Abstract

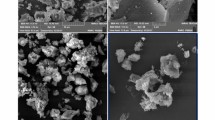

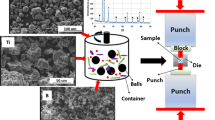

The current study aimed at assessing the effect of HfN addition on the microstructure and mechanical properties of mullite-CNT composite. Accordingly, aluminum nitrate nonahydrate (ANN) and colloidal silica were mixed as the corresponding composition of stoichiometric mullite precursors. Afterward, 0.1 wt% CNTs was blended with calcined mullite precursors in ethanol media. Then, 10 wt% HfN powders was added to the mullite-0.1 wt% CNT mixture to prepare the hybrid composite. Both composites’ batches were spark plasma sintered at 1350 °C with the initial and final applied pressure of 10 and 50 MPa, respectively, under the vacuum condition of 15–25 Pa. Relative densities more than 99% of theoretical density were obtained for both prepared composites. XRD pattern of the hybrid composite demonstrated mullite, HfN, and HfO2 peaks as the only crystalline phases, while the related XRD pattern of the mullite-CNT sample consisted of only mullite peaks. The FESEM images also revealed the uniform distribution of reinforcement phases in the mullite matrix for both prepared composites. Thus, the highest bending strength of 537 ± 21 MPa, Vickers hardness of 18.33 ± 0.25 GPa, and fracture toughness of 4.79 ± 0.18 MPa·m1/2 were obtained for the hybrid composite.

Graphical abstract

Similar content being viewed by others

References

R. Mishra, R.S. Ningthoujam, High-temperature ceramics, in: A.K. Tyagi, S.B.T.-M.U.E.C. Banerjee (Eds.), Mater. Under Extrem. Cond., Elsevier, Amsterdam 377–409 (2017) https://doi.org/10.1016/B978-0-12-801300-7.00011-5

Ghasali, E., Orooji, Y., Faeghi-nia, A., Alizadeh, M., Ebadzadeh, T.: Characterization of mullite-Nd2O3 composite prepared through spark plasma sintering. Ceram. Int. 47, 16200–16207 (2021). https://doi.org/10.1016/j.ceramint.2021.02.198

Ghasali, E., Saeidabadi, E.K., Alizadeh, M., Fazili, A., Rajaei, H., Jam, A., Kazemzadeh, H., Ebadzadeh, T.: Preparation of mullite/B4C composites: a comparative study on the effect of heating methods. Ceram. Int. 44, 18743–18751 (2018). https://doi.org/10.1016/j.ceramint.2018.07.104

Schneider, H., Fischer, R.X., Schreuer, J.: Mullite: crystal structure and related properties. J. Am. Ceram. Soc. 98, 2948–2967 (2015). https://doi.org/10.1111/jace.13817

Sadik, C., El Amrani, I.E., Albizane, A.: Recent advances in silica-alumina refractory: a review. J. Asian Ceram. Soc. 2, 83–96 (2014). https://doi.org/10.1016/j.jascer.2014.03.001

Zhang, W., Ma, Q., Zeng, K., Liang, S., Mao, W.: Mechanical properties and thermal stability of carbon fiber cloth reinforced sol-derived mullite composites. J. Adv. Ceram. 8, 218–227 (2019). https://doi.org/10.1007/s40145-018-0307-z

Cui, K., Zhang, Y., Fu, T., Wang, J., Zhang, X.: Toughening mechanism of mullite matrix composites: a review. Coatings 10, 672 (2020). https://doi.org/10.3390/coatings10070672

Choo, T.F., Salleh, M.A.M., Kok, K.Y., Matori, K.A.: A review on synthesis of mullite ceramics from industrial wastes. Recycling. 4, 39 (2019). https://doi.org/10.3390/recycling4030039

Bodhak, S., Bose, S., Bandyopadhyay, A.: Densification study and mechanical properties of microwave-sintered mullite and mullite-zirconia composites. J. Am. Ceram. Soc. 94, 32–41 (2011). https://doi.org/10.1111/j.1551-2916.2010.04062.x

