscale viscoelastic parameters of cells directly from AFM force-displacement curves. Sci Rep 7:1–14. https://doi.org/10.1038/s41598-017-01784-3

Schierbaum N, Rheinlaender J, Schäffer TE (2019) Combined atomic force microscopy (AFM) and traction force microscopy (TFM) reveals a correlation between viscoelastic material properties and contractile prestress of living cells. Soft Matter 15:1721–1729. https://doi.org/10.1039/c8sm01585f

Krieg M, Fläschner G, Alsteens D et al (2019) Atomic force microscopy-based mechanobiology. Nat Rev Phys 1:41–57. https://doi.org/10.1038/s42254-018-0001-7

Kreutzer J, Viehrig M, Pölönen RP et al (2020) Pneumatic unidirectional cell stretching device for mechanobiological studies of cardiomyocytes. Biomech Model Mechanobiol 19:291–303. https://doi.org/10.1007/s10237-019-01211-8

Qi MC, Hu J, Zou SJ et al (2008) Mechanical strain induces osteogenic differentiation: Cbfa1 and Ets-1 expression in stretched rat mesenchymal stem cells. Int J Oral Maxillofac Surg 37:453–458. https://doi.org/10.1016/J.IJOM.2007.12.008

Trepat X, Deng L, An SS et al (2007) Universal physical responses to stretch in the living cell. Nature 447:592–595. https://doi.org/10.1038/nature05824

Sniadecki NJ, Anguelouch A, Yang MT et al (2007) Magnetic microposts as an approach to apply forces to living cells. Proc Natl Acad Sci USA 104:14553–14558. https://doi.org/10.1073/pnas.0611613104

Izzo L, Tunesi M, Boeri L et al (2019) Influence of the static magnetic field on cell response in a miniaturized optically accessible bioreactor for 3D cell culture. Biomed Microdev 21:1–12. https://doi.org/10.1007/s10544-019-0387-8

Heidemann SR, Wirtz D (2004) Towards a regional approach to cell mechanics. Trends Cell Biol 14:160–166. https://doi.org/10.1016/j.tcb.2004.02.003

Barthes J, Özçelik H, Hindié M et al (2014) Cell microenvironment engineering and monitoring for tissue engineering and regenerative medicine: the recent advances. Biomed Res Int 2014:921905. https://doi.org/10.1155/2014/921905

Halldorsson S, Lucumi E, Gómez-Sjöberg R et al (2015) Advantages and challenges of microfluidic cell culture in polydimethylsiloxane devices. Biosens Bioelectron 63:218–231. https://doi.org/10.1016/j.bios.2014.07.029

Kim L, Toh YC, Voldman J et al (2007) A practical guide to microfluidic perfusion culture of adherent mammalian cells. Lab Chip 7:681–694. https://doi.org/10.1039/b704602b

Kluge JA, Leisk GG, Cardwell RD et al (2011) Bioreactor system using noninvasive imaging and mechanical stretch for biomaterial screening. Ann Biomed Eng 39:1390–1402. https://doi.org/10.1007/s10439-010-0243-8

Walker M, Godin M, Pelling AE (2018) A vacuum-actuated microtissue stretcher for long-term exposure to oscillatory strain within a 3D matrix. Biomed Microdev 20(2):1–10. https://doi.org/10.1007/s10544-018-0286-4

Vanderploeg EJ, Imler SM, Brodkin KR et al (2004) Oscillatory tension differentially modulates matrix metabolism and cytoskeletal organization in chondrocytes and fibrochondrocytes. J Biomech 37:1941–1952. https://doi.org/10.1016/j.jbiomech.2004.02.048

Connelly JT, Vanderploeg EJ, Mouw JK et al (2010) Tensile loading modulates bone marrow stromal cell differentiation and the development of engineered fibrocartilage constructs. Tissue Eng Part A 16:1913–1923. https://doi.org/10.1089/ten.tea.2009.0561

Doroski DM, Levenston ME, Temenoff JS (2010) Cyclic tensile culture promotes fibroblastic differentiation of marrow stromal cells encapsulated in poly(ethylene glycol)-based hydrogels. Tissue Eng Part A 16:3457–3466. https://doi.org/10.1089/ten.tea.2010.0233

Grier WK, Moy AS, Harley BAC (2017) Cyclic tensile strain enhances human mesenchymal stem cell SMAD 2/3 activation and tenogenic differentiation in anisotropic collagen-glycosaminoglycan scaffolds. Eur Cells Mater 33:227–239. https://doi.org/10.22203/eCM.v033a14