Wang, Y., Liu, J.: Aluminum phosphate-mullite composites for high-temperature radome applications. Int. J. Appl. Ceram. Technol. 6, 190–194 (2009)

Popovskaya, N.F., Bobkova, N.M.: Mullite-tialite ceramic materials based on chemically precipitated mixtures (a review). Glas. Ceram. (English Transl Steklo i Keramika) 59, 234–236 (2002). https://doi.org/10.1023/a:1020979228914

Majidian, H., Ghasali, E., Ebadzadeh, T., Razavi, M.: Effect of heating method on microstructure and mechanical properties of zircon reinforced aluminum composites. Mater. Res. 19, 1443–1448 (2016). https://doi.org/10.1590/1980-5373-MR-2016-0390

Pabst, W., Gregorová, E., Uhlířová, T., Musilová, A.: Elastic properties of mullite and mullite-containing ceramics part 1: theoretical aspects and review of monocrystal data. Ceram. - Silikaty. 57, 265–274 (2013)

Aksay, I.A., Dabbs, D.M., Sarikaya, M.: Mullite for structural, electronic, and optical applications. J. Am. Ceram. Soc. 74, 2343–2358 (1991). https://doi.org/10.1111/j.1151-2916.1991.tb06768.x

Chawla, K.K.: Interface engineering in mullite fiber/mullite matrix composites. J. Eur. Ceram. Soc. 28, 447–453 (2008)

Chawla, K.K., Xu, Z.R., Ha, J.S.: Processing, structure, and properties of mullite fiber/mullite matrix composites. J. Eur. Ceram. Soc. 16, 293–299 (1996). https://doi.org/10.1016/0955-2219(95)00136-0

K.R. Venkatachari, L.T. Moeti, M.D. Sacks, J.H. Simmons,: Preparation of mullite-based fibers by sol-gel processing, in: 14th Annu. Conf. Compos. Adv. Ceram. Mater. Ceram. Eng. Sci. Proc., Wiley Online Library 1512–1525 (1990)

A.I. Abdallah, M. Sayed, M. Awaad, A.H.E. Yousif, S.M. Naga.: Characterization of in-situ zirconia/mullite composites prepared by sol-gel technique, J. Asian Ceram. Soc. (2021) 1–7. https://doi.org/10.1080/21870764.2021.1929738.

Ilić, S., Zec, S., Miljković, M., Poleti, D., Pošarac-Marković, M., Janaćković, D., Matović, B.: Sol–gel synthesis and characterization of iron doped mullite. J. Alloys Compd. 612, 259–264 (2014). https://doi.org/10.1016/j.jallcom.2014.05.204

Ananthakumar, S., Jayasankar, M., Warrier, K.G.K.: Microstructural, mechanical and thermal characterisation of sol–gel-derived aluminium titanate–mullite ceramic composites. Acta Mater. 54, 2965–2973 (2006). https://doi.org/10.1016/j.actamat.2006.02.032

Roy, J., Das, S., Maitra, S.: Solgel-processed mullite coating - a review. Int. J. Appl. Ceram. Technol. 12, E71–E77 (2015). https://doi.org/10.1111/ijac.12230

Lee, W.E., Iqbal, Y.: Influence of mixing on mullite formation in porcelain. J. Eur. Ceram. Soc. 21, 2583–2586 (2001). https://doi.org/10.1016/S0955-2219(01)00274-6

Miao, X.: Porous mullite ceramics from natural topaz. Mater. Lett. 38, 167–172 (1999). https://doi.org/10.1016/S0167-577X(98)00153-0

Li, S., Du, H., Guo, A., Xu, H., Yang, D.: Preparation of self-reinforcement of porous mullite ceramics through in situ synthesis of mullite whisker in flyash body. Ceram. Int. 38, 1027–1032 (2012). https://doi.org/10.1016/j.ceramint.2011.08.026

Jayasankar, M., Anilkumar, G.M., Smitha, V.S., Mukundan, P., Madhusoodana, C.D., Warrier, K.G.K.: Low temperature needle like mullite grain formation in sol-gel precursors coated on SiC porous substrates. Thin Solid Films 519, 7672–7676 (2011). https://doi.org/10.1016/j.tsf.2011.05.053