Subramanian G, Elsaadany M, Bialorucki C et al (2017) Creating homogenous strain distribution within 3D cell-encapsulated constructs using a simple and cost-effective uniaxial tensile bioreactor: design and validation study. Biotechnol Bioeng 114:1878–1887. https://doi.org/10.1002/bit.26304

Ralphs JR, Waggett AD, Benjamin M (2002) Actin stress fibres and cell–cell adhesion molecules in tendons: organisation in vivo and response to mechanical loading of tendon cells in vitro. Matrix Biol 21:67–74. https://doi.org/10.1016/S0945-053X(01)00179-2

Simmons CA, Matlis S, Thornton AJ et al (2003) Cyclic strain enhances matrix mineralization by adult human mesenchymal stem cells via the extracellular signal-regulated kinase (ERK1/2) signaling pathway. J Biomech 36:1087–1096. https://doi.org/10.1016/S0021-9290(03)00110-6

Sumanasinghe RD, Bernacki SH, Loboa EG (2006) Osteogenic differentiation of human mesenchymal stem cells in collagen matrices: effect of uniaxial cyclic tensile strain on bone morphogenetic protein (BMP-2) mRNA expression. Tissue Eng 12:3459–3465. https://doi.org/10.1089/ten.2006.12.3459

Saha S, Ji L, De Pablo JJ et al (2006) Inhibition of human embryonic stem cell differentiation by mechanical strain. J Cell Physiol 206:126–137. https://doi.org/10.1529/biophysj.107.119891

Ku CH, Johnson PH, Batten P et al (2006) Collagen synthesis by mesenchymal stem cells and aortic valve interstitial cells in response to mechanical stretch. Cardiovasc Res 71:548–556. https://doi.org/10.1016/j.cardiores.2006.03.022

Luo J, Qin L, Zhao L et al (2020) Tissue-engineered vascular grafts with advanced mechanical strength from human iPSCs. Cell Stem Cell 26:251–261. https://doi.org/10.1016/j.stem.2019.12.012

Kroll K, Chabria M, Wang K et al (2017) Electro-mechanical conditioning of human iPSC-derived cardiomyocytes for translational research. Prog Biophys Mol Biol 130:212–222. https://doi.org/10.1016/j.pbiomolbio.2017.07.003

Sitticholechaiwut A, Edwards JH, Scutt AM et al (2010) Short bouts of mechanical loading are as effective as dexamethasone at inducing matrix production by human bone marrow mesenchymal stem cells. Eur Cells Mater 20:45–57. https://doi.org/10.22203/eCM.v020a05

Sittichockechaiwut A, Scutt AM, Ryan AJ et al (2009) Use of rapidly mineralising osteoblasts and short periods of mechanical loading to accelerate matrix maturation in 3D scaffolds. Bone 44:822–829. https://doi.org/10.1016/j.bone.2008.12.027

Kong Z, Li J, Zhao Q et al (2012) Dynamic compression promotes proliferation and neovascular networks of endothelial progenitor cells in demineralized bone matrix scaffold seed. J Appl Physiol 113:619–626. https://doi.org/10.1152/japplphysiol.00378.2011

Okazaki Y, Furumatsu T, Kamatsuki Y et al (2021) Differences between the root and horn cells of the human medial meniscus from the osteoarthritic knee in cellular characteristics and responses to mechanical stress. J Orthop Sci 26:230–236. https://doi.org/10.1016/j.jos.2020.02.015

Chang SH, Mori D, Kobayashi H et al (2019) Excessive mechanical loading promotes osteoarthritis through the gremlin-1–NF-κB pathway. Nat Commun 10:1–5. https://doi.org/10.1038/s41467-019-09491-5

Nam HY, Murali MR, Ahmad RE et al (2020) Mechanical strain-mediated tenogenic differentiation of mesenchymal stromal cells is regulated through epithelial sodium channels. Stem Cells Int 2020:5385960. https://doi.org/10.1155/2020/5385960

Takahashi K, Ito S, Furuya K et al (2017) Real-time imaging of mechanically and chemically induced ATP release in human lung fibroblasts. Respir Physiol Neurobiol 242:96–101. https://doi.org/10.1016/j.resp.2017.04.008

Kamotani Y, Bersano-Begey T, Kato N et al (2008) Individually programmable cell stretching microwell arrays actuated by a Braille display. Biomaterials 29:2646–2655. https://doi.org/10.1016/j.biomaterials.2008.02.019

Gere JM, Timoshenko SP (1984) Mechanics of Materials (2nd Ed.). Brooks/Cole Engineering, Escondido

Mauney JR, Sjostorm S, Blumberg J et al (2004) Mechanical stimulation promotes osteogenic differentiation of human bone marrow stromal cells on 3-D partially demineralized bone scaffolds in vitro. Calcif Tissue Int 74:458–468. https://doi.org/10.1007/s00223-003-0104-7

Byrne EM, Farrell E, McMahon LA et al (2008) Gene expression by marrow stromal cells in a porous collagen–glycosaminogly scaffold is affected by pore size and mechanical stimulation. J Mater Sci Mater Med 19:3455–3463. https://doi.org/10.1007/s10856-008-3506-2

Jagodzinski M, Drescher M, Zeichen J et al (2004) Effects of cyclic longitudinal mechanical strain and dexamethasone on osteogenic differentiation of human bone marrow stromal cells. Eur Cells Mater 7:35–41. https://doi.org/10.22203/eCM.v007a04

Huh D, Matthews BD, Mammoto A et al (2010) Reconstituting organ-level lung functions on a chip. Science 328(5986):1662–1668. https://doi.org/10.1126/science.1188302

Butcher JT, Barrett BC, Nerem RM (2006) Equibiaxial strain stimulates fibroblastic phenotype shift in smooth muscle cells in an engineered tissue model of the aortic wall. Biomaterials 27:5252–5258. https://doi.org/10.1016/j.biomaterials.2006.05.040

Moraes C, Chen JH, Sun Y et al (2010) Microfabricated arrays for high-throughput screening of cellular response to cyclic substrate deformation. Lab Chip 10:227–234. https://doi.org/10.1039/b914460a

Tan W, Scott D, Belchenko D et al (2008) Development and evaluation of microdevices for studying anisotropic biaxial cyclic stretch on cells. Biomed Microdev 10:869–882. https://doi.org/10.1007/s10544-008-9201-8

Gould RA, Chin K, Santisakultarm TP et al (2012) Cyclic strain anisotropy regulates valvular interstitial cell phenotype and tissue remodeling in three-dimensional culture. Acta Biomater 8:1710–1719. https://doi.org/10.1016/j.actbio.2012.01.006

Terraciano V, Mizrahi J, Moroni L et al (2007) Differential response of adult and embryonic mesenchymal progenitor cells to mechanical compression in hydrogels. Stem Cells 25:2730–2738. https://doi.org/10.1634/stemcells.2007-0228

Mouw JK, Connelly JT, Wilson CG et al (2006) Dynamic compression regulates the expression and synthesis of chondrocyte-specific matrix molecules in bone marrow stromal cells. Stem Cells 25:655–663. https://doi.org/10.1634/stemcells.2006-0435

Rath B, Nam J, Knobloch TJ et al (2008) Compressive forces induce osteogenic gene expression in calvarial osteoblasts. J Biomech 41:1095–1103. https://doi.org/10.1016/j.jbiomech.2007.11.024

Ravichandran A, Lim J, Chong MSK et al (2017) In vitro cyclic compressive loads potentiate early osteogenic events in engineered bone tissue. J Biomed Mater Res Part B Appl Biomater 105:2366–2375. https://doi.org/10.1002/jbm.b.33772

Moraes C, Wang GH, Sun Y et al (2010) A microfabricated platform for high-throughput unconfined compression of micropatterned biomaterial arrays. Biomaterials 31:577–584. https://doi.org/10.1016/j.biomaterials.2009.09.068

Lee D, Erickson A, You T et al (2018) Pneumatic microfluidic cell compression device for high-throughput study of chondrocyte mechanobiology. Lab Chip 18:2077–2086. https://doi.org/10.1039/c8lc00320c

Moraes C, Zhao R, Likhitpanichkul M et al (2011) Semi-confined compression of microfabricated polymerized biomaterial constructs. J Micromech Microeng 21:054014. https://doi.org/10.1088/0960-1317/21/5/054014

Zhang ZZ, Chen YR, Wang SJ et al (2019) Orchestrated biomechanical, structural, and biochemical stimuli for engineering anisotropic meniscus. Sci Transl Med 11:eaao0750. https://doi.org/10.1126/scitranslmed.aao0750

Analytics C Web of Knowledge—Derwent Innovation Index. http://www.webofknowledge.com