Ando, K., Chu, M.C., Tsuji, K., Hirasawa, T., Kobayashi, Y., Sato, S.: Crack healing behaviour and high-temperature strength of mullite/SiC composite ceramics. J. Eur. Ceram. Soc. 22, 1313–1319 (2002). https://doi.org/10.1016/S0955-2219(01)00431-9

Ghahremani, D., Ebadzadeh, T., Maghsodipour, A.: Densification, microstructure and mechanical properties of mullite-TiC composites prepared by spark plasma sintering. Ceram. Int. 41, 1957–1962 (2015). https://doi.org/10.1016/j.ceramint.2014.07.146

Garrido, L.B., Aglietti, E.F., Martorello, L., Camerucci, M.A., Cavalieri, A.L.: Hardness and fracture toughness of mullite-zirconia composites obtained by slip casting. Mater. Sci. Eng. A. 419, 290–296 (2006). https://doi.org/10.1016/j.msea.2006.01.035

Romero, M., Padilla, I., Contreras, M., López-delgado, A.: Mullite-based ceramics from mining waste: a review. Minerals. 11, 332 (2021). https://doi.org/10.3390/min11030332

H. Schneider, S. Komarneni, Mullite, John Wiley & Sons, 2006.

Orooji, Y., Ghasali, E., Moradi, M., Derakhshandeh, M.R., Alizadeh, M., Asl, M.S., Ebadzadeh, T.: Preparation of mullite-TiB2-CNTs hybrid composite through spark plasma sintering. Ceram. Int. 45, 16288–16296 (2019). https://doi.org/10.1016/j.ceramint.2019.05.154

Ruh, R., Mazdiyasni, K.S., Mendiratta, M.G.: Mechanical and microstructural characterization of mullite and mullite-SiC-whisker and ZrO2-toughened-mullite—SiC-whisker composites. J. Am. Ceram. Soc. 71, 503–512 (1988). https://doi.org/10.1111/j.1151-2916.1988.tb05902.x

Yeh, C.L., Kang, C.H.: Fabrication of TaB2/mullite composites by combustion synthesis with excess silicon and B2O3 additions. Ceram. Int. 42, 11015–11019 (2016). https://doi.org/10.1016/j.ceramint.2016.03.242

Derakhshandeh, S.M.R., Gohari, M.S., Saeidabadi, E.K., Jam, A., Rajaei, H., Fazili, A., Alizadeh, M., Ghasali, E., Pakseresht, A.H., Ebadzadeh, T.: Comparison of spark plasma and microwave sintering of mullite based composite: mullite/Ta2O5 reaction. Ceram. Int. 44, 13176–13181 (2018). https://doi.org/10.1016/j.ceramint.2018.04.142

Wang, J., Kou, H., Liu, X., Pan, Y., Guo, J.: Reinforcement of mullite matrix with multi-walled carbon nanotubes. Ceram. Int. 33, 719–722 (2007). https://doi.org/10.1016/j.ceramint.2005.12.009

Ru, J., Fan, Y., Zhou, W., Zhou, Z., Wang, T., Liu, R., Yang, J., Lu, X., Wang, J., Ji, C., Wang, L., Jiang, W.: Electrically conductive and mechanically strong graphene/mullite ceramic composites for high-performance electromagnetic interference shielding. ACS Appl. Mater. Interfaces. 10, 39245–39256 (2018). https://doi.org/10.1021/acsami.8b12933

Xavior, M.A., Kumar, J.P.A.: Machinability of hybrid metal matrix composite - a review. Procedia Eng. 174, 1110–1118 (2017). https://doi.org/10.1016/j.proeng.2017.01.264

Ghasali, E., Alizadeh, M., Shirvanimoghaddam, K., Mirzajany, R., Niazmand, M., Faeghi-Nia, A., Ebadzadeh, T.: Porous and non-porous alumina reinforced magnesium matrix composite through microwave and spark plasma sintering processes. Mater. Chem. Phys. 212, 252–259 (2018). https://doi.org/10.1016/j.matchemphys.2018.03.058

Jeevi, G., Nayak, S.K., Abdul Kader, M.: Review on adhesive joints and their application in hybrid composite structures. J. Adhes. Sci. Technol. 33, 1497–1520 (2019)

Orooji, Y., Alizadeh, A., Ghasali, E., Derakhshandeh, M.R., Alizadeh, M., Asl, M.S., Ebadzadeh, T.: Co-reinforcing of mullite-TiN-CNT composites with ZrB2 and TiB2 compounds. Ceram. Int. 45, 20844–20854 (2019). https://doi.org/10.1016/j.ceramint.2019.07.072

Huang, Z., Shen, Z., Lin, L., Nygren, M., Jiang, D.: Spark-plasma-sintering consolidation of SiC-whisker-reinforced mullite composites. J. Am. Ceram. Soc. 87, 42–46 (2004). https://doi.org/10.1111/j.1151-2916.2004.tb19942.x

Niihara, K., Morena, R., Hasselman, D.P.H.: Evaluation of KIc of brittle solids by the indentation method with low crack-to-indent ratios. J. Mater. Sci. Lett. 1, 13–16 (1982). https://doi.org/10.1007/BF00724706

Pacewska, B., Keshr, M.: Thermal transformations of aluminium nitrate hydrate. Thermochim. Acta. 385, 73–80 (2002). https://doi.org/10.1016/S0040-6031(01)00703-1

Myronyuk, I.F., Mandzyuk, V.I., Sachko, V.M., Gun’ko, V.M.: Structural and morphological features of disperse alumina synthesized using aluminum nitrate nonahydrate. Nanoscale Res. Lett. 11, 153 (2016). https://doi.org/10.1186/s11671-016-1366-0

Schulz, B.C., Butts, D., Thompson, G.B.: Oxidation behavior of vacuum plasma-sprayed hafnium-tantalum nitrides. J. Mater. Res. 30, 2949–2957 (2015). https://doi.org/10.1557/jmr.2015.191

Glechner, T., Hudak, O.E., Wojcik, T., Haager, L., Bohrn, F., Hutter, H., Hunold, O., Ramm, J., Kolozsvári, S., Pitthan, E., Primetzhofer, D., Riedl, H.: Influence of the non-metal species on the oxidation kinetics of Hf, HfN, HfC, and HfB2 coatings. Mater. Des. 211, 110136 (2021). https://doi.org/10.1016/j.matdes.2021.110136

Voitovich, R.F., Pugach, E.A.: High-temperature oxidation of the nitrides of the group IV transition metals - II. Oxidation of zirconium and hafnium nitrides. Sov. Powder Metall. Met. Ceram. 14, 747–750 (1975). https://doi.org/10.1007/BF00800246

Tishchenko, Y.S., Lakiza, S.M., Redko, V.P., Lopato, L.M.: Isothermal sections of the Al2O3–HfO2–Er2O3 phase diagram at 1250 and 1600°C, Powder Metall. Met. Ceram. 51, 594–601 (2013). https://doi.org/10.1007/s11106-013-9473-2

Shin, D., Arróyave, R., Liu, Z.K.: Thermodynamic modeling of the Hf-Si-O system. Calphad Comput. Coupling Phase Diagrams Thermochem. 30, 375–386 (2006). https://doi.org/10.1016/j.calphad.2006.08.006

Verdon, C., Szwedek, O., Allemand, A., Jacques, S., Le Petitcorps, Y., David, P.: High temperature oxidation of two- and three-dimensional hafnium carbide and silicon carbide coatings. J. Eur. Ceram. Soc. 34, 879–887 (2014). https://doi.org/10.1016/j.jeurceramsoc.2013.10.019

Acknowledgements

We would like to acknowledge the Islamic Azad University of Shahrood for its support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Moslemi-firoozabadi, H., Manafi, S. & Ghahremani, D. Microstructure and properties evolution of spark plasma sintered mullite-CNT composite with HfN addition. J Aust Ceram Soc 58, 1481–1490 (2022). https://doi.org/10.1007/s41779-022-00787-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-022-00787-2