Google Patents. https://patents.google.com

Moraes C, Simmons C, Sun Y (2009) A system, apparatus and method for applying mechanical force to a material (Patent No. WO2009039640A9). https://patents.google.com/patent/WO2009039640A1/en

Banes AJ (1989) Apparatus for applying stress to cell cultures (Patent No. US4839280). https://patents.google.com/patent/US4839280?oq=US4839280

Tae Yoon L, Hee Tak H, Jung Mok S et al (2019) Cell stimulation apparatus (Patent No. US 10,246,676 B2). https://patents.google.com/patent/US10246676B2

Banes AJ (2002) Loading station assembly and method for tissue engineering (Patent No. US 6,472,202 Bl). https://patents.google.com/patent/US6472202B1/en

Sittampalam GS, Nirmalanandhan VS (2013) Systems and methods for mechanically strained cell culture (Patent No. US 2013/0059324 Al). https://patents.google.com/patent/US20130059324A1/en

Simmons CS, Pruitt BL, Sim JY et al (2015) Cell culture strain array systems and methods for using the same (Patent No. US2015/0050722Al). https://patents.google.com/patent/US20150050722A1/en

Kiesow A, Schwan S, Bartling B et al (2011) Bioreactor for multi-dimensional, mechanical stimulation of cells, cell complexes and/or cell tissue, comprises a first and a second reactor part volumes that are separated from each other through a carrier membrane (Patent No. DE102009057698A1). https://patents.google.com/patent/DE102009057698A1/de

Min-Hsien W, Chun-Li L, Shiao-Wen T et al (2015) Apparatus for high-throughput cell culture with mechanical compression stimulation (Patent No. US 8980624 B2). https://patents.google.com/patent/US8980624B2/en

Kasra M (2016) Hydrostatic pressure generator device (Patent No. US 9303244 Bl). https://patents.google.com/patent/US9303244B1/en

Dan-Jae L, Ming-Tzu T, Chao-Wei H et al (2020) Cell mechanical stimulating device (Patent No. US 2020/0339936 Al). https://patents.google.com/patent/US20200339936A1/en

Lagana K, Raimondi MT, Dubini G et al (2009) Bioreactor for generation and complex mechanical stimulation of engineered biological tissue (Patent No. WO 2009/047045 A2). https://patents.google.com/patent/WO2009047045A2/en

Wang BC, Zhu LQ, Zhou J et al (2006) Microstress applicator for in vitro cell (Patent No. CN1834220A). https://patents.google.com/patent/CN1834220A/en

Subramanian G, Elsaadany M, Yildirim-Ayan E (2017) Loading platform for three-dimensional tissue engineered scaffolds (Patent No. CN1834220A). https://patents.google.com/patent/CN1834220A/en

Franck C, Bar-kochba E (2013) Device and system for mechanical measurement of biomaterial (Patent No. WO 2013/090738 A9). https://patents.google.com/patent/WO2013090738A9/en

Fan YB, Li JC, Zou YW et al (2008) Tissue engineering reactor having tissue cultures tension-compression and rotation functions (Patent No. CN101372664A). https://patents.google.com/patent/CN101372664A/en

Fan YB, Li P, Liu ML et al (2012) Stretch-electricity combined stimulation three-dimensional cell culture device (Patent No. CN102433258B). https://patents.google.com/patent/CN102433258B/en

Zhang B, Feng ZQ, Wang QF et al (2014) Culture device applied to cell tensile stress and method (Patent No. CN103966094A). https://patents.google.com/patent/CN103966094A/en

Lu HH, Castillo M, Dargis BR (2012) Bioreactor system for mechanical stimulation of biological samples (Patent No. US 2012/0100602 Al). https://patents.google.com/patent/US20120100602A1/en

Lee PGW, Tillostson DL, Udale RT et al (2017) Apparatus and method for culturing cells and tissue (Patent No. US 9617507 B2). https://patents.google.com/patent/US9617507B2/en

Lee PGW, Tillostson DL, Udale RT et al (2019) Apparatus and method for culturing cells and tissue (Patent No. US 10,421,955 B2). https://patents.google.com/patent/US10421955B2/en

Meckel T, Sapper E, Schmitt LA (2018) Testing arrangement for examining a cell culture under the effect of a dynamic force (Patent No. US20180164278A1). https://patents.google.com/patent/US20180164278A1/en

Biagiotti L, Cavalcanti S, Giordano E et al (2011) Bio reactor for stem cells stimulation (Patent No. WO 2011/013067 A2). https://patents.google.com/patent/WO2011013067A2/en

Bayés Genís A, Llucià Valldeperas A, Soler Botija C et al (2017) Method for conditioning stem cells (Patent No. WO 2017/125159 Al). https://patents.google.com/patent/WO2017125159A1/en

Muthiah M, Lane EB (2012) Mechanical stretching device (Patent No. US 2012/0219981 Al). https://patents.google.com/patent/US20120219981A1/en

Jing H, Qin YX, Hai T et al (2009) Extension and compression device of multi-unit cells (Patent No. CN101649291A). https://patents.google.com/patent/CN101649291A/en

Krishnan R, Park CY, Tschumperlin D et al (2008) Bio-matrix stretcher (Patent No. WO 2009/032174 Al). https://patents.google.com/patent/WO2009032174A1/en

Shapiro AR, Gray ML, Melendez LA et al (1994) Cell stretching method (Patent No. US 5,348,879). https://patents.google.com/patent/US5348879A/en

Baker A, Wong M (2014) High-throughput mechanical strain generating system for cell cultures and applications thereof (Patent No. WO 2014/165056 Al). https://patents.google.com/patent/WO2014165056A1/en

Quinn T, Majd H (2006) Device for cell culture on deformable surfaces (Patent No. EP 1 679 366 A1).

Campbell S, Schwan J, Kwaczala A et al (2018) System and method for generating biological tissue (Patent No. US 2018/0216057 Al). https://patents.google.com/patent/US20180216057A1/en

Roberts EG (2020) Flexible device and its application for bio-cell in-vitro electrical and mechanical stimulation characterization (Patent No. US 2020/0199515 Al). https://patents.google.com/patent/US20200199515A1/en

Takagi T, Watanabe S (2004) Cell and structure incubator (Patent No. EP 1 428 869 A1).

Bottlang M, Sommers MB (2008) Method and systems for tissue culture (Patent No. US2008/0026419A). https://patents.google.com/patent/US20080026419A1/en

Rosell Ferrer FX, Sánchez Terrones B, Bragós Bardia R et al (2016) Methods and devices for mechanical and electrical stimulation of stem cell monolayer and 3D cultures for tissue engineering applications (Patent No. US 2016/0032234A1). https://patents.google.com/patent/US20160032234A1/en

Lee H, Park H, Solorio L et al (2021) High-throughput magnetic actuation platform for cancer treatment screening (Patent No. US 2021/0040427 Al). https://patents.google.com/patent/US20210040427A1/en

Jiang XY, Zheng WF, Zhang W et al (2013) High-flux microfluidic biomechanical long-term stimulation system and use thereof (Patent No. CN103146574A). https://patents.google.com/patent/CN103146574A/en

Boronyak SM, Engelmayr GC, Ramaswamy S et al (2014) Flow-stretch-flexure bioreactor (Patent No. US 8,852,923 B2). https://patents.google.com/patent/US8852923B2/en

Kishida A, Furunzono T, Miyazaki K et al (2013) Method for controlling biological function with mechanical vibration and device therefor (Patent No. US 8465971). https://patents.google.com/patent/US8465971B2/en

Choi HS, Lee WJ, Jung JT (2015) Cell stimulating system (Patent No. WO2015167097A1). https://patents.google.com/patent/WO2015167097A1/en

Choi HS, Lee WJ, Jung JT (2019) Cell stimulating system (Patent No. US 10,260,035 B2). https://patents.google.com/patent/US10260035B2/en

Botvinick EL, Venugopalan V, Compton J et al (2014) Mechanical stress response analysis of cells and tissues (Patent No. US 2014/0100138A1). https://patents.google.com/patent/US20140100138A1/en

Sutton AA, Shirman T, Aizenberg J et al (2015) Environmentally responsive microstructured hybrid actuator assemblies for use in mechanical stimulation of cells (Patent No. US 2015/0093823Al). https://patents.google.com/patent/US20150093823A1/en

Zhang W, Huang G, Xu F (2020) Engineering biomaterials and approaches for mechanical stretching of cells in three dimensions. Front Bioeng Biotechnol 8:1–14. https://doi.org/10.3389/fbioe.2020.589590

Birla RK, Huang YC, Dennis RG (2007) Development of a novel bioreactor for the mechanical loading of tissue-engineered heart muscle. Tissue Eng 13:2239–2248. https://doi.org/10.1089/ten.2006.0359

Gasik M (2017) Understanding biomaterial-tissue interface quality: combined in vitro evaluation. Sci Technol Adv Mater 18:550–562. https://doi.org/10.1080/14686996.2017.1348